Multi-protection pulse current source

A pulse current, multiple protection technology, applied in the field of electronics, can solve the problems of single machine work, can not be dealt with in time, does not have overcurrent protection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

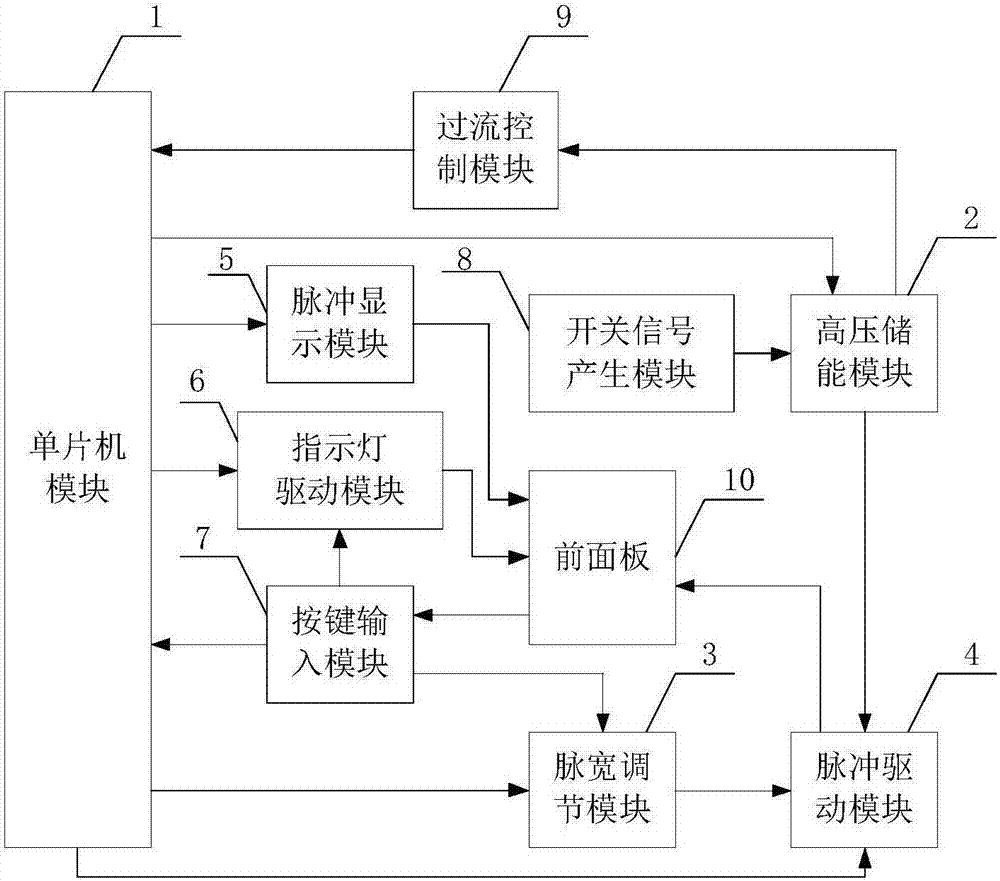

[0038] Example 1 Overall structure of the system

[0039] like figure 1 As shown, the system structure includes a single-chip microcomputer module 1, a high-voltage energy storage module 2, a pulse width adjustment module 3, a pulse drive module 4, a pulse display module 5, an indicator light drive module 6, a key input module 7, a switch signal generation module 8, a Flow control module 9 and front panel 10.

