Automobile cleaning and maintaining room and using method

A technology for maintenance rooms and automobiles. It is used in vehicle maintenance/repair, vehicle exterior cleaning devices, vehicle maintenance, etc. It can solve the problems of simultaneous operation, large area, difficult maintenance, etc., to achieve the best support for the car and improve the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

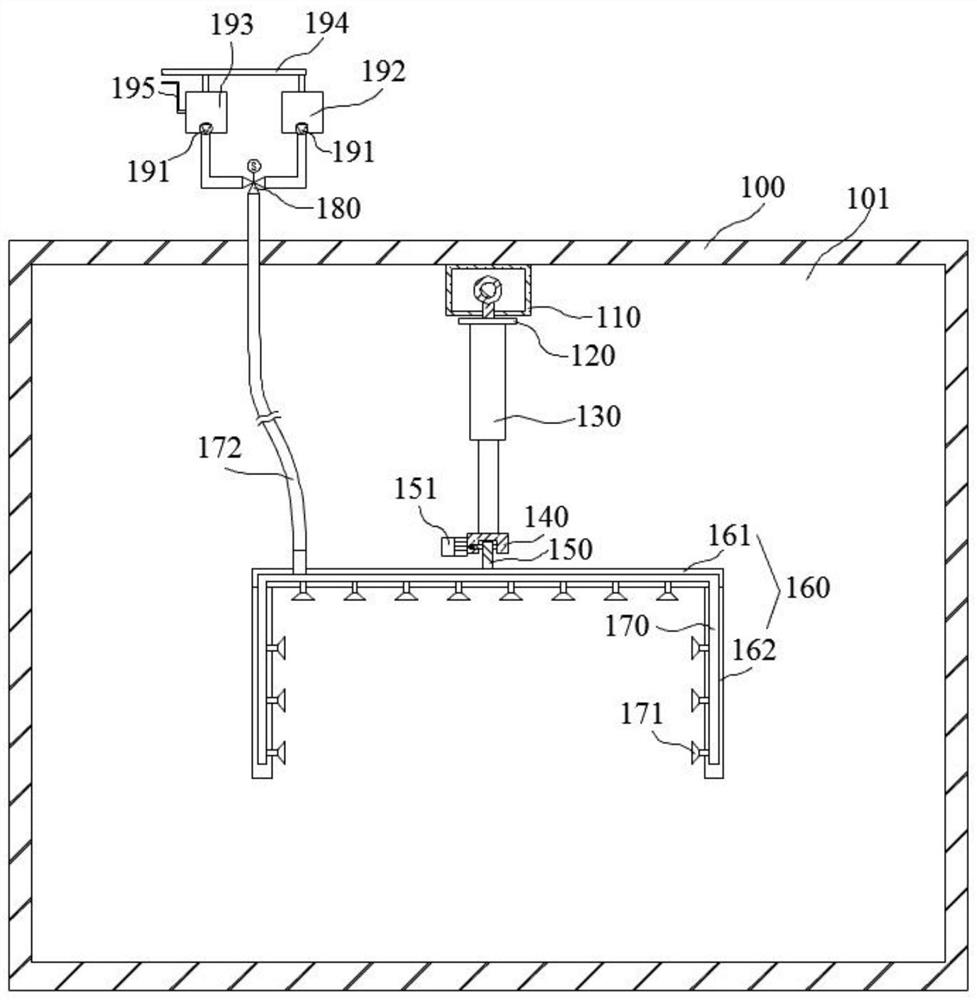

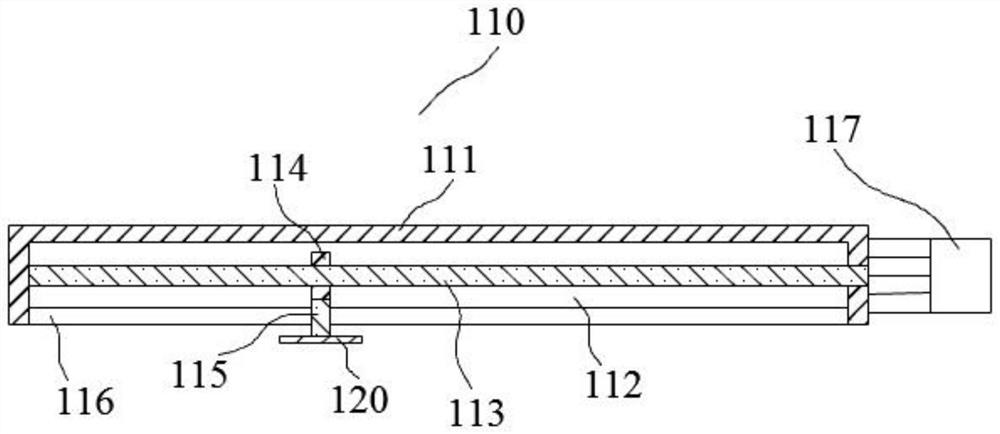

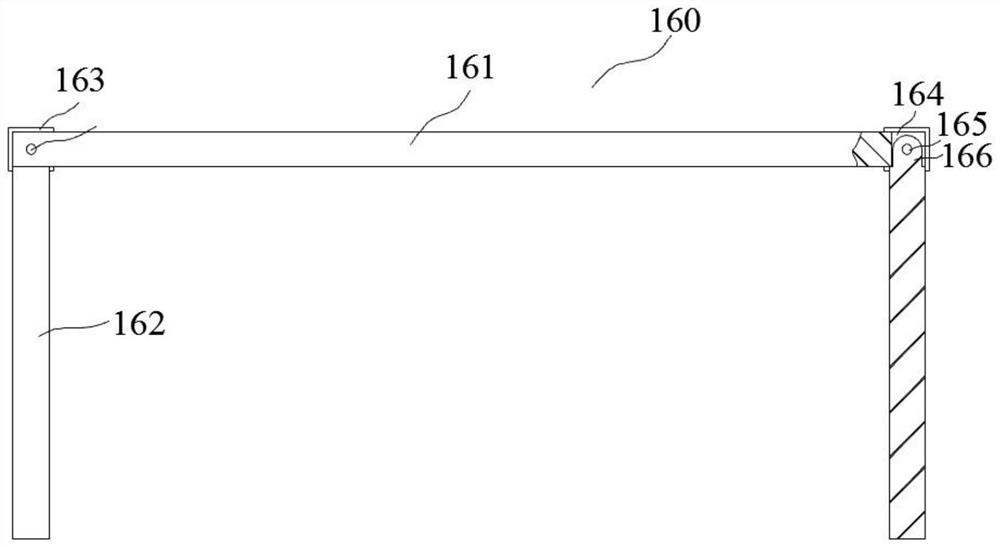

[0061] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment provides a car cleaning device, including a device body 100, the device body 100 is provided with an accommodating cavity 101, the top of the accommodating cavity 101 is provided with a linear actuator 110, and the linear actuator 110 is provided with a The mobile plate 120 that can move back and forth, the bottom surface of the mobile plate 120 is connected with the electric telescopic rod 130, the bottom of the electric telescopic rod 130 is connected with the mounting block 140, and the bottom of the mounting block 140 is connected with the movable rod 150 that can rotate forward and backward, and the movable rod 150 is formed by the first The motor 151 is driven; the bottom of the movable bar 150 is connected with a concave mounting platform 160; the mounting platform 160 includes a cross bar 161, and the two ends of the cross bar 161 are respectively connected to a vertical rod...

Embodiment 2

