Direct-current brushless shaftless frequency conversion wave making pump

A DC brushless and shaftless technology, applied in the field of wave pumps, can solve problems such as vibration and noise of the central shaft of the motor, and achieve the effects of low vibration, low friction and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

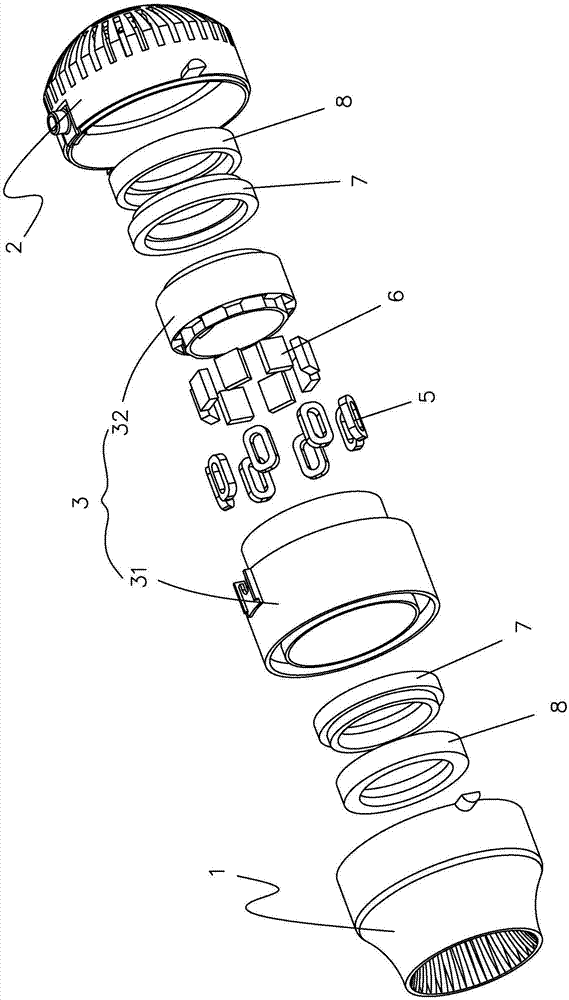

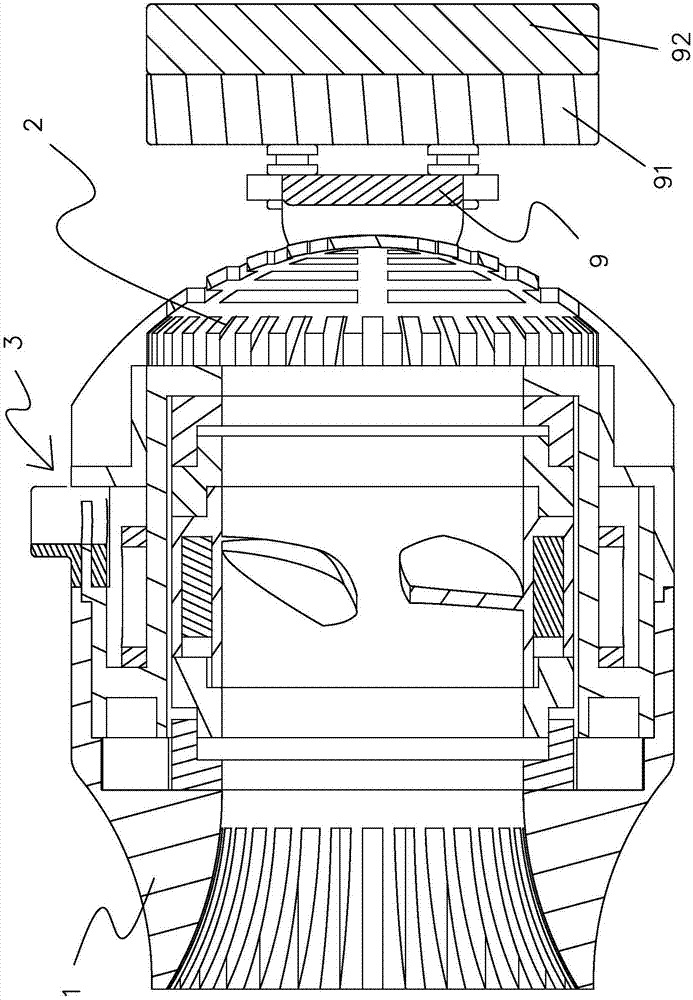

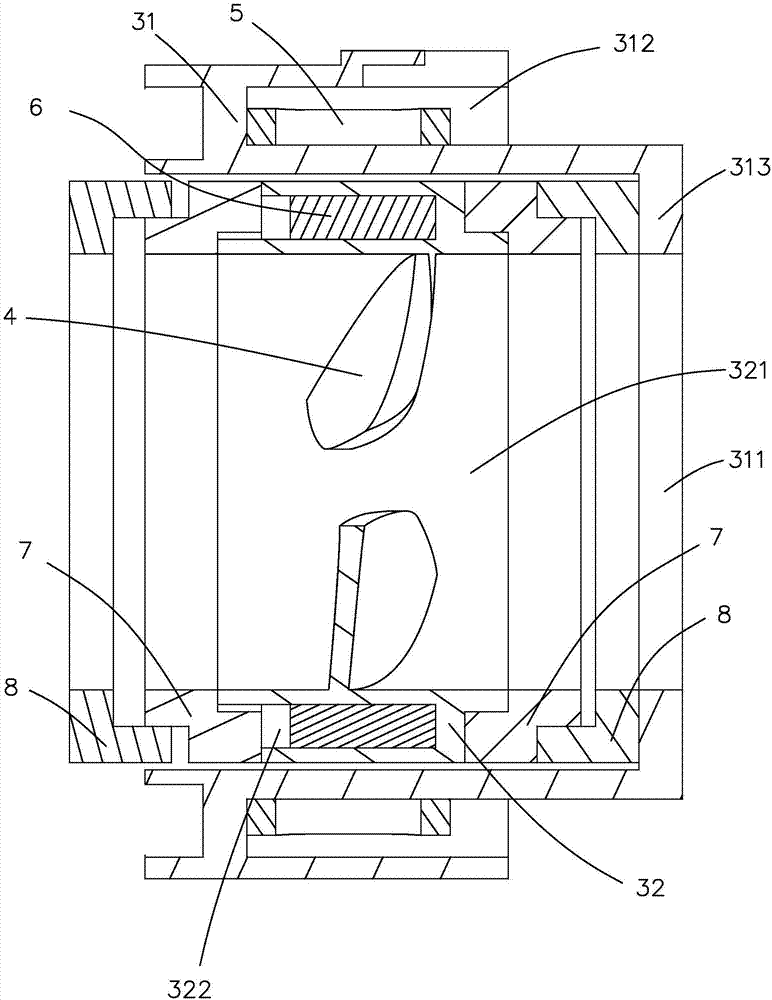

[0018] A DC brushless shaftless variable-frequency wave-making pump, comprising a hollow front cover 1, a hollow rear sand-separation cover 2, and a motor 3 arranged between the front-end cover 1 and the rear sand-separation cover 2, and the motor includes a motor housing 31 And the impeller permanent magnet rotor 32, the motor casing 31 is provided with the through hole 311 of the inner wall of the motor casing along the axial direction, the impeller permanent magnet rotor 32 is rotatably arranged in the through hole 311 of the inner wall of the motor casing, and the impeller permanent magnet rotor 32 is arranged along the axial direction. The rotor inner wall through hole 321 is provided, the hollow cavity of the front end cover 1 and the rear sand separation cover 2 and the rotor inner wall through hole 321 form a water channel for water flow through, and the rotor inner wall through hole 321 is provided with blades 4 driving the water flow along the circumference.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com