Automobile hexagonal flange bolt electrophoretic paint spraying equipment

A flange surface bolt, spraying equipment technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of reduced safety, lack of protection function, unadjustable spraying position, etc., to prevent the diffusion of heavy metals and odors, Avoid human inhalation and improve the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

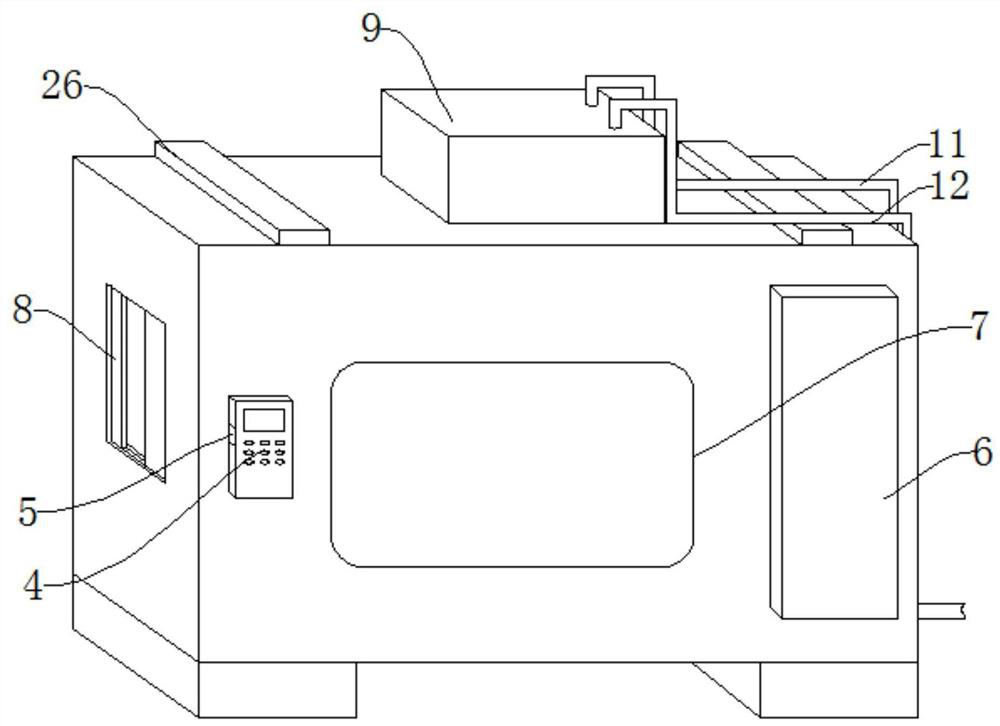

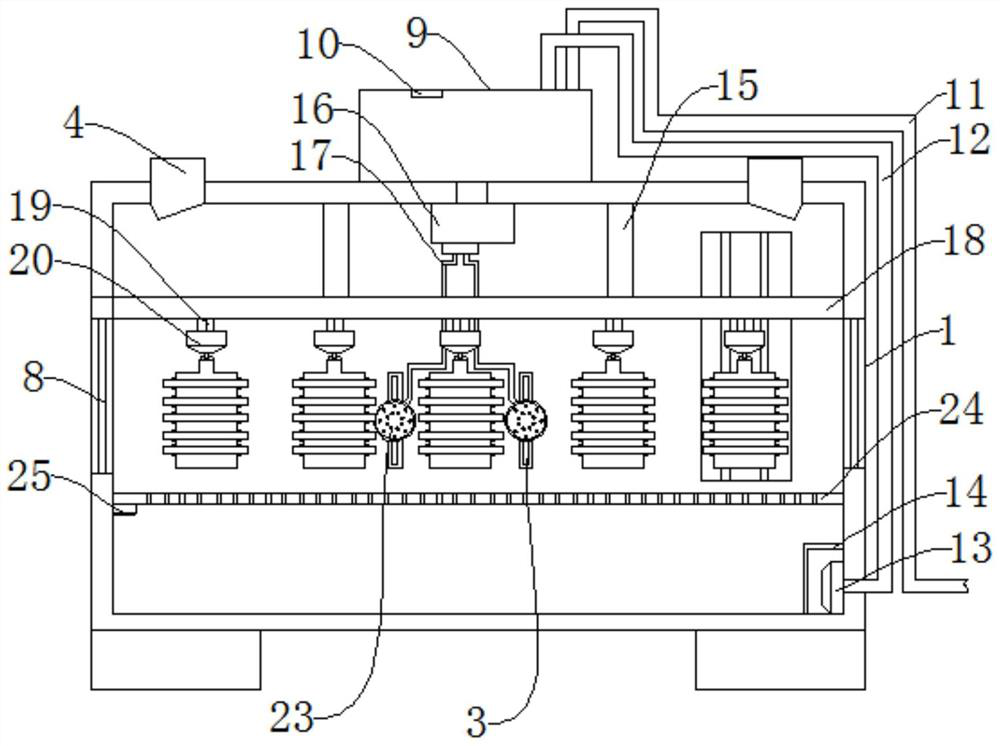

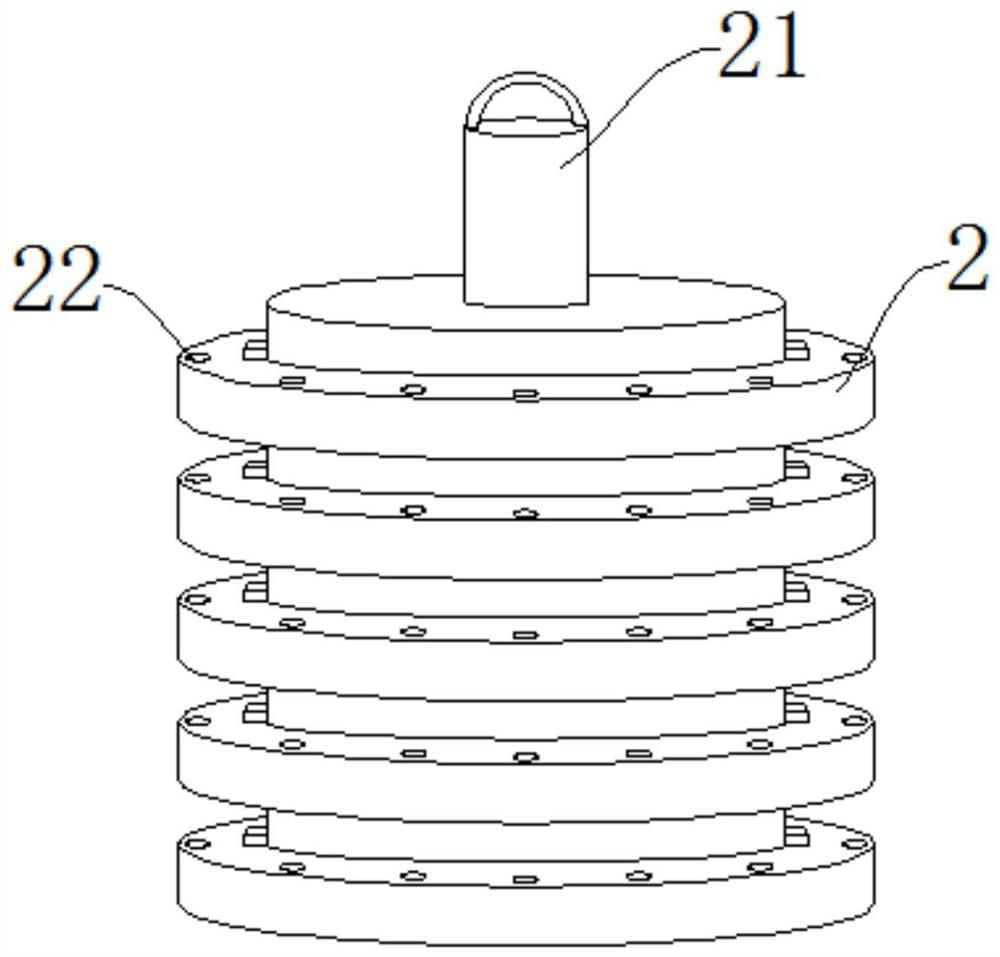

[0038] like Figure 1-Figure 4 As shown, a kind of electrophoretic paint spraying equipment for automobile hexagonal flange surface bolts includes a chassis 1, a placement frame 2 and a miniature electric slide rail 3, an operation panel 4 is arranged on the side wall of the chassis 1, and an operation panel 4 is arranged on the operation panel 4. A microprocessor 5 is installed, an observation window 7 is installed on one side of the operation panel 4, an electric door 8 is symmetrically installed on the two side walls of the cabinet 1, and a dryer 6 is fixed on the other two side walls of the cabinet 1 , the dryer 6 can quickly dry the sprayed bolts, two fans 26 are symmetrically installed on both sides of the upper end of the cabinet 1, and a material storage box 9 is arranged between the fans 26, and the storage box 9 A liquid level sensor 10 is fixed on the inner top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com