Modular closed bending machine back stop device

A closed type bending machine technology, applied in the field of bending machines, can solve the problems of loose and complicated installation, poor material blocking accuracy, and low installation efficiency, and achieve the effects of strong load impact resistance, strong bearing capacity, and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

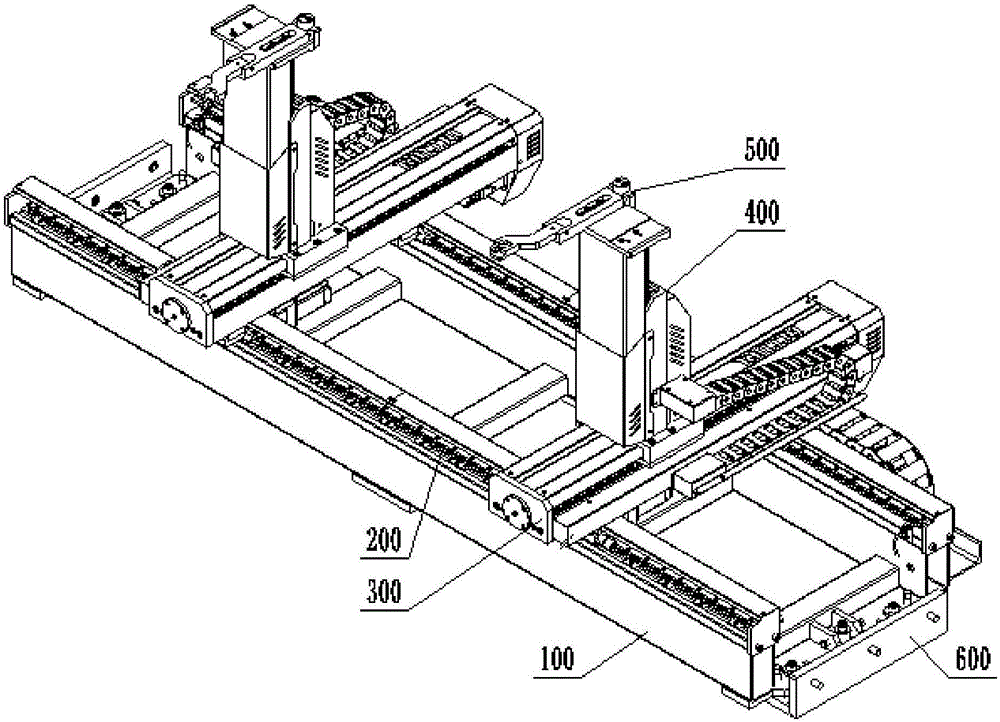

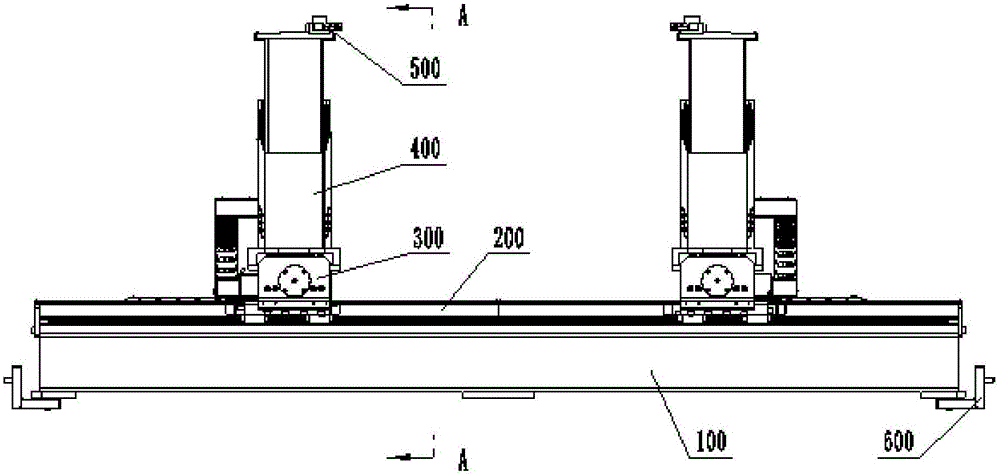

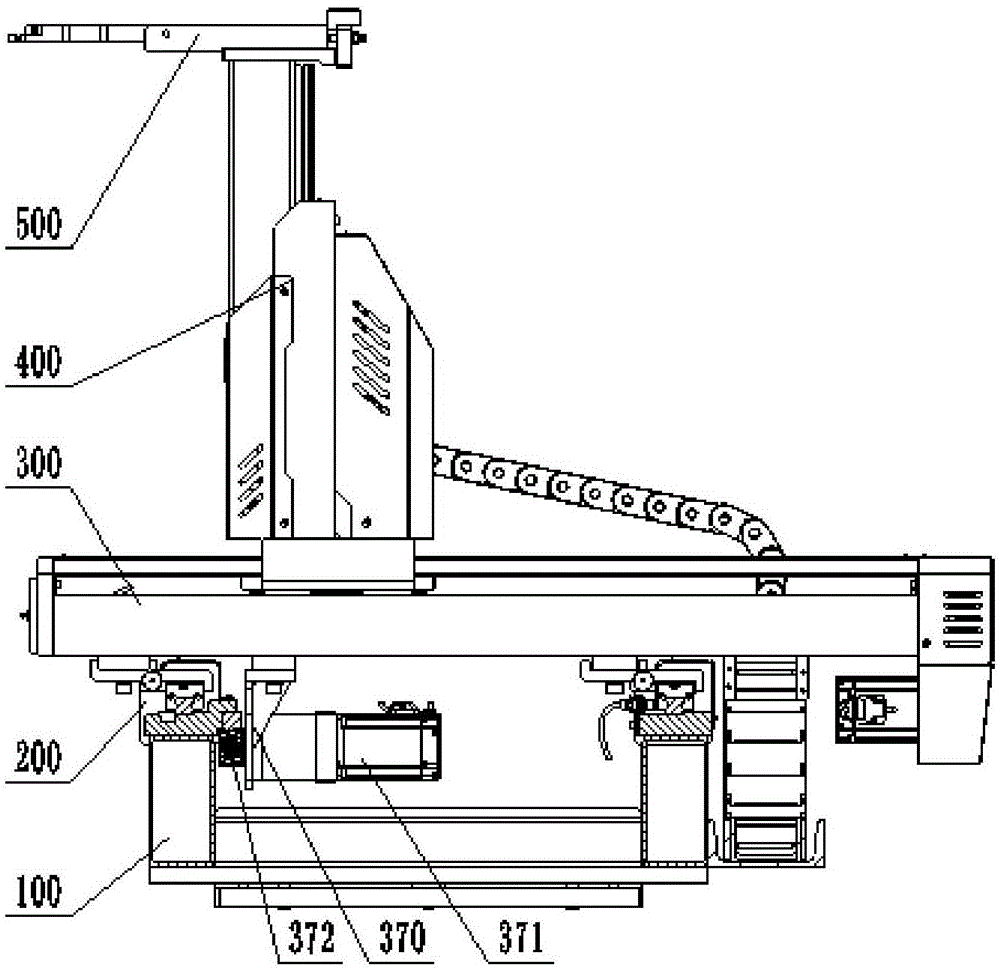

[0056] Such as figure 1 , figure 2 , image 3 As shown, this embodiment is a modular closed type bending machine back gauge, which is mainly composed of a pair of beams 100, an X-axis assembly 200, a Y-axis assembly 300, a Z-axis assembly 400, and a finger stop assembly 500. Among them, the X-axis assembly 200 is installed on the beam 100, the whole device is also installed on the bending machine through the beam 100, the Y-axis assembly 300 is installed on the X-axis assembly 200, and the X-axis assembly 200 is used to drive the Y-axis assembly 300 along the X-axis. The direction movement is the length direction of the bending machine; the Z-axis assembly 400 is installed on the Y-axis assembly 300, and the Y-axis assembly 300 is used to drive the movement of the Z-axis assembly 400 along the Y-axis direction, which is the width direction of the bending machine; The finger stop assembly 500 is installed on the Z axis assembly 400. The Z axis assembly 400 is used to drive the f...

Embodiment 2

[0068] This embodiment is an integrated and interoperable backgauge device for a bending machine. Its structure is basically the same as that of the first embodiment, except that the structure installed on the bending machine is optimized. It can be seen from Example 1 that the back gauge is installed by fixing the two ends of the beam 100 to the left and right wall panels of the bending machine. However, due to processing and installation errors, it will inevitably lead to the installation of the back gauge. There is a slight difference in the height of the two beams 100 in the vertical direction, and the two ends of the beam 100 will also be offset in the front and rear directions, which will cause the X-axis, Y-axis, and Z-axis to move greatly. The error caused by the inaccuracy of the stopper position, and this error cannot be eliminated by the adjustment of each axis motor, so the structure of the beam 100 installed on the bending machine is very important to the accuracy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com