Patents

Literature

32results about How to "Easy to install automatically" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

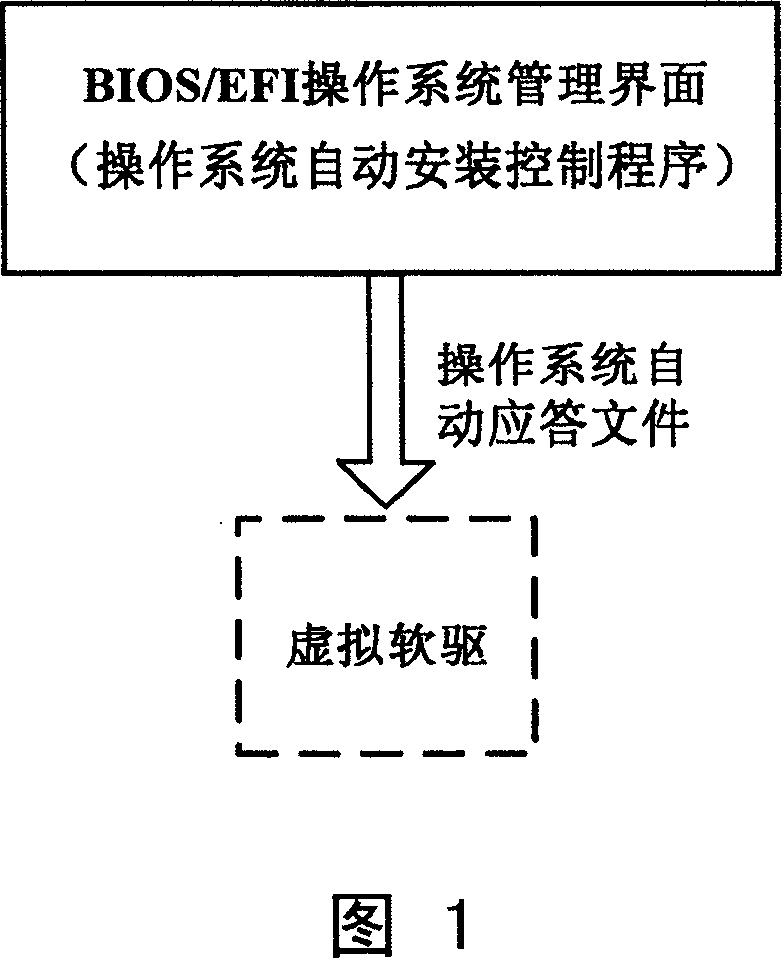

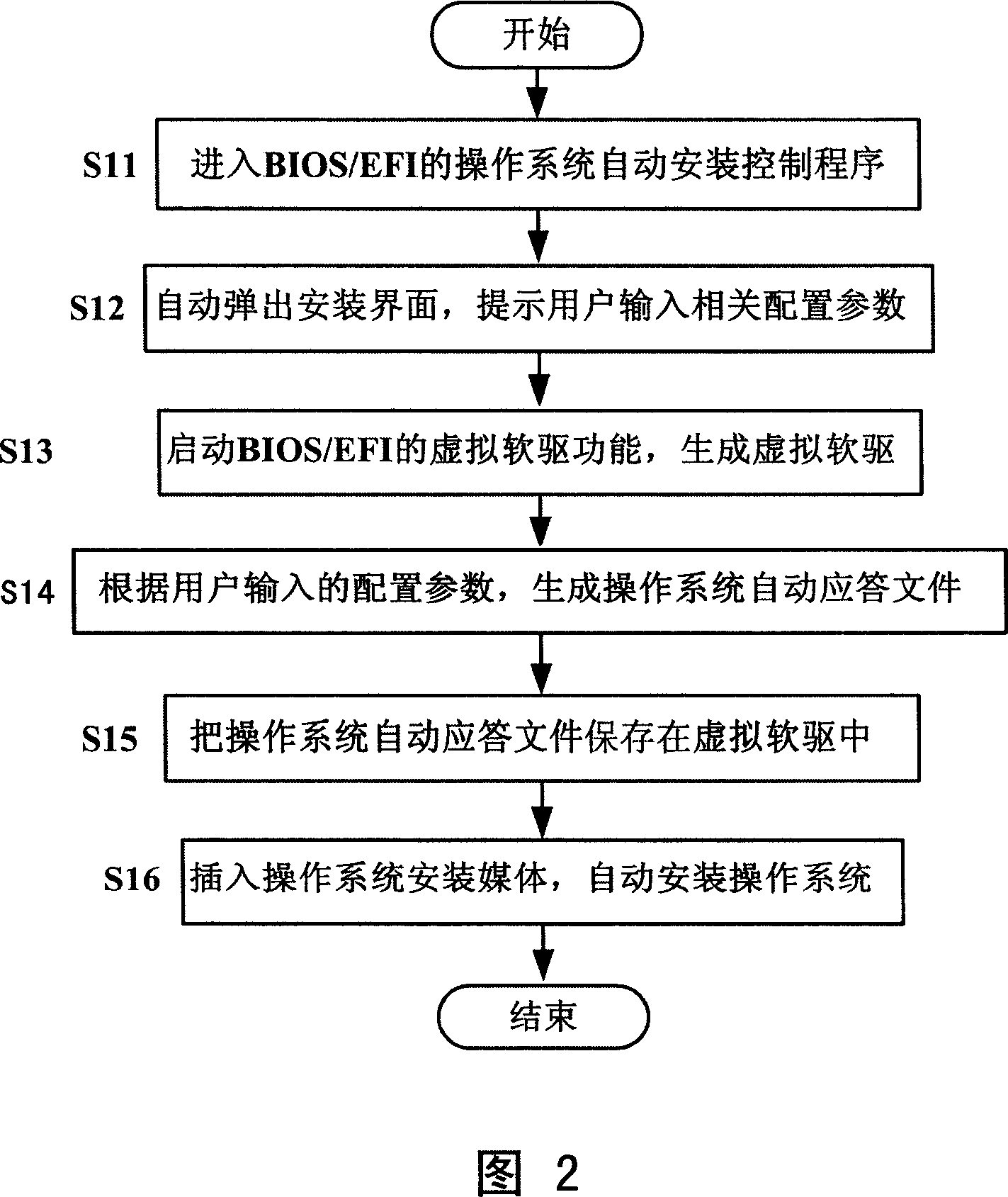

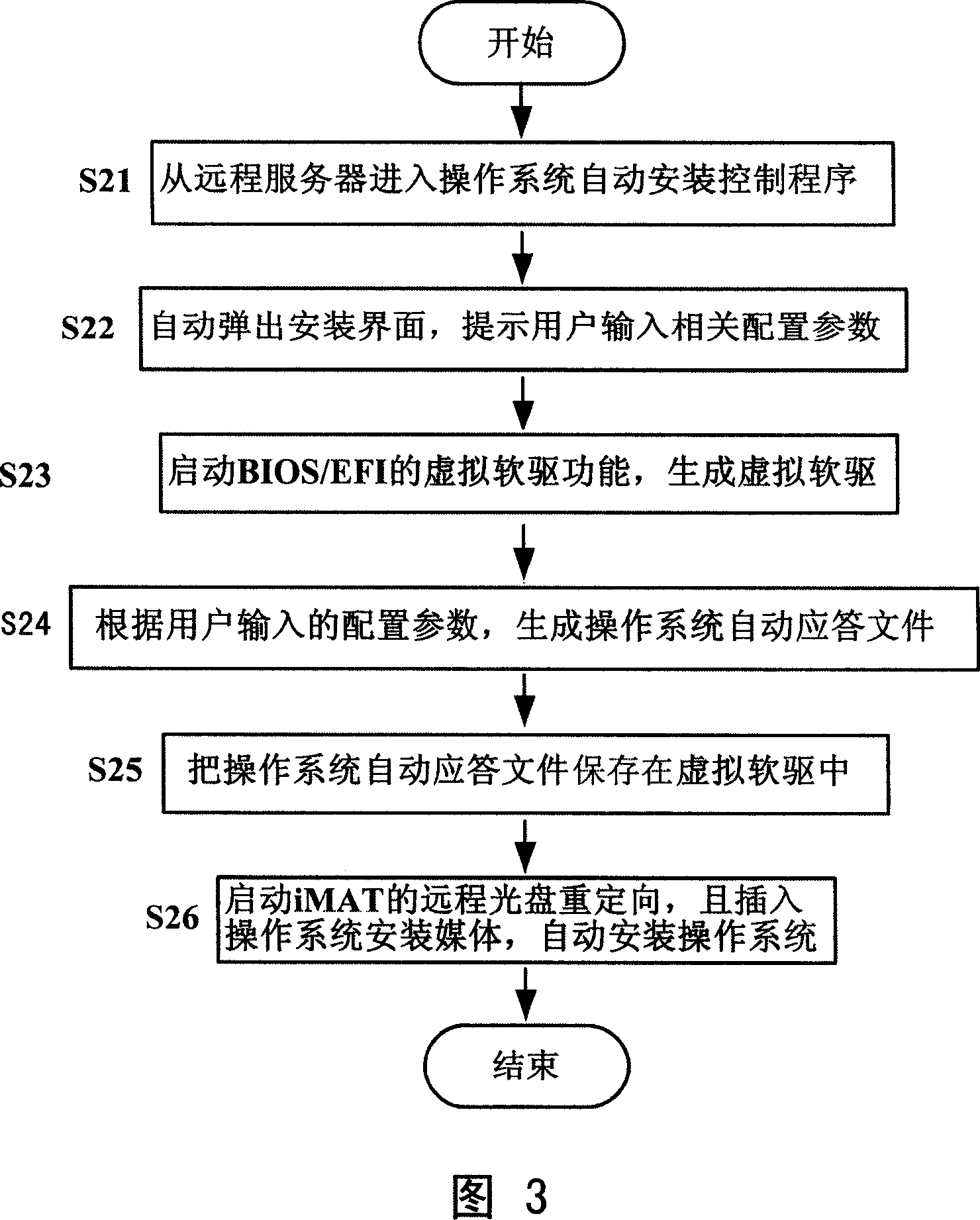

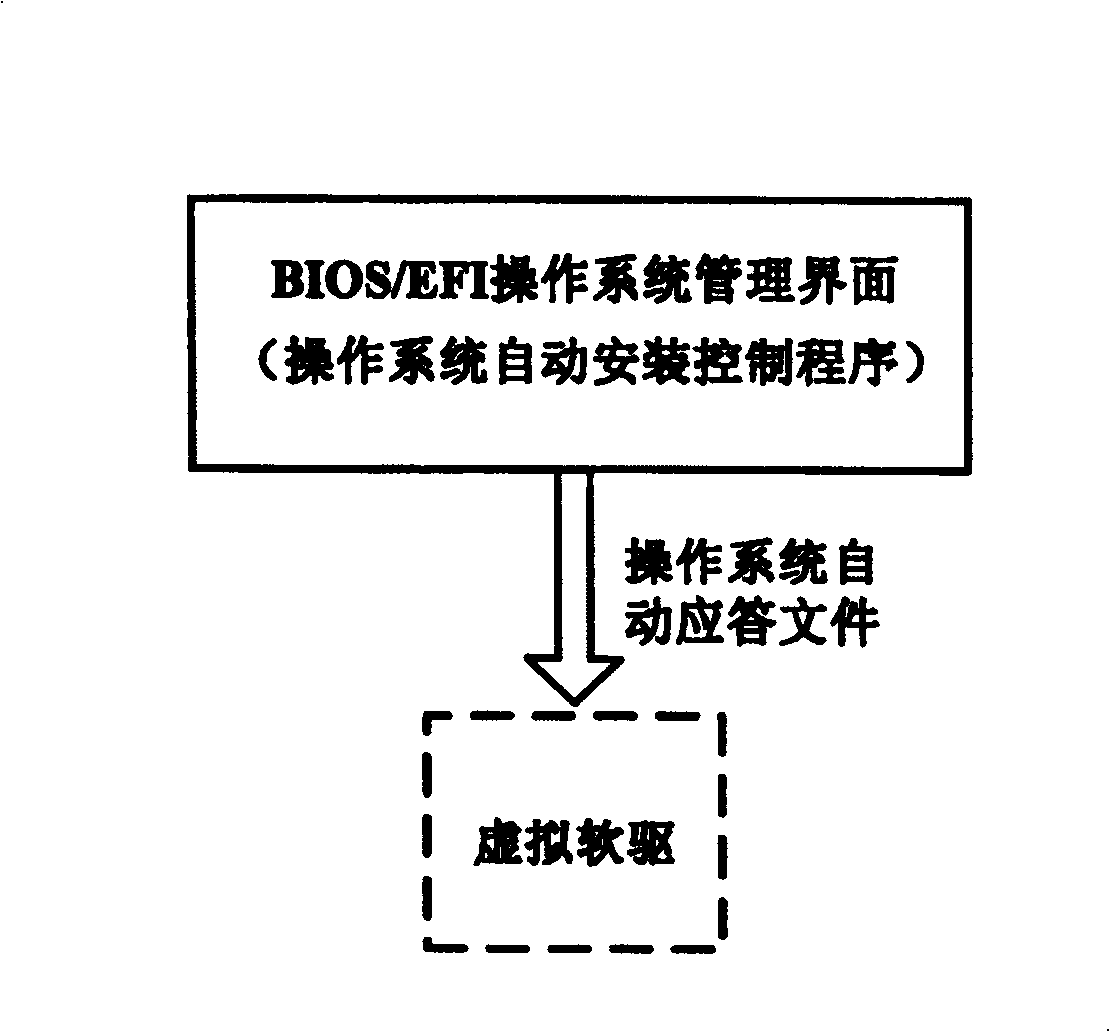

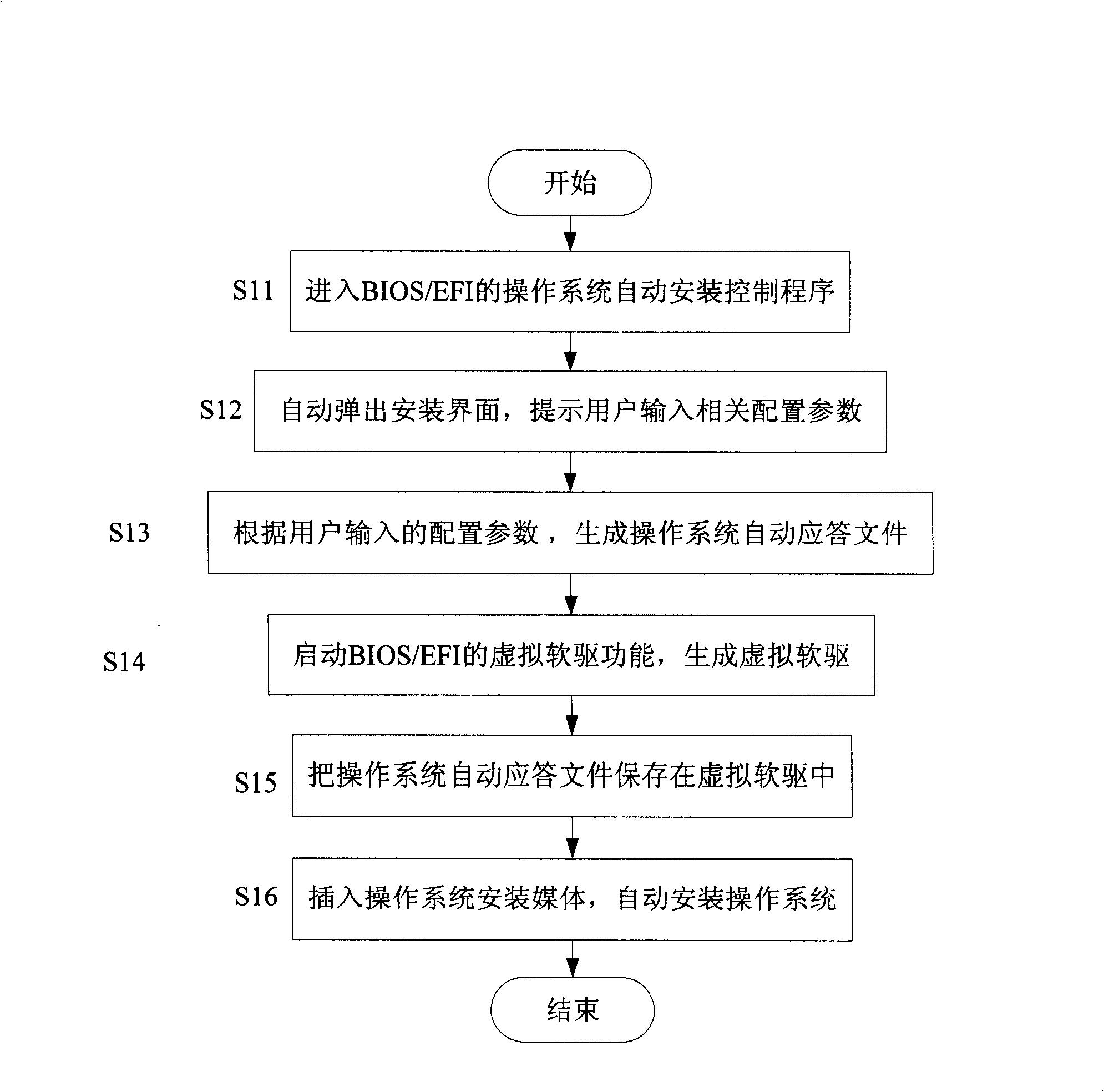

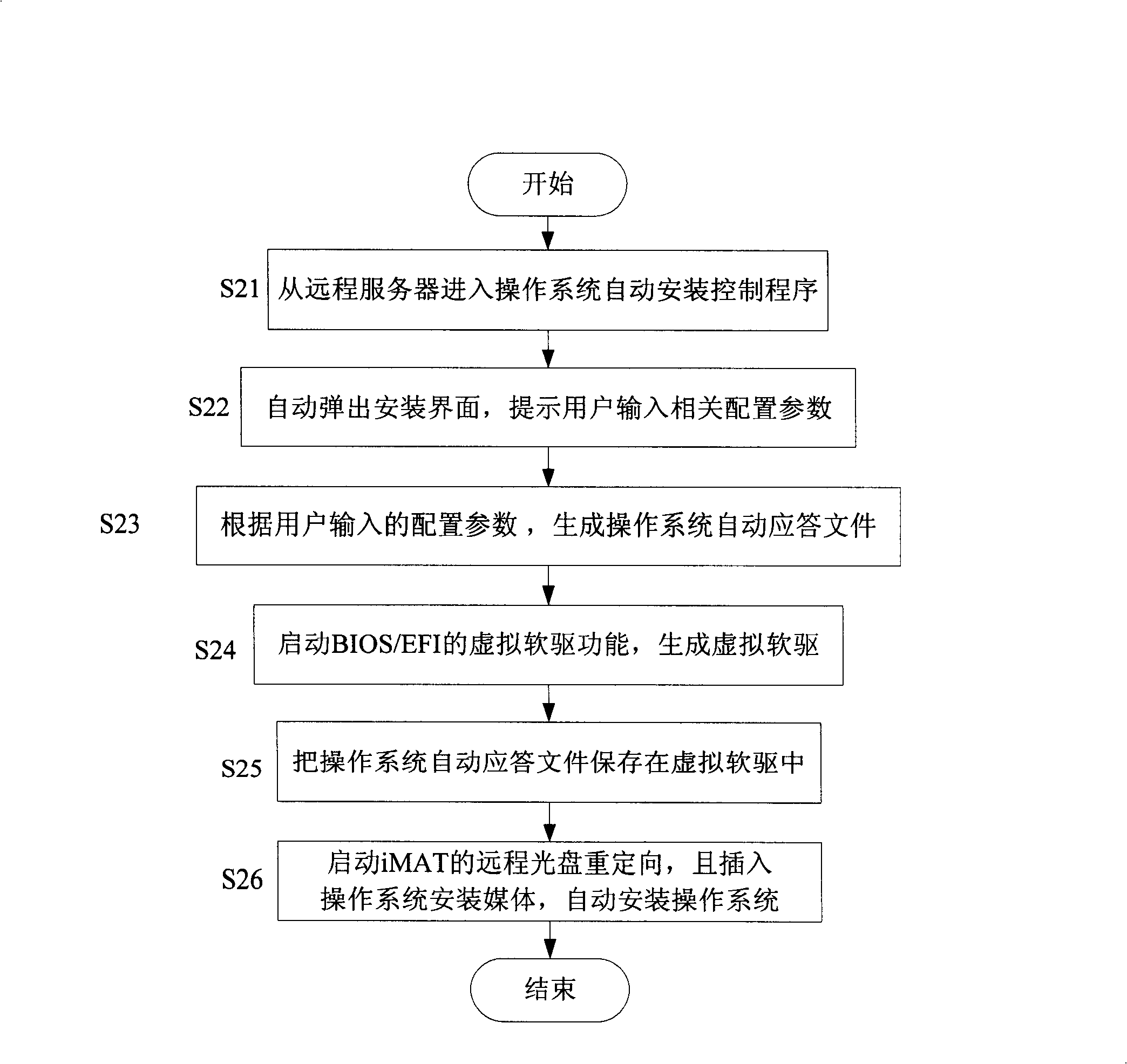

Method for automatically installing operating system

The invention provides a method for automatically installing operating system, for installing operating system on BIOS / EFI interface of a computer, comprising the steps of: generating operating system automatic response file; starting BIOS / EFI virtual FD function to generate virtual FD; copying the operating system response file into the virtual FD; and inserting operating system installation media into the computer and according to the operating system installation media and the operating system automatic response file, making automatic installing of the operating system, thus making a computer thoroughly discarding the physical FD, reducing the cost and improving file read-write reliability, and implementing simpler and more reliable operating system automatic installation.

