Adjustable-type end beam assembly for bridge crane

A bridge crane, adjustable technology, applied in the direction of crane, traveling mechanism, load hanging element, etc., to achieve the effect of facilitating operation, reducing the wheel detachment from the guide rail, and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

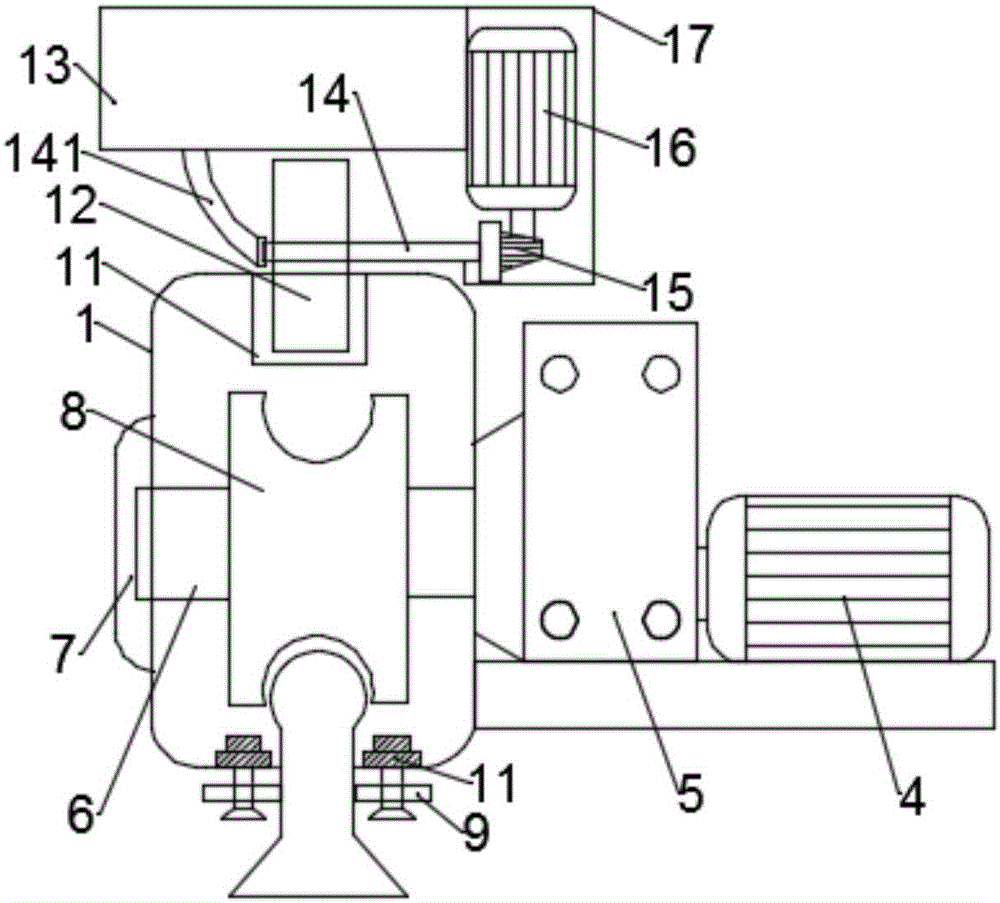

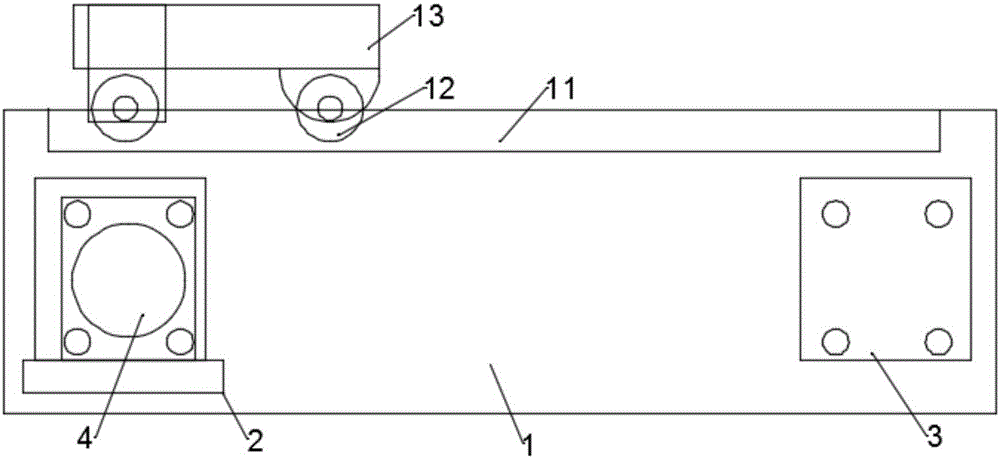

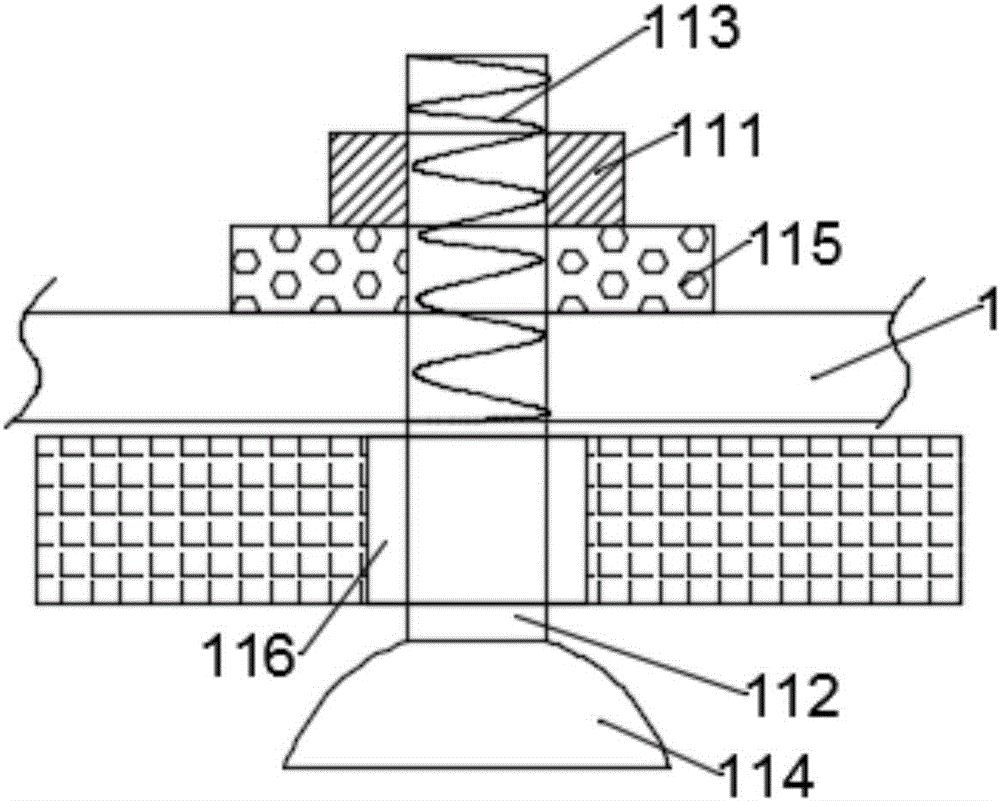

[0022] Such as figure 1 As shown, the present invention provides an adjustable end beam assembly of a bridge crane, including an end beam main frame 1, a driving wheel assembly 2 and a driven wheel assembly 3, and the driving wheel assembly 2 and the driven wheel assembly 3 are installed on the end beam assembly respectively. The two ends of the beam main frame 1, and the drive motor 4 is installed on the outer bottom plate of the driving wheel assembly 2, and the drive motor 4 is connected with the driving shaft 6 through the reducer 5, wherein one end of the driving shaft 6 is connected to the bearing The cover plate 7 is connected, and the other end of the driving shaft 6 is connected with the reducer 5, and the drive motor 4 will drive the driving shaft 6 to rotate evenly through the reducer 5, so that the driving shaft 6 drives the driving wheel 8 to rotate, and the The driving shaft 6 is fixedly installed inside the end beam main frame 1 through the bearing sleeve plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com