Example Embodiment

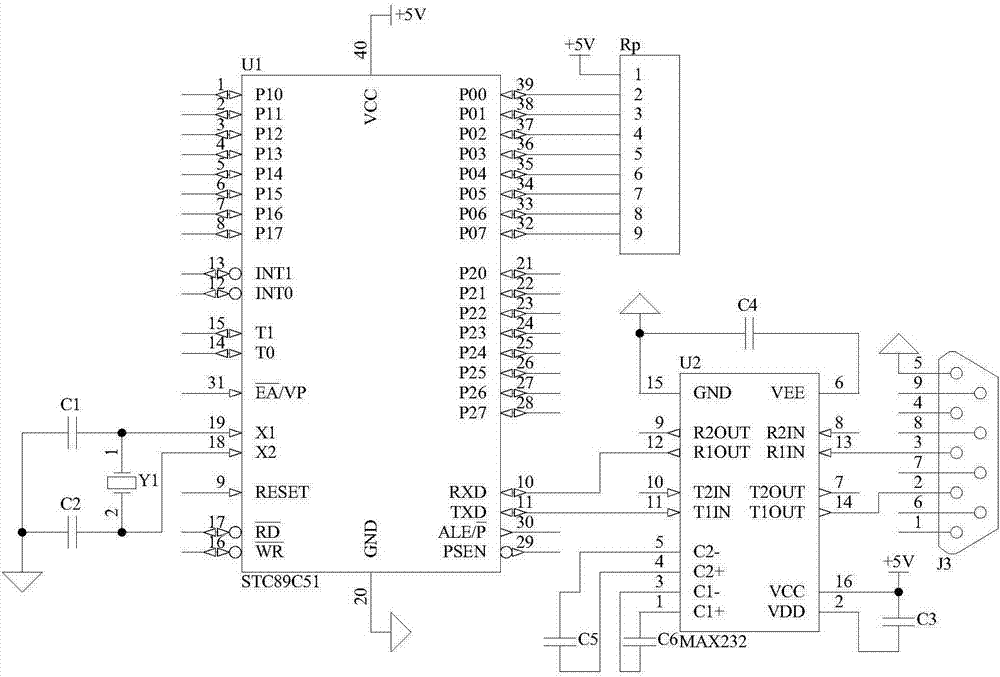

[0040] Embodiment 2 SCM module

[0041] like figure 2 As shown, the structure of the single-chip microcomputer module 1 is that the port VCC and port GND of the single-chip microcomputer U1 are respectively connected to +5V power supply and digital ground, the crystal oscillator Y1 is connected between the port X1 and the port X2, and the port X1 and the port X2 are also connected through the capacitor C1. And capacitor C2 is connected to digital ground, common terminal 1 of resistance Rp is connected to +5V power supply, other pins are respectively connected to ports P00~P07 of microcontroller U1, port VCC and port GND of level conversion chip U2 are respectively connected to +5V power supply and digital ground, port VDD is connected to +5V power supply through capacitor C3, port VEE is connected to digital ground through capacitor C4, capacitor C5 is connected between port C2+ and port C2-, capacitor C6 is connected between port C1+ and port C1-, port T1IN and port R1OUT C...

Example Embodiment

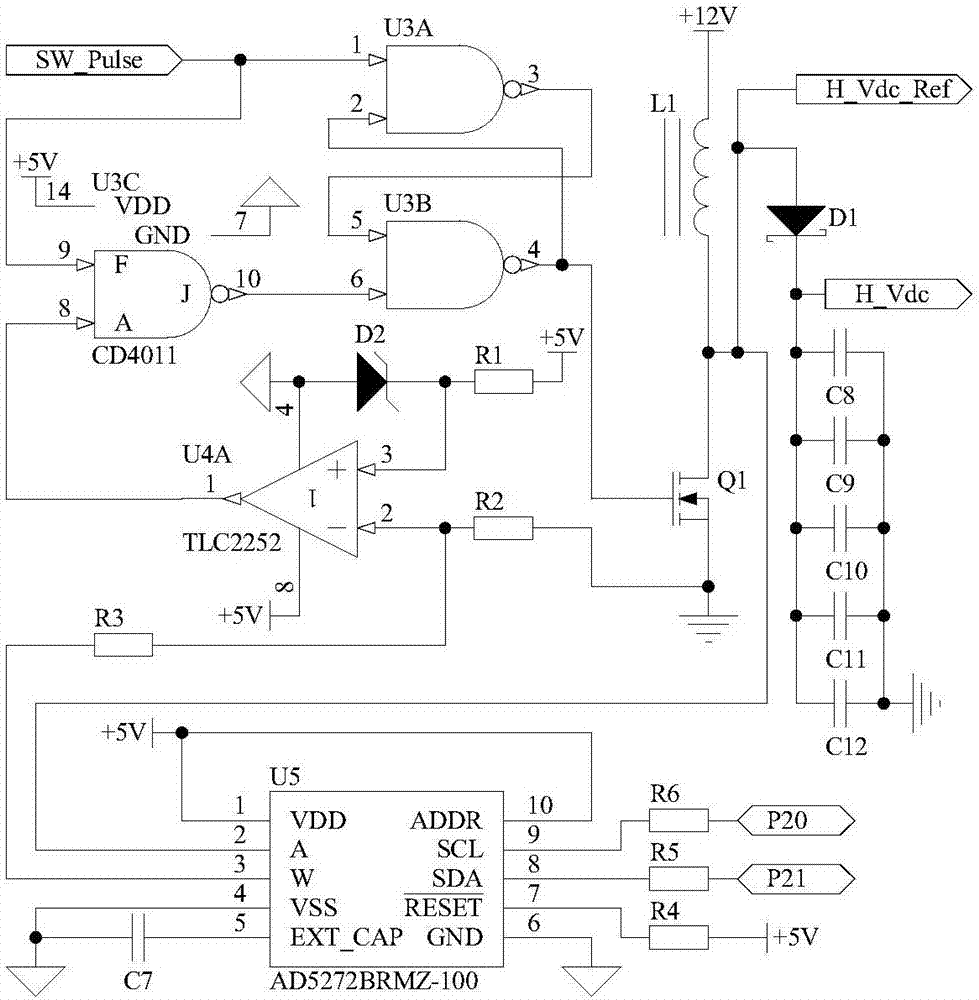

[0043] Embodiment 3 Switch signal generation module

[0044] like Figure 9 As shown, the structure of the switch signal generating module 8 is as follows: the port VCC and port GND of the 555 timer U12 are connected to the +5V power supply and the digital ground respectively, the port RST is connected to the +5V power supply, and the port DISC is connected to the +5V power supply through the resistor R32. , the port DISC is connected to the port THR and the port TRIG through the resistor R33, the port TRIG is connected to the digital ground through the capacitor C24, the port CVOLT is connected to the digital ground through the capacitor C25, and the port OUT is used as the output of the switch signal generation module 8. The model of 555 timer U12 is TLC555;

[0045] The switching signal generating module 8 is used for generating a square wave with a frequency of 35.37 kHz and a duty ratio of 85.1%, and provides a switching signal for the high-voltage energy storage module ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap