Discharging and packaging device for printing paper roll

A paper roll and output slot technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problems of low packaging efficiency and labor consumption, and achieve the effect of convenient automatic installation and convenient packaging operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

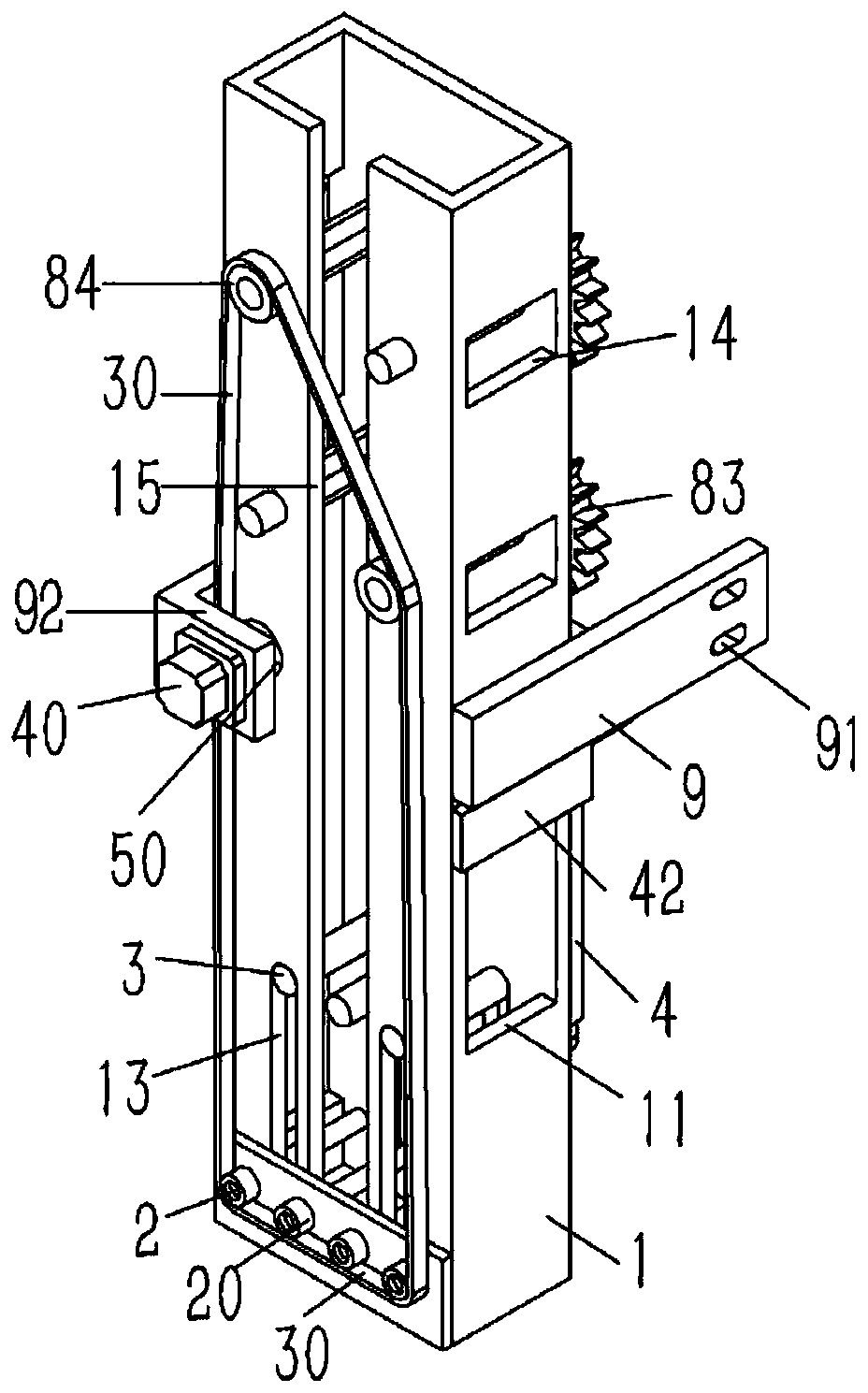

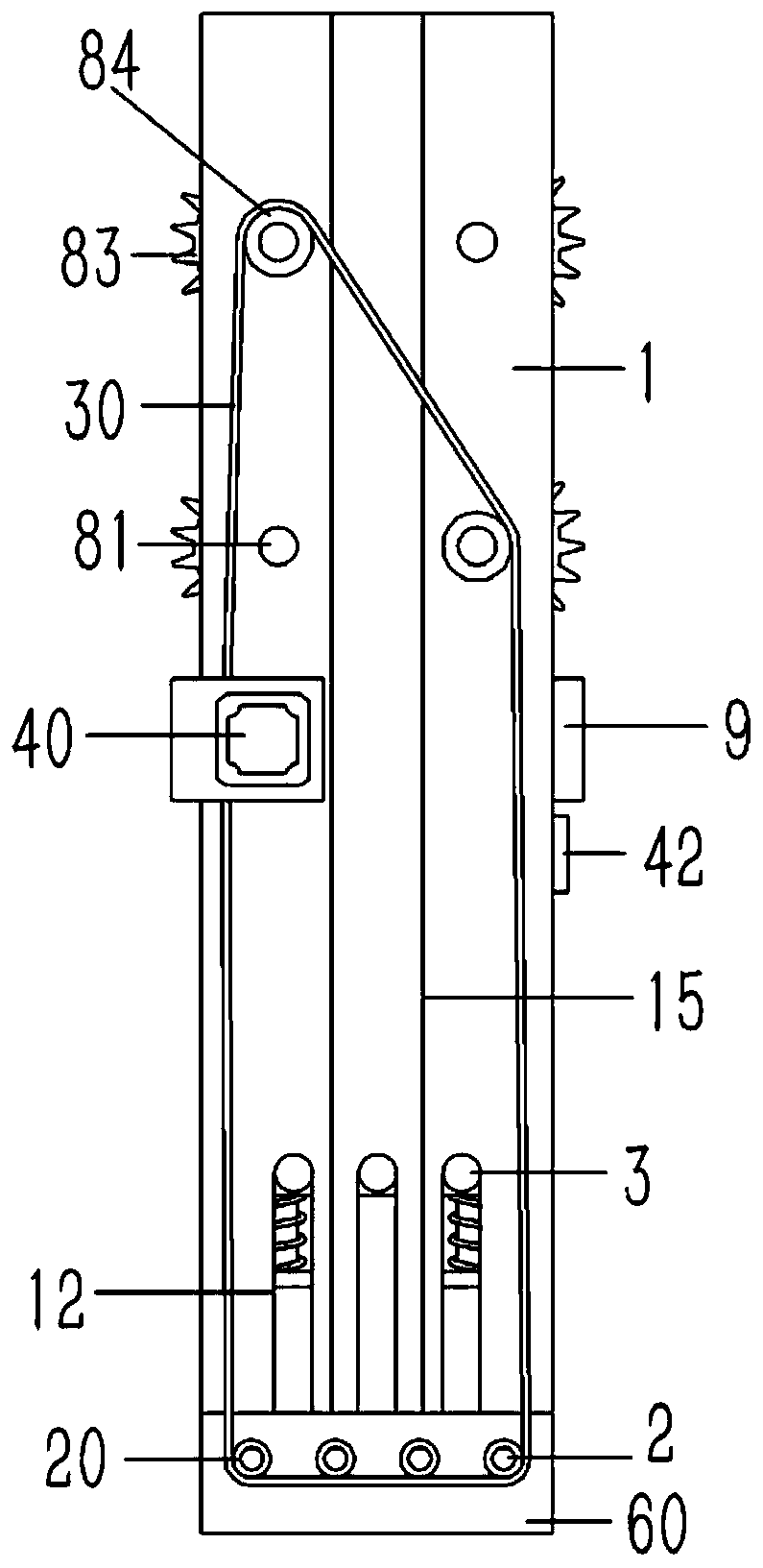

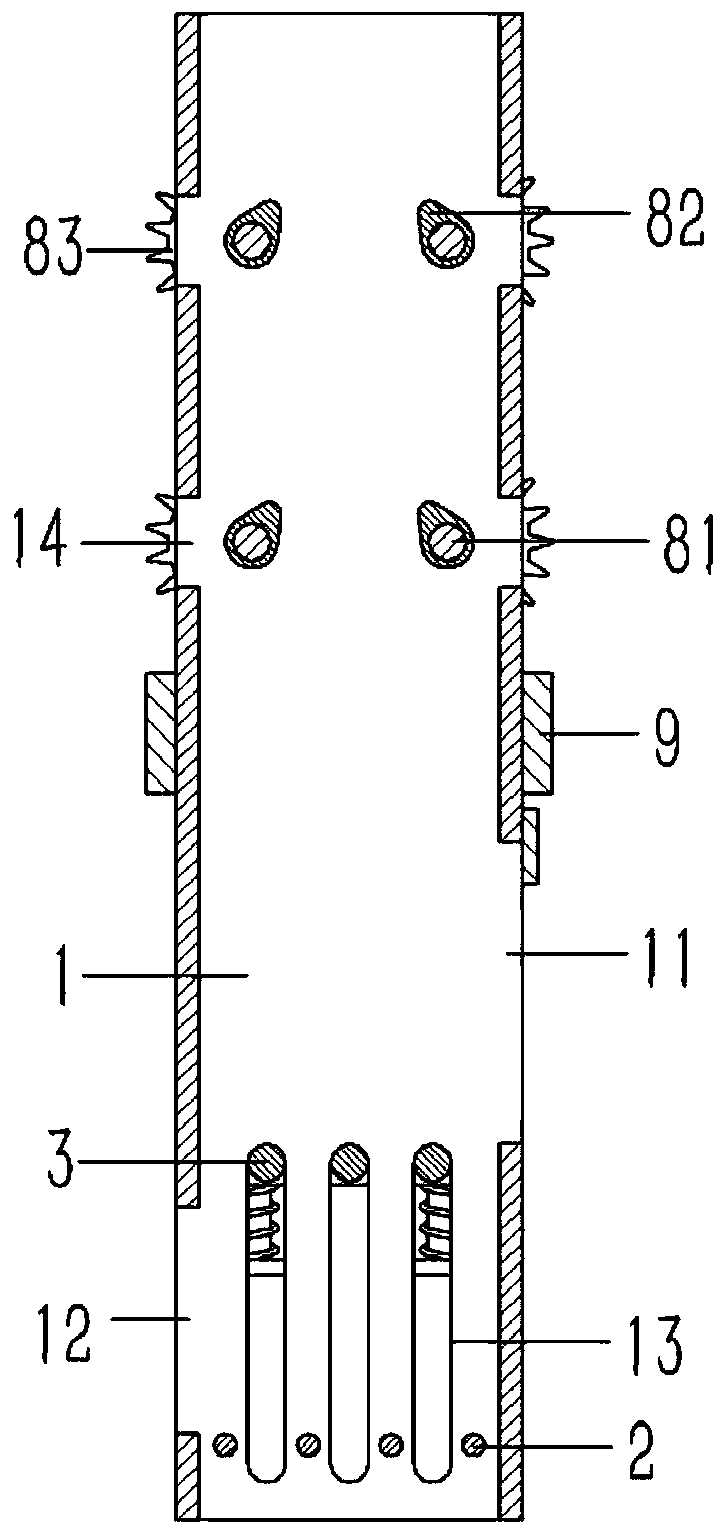

[0021] Example: see Figures 1 to 4 As shown, a discharge packaging device for printing paper rolls includes a rectangular and vertical output channel 1, the lower end of the output channel 1 is inserted with a number of longitudinal rollers 2, and the two ends of the rollers 2 are hinged On the output channel 1, the front end of the roller shaft 2 passes through the support plate 60 to insert and fix the first pulley 20, and the support plate 60 is fixed on the front end surface of the output channel 1, and the output between the roller shafts 2 A vertical guide groove 13 is formed on the front and rear end surfaces of the channel 1, and a longitudinal support rod 3 is inserted in the guide groove 13. The rear end of the support rod 3 is fixed on the slide plate 4, and the slide plate 4 is against the output On the rear end surface of the channel 1, a horizontal branch plate 41 is formed on the upper end of the slide plate 4, and a plurality of T-shaped guide rods 5 are inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com