A belt conveyor idler roller replacement device

A belt conveyor and idler technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of long operation time, poor safety, and affecting the operation efficiency of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

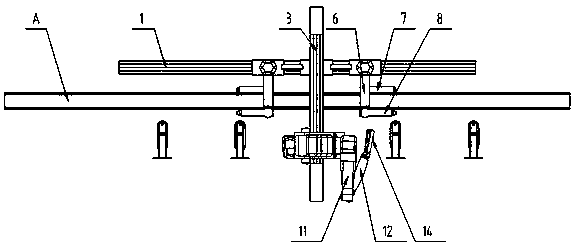

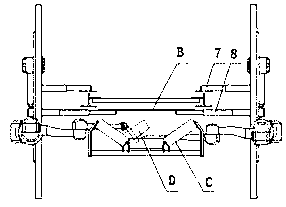

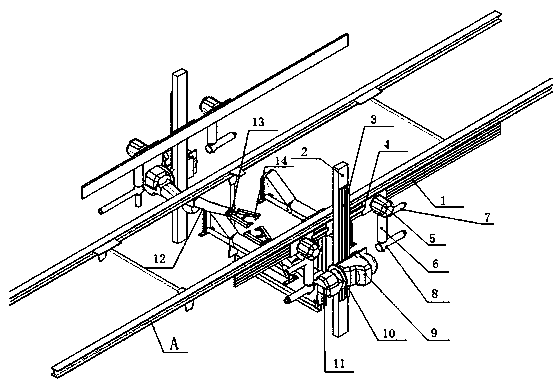

[0013] Referring to the accompanying drawings, a belt conveyor idler replacement device includes a first carriage 1, a first connecting plate 2, a second carriage 3, a second connecting plate 4, a supporting belt base 5, and a supporting belt base 6. The first telescopic arm 7, the second telescopic arm 8, the base 9, the base turntable 10, the big arm 11, the small arm 12, the gripper turntable 13, the gripper 14, the first carriage 1 is made of steel plate Composition, the slideway is arranged on the first carriage 1, and the first carriage 1 is fixed on the maintenance walking mechanism A that realizes the left and right movement of the idler roller replacement device of the belt conveyor. The first connecting plate 2 is composed of steel plates. It is fixed on the second connecting plate 4, and a slideway is set on the back of the second connecting plate 4. The second connecting plate 4 is connected with the first carriage 1, and the second carriage 3 is fixed on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com