Painting device

A paint spraying head and paint material technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problems of complex equipment, long processing time, high cost, etc., to reduce the number of spraying times, weaken the backflow phenomenon, and improve the uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

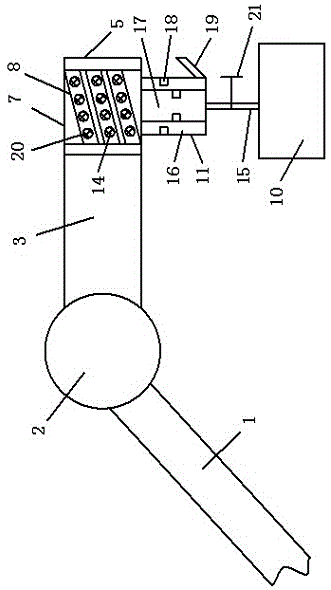

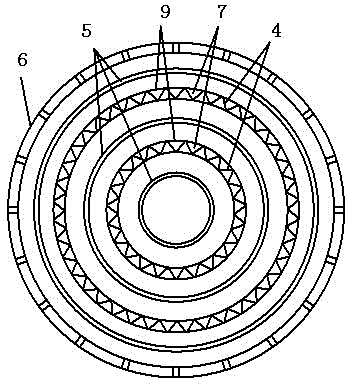

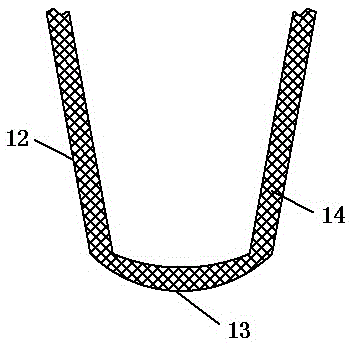

[0019] refer to Figure 1-3 , the specific embodiment comprises an air inlet pipe 1, the air inlet pipe 1 is connected with a paint spray head 3 through a universal joint 2, and a paint container 10 is hung outside the paint spray head 3, and two paint spray rings 7 are arranged on the paint spray head 3, and the paint spray ring 7 is formed by connecting several tooth-shaped slits 4 end to end. The inner and outer sides of the paint spray ring 7 are respectively provided with an air outlet ring 5, and the outer edge of the paint spray head 3 is provided with a negative pressure suction ring 6. The height of the paint spray ring 7 is higher than that of the air outlet. Ring 5, spray paint ring 7 are concentric with paint spray head 3 and are set independently of each other. Spiral blade 8 is arranged inside paint spray ring 7, and the Teflon sealing ring 9 is slidingly connected between paint spray ring 7 and paint spray head 3; air intake pipe 1 is respectively connected To t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com