Permanent magnetic direct drive ceramic mill ball throwing starting method

A permanent magnet direct drive, permanent magnet motor technology, applied in grain processing and other directions, can solve the problems of unreasonable resource allocation, large horse-drawn trolleys, large energy waste, etc., to save economic expenses, small starting torque, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

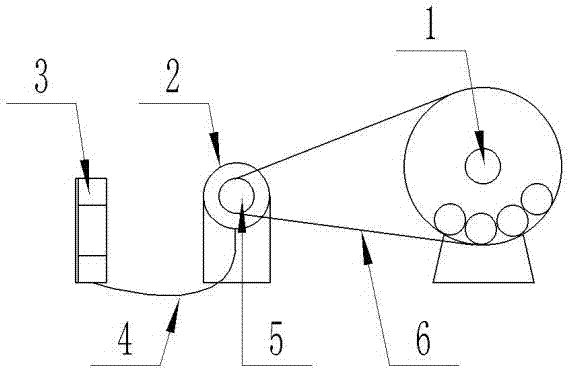

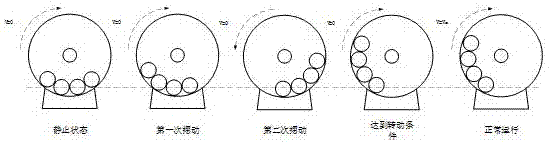

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a permanent magnet direct drive ceramic mill throwing ball starting method includes a ball mill 1, a permanent magnet motor 2, a transmission mechanism and a controller 3, and is characterized in that the starting technique of the ball mill 1 includes the following steps: 1 ) The controller 3 starts the permanent magnet motor 2, and the permanent magnet motor 2 drives the ball mill 1 to rotate in the forward direction; 2) When the permanent magnet motor 2 reaches its maximum output power and the ball mill 1 does not meet the rotation condition, the controller 3 automatically controls the permanent magnet motor 2. Reverse acceleration rotation; 3) When the permanent magnet motor 2 reaches its maximum output power again and the ball mill 1 does not meet the rotation condition, the controller 3 controls the permanent magnet motor 2 to accelerate forward r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com