Substrate processing apparatus, maintenance tool, and maintenance method for substrate processing apparatus

A technology for a substrate processing device and a processing container, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve problems such as the inability to detect the height position of lifting pins, and achieve easy detection, fast maintenance, and restraint downtime. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

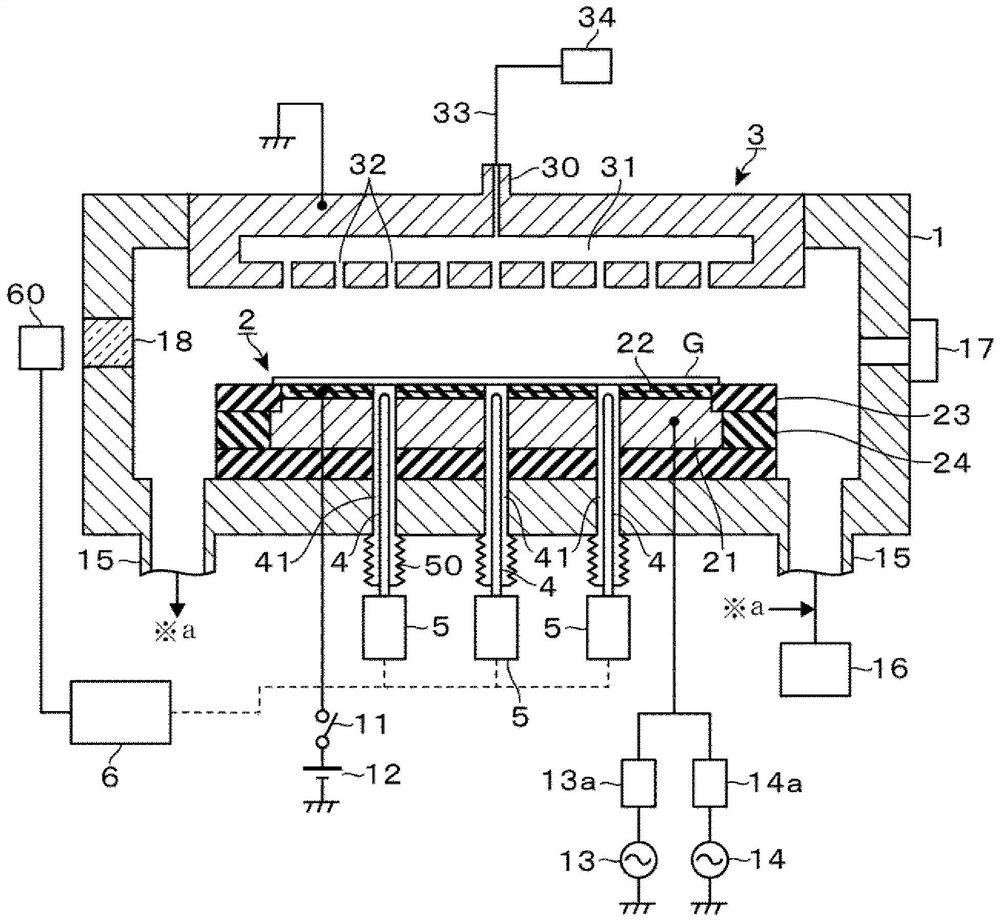

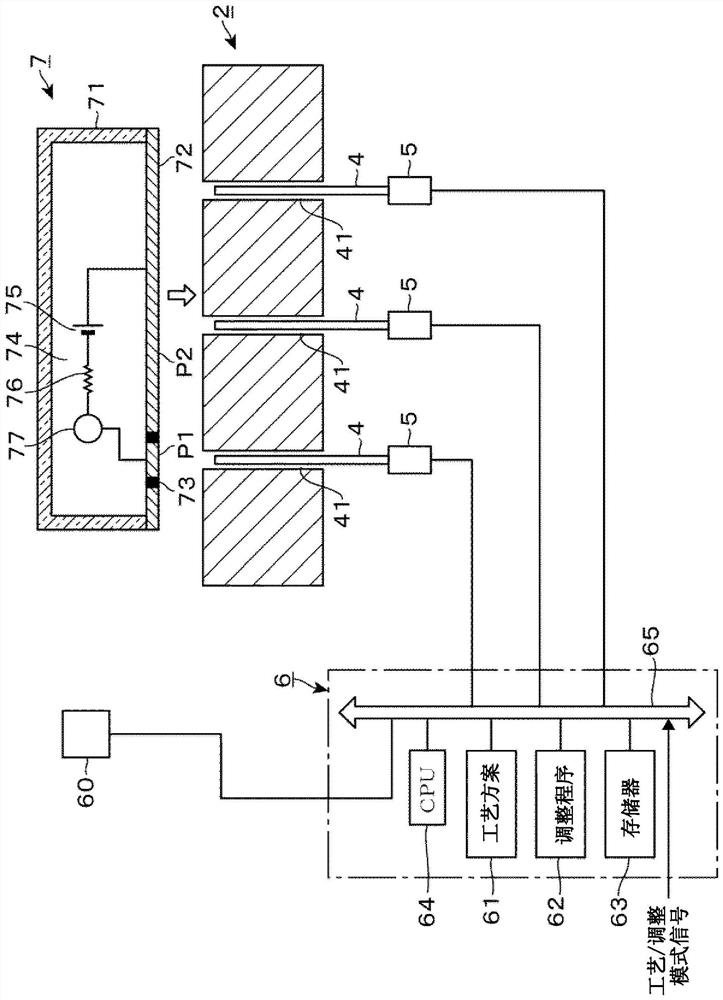

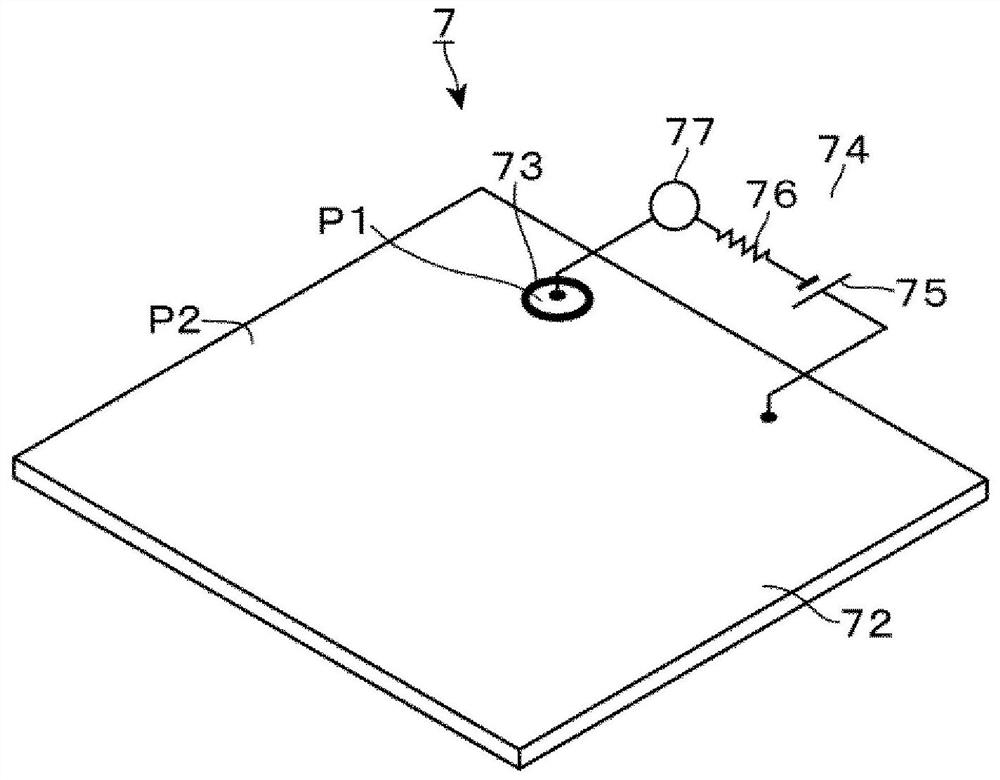

[0065] An embodiment in which the present invention is applied to a plasma etching apparatus as a vacuum processing apparatus will be described. The plasma etching apparatus 100 is configured as a capacitively coupled parallel plate plasma etching apparatus for etching a rectangular substrate G for FPD. Examples of the FPD include a liquid crystal display (LCD), an electroluminescence (EL) display, a plasma display panel (PDP), and the like.

[0066] The plasma etching apparatus 100 has a processing container 1 which is a vacuum container made of aluminum and formed in a rectangular tube shape. The surface of the processing container 1 is subjected to anodic oxidation treatment (aluminum oxide film treatment) as necessary. On the bottom of the processing container 1 , a mounting table 2 serving also as a lower electrode and on which a substrate G is mounted is provided with an insulator 10 interposed therebetween. The mounting table 2 has a main body 21 made of a conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com