Hardware product automatic spraying device

An automatic spraying and product technology, applied in the direction of coating, spray booth, spraying device, etc., can solve the problems of low work efficiency, waste of manpower, troubles in the spraying process of hardware products, etc., and achieve the effect of saving production cost and inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

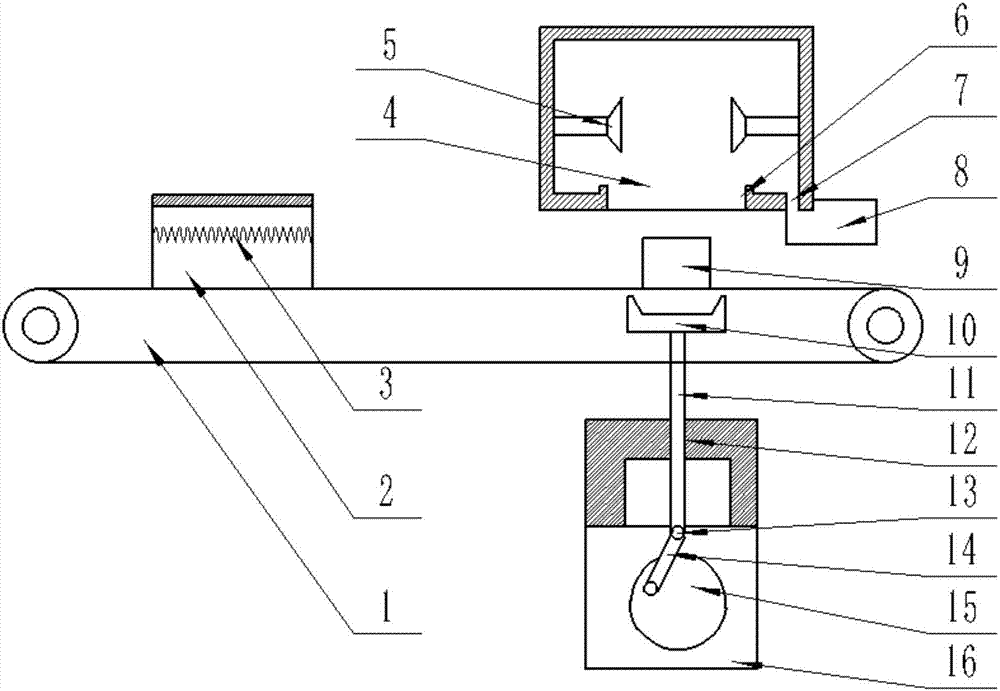

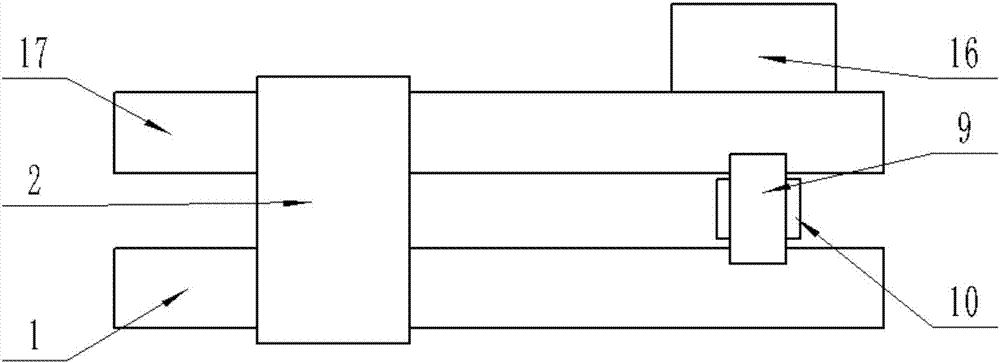

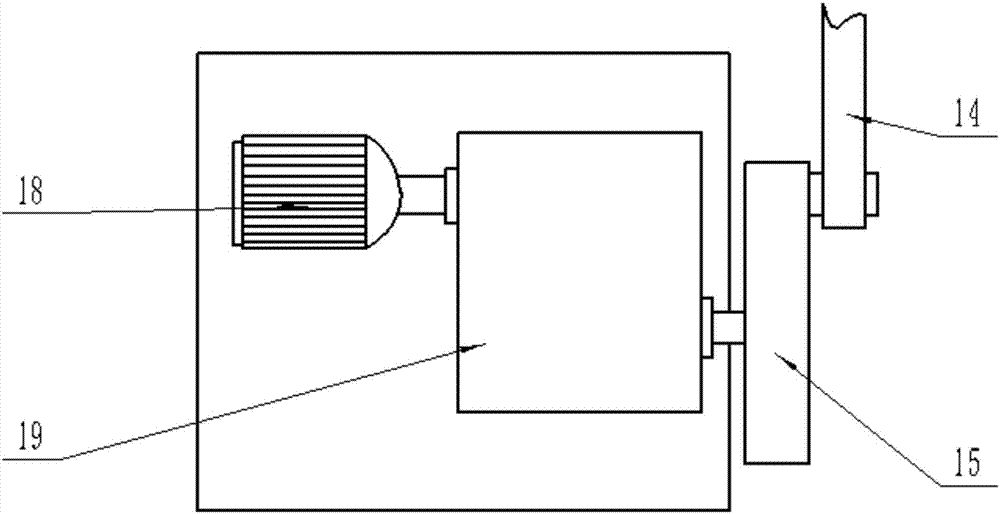

[0015] see Figure 1-3 , an automatic spraying equipment for hardware products, comprising a first conveyor belt 1, a second conveyor belt 17, a tray 10, a reduction box 16, a spray box 4 and a drying box 2; the first conveyor belt 1 and the second conveyor belt 17 are placed in parallel, A gap smaller than the size of the workpiece 9 is left in the middle, and the workpiece 9 can be slowly sent from the right end to the left end; the pallet 10 is arranged at the gap between the first conveyor belt 1 and the second conveyor belt 17, and can be moved without touching the conveyor belt. Hold up the workpiece 9 to move up and down, and the lower end is connected with a support rod 11; the support rod 11 is stuck in the card slot 12, can slide up and down freely, and the lower end is connected with the connecting rod 14 through the hinge 13; the card s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap