3D printing head assembly, 3D printer and printing method thereof as well as storage medium

A technology of 3D printers and print heads, applied in 3D object support structures, additive manufacturing, coating devices, etc., can solve the problems of rigid use of colors, inability to use various colors flexibly, and insufficient color variety, etc., to achieve Achieve full-color printing, flexible use, and achieve color-changing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

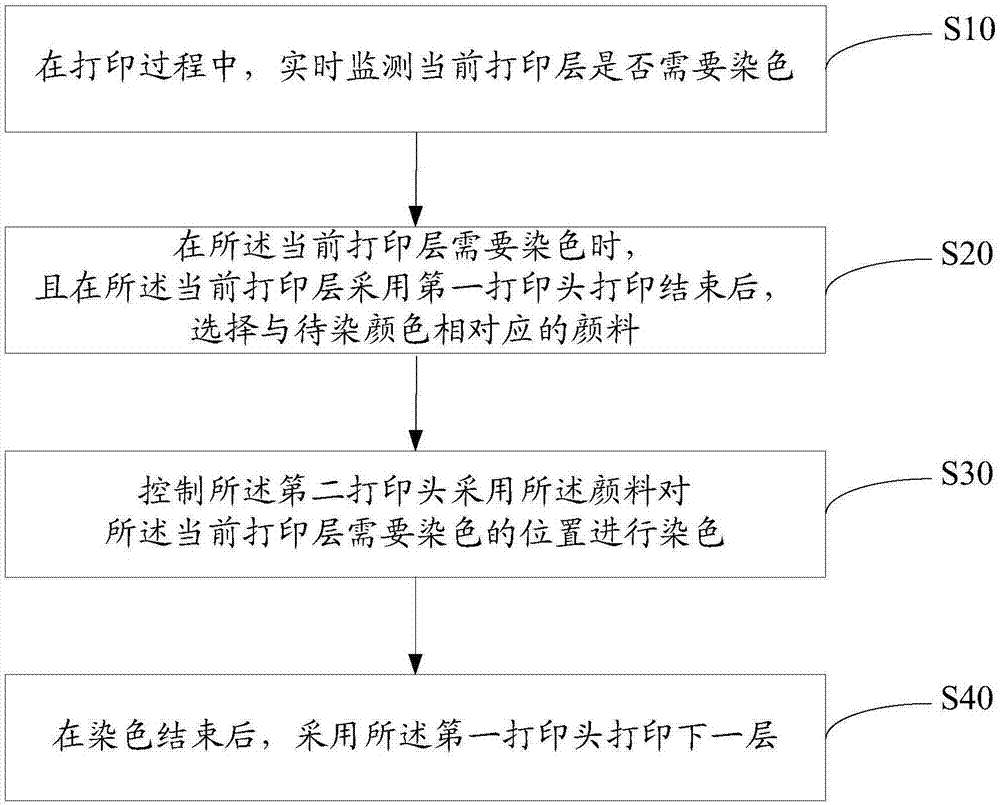

[0080] refer to image 3 , the first embodiment of the printing method of the 3D printer provided by the present invention, the printing method of the 3D printer in this embodiment includes:

[0081] Step S10, during the printing process, monitor in real time whether the current printing layer needs to be dyed;

[0082] When printing colorful or multicolored portraits, animals or scenes, it is necessary to analyze and process the dyed area of the print to determine which layer needs to be dyed and the position to be dyed in the printed layer that needs to be dyed when the slice is layered. .

[0083] The judgment of whether the current printing layer needs to be dyed and the position that needs to be dyed can be judged according to the color boundary in the current printing layer. Specifically, the software can be used to identify whether there are parts with different colors on the to-be-printed piece, and then analyze whether the current printing layer has color Differen...

no. 4 example

[0110] refer to Figure 6 , the fourth embodiment of the printing method of the 3D printer provided by the present invention, based on all the above-mentioned embodiments, the printing method of the 3D printer includes:

[0111] Step S50, when receiving the printing instruction, acquire the dyed area of the to-be-printed piece in the model file of the to-be-printed piece;

[0112] The dyed area is an area where the part to be printed needs to be dyed, or an area that is different from the color of the main body of the printed part. The dyed area can be a single-color area or a multi-color area. The dyed area can be based on Different from the color of the to-be-printed piece, the position of the dyed area can also be analyzed according to the model of the to-be-printed piece to obtain the dyed area.

[0113] Step S60, acquiring the position of the dyed area according to the dyed area, so as to monitor in real time whether the current printing layer needs to be dyed accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com