A temperature-sensitive color-changing wall

A temperature-sensitive discoloration and wall technology, applied to walls, buildings, building components, etc., can solve problems such as inability to effectively meet market demand, limit the pursuit of living room space, and single color, so as to achieve clear presentation and meet the needs of the market demand, to achieve the effect of effective conduction of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

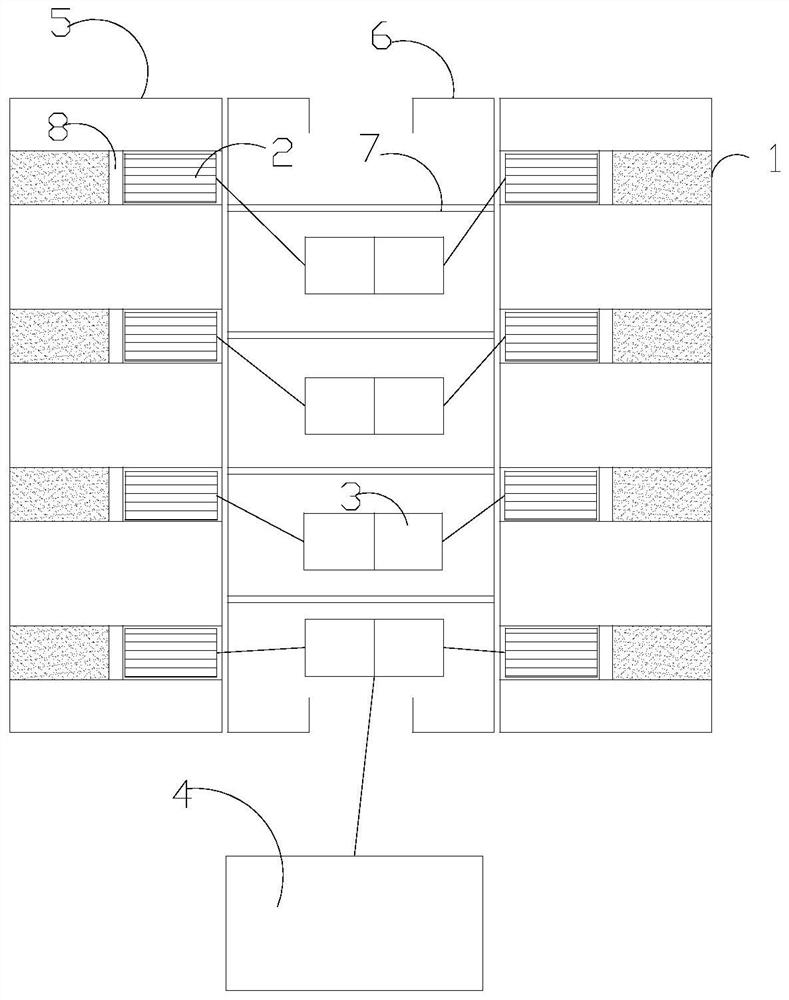

[0041] combine figure 1 As shown, Embodiment 1 of the present invention provides a temperature-sensitive color-changing wall, including gypsum boards 5 arranged on both sides of the wall, and keel units located inside the wall and used to connect the gypsum boards 5. The above-mentioned keel units are used In order to form a skeleton supporting the gypsum boards 5 on both sides of the wall, to realize the stable connection of the gypsum boards 5 .

[0042] In this embodiment, the above-mentioned temperature-sensitive color-changing wall body also includes a color-changing component 1, a heating component 2 and a control circuit; wherein, a through hole is provided on the gypsum board 5, and the color-changing component 1 and the heating component 2 are all arranged in the through hole; Component 1 is arranged at the end of the through hole close to the front of the gypsum board 5, and the heating component 2 is arranged at the end of the through hole close to the back of the g...

Embodiment 2

[0055] Embodiment 2 of the present invention provides a temperature-sensitive color-changing wall. The main structure is similar to that of Embodiment 1. It also includes gypsum boards arranged on both sides of the wall, and keel units arranged inside the wall and used to connect the gypsum boards. The temperature-sensitive color-changing wall also includes a color-changing component, a heating component, and a control circuit; for the specific configuration of the main structure, please refer to the detailed description in Embodiment 1, and the purpose here is to explain the difference between the two.

[0056] In this embodiment, the above-mentioned color-changing material includes a material box and a temperature-sensitive color-changing material filled in the material box, and the material box is set as a transparent material box.

[0057] In the specific operation, the above-mentioned material box is preferably a material box of light-transmitting glass. The setting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com