Sliding spray coater

A technology of spraying machine and sliding platform, applied in the field of machinery, can solve the problems of increasing production cost, high skill requirements, shortage of employees, etc., and achieves the effect of comprehensive and uniform spraying surface, wide spraying area, and uniform spraying gun operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

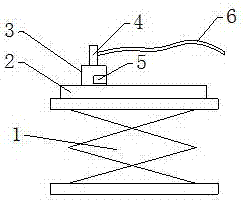

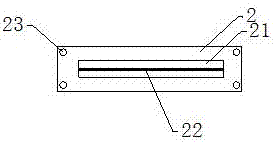

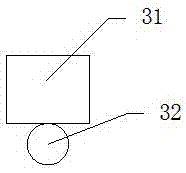

[0015] Such as Figure 1 to Figure 3 As shown, the sliding spraying machine includes a lifting platform 1, a sliding platform 2, a matching block 3, a spray gun 4, a controller 5 and a feeding pipe 6, and the sliding platform 2 has a groove 21, and the groove 21 The middle position is provided with raised strips 22, and round holes 23 are arranged around the sliding platform 2. The matching block is composed of a fixed block 31 and a pulley 32. The sliding platform 2 is fixedly installed on the lifting platform 1, and the matching block 3 is installed on the sliding platform 2 through the cooperation of the pulley 32 and the protruding strip 22, the spray gun 4 is fixedly installed on the upper surface of the matching block 3, and the controller 6 is fixedly installed on the side of the matching block 3, and the spray gun 4 is provided with a feeding pipe 6 matching h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com