Manipulator storage cabinet

A technology of manipulators and storage cabinets, which is applied in the field of storage cabinets and can solve problems such as the inability to apply automatic manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

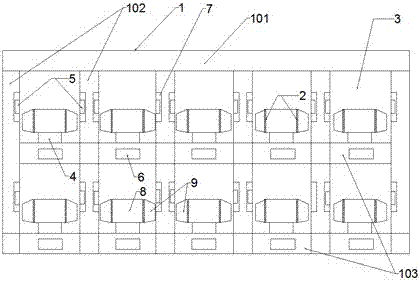

[0018] The manipulator storage cabinet includes: storage cabinet fixing rods 1, partitions fixed between the storage cabinet fixing rods 1, a storage room 3 formed between the partitions and storing the manipulator operation head, set in the storage room 3 and fixedly operated The manipulator fixing assembly at the rear end of the head pushes the manipulator out of the storage room 3 and is fixed to the pusher 4 at the rear end of the manipulator fixing assembly, and is arranged on the positioning assembly on the storage cabinet fixing rod 1 .

[0019] The storage cabinet fixed rod 1 is composed of: a push rod 101 arranged on the storage room 3 , a side bar 102 arranged on both sides of the storage room 3 , and a bottom bar 103 arranged under the storage room 3 . The positioning assembly consists of: a first induction block 5 arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com