Card holder, and manufacturing method thereof

A card tray and electronic card technology, applied in the direction of electrical components, transmission systems, etc., can solve the problems of poor appearance performance and poor one-time molding performance, and achieve good molding performance, stable overall structure, and favorable overall thinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

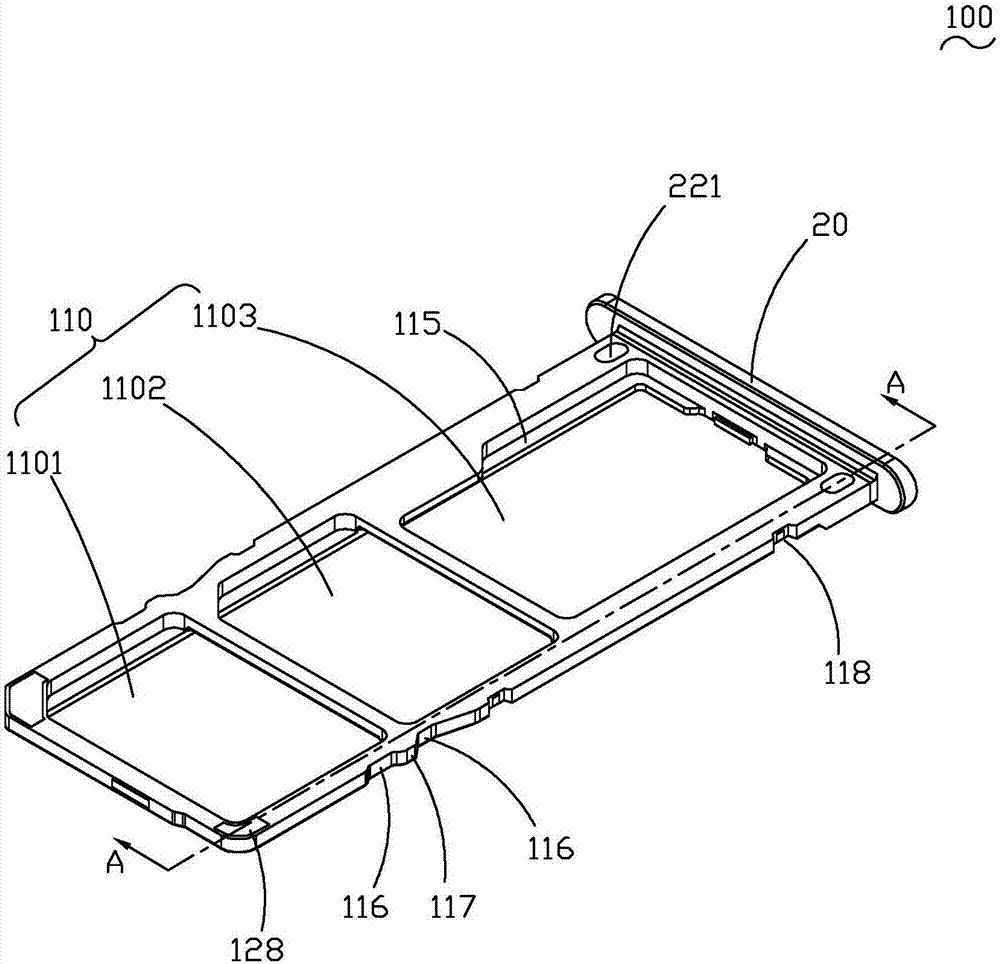

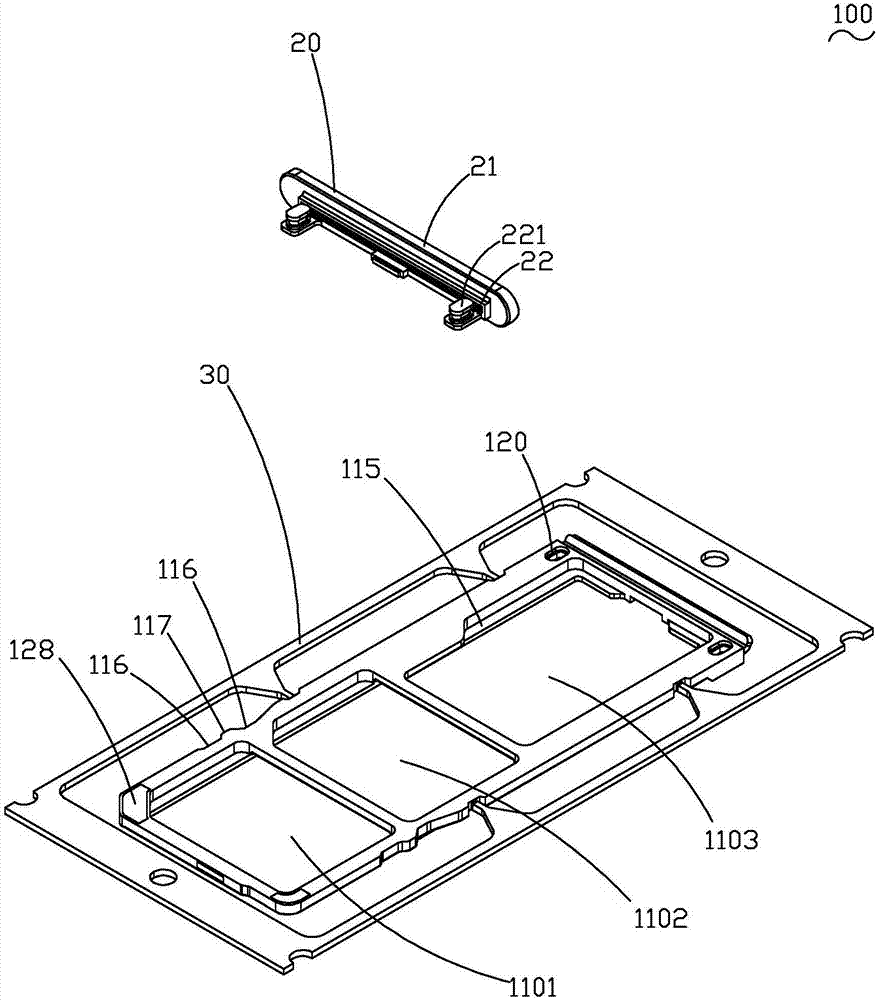

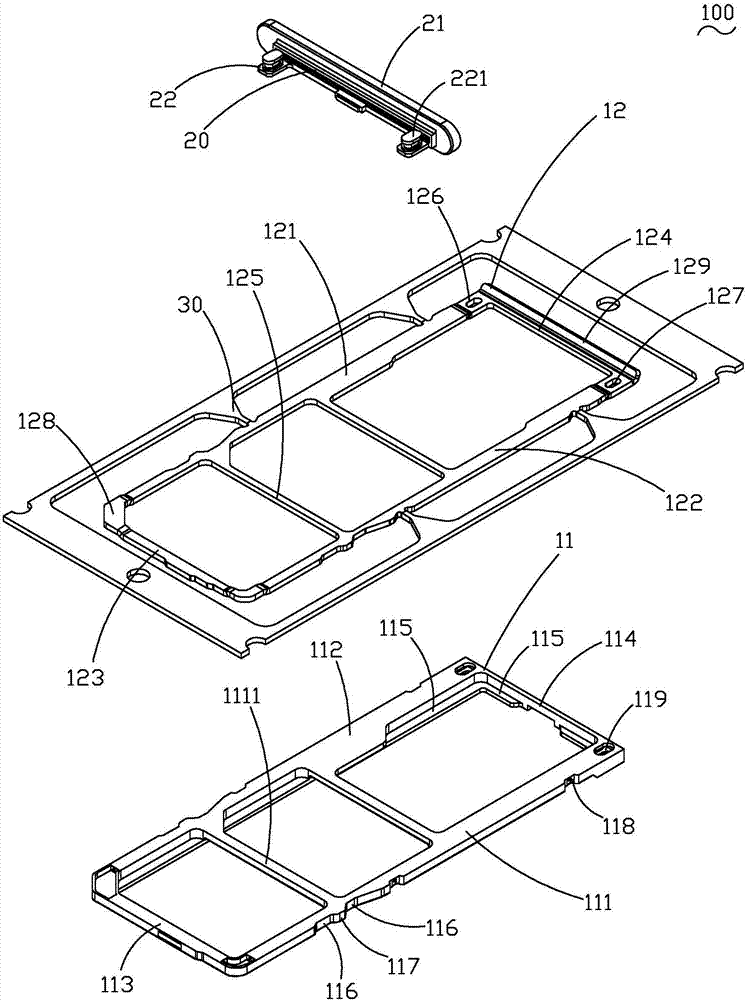

[0027] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. For the convenience of the full text, please refer to all the following directions figure 1 , wherein the insertion end of the card tray is regarded as the front end, and the end where the operation part 12 is located is regarded as the rear end, and the width direction of the card tray 100 is also the left-right direction.

[0028] see Figure 1 to Figure 4 As shown, the present invention discloses a card holder 100 , which includes a substantially frame-shaped main body 10 and an operating portion 20 integrally provided with one end of the main body 10 . The main body portion 10 includes a main body insulating portion 11 and a main body metal portion 12 embedded in the main body insulating portion 11 through integral molding.

[0029] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com