Integrated overturning roller bed

A technology that integrates turning and turning rollers, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of the large influence of the technical level of assembly personnel on assembly accuracy, the long lifting distance of the jacking and turning mechanism, and the prolonged occupation time, etc. problems, to achieve the effect of meeting the requirements of large-angle flipping, improving the qualified rate of press-fitting, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

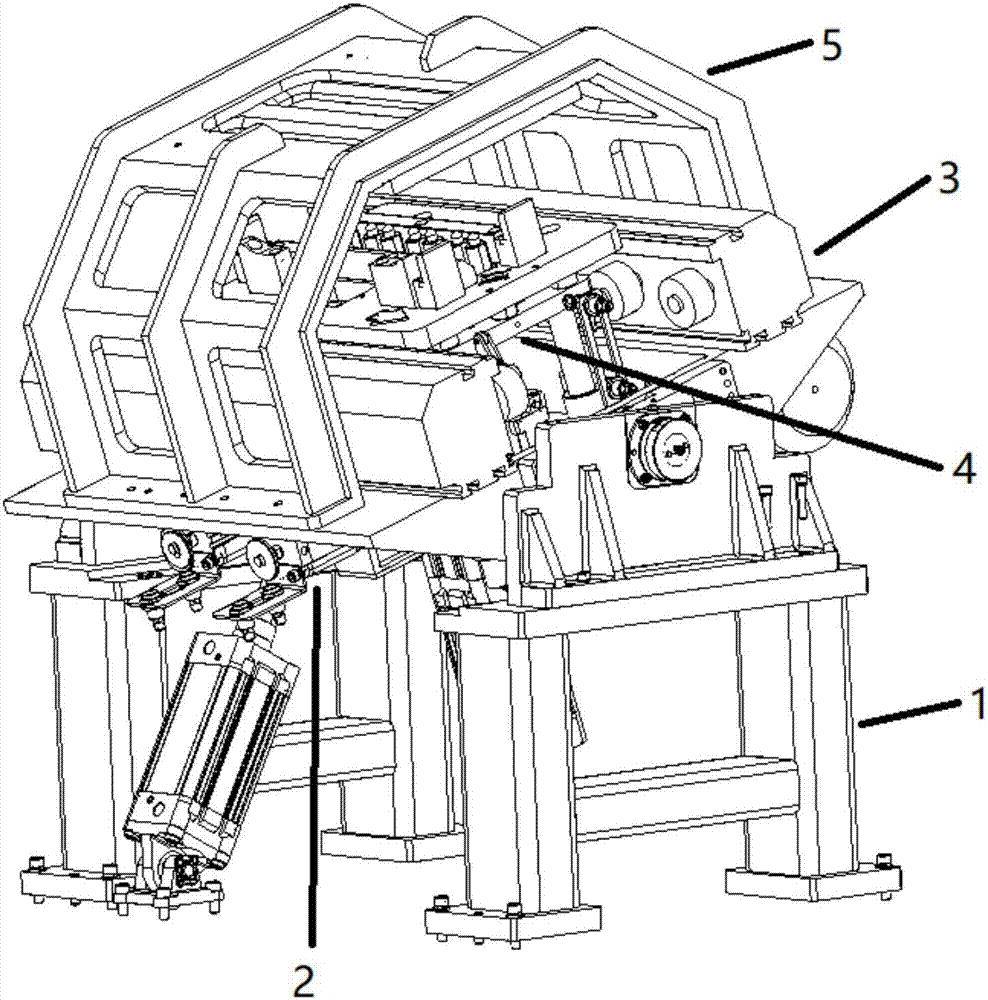

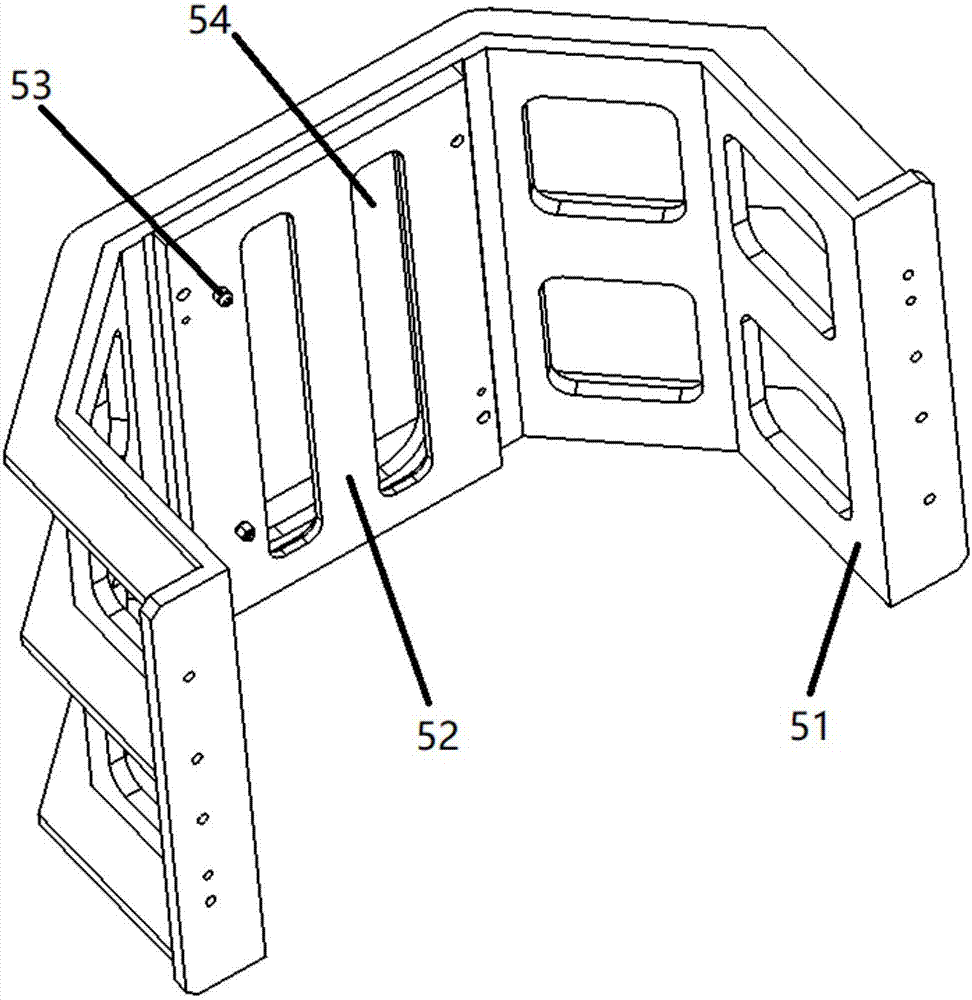

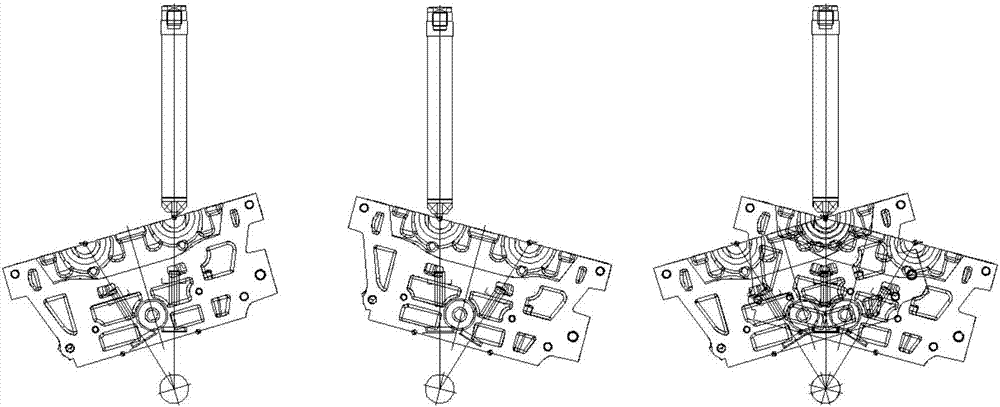

[0022] like figure 1 The integrated overturning roller table shown, the integrated overturning roller table includes: a bracket 1, a rotating mechanism 2, a roller table mechanism 3, a jacking mechanism 4 and an integrated positioning fixture 5, and the rotating mechanism 2 is arranged on the bracket 1 , the roller mechanism 3 is arranged on the rotating mechanism 2, the jacking mechanism 4 is arranged between the roller mechanism 3 and fixed on the rotating mechanism 2, the integrated The positioning fixture 5 is set above the roller table mechanism 3 and connected to the rotation mechanism 2. The workpiece flows into the integrated turning roller table on the pallet, and an RFID radio frequency reading and writing device is installed on the roller table, and the RFID radio frequency reading and writing device confirms the tray Does the upper workpiece need to be operated at this station? When the workpiece does not need to be operated at this station, the pallet flows direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com