Intelligent integrated seeding equipment and working method thereof

A working method and equipment technology, applied in the field of intelligent integrated seeding equipment, can solve problems such as affecting the speed of cultivation, occupying a large space, and different depths of sowing, so as to reduce the floor space, reduce the space occupied, and improve the accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

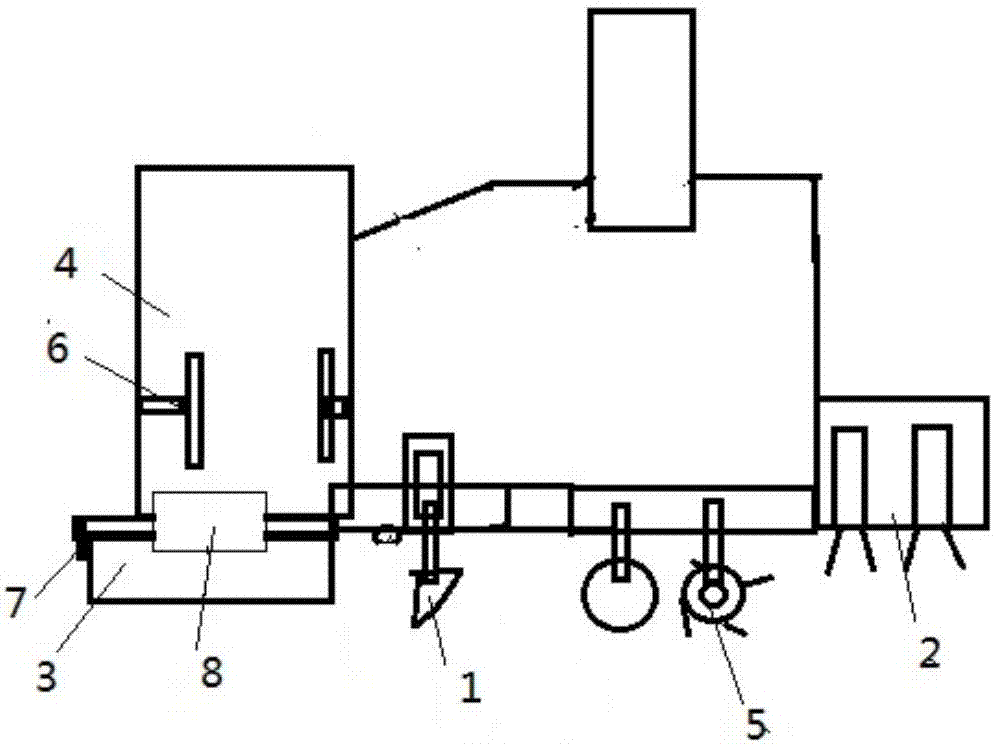

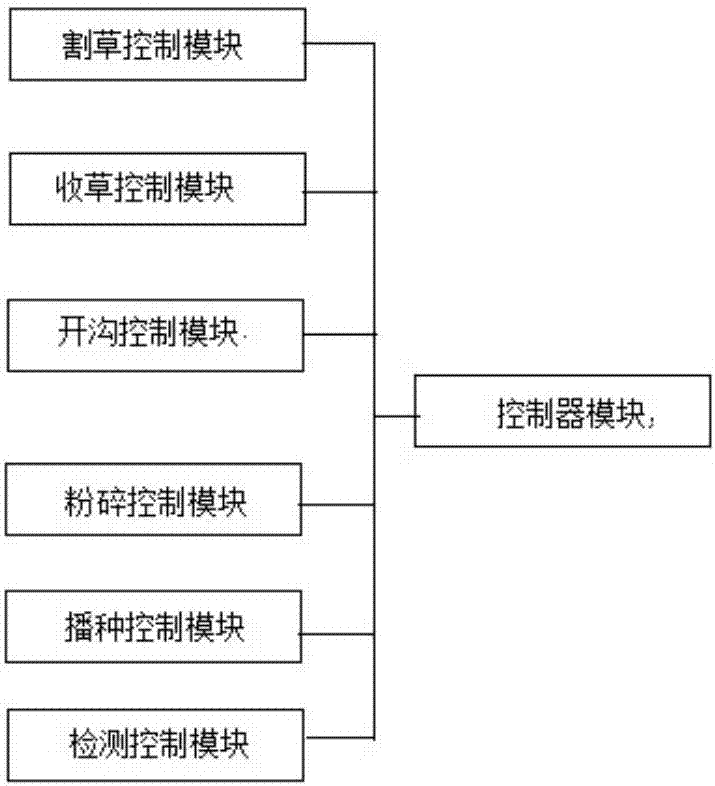

[0041] A working method of intelligent integrated sowing equipment as shown in the figure, wherein the sowing equipment includes: a ditching mechanism 1, a sowing mechanism 2 and a control device, wherein the control device is provided with a ditching control mechanism, a sowing control mechanism and A control mechanism, the ditching control mechanism is provided with a depth adjustment mechanism for adjusting the ditching depth according to the type of crops, and the sowing control mechanism is provided with a type adjustment mechanism for sowing different crops, the ditching control mechanism and The ditching mechanism 1 is connected, the sowing control mechanism is connected with the sowing mechanism 2, and the ditching mechanism 1, the sowing mechanism 2, the ditching control mechanism and the sowing control mechanism are all connected with the control mechanism.

[0042] In this embodiment, a mowing mechanism 3, a grass collecting mechanism 4 and a silt mechanism 5 are als...

Embodiment 2

[0053] A working method of intelligent integrated sowing equipment as shown in the figure, wherein the sowing equipment includes: a ditching mechanism 1, a sowing mechanism 2 and a control device, wherein the control device is provided with a ditching control mechanism, a sowing control mechanism and A control mechanism, the ditching control mechanism is provided with a depth adjustment mechanism for adjusting the ditching depth according to the type of crops, and the sowing control mechanism is provided with a type adjustment mechanism for sowing different crops, the ditching control mechanism and The ditching mechanism 1 is connected, the sowing control mechanism is connected with the sowing mechanism 2, and the ditching mechanism 1, the sowing mechanism 2, the ditching control mechanism and the sowing control mechanism are all connected with the control mechanism.

[0054] In this embodiment, a mowing mechanism 3, a grass collecting mechanism 4 and a silt mechanism 5 are als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com