A kind of operation method of hot rolling automatic steel

A technology of automatic steel request and operation method, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., which can solve the large differences in operating time between teams and personnel, increase the burden on operators, and uneven tapping gaps, etc. problems, to achieve the effect of increasing the burden on operators, avoiding large differences in operating time, and improving the rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

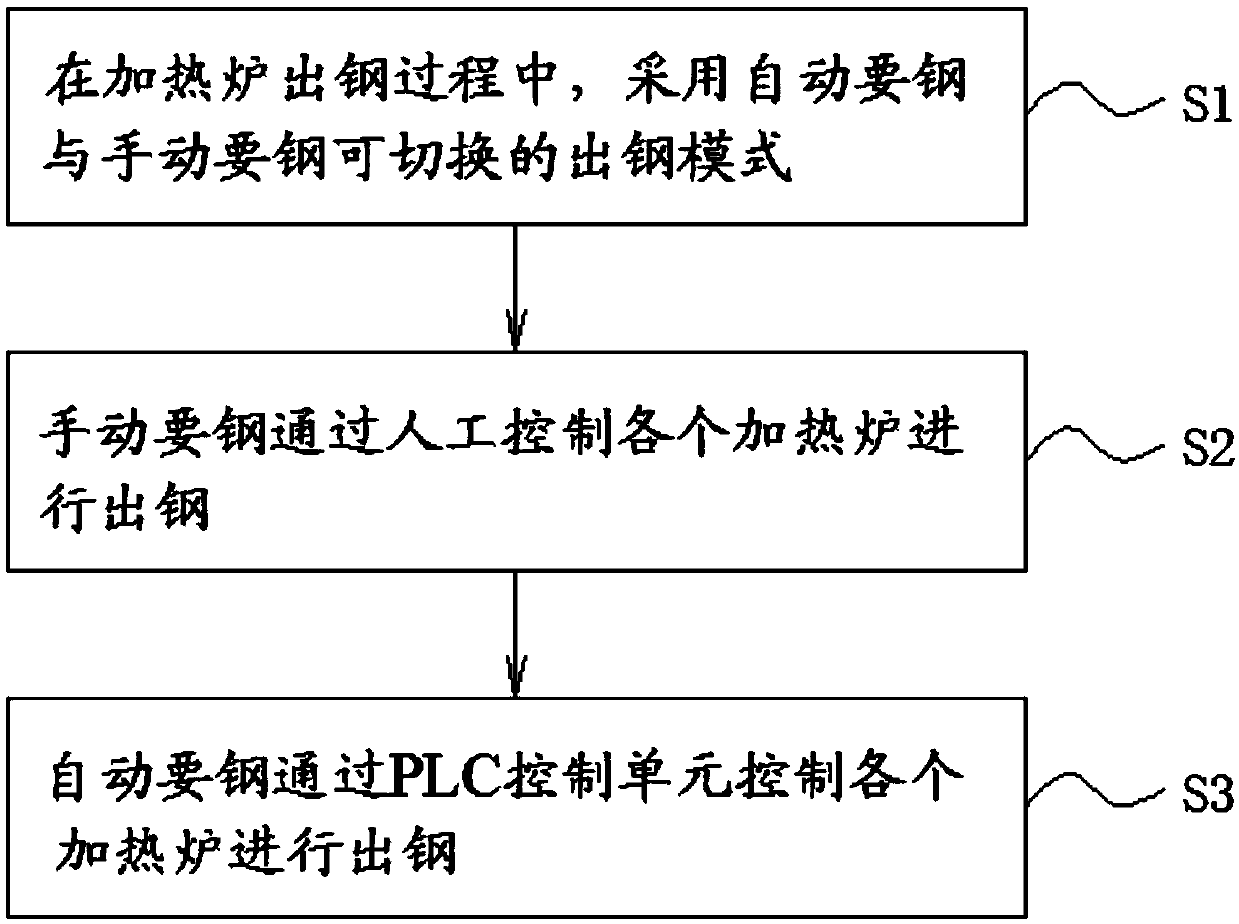

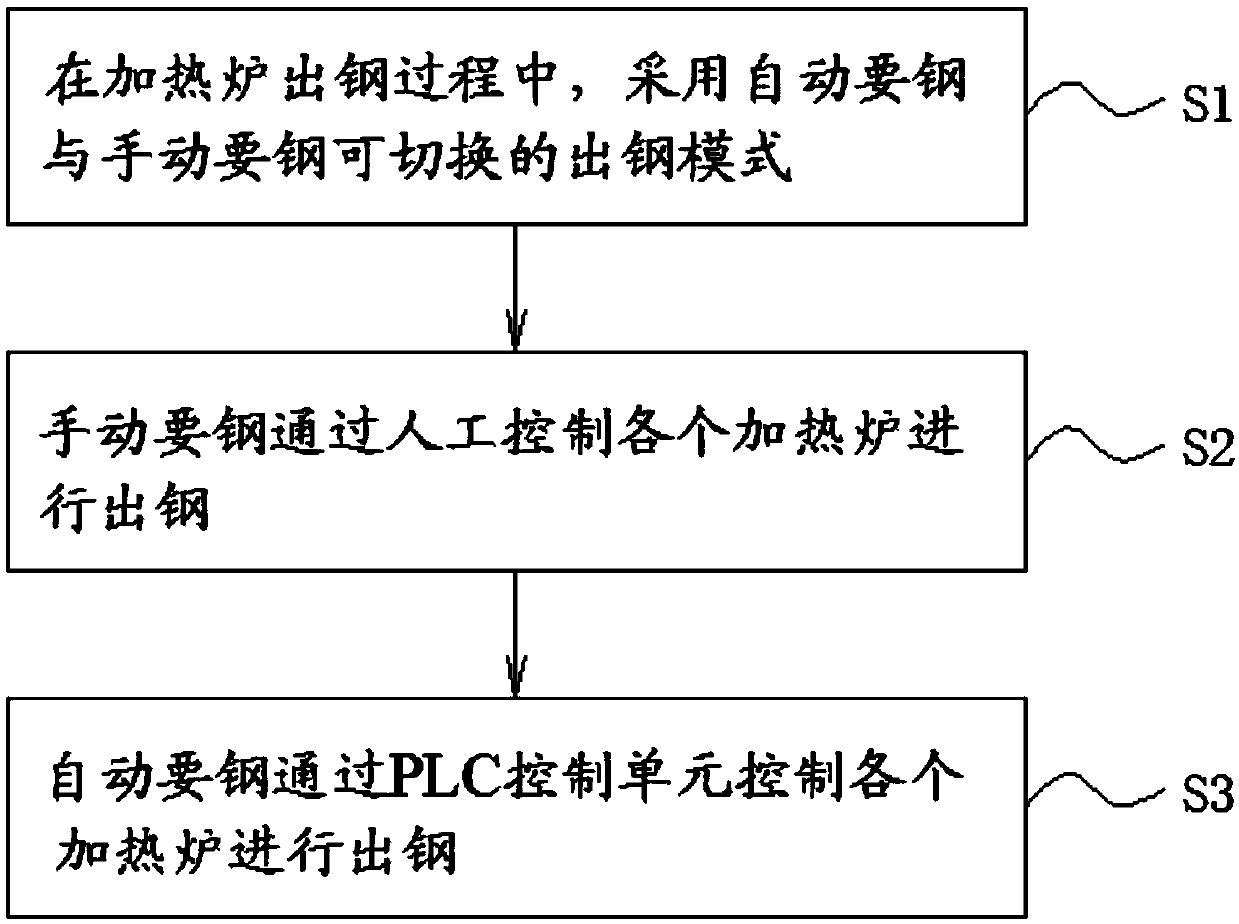

[0024] The embodiment of the present application provides an operation method for automatic hot-rolling steel extraction, which solves or partially solves the uneven tapping gap caused by the first-level steel extraction method in the prior art, and the large difference in operating time between teams and personnel, which increases the Operators are burdened by the technical problems that are likely to cause accidents. During the tapping process of the heating furnace, the tapping mode of automatic steel and manual steel can be switched; manual steel is tapped through manual control of each heating furnace; automatic steel is tapped The steel is tapped by controlling each heating furnace through the PLC control unit; the time required for the steel to be solidified at the first level is realized, the uneven tapping gap and the large difference in operating time are avoided, and the technical effect of reducing the burden on the operator is achieved.

[0025] The present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com