Installation mobile support for bridge floor flange bottom surface pipe of in-service bridge and operation method

A technology for installation of mobile brackets and pipes, which is applied to bridges, bridge parts, bridge construction, etc., and can solve problems such as unsuitable for section-by-section installation, limited longitudinal length, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

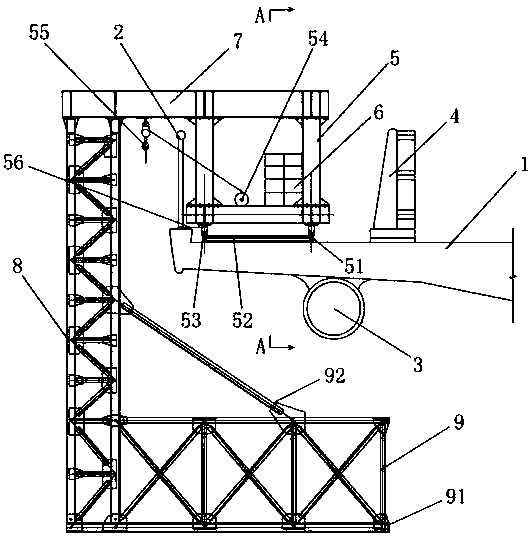

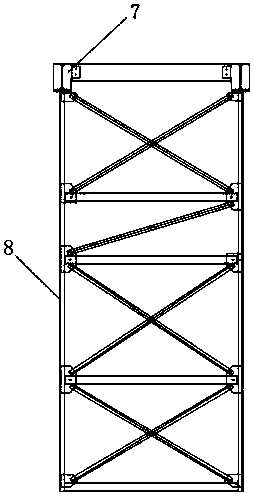

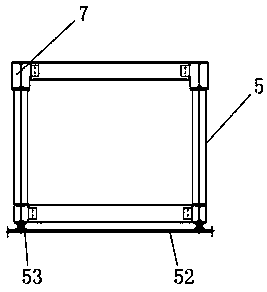

[0072] Such as Figure 1~Figure 4 As shown, 1. Bridge deck flange, 2. Railing, 3. Pipeline, 4. Water horse, 5. Driving, 51. Track, 52. Axle, 53. Moving wheel, 54. Hoist, 55. Hook, 56 .Wire rope, 6. Counterweight, 7. Beam, 8. Vertical truss, 9. Working platform, 91. Bottom plate, 92. Slanting bar.

[0073] Installation of mobile brackets and operation methods for pipelines on the underside of flanges of bridge decks in service, such as Figure 1~Figure 3 As shown, it is mainly used to quickly, conveniently, flexibly and firmly install the pipeline 3 section by section on the bottom surface of the deck flange 1 of the bridge in service.

[0074] Among them, the mobile support is installed along the longitudinal direction of the top surface of the flange 1 of the bridge deck, and the structure of each mobile support is exactly the same, according to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com