Window protective glass and manufacturing method

A technology of protective glass and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of thickness difference, corrugation, and high thickness requirements of the cover plate, so as to prevent corrugation and avoid thickness difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

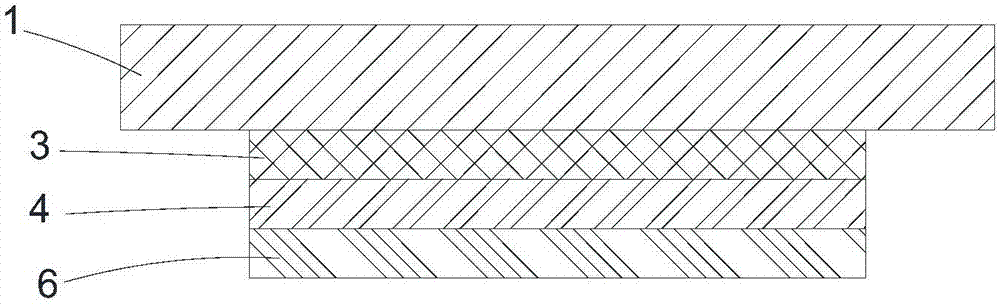

[0046] The difference between embodiment 2 and embodiment 1 is only that the optical adhesive layer 5 in embodiment 2 has an integrated structure, while the optical adhesive layer 5 in embodiment 1 is divided into two parts, and the structures of the remaining parts are the same. In embodiment 2 Among them, the maximum thickness of the optical adhesive layer 5 is 100um.

[0047] Such as Figure 2-5 Shown, the manufacture method of a kind of protective glass of the window of the embodiment of the present invention 2 comprises the steps:

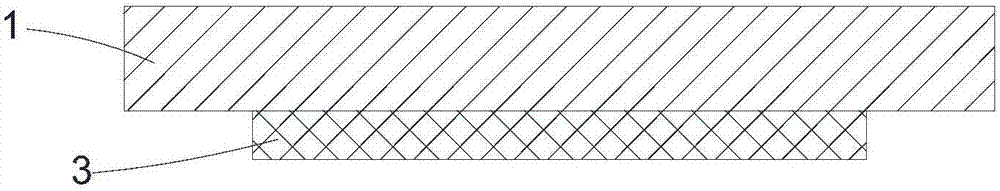

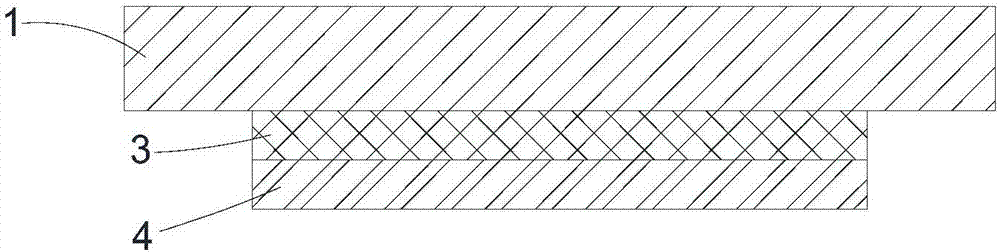

[0048] Step S1, such as diagram 2-1 As shown, a cover plate 1 is provided, and an ink layer 2 is arranged on one side surface of the cover plate 1 outside the visible area. Specifically, the ink layer 2 can be pasted on the cover plate 1 by ink film or printing the ink layer 2 by printing;

[0049] Step S2, such as Figure 2-2 As shown, a polarizer layer 3 is provided between the ink layers 2 in the visible area of the cover plate 1. Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com