Glass connection claw of extra large hidden type glass curtain wall and mounting structure of glass connection claw

A glass curtain wall and installation structure technology, applied to the installation of window glass, walls, building components, etc., can solve the problems of insufficient indoor perception, excessive use of main keels, and unsatisfactory permeability, etc., to improve construction efficiency and quality , improve safety, and exert reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

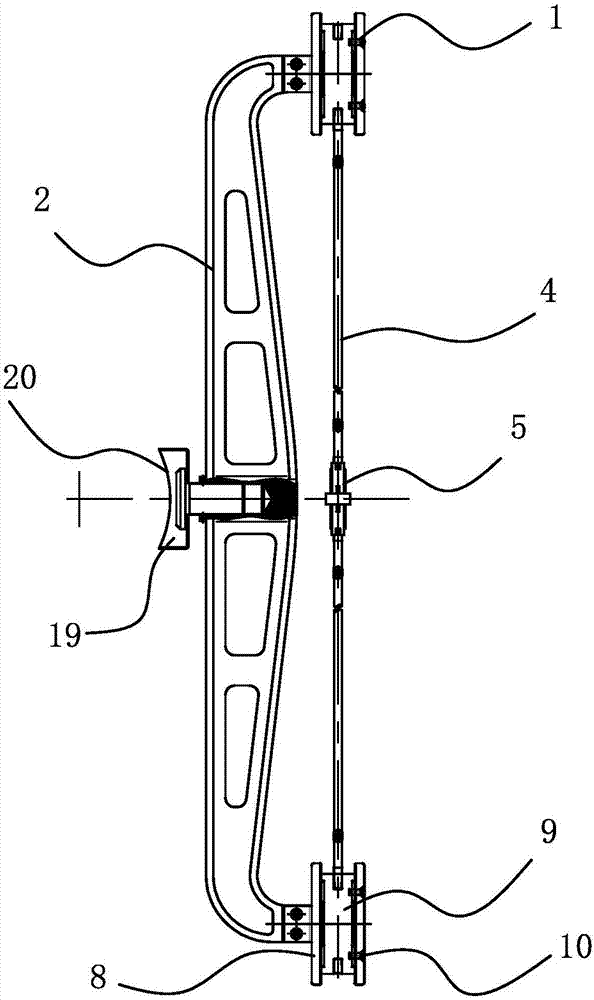

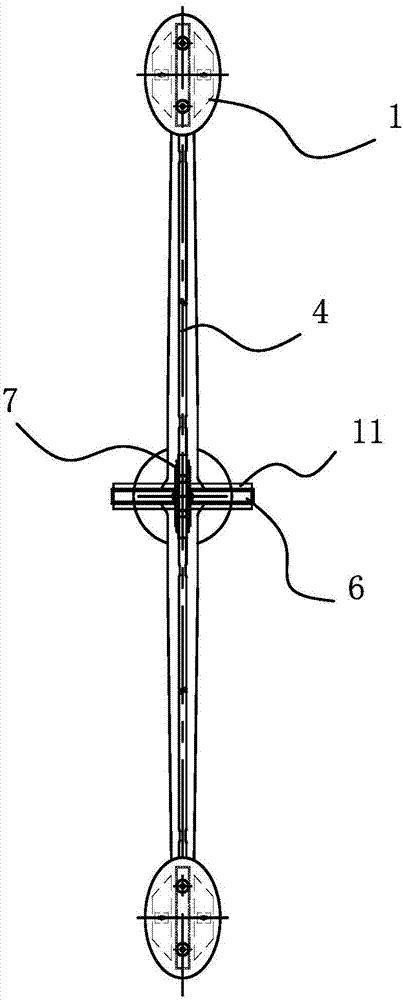

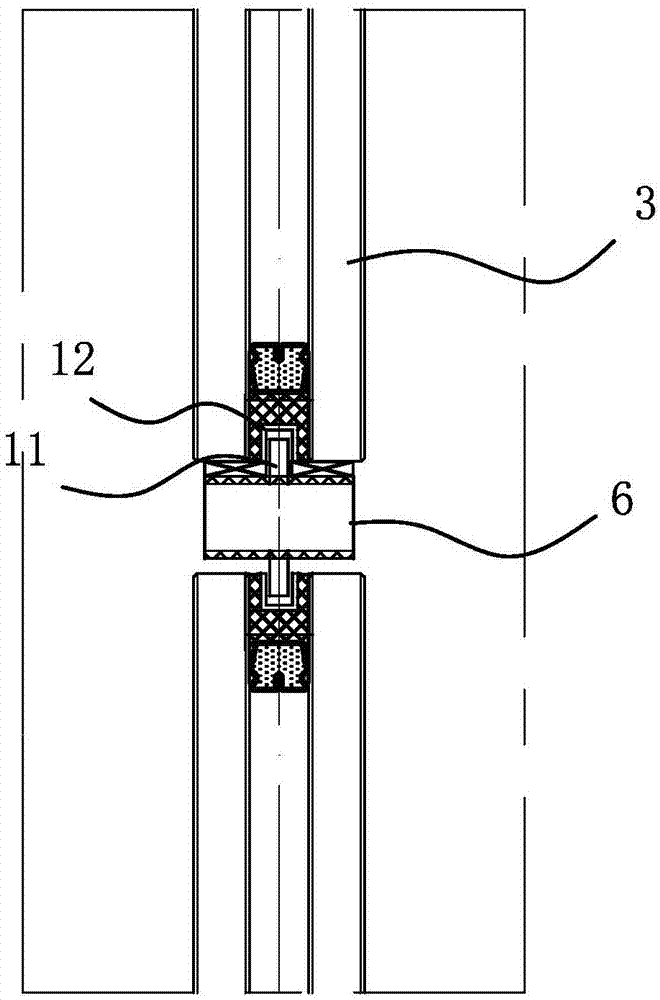

[0033] Embodiment one: see Figure 1~4 As shown, a glass joint claw structure for super large hidden glass curtain wall, including several clamps 1, connecting pieces 2 connecting each clamp 1 and pull rods 4 embedded in the longitudinal joints of adjacent glass 3, said One end of the pull rod 4 is fixed on the fixture 1, and the other end is fixed on a load-bearing connector 5, which is located in the transverse seam between the upper and lower adjacent glass 3, and the load-bearing connector 5 is a The "ten" character includes a load-bearing bracket 6 arranged horizontally, and a sleeve 7 arranged vertically, and the pull rod 4 is fixed in the sleeve 7 . Described fixture 1 comprises splint 8 on both sides and the stainless steel plate 9 that connects splint 8, and described splint 8 is provided with plural glass clamping parts 10 (spherical hinge), and described stainless steel plate 9 upper and lower ends are respectively provided with There are screw holes, and the pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com