Pneumatic one-way tensioning hook pin device

A one-way, cylinder technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of insufficient stroke of the pressing block, inconvenient operation and maintenance, and cumbersome device design, so as to achieve convenient operation. , the effect of reducing labor and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

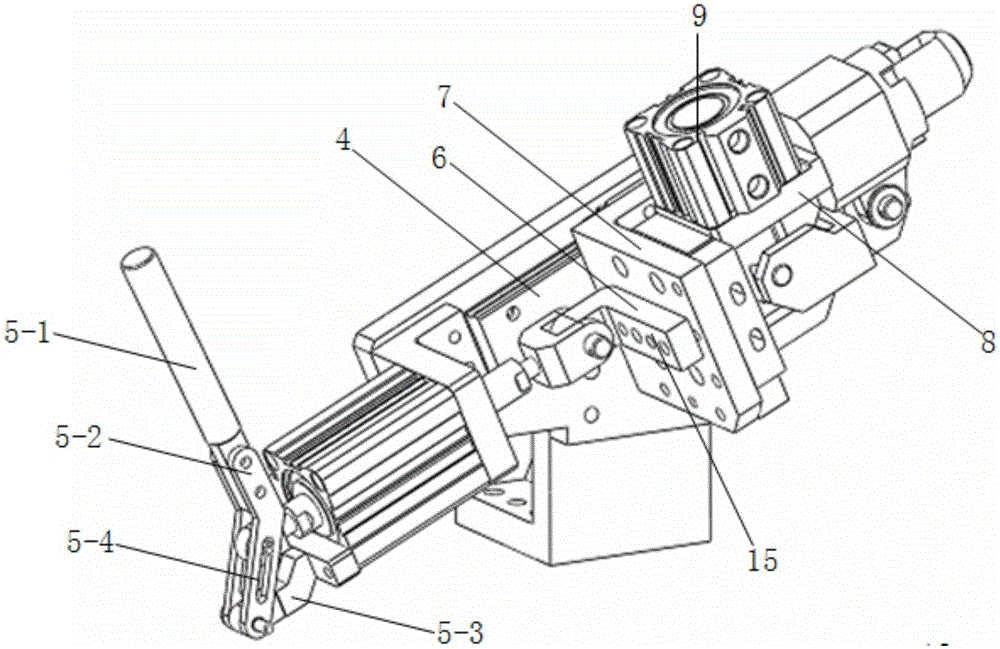

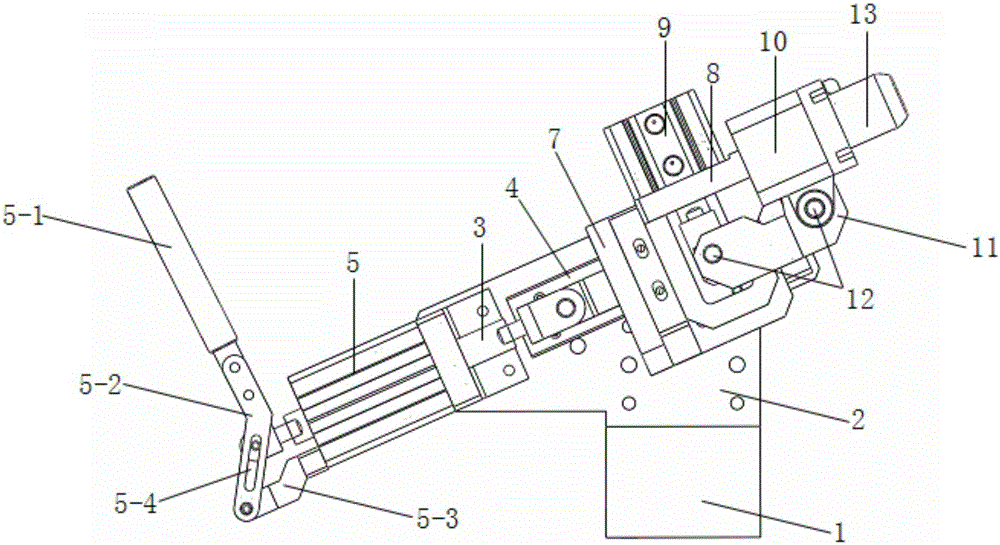

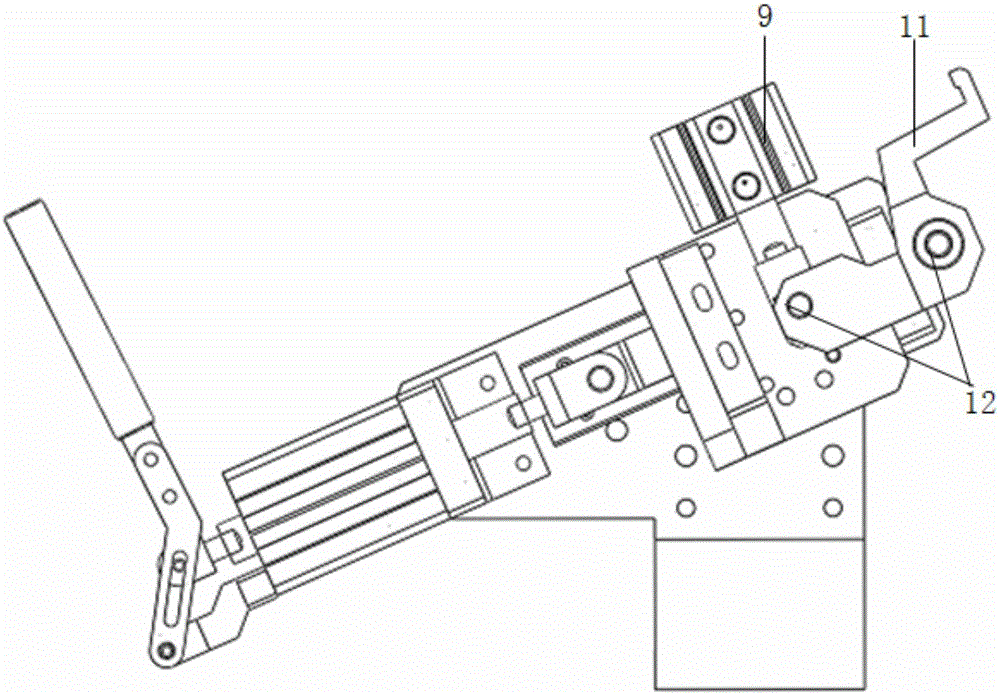

[0018] See attached Figure 1-7 As shown, a pneumatic one-way tensioning decoupling device includes a base 1 and a mounting frame 2 arranged on the base 1, and a first mounting bracket 3 and a linear guide rail 4 are sequentially installed on the mounting frame 2, Set on the first mounting bracket 3 is a first cylinder 5, connected to the first cylinder 5 is an L-shaped connecting piece 6, connected to the L-shaped connecting piece 6 is a sliding seat 7, and the sliding seat 7 is connected to the first connecting piece 6. The seat 7 is installed on the linear guide rail 4, and the second mounting bracket 8 is arranged on the sliding seat 7. What is located on the second mounting bracket 8 is the second cylinder 9 and the counter pin mounting seat 10, and the counter pin 11 It is connected to the second cylinder 9 and the detent mounting seat 10 through a pin shaft 12 , a positioning pin cap 13 is provided on the deactivation pin mounting seat 10 , and an opening 14 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com