Four-belt lifting self-propelled trolley sling

A self-propelled trolley and spreader technology, applied in the direction of load block, load hanging components, transportation and packaging, etc., to achieve the effect of eliminating shaking, ensuring balance and meeting height requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

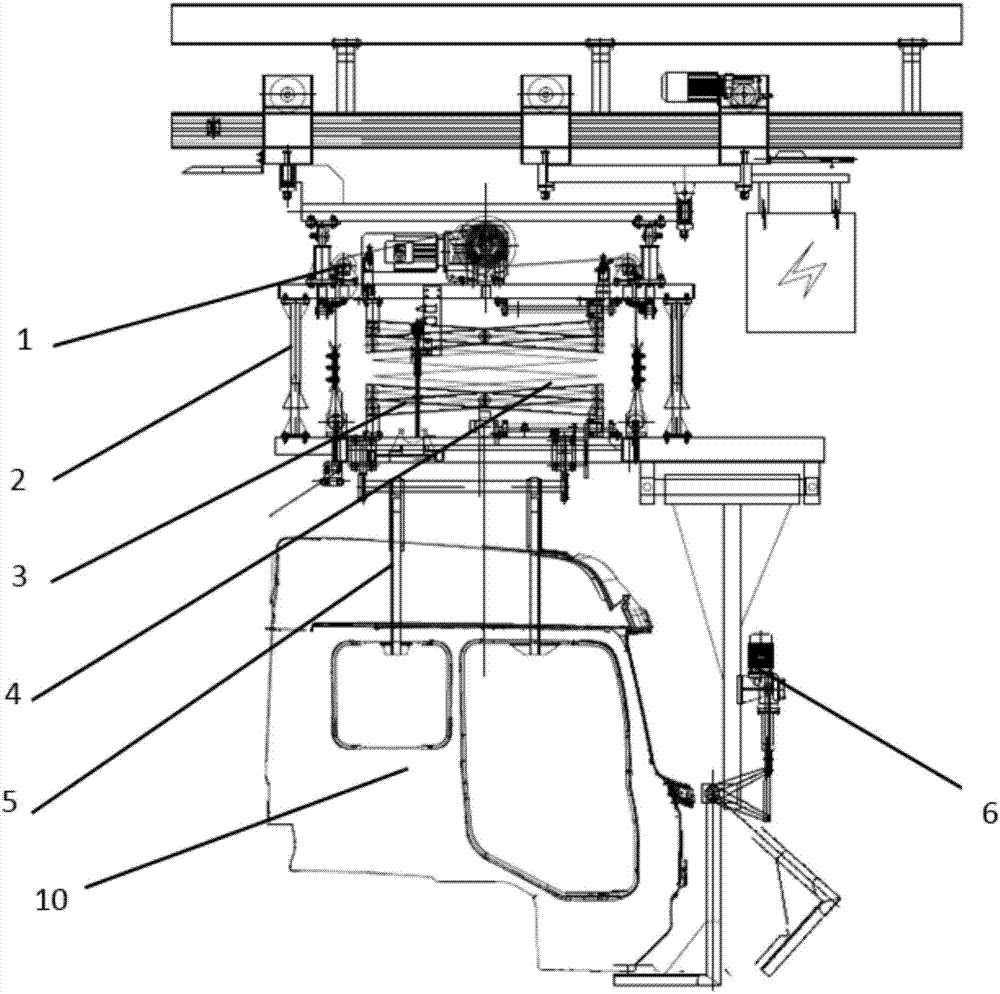

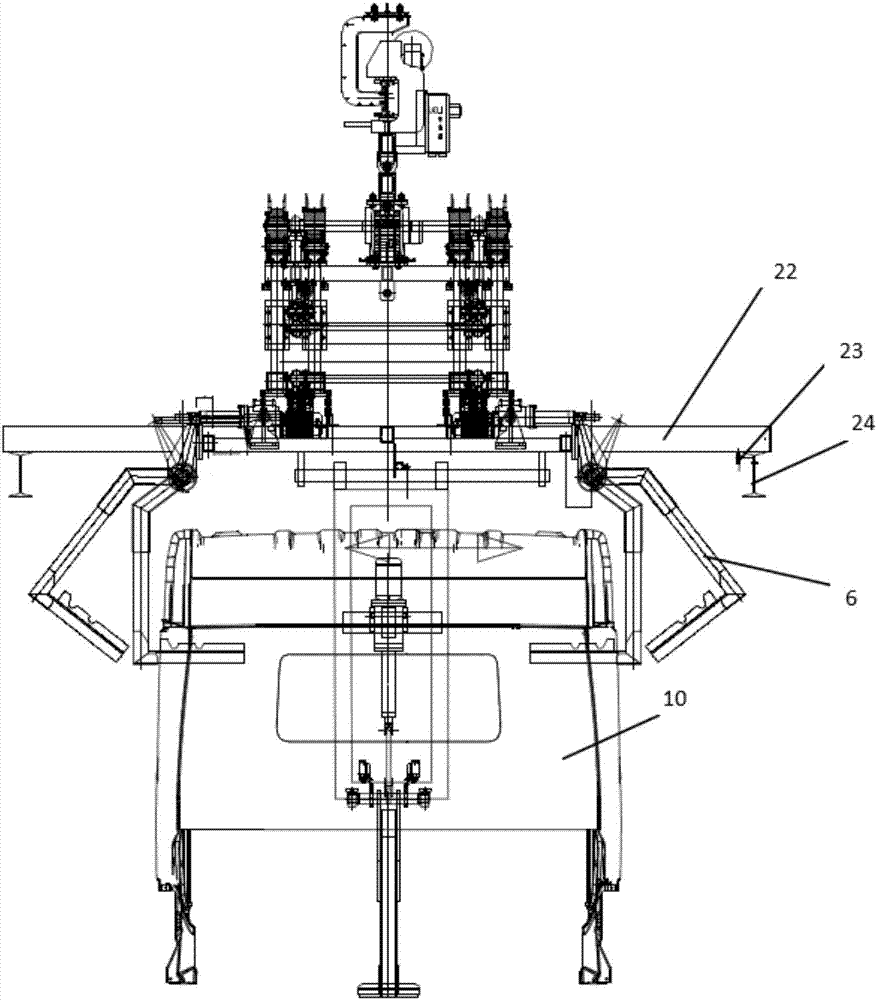

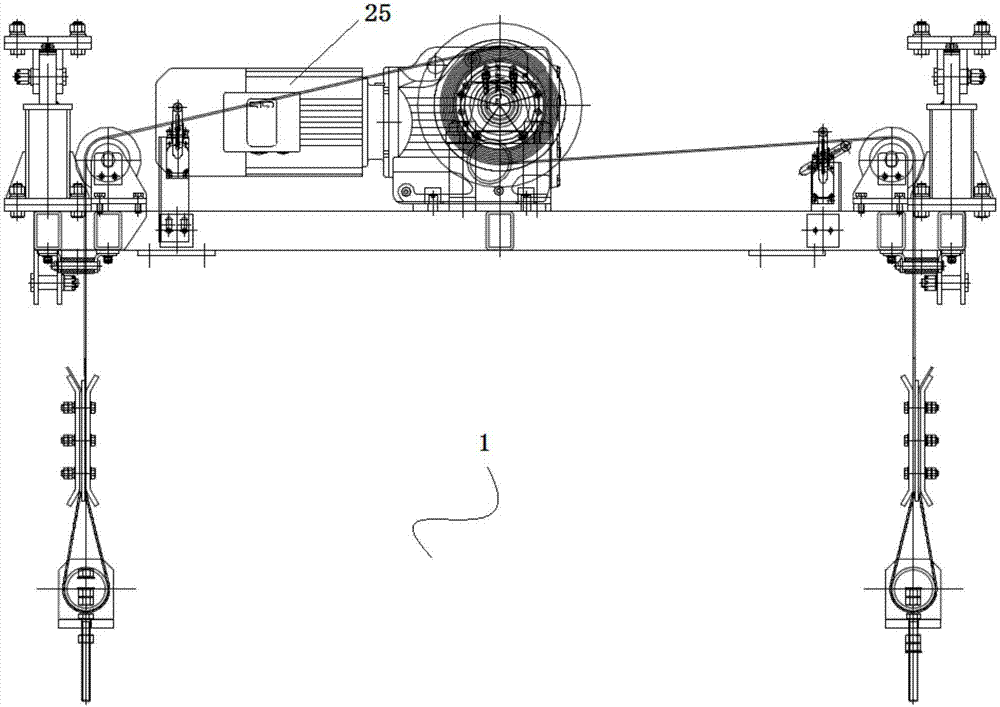

[0025] Such as Figures 1 to 8 As shown, the present invention provides a four-belt lifting self-propelled trolley spreader, which includes: a four-belt lifting device 1, a vehicle body spreader 5 and a cab assembly 10, wherein: the four-belt lifting device 1 and the vehicle body hanger Vertically arranged between the tools 5 are: an anti-sway device 2, an upper limit device 3 and a scissor balance mechanism 4; An arm 11 and a position-limiting support arm 12 , the rotating connection arm 11 is rotationally connected with the vehicle body hanger 5 , and the position-limiting support arm 12 abuts against the cab assembly 10 in position-limiting contact.

[0026] As a further improvement, a driving motor 13 is bolt-connected to the longitudinal connecting arm of the vehicle body hanger 5 , and the connecting end of the rotating connecting arm 11 is drivingly connected to the driving motor 13 .

[0027] As a further improvement, a limit block 14 is arranged on the limit support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com