[0092] Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, this embodiment provides a car wiper device, including a device body 100, a housing cavity 101 is provided in the device body 100, and two first linear modules 210 are arranged on the top of the housing cavity 101. A connecting rod 211 that can move back and forth is connected to the bottom of the straight line module 210, a second straight line module 220 is fixedly connected to the bottom of the connecting rod 211, and a movable plate 221 that can move left and right is connected to the bottom of the second straight line module 220. The bottom of 221 is fixedly connected with an electric lifting rod 230, and the bottom of the electric lifting rod 230 is connected with a first mounting plate 241. The inside of the first mounting plate 241 is provided with a rotatable first round rod 251, and the first round rod 251 is controlled by a first servo. Motor 261 drives rotation; The first round rod 251 inne...

Embodiment 3

[0113] Such as Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, the present embodiment provides a vehicle maintenance platform, including a device body 100, a housing cavity 101 is provided in the device body 100, a housing groove 300 is provided at the bottom of the housing chamber 101, and a housing groove 300 is provided at the bottom of the housing tank 300. There is a support plate 310, the top surface of the support plate 310 is provided with a plurality of groove rails 311, and any groove rail 311 is equipped with a plurality of rollers 320 that can roll left and right, and all the rollers 320 are installed on the bottom surface of a lifting platform 330; A first linear module 340 is arranged in the middle of the plate 310, and a connecting plate 341 that can move left and right is arranged above the first linear module 340, and the connecting plate 341 is fixedly connected to the bottom surface of the lifting platform 330;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com