Method and device for controlling constant pressure of boiler under constant pressure system and constant pressure system

A board control and auxiliary control technology, applied in boiler cleaning devices, control systems, steam generation methods, etc., can solve problems such as unstable and substandard steam volume indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, rather than to limit the embodiments of the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the embodiments of the present invention.

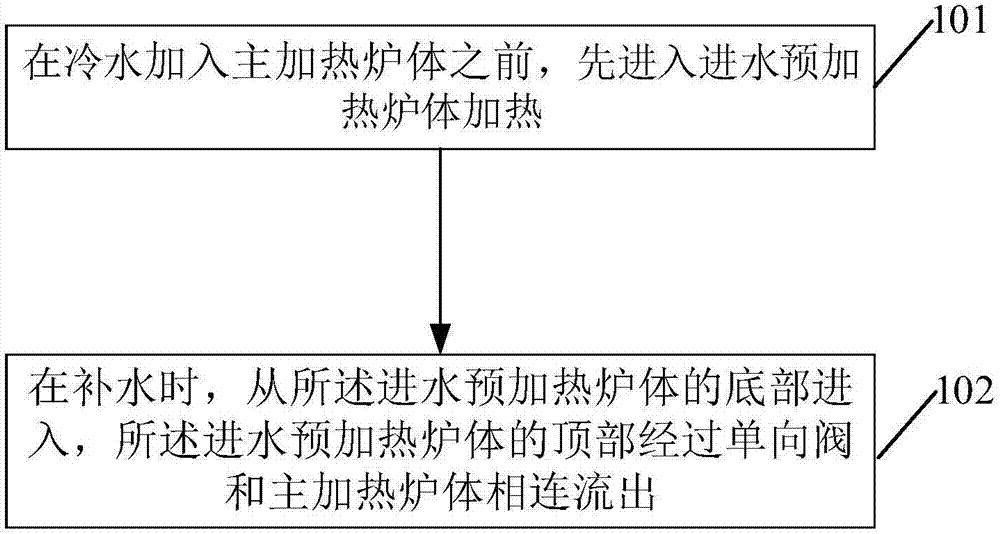

[0049] refer to figure 1 , the method of controlling the constant pressure of the boiler under the constant pressure system includes:

[0050] Step 101, before adding cold water into the main heating furnace body, heating the incoming water to preheat the furnace body;

[0051] Wherein, the heating inlet preheating furnace body includes:

[0052] The temperature sensor controls the third electric heating tube of the main control board and the auxiliary control boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com