Synthesis reaction stirring paddle

A synthesis reaction and stirring paddle technology, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems affecting the synthesis reaction and low uniformity of stirring, and achieve uniform stirring, The effect of improving the synthesis reaction efficiency

Inactive Publication Date: 2017-12-22

江阴耀大道路材料有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, the stirring blades were linear, and the uniformity of stirring was not high, which affected the synthesis reaction.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

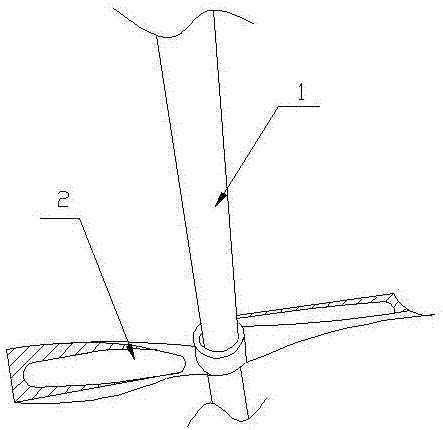

[0011] see figure 1 , the present invention relates to a synthetic reaction stirring blade, which includes a drive shaft 1 and a stirring blade 2 arranged on the driving shaft 1, the stirring blade 2 includes two pieces, and the two stirring blades 2 are reversed Spiral set.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a synthetic reaction stirring blade, which comprises a driving shaft (1) and a stirring blade (2) arranged on the driving shaft (1), at least two stirring blades (2), characterized in that The above two stirring paddles (2) are set in reverse helical shape. In the invention, the stirring paddles are arranged in a spiral shape, so that the stirring is more uniform and the synthesis reaction efficiency is improved.

Description

technical field [0001] The invention relates to a synthetic reaction stirring paddle, in particular to a synthetic reaction stirring paddle for asphalt processing. Background technique [0002] The core equipment of the synthetic reaction device in asphalt processing is the reactor, and the prepared asphalt raw materials are generally added to the reactor to carry out the synthesis reaction. During the reaction in the reactor, the internal stirring blade continuously stirs the slurry to improve the efficiency of the synthesis reaction. In the past, the stirring blades were linear, and the uniformity of stirring was not high, which affected the synthesis reaction. Contents of the invention [0003] The purpose of the present invention is to overcome the above disadvantages and provide a synthesis reaction stirring paddle, which makes the stirring more uniform and improves the efficiency of the synthesis reaction. [0004] The object of the present invention is achieved in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J19/00

CPCB01J19/0066

Inventor 仲裕忠

Owner 江阴耀大道路材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com