Owner:LENOVO (BEIJING) CO LTD

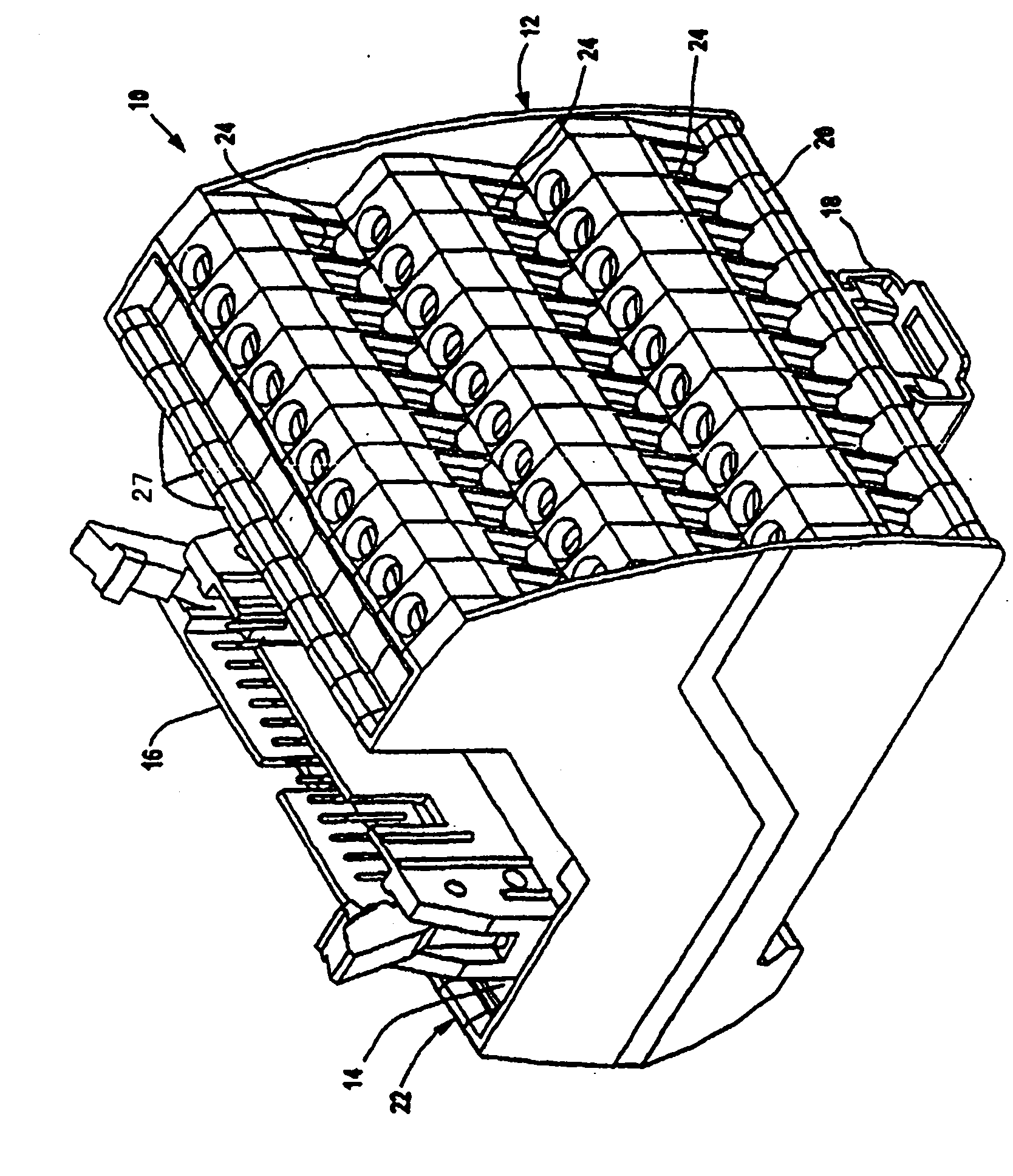

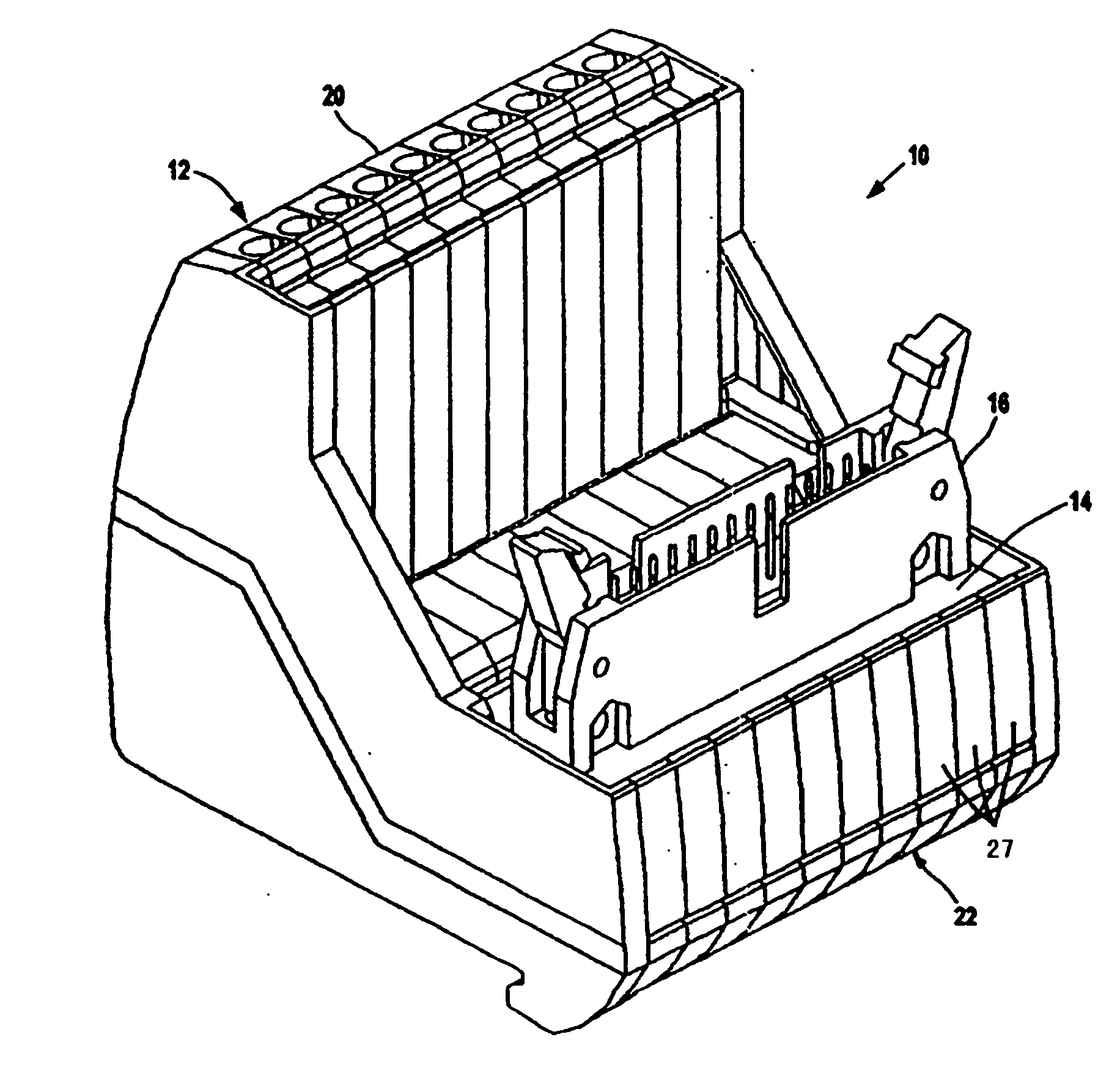

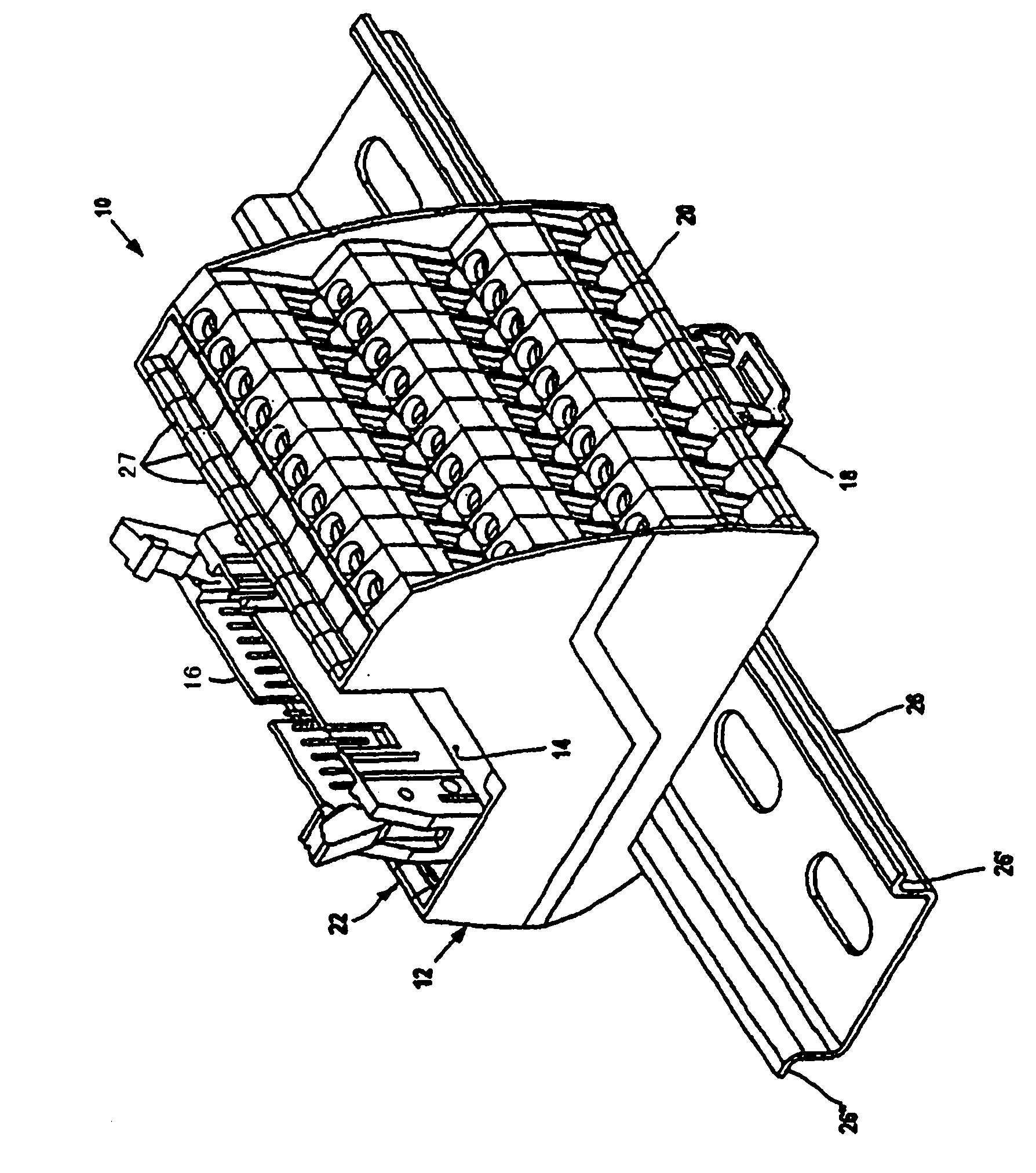

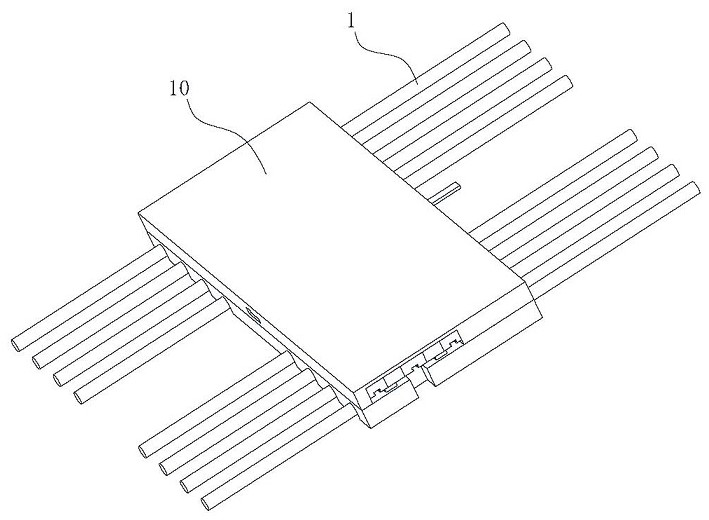

Connection block

ActiveCN102084554AEasy to installEasy to install automaticallyCoupling contact membersFixed connectionsElectrical conductorPrinted circuit board

The present invention relates to a connection block for the electrical wiring and cabling of interfaces, having a modular terminal block (12) and a printed circuit board (14) mounted on the terminal block. The modules (27) form, by way of their module housings (28), a conductor housing (46) for a large number of conductors (44) which are separately conducted out of the conductor housing (46) in the form of conductor pins (74). The printed circuit board (14) has plug-through contacts (168) with which it is plugged onto the separate conductor pins (74). An orientation plate (158) with passage holes (164) is provided for positioning the conductor pins (74), and accordingly the conductors (74) are held in the conductor housing (46) such that they can firstly withstand the forces acting on them when the orientation plate (134) and the printed circuit board (14) are fitted, and secondly can yield for corrective orientation.

Owner:PHOENIX CONTACT GMBH & CO KG

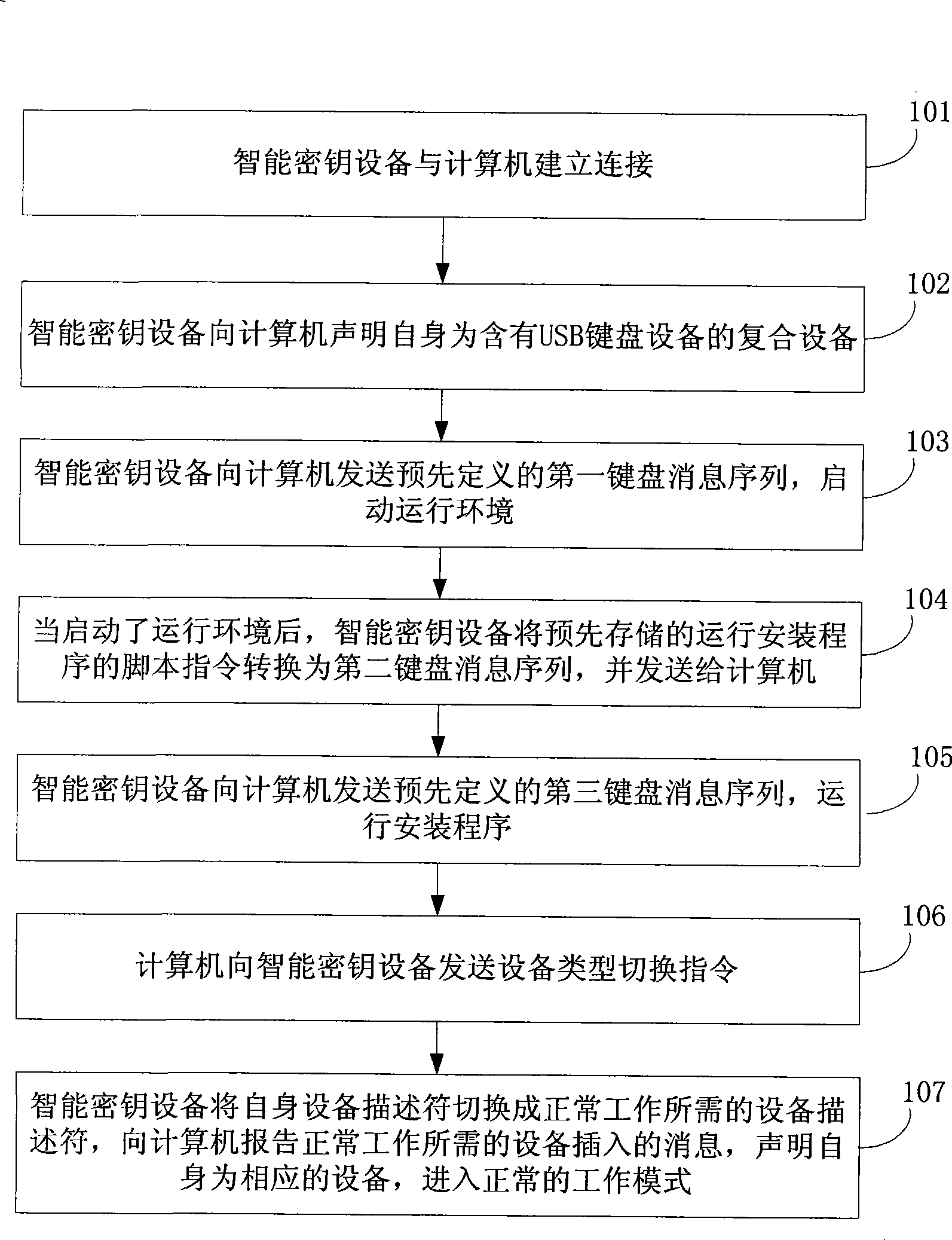

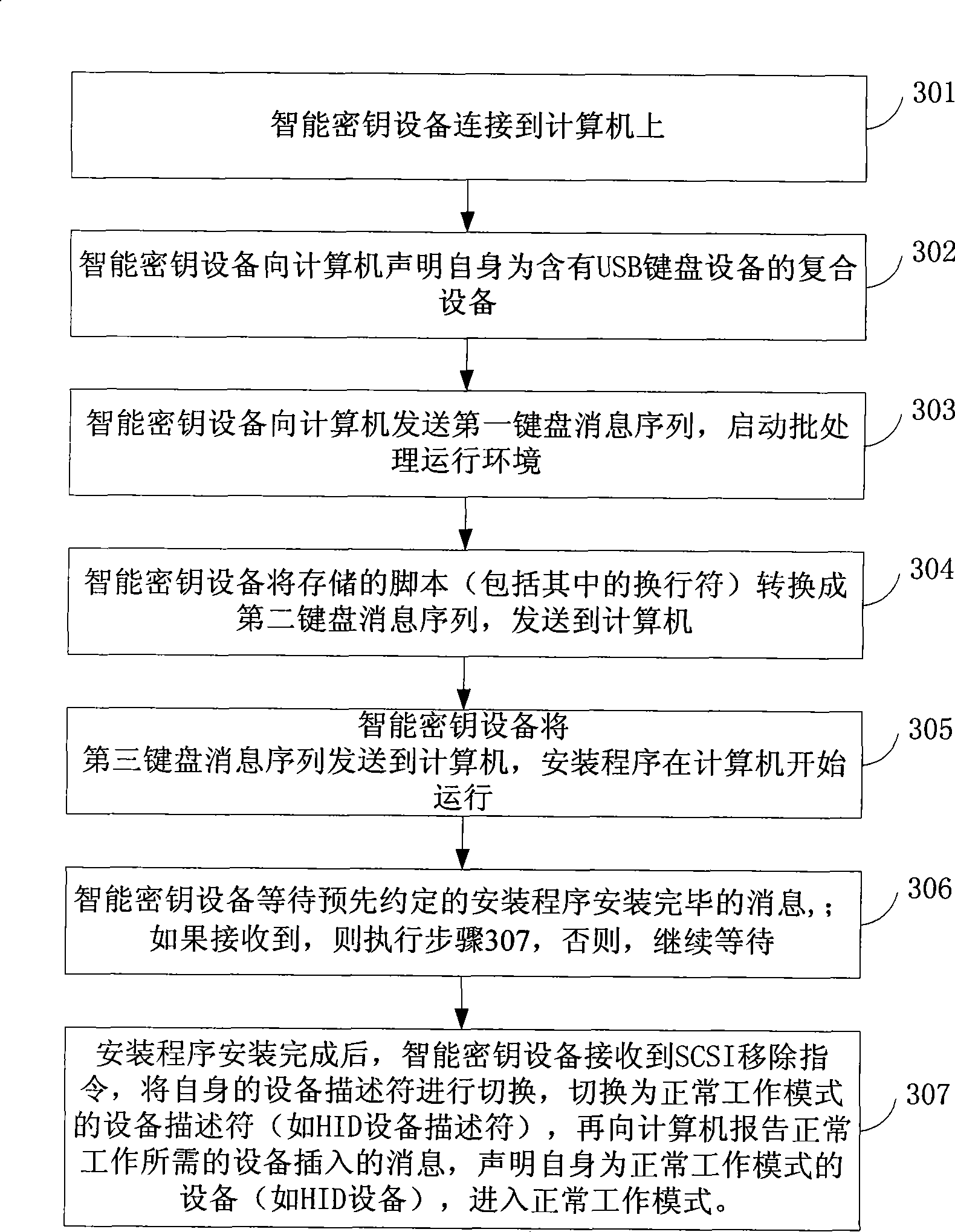

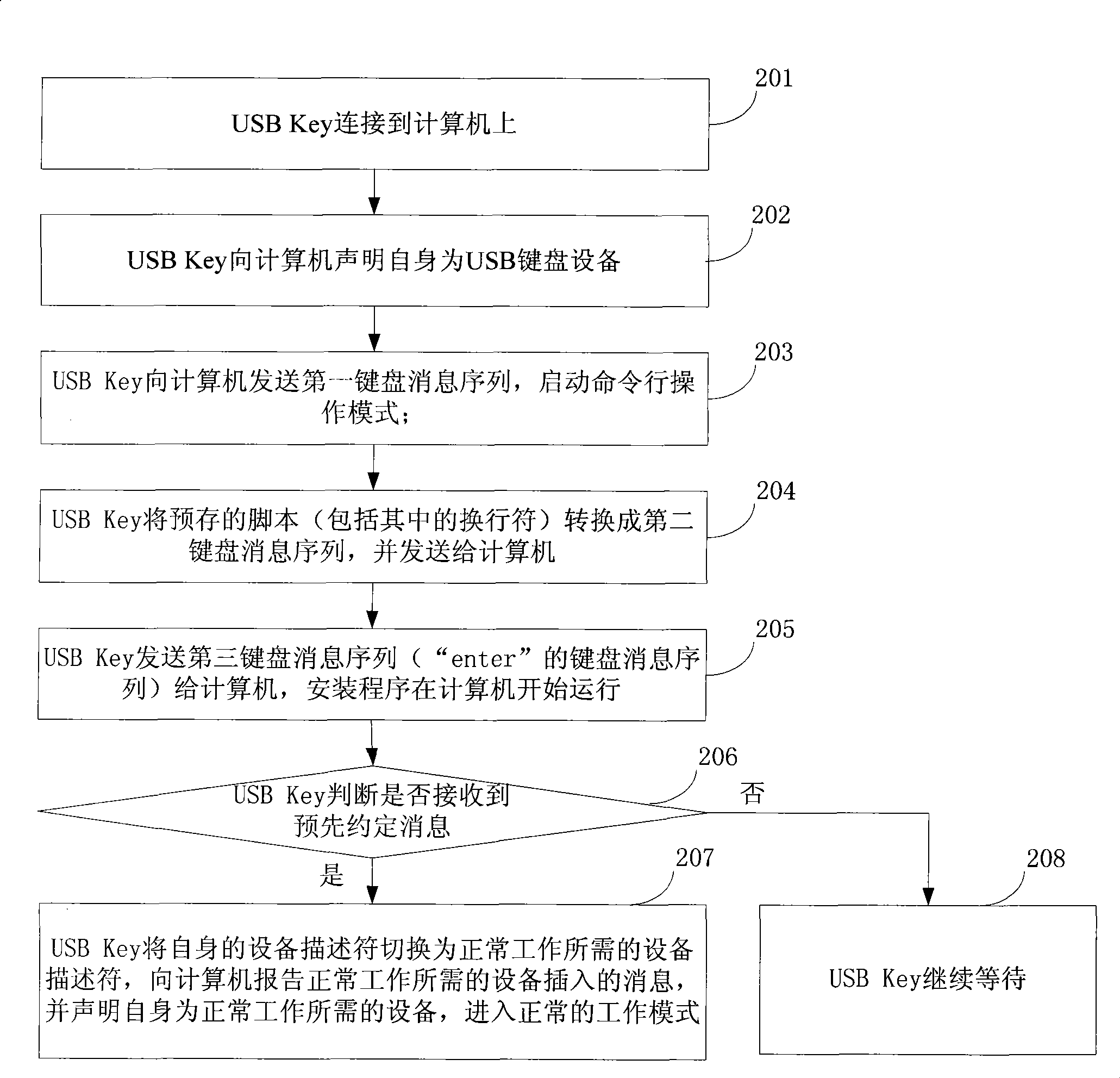

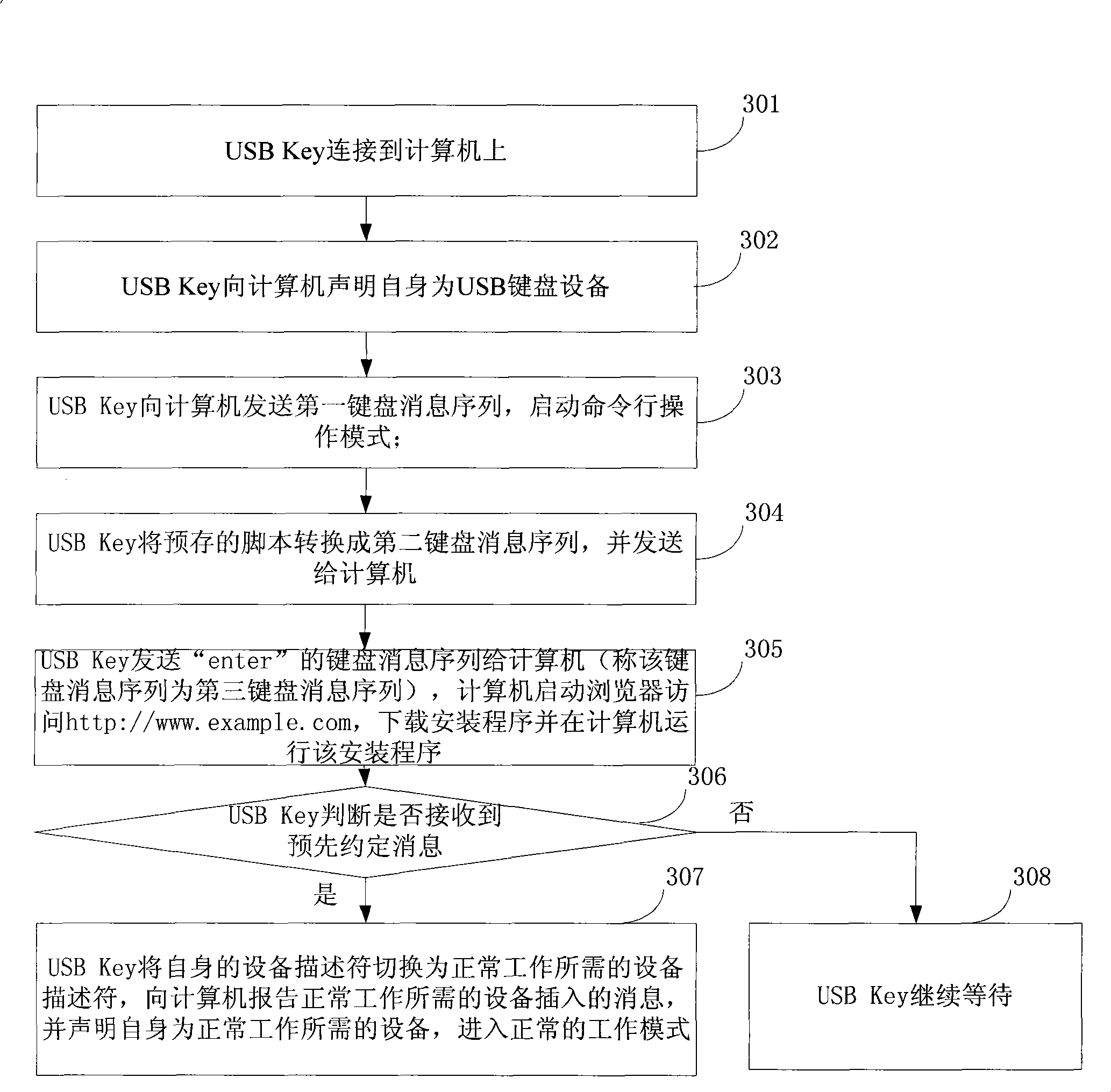

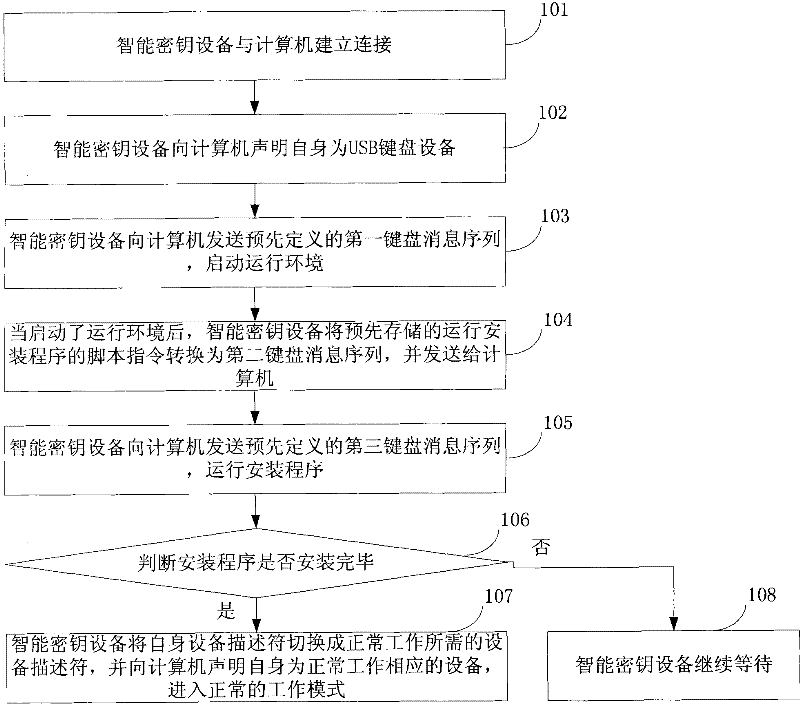

Method and system for implementing automatic installation of intelligent cipher key equipment

ActiveCN101382904ASolve the problem that automatic installation cannot be realizedEasy to install automaticallyPlatform integrity maintainanceProgram loading/initiatingSmart cardUSB

The invention discloses a method and a system for realizing the automatic installation of smart key equipment, which pertains to the smart card field. The method comprises the steps: the smart key equipment connects with a computer; the smart key equipment declares as composite equipment containing USB keyboard equipment to the computer; a pre-defined first keyboard message sequence is sent to the computer and is used for starting up the operation environment of the computer; after the starting up of the operation environment, a second keyboard message sequence is obtained by the conversion of the script instruction of a pre-stored operation installation program and sent to the computer; and a pre-defined third keyboard message sequence is sent to the computer and used for the operation of the installation program. The system comprises the smart key equipment and the computer. The method and the system for realizing the automatic installation of smart key equipment, through the alternation between the smart key equipment and the computer, solve the problem that the smart key equipment cannot realize the automatic installation when the autorun function of Windows is shielded, thus facilitating the automatic installation of the smart key equipment.

Owner:FEITIAN TECHNOLOGIES

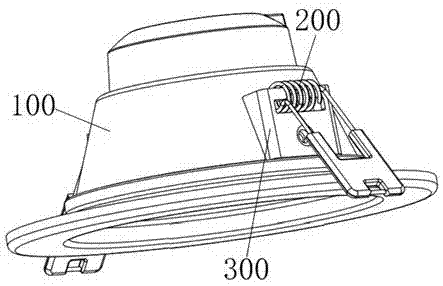

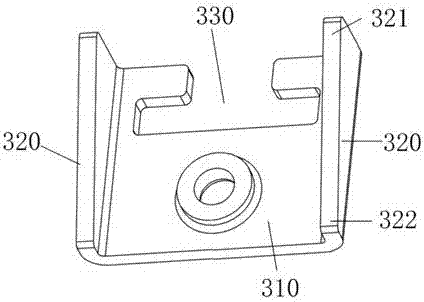

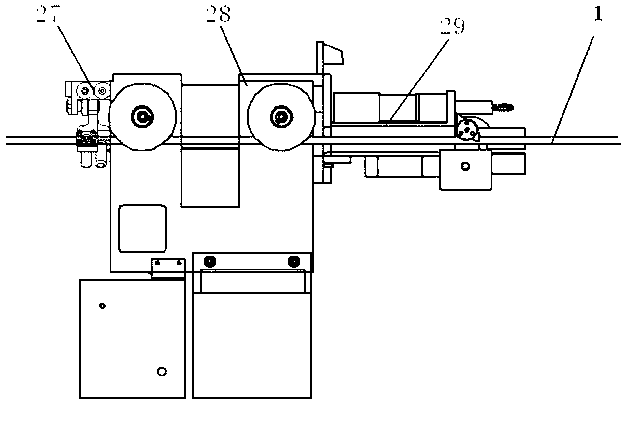

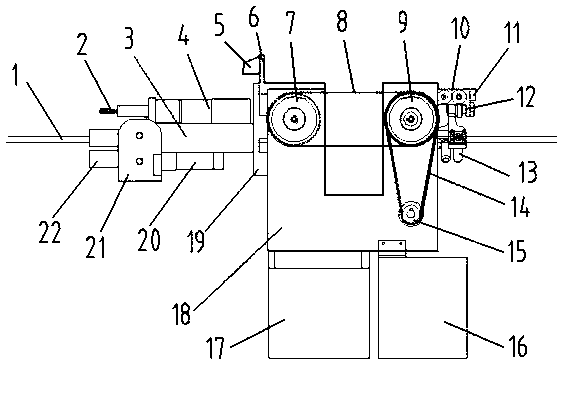

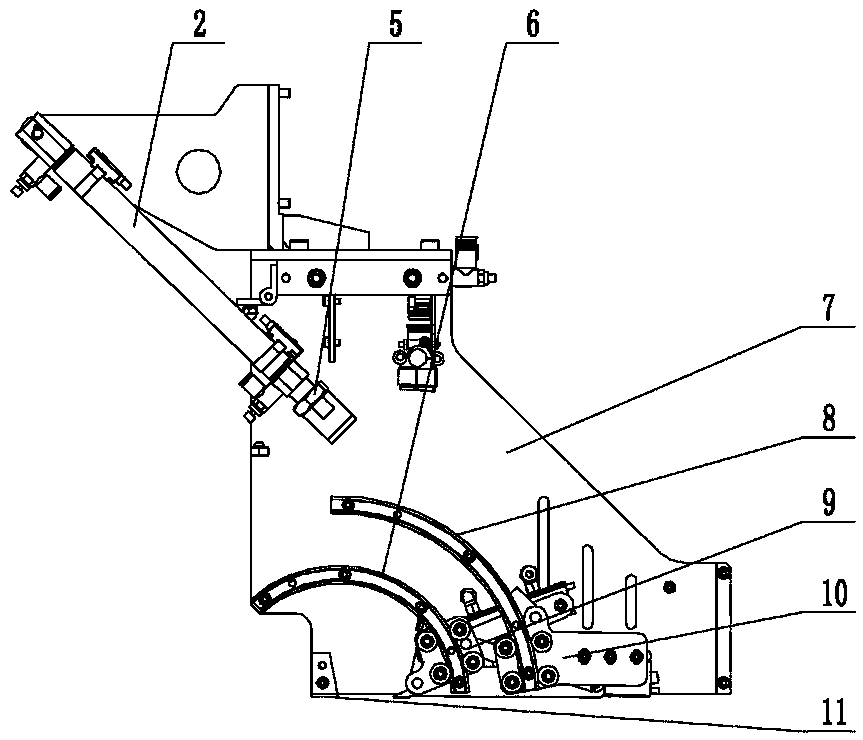

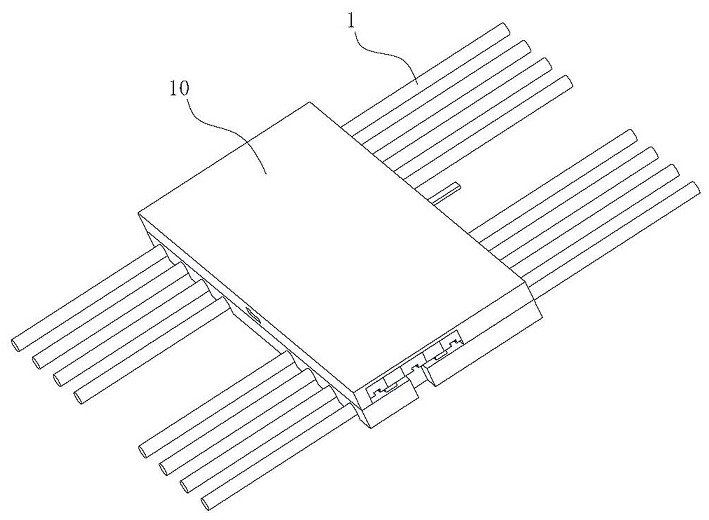

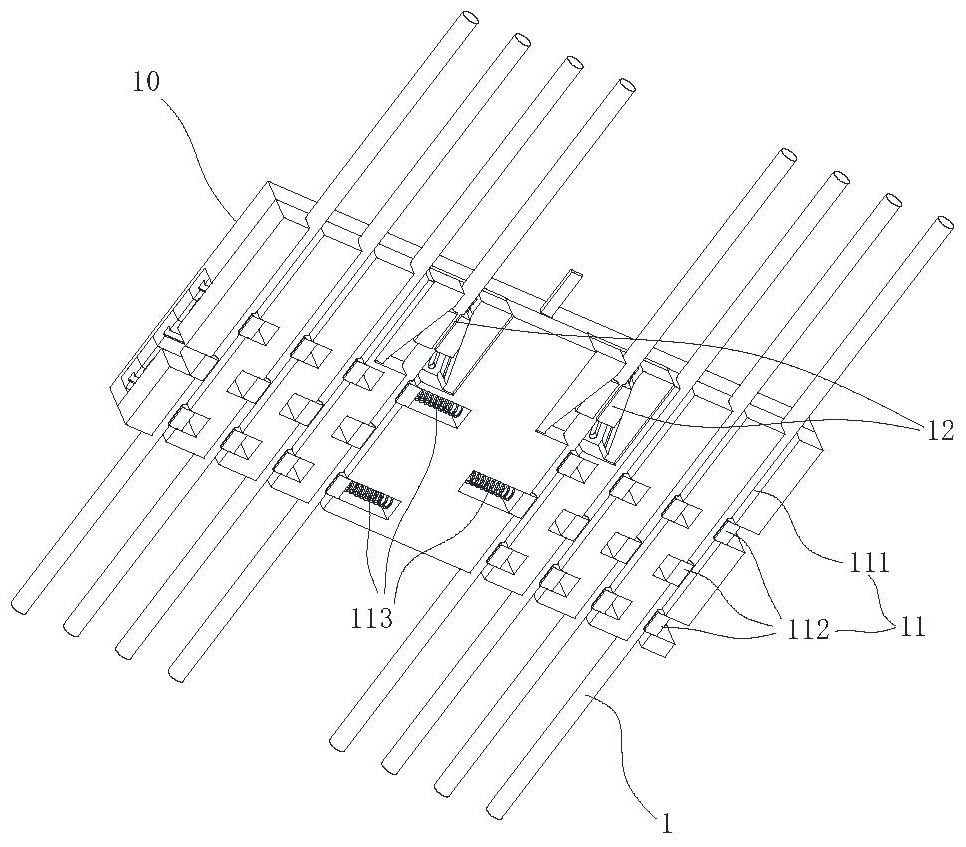

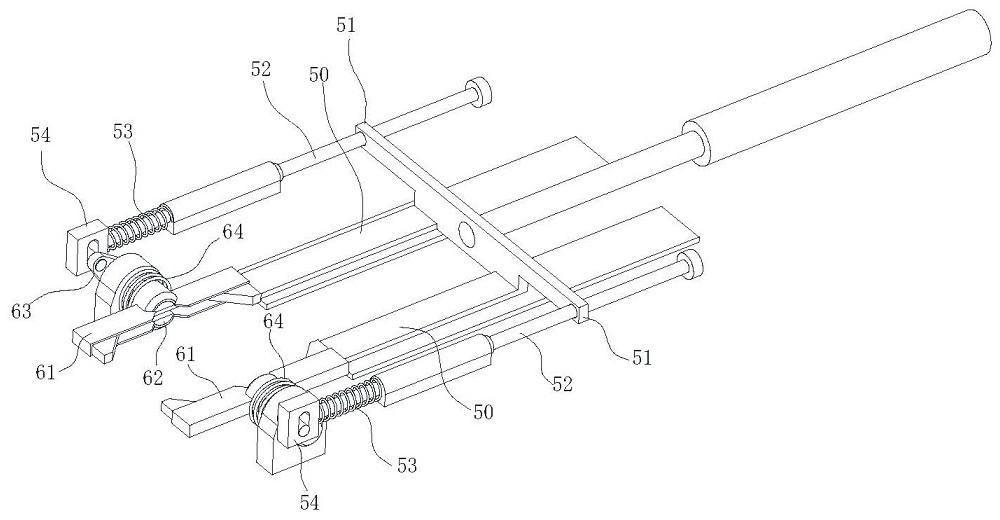

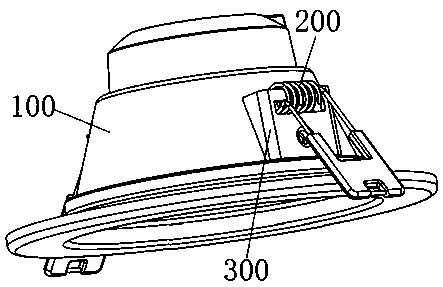

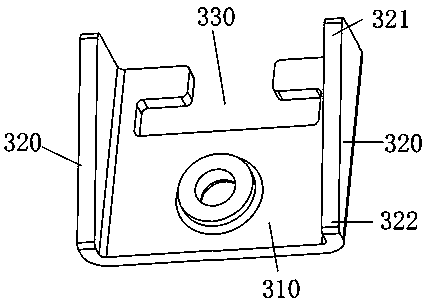

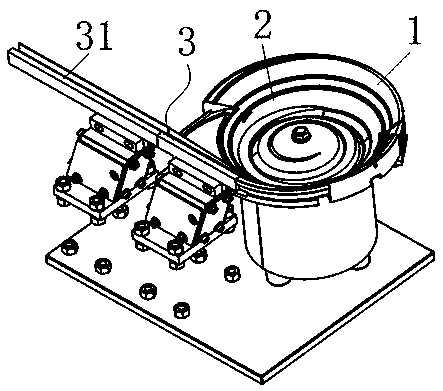

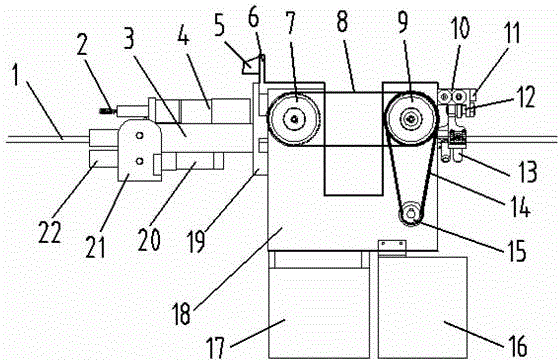

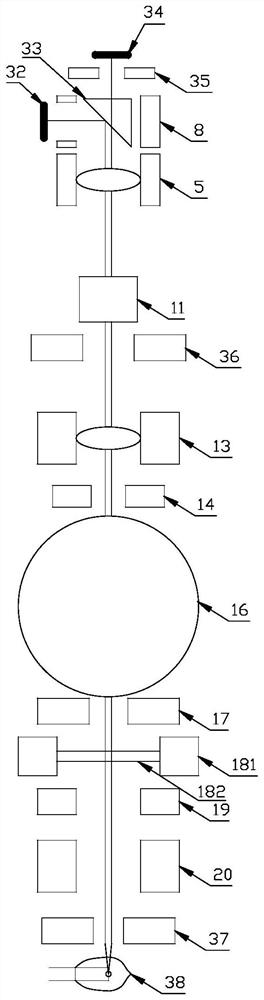

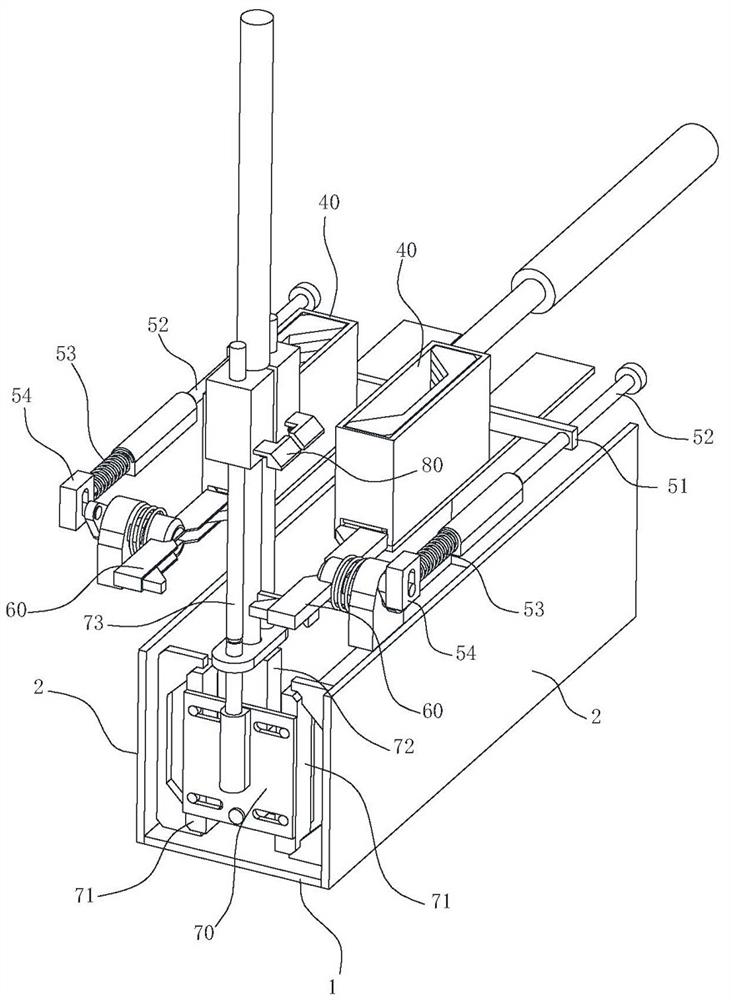

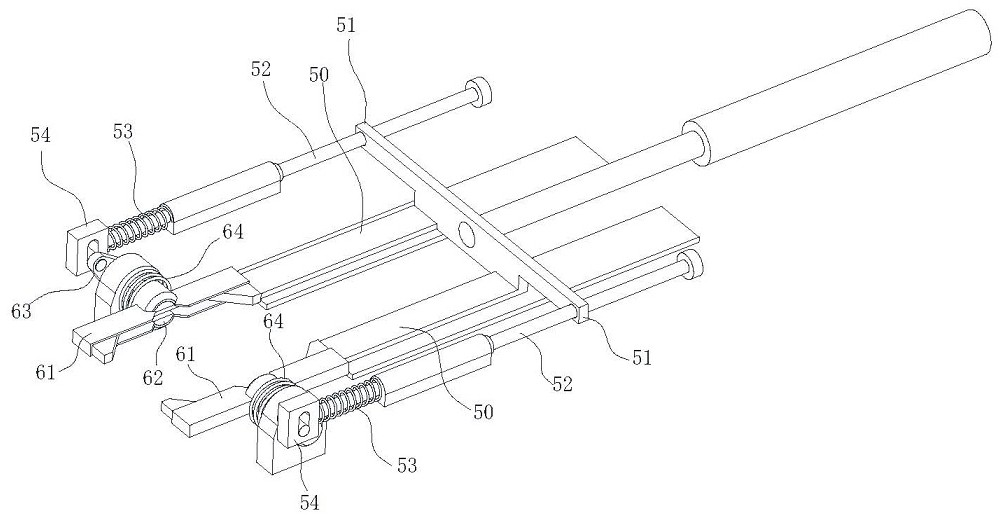

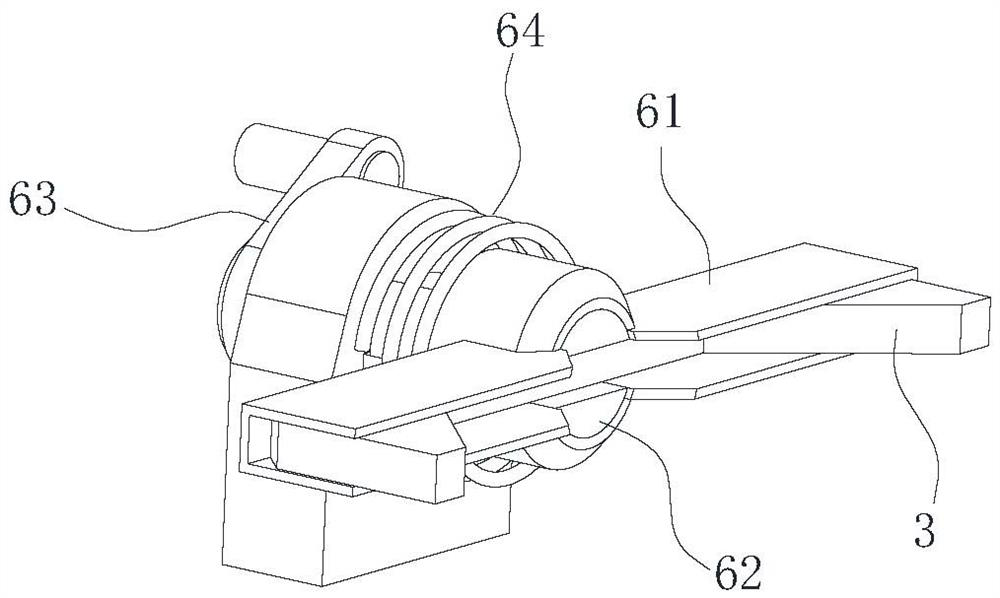

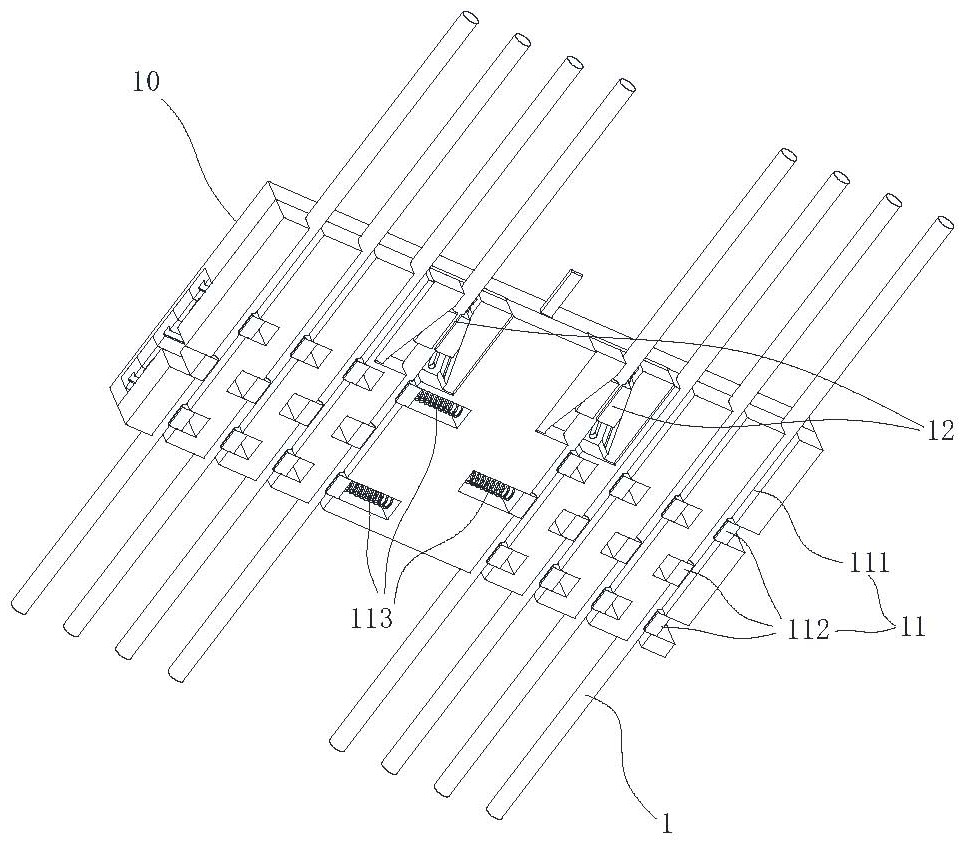

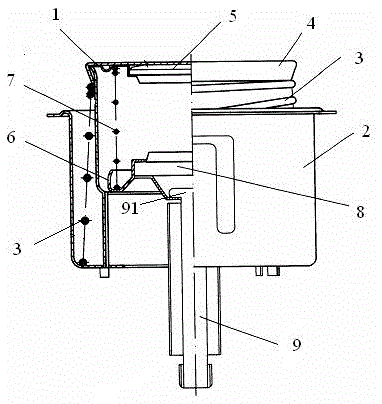

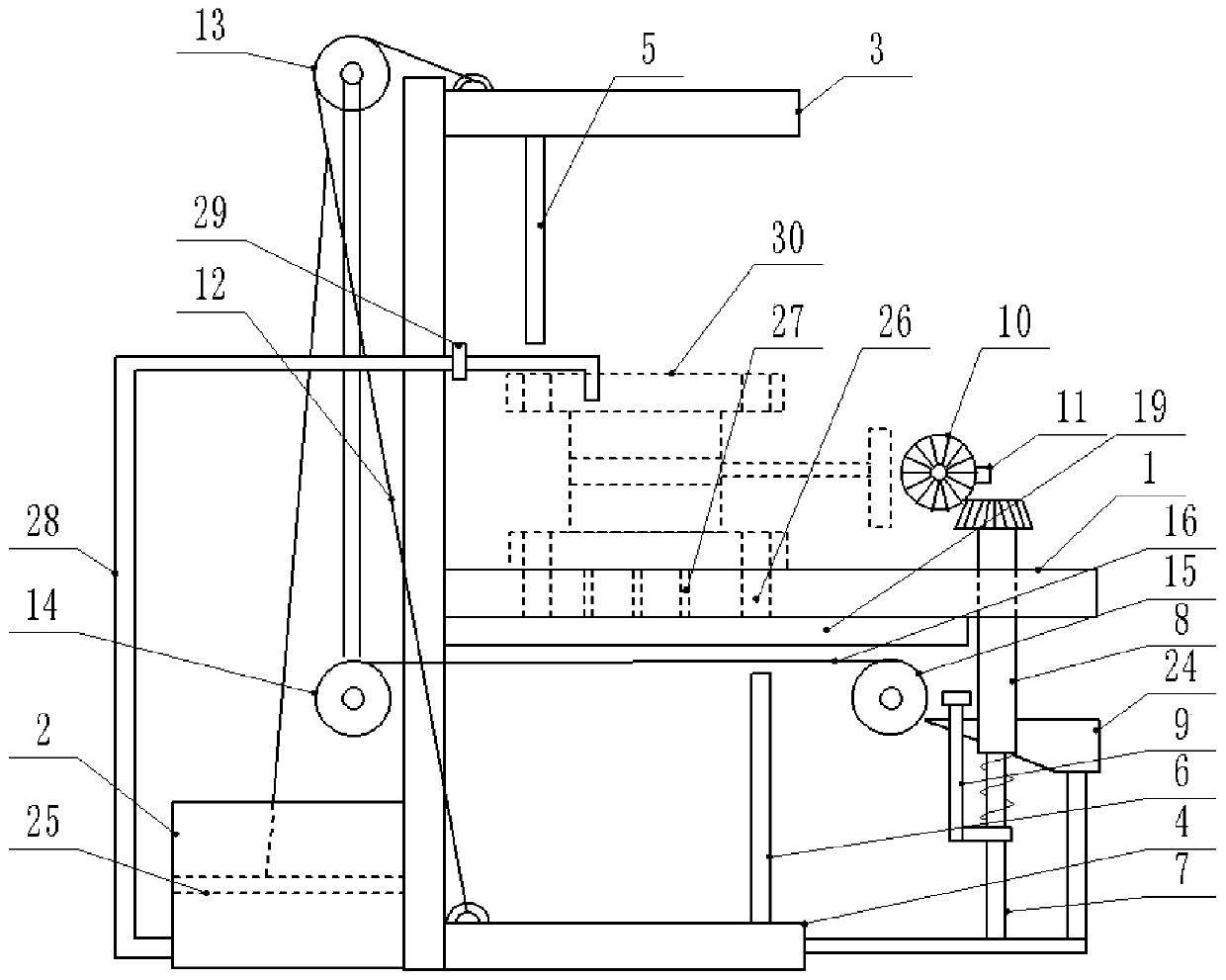

Automatic feeding mechanism for down lamp lug buckle

ActiveCN107380922AEasy to install automaticallySimple structureJigging conveyorsConveyor partsEdge segmentEngineering

The invention discloses an automatic feeding mechanism for a down lamp lug buckle. The mechanism comprises a vibrating disc used for holding the lug buckle, a vibrating rail arranged around the side wall of the vibrating disc, and a horizontal feeding rail connected with the tail end of the vibrating rail. The bottom surface of the vibrating rail is an inclined surface which is arranged obliquely downwards from inside to outside. The lower end of the inclined surface is provided with a stopping edge used for preventing the lug buckle from falling off. The vibrating rail comprises an overlapping rejecting segment, an outwards turning rejecting segment, a reverse end rejecting segment, a rotating guide segment and an overturning guide segment which are arranged in sequence. Overlapping rejecting bars are mounted on the overlapping rejecting segment; at least part of the portion, located at the outwards turning rejecting segment, of the stopping edge is provided with short edge segments; the portion, located at the reverse end rejecting segment, of the inclined surface is provided with a rejecting port and an upwards pushing bar; the rotating guide segment is provided with a rotating guide mechanism used for driving the lug buckle to rotate and enabling the thin end of the lug buckle to face forwards ; and the overturning guide segment is provided with an overturning guide mechanism used for driving the lug buckle to overturn until a main plate portion faces upwards. By adopting the automatic feeding mechanism provided by the invention, the lug buckle can be automatically fed unidirectionally.

Owner:FOSHAN ELECTRICAL & LIGHTING

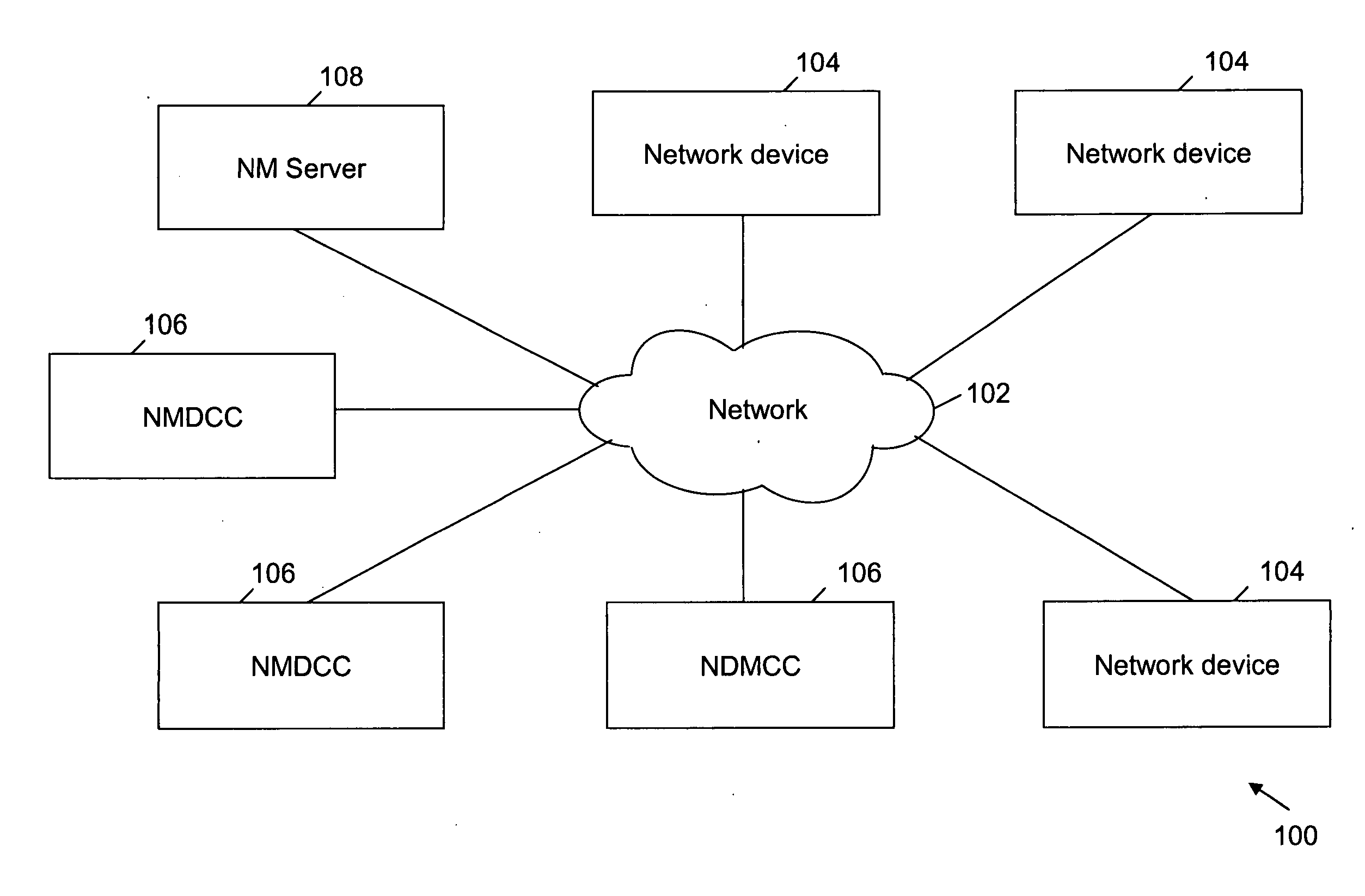

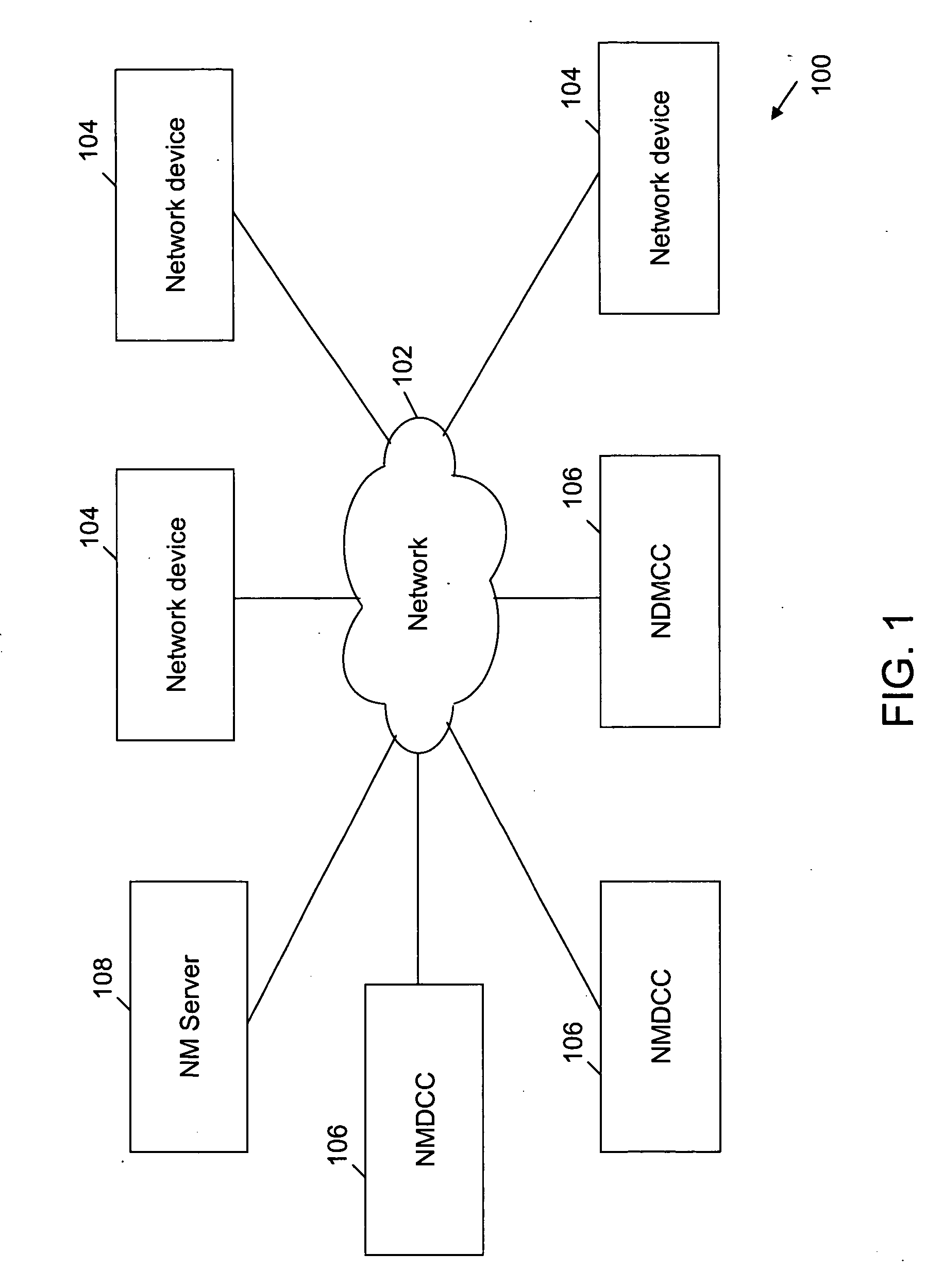

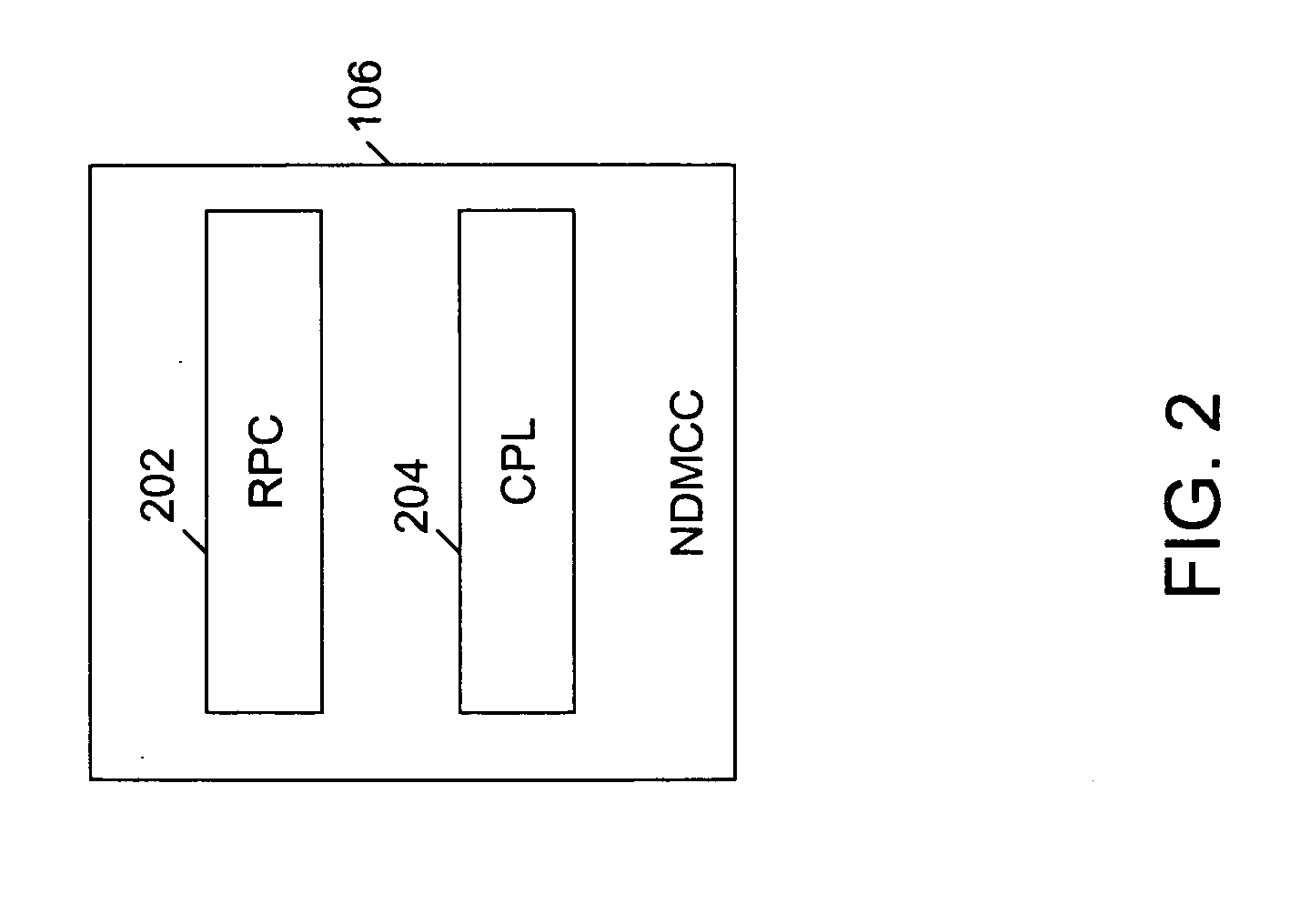

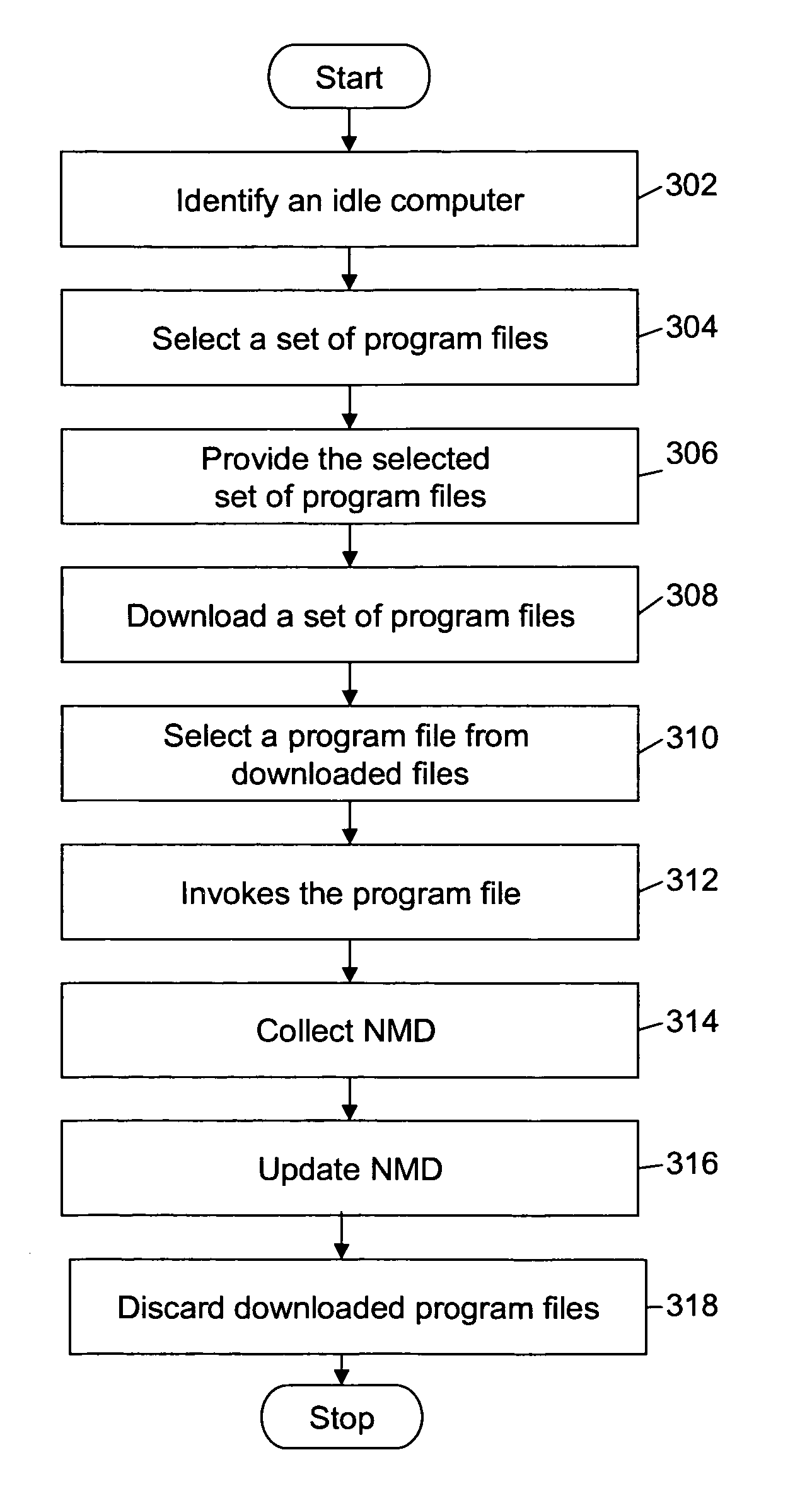

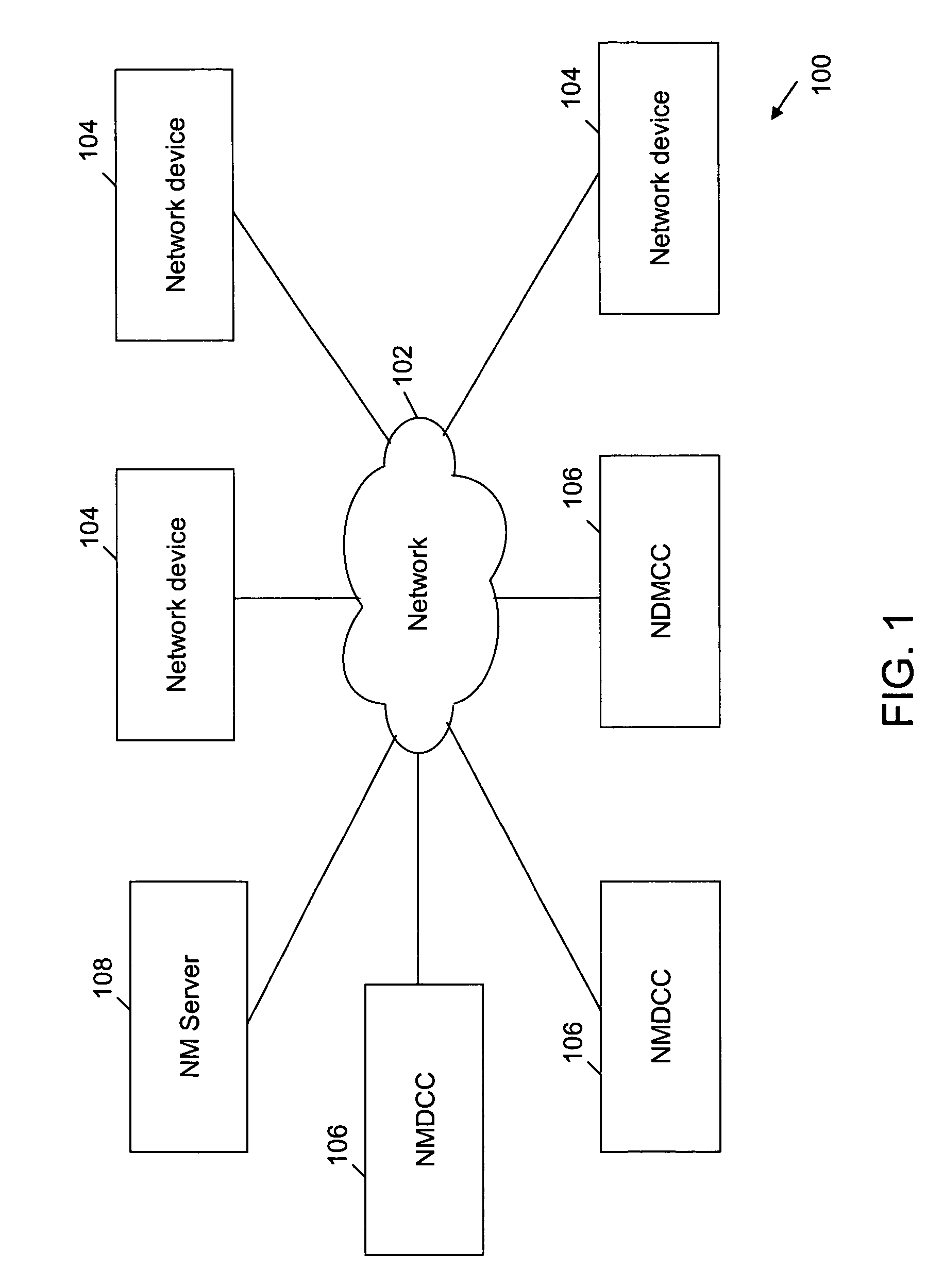

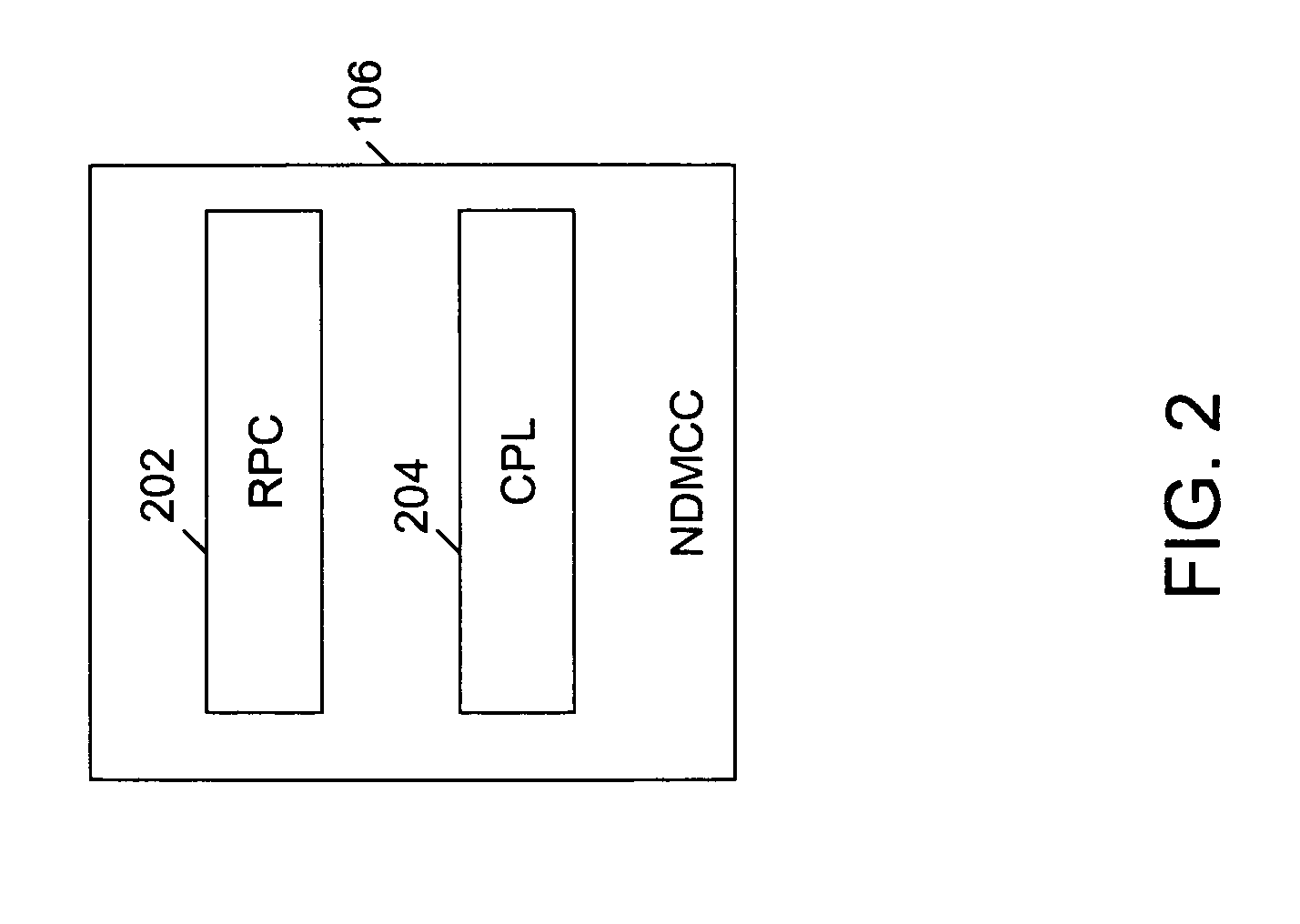

Method and system for network management data collection

ActiveUS20070198680A1Facilitates taskEfficient managementDigital computer detailsProgram loading/initiatingWeb serviceNetwork management

Methods and systems for network management data collection have been provided. Underutilized computers in the network are allocated as a Network Management Data Collection Client (NMDCC) to collect network management data. The NMDCC receives program files from the network management server. The received program files are downloaded by the NMDCC in a compressed manner via a web service. The downloaded program files are executed for collecting the Network Management Data (NMD). The collected NMD is updated back on the network management server. The downloaded program files are discarded when the NMDCC is not collecting the network management data.

Owner:CISCO TECH INC

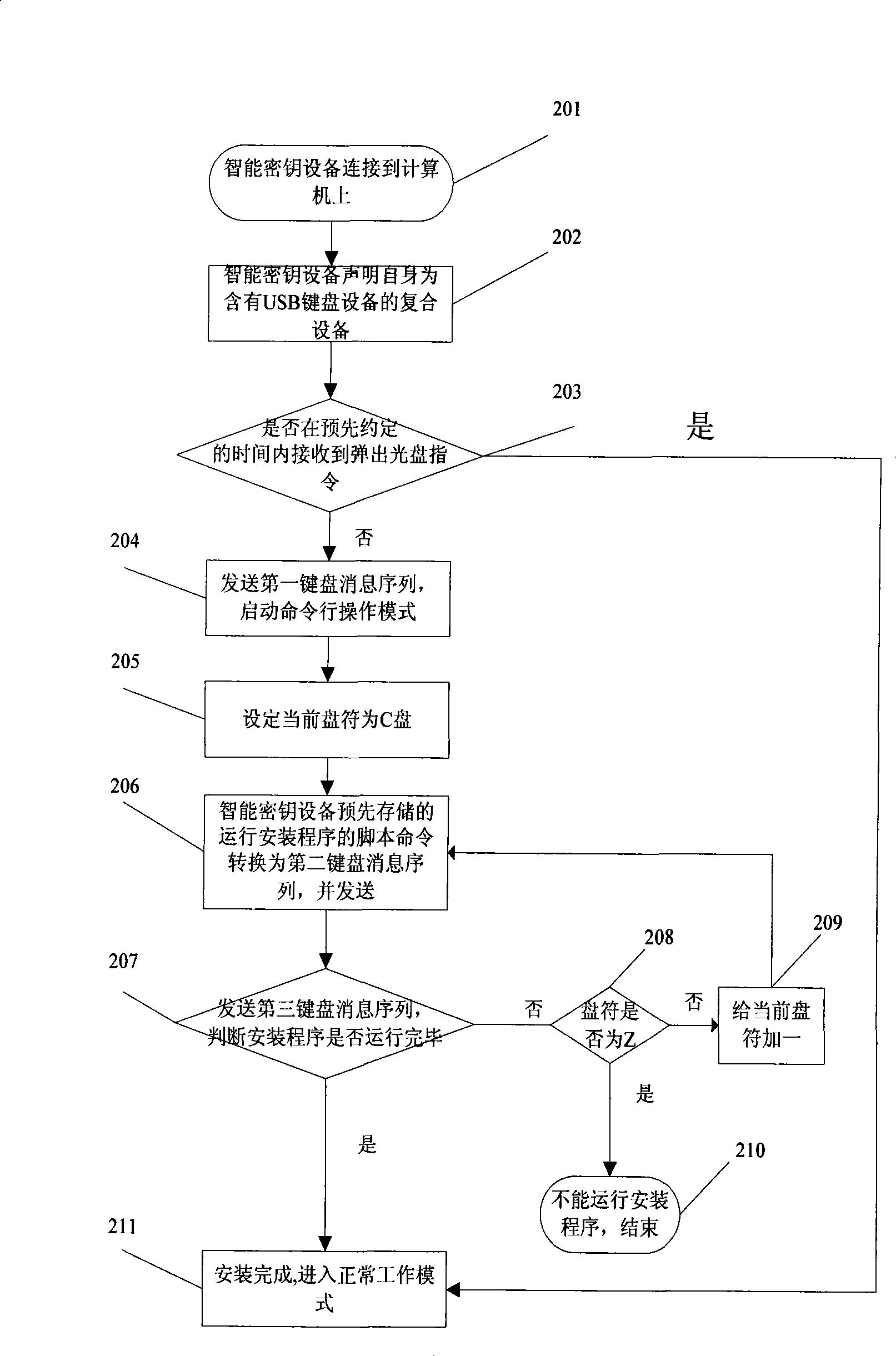

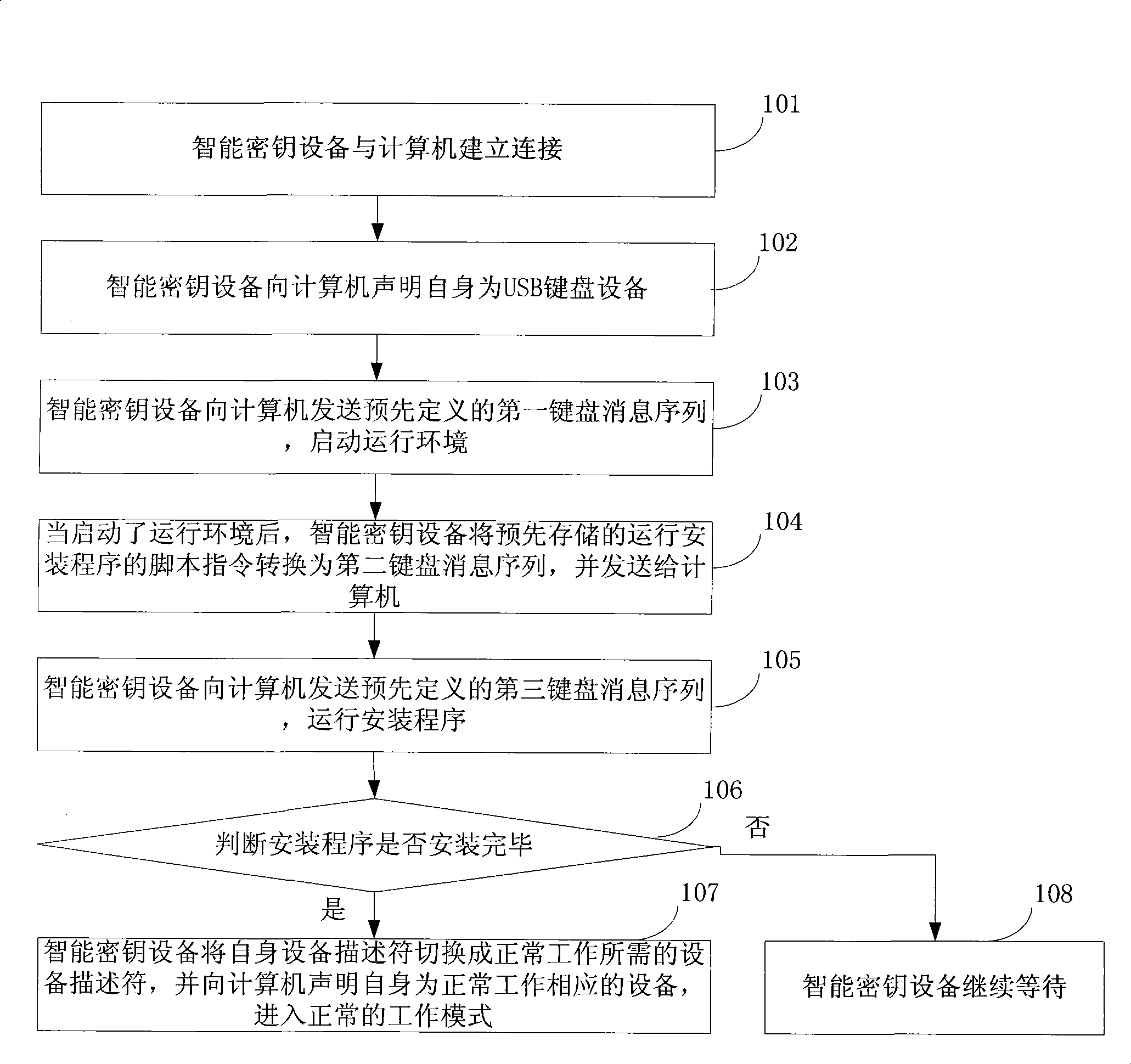

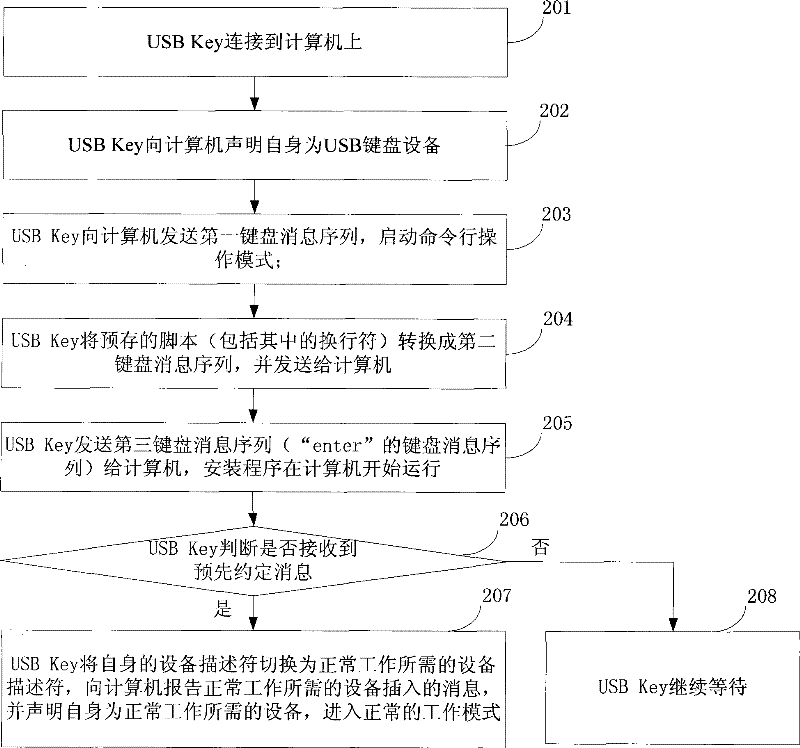

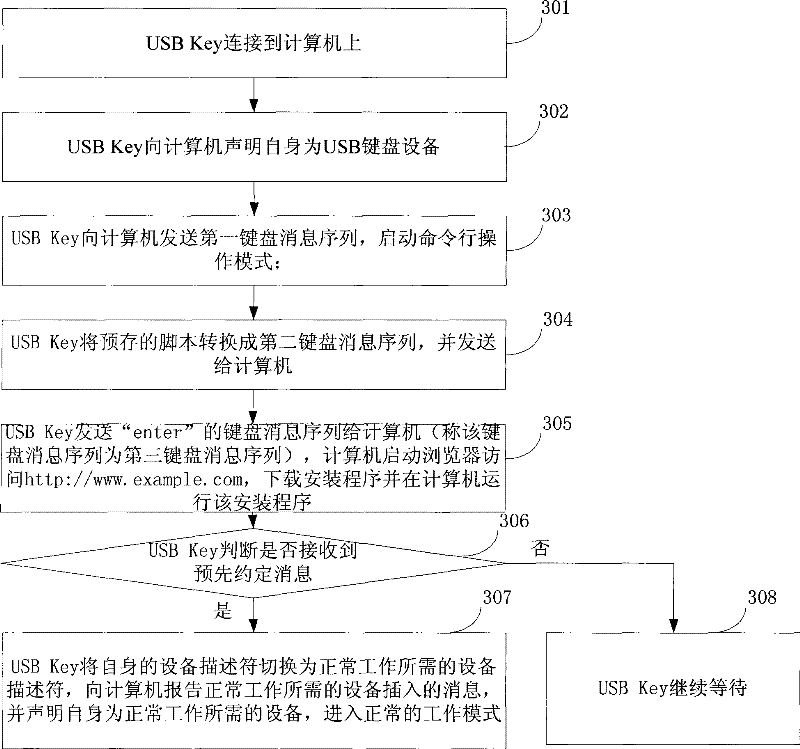

Method and system for implementing automatic installation of intelligent cipher key equipment

ActiveCN101382903AAutomatic installation is convenientSolve the problem that automatic installation cannot be realizedComputer security arrangementsProgram loading/initiatingDevice descriptorSoftware engineering

The invention discloses a method and a system for realizing the automatic installation of smart key equipment, which pertains to the smart card field. The method comprises the steps: the smart key equipment declares as USB keyboard equipment to a computer; a pre-defined first keyboard message sequence is sent to the computer and a second keyboard message sequence is obtained by the conversion of the script instruction of a pre-stored operation installation program and sent to the computer; a third keyboard message sequence is sent to the computer and used for the operation of the installation program; and when the installation of the installation program is finished, the equipment descriptor is switched into the equipment descriptor required for the normal operation and the equipment declares as the equipment corresponding to the normal operation to the computer. The system comprises the smart key equipment and the computer. The method and the system for realizing the automatic installation of smart key equipment, through the alternation between the smart key equipment and the computer, solve the problem that the smart key equipment can not realize the automatic installation when the autorun function of Windows is shielded, thus facilitating the automatic installation of the smart key equipment.

Owner:FEITIAN TECHNOLOGIES

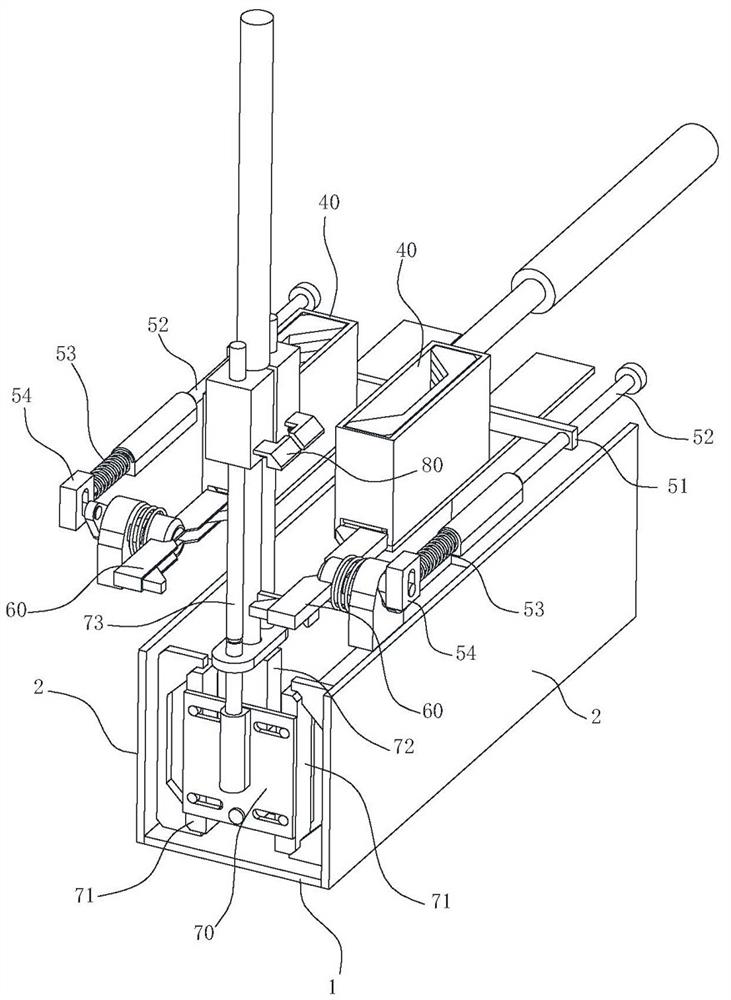

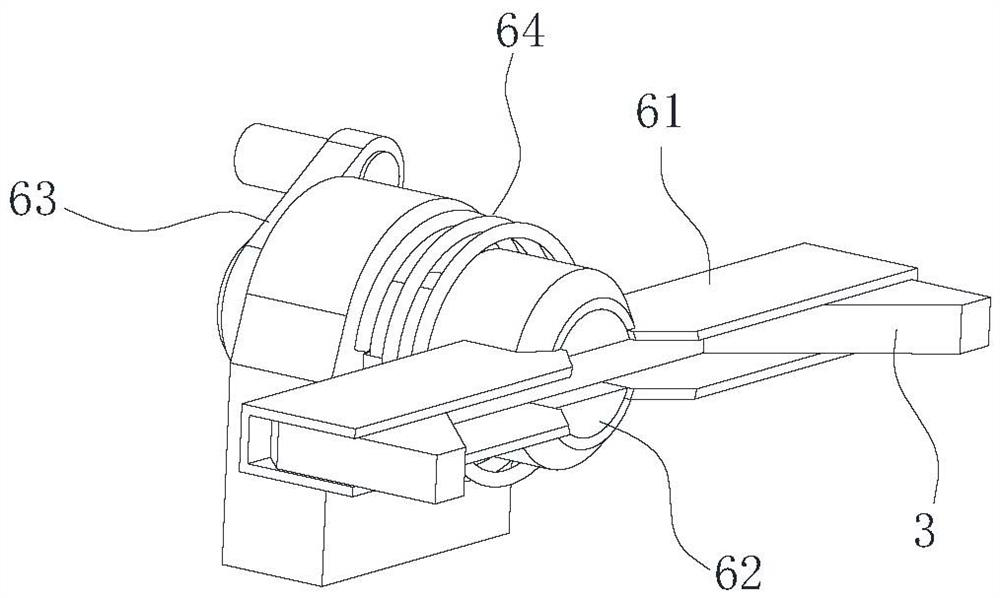

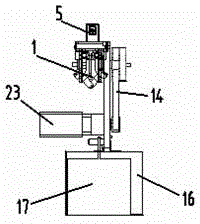

Robot for automatically loading and unloading aviation marker balls

The invention discloses a robot for automatically loading and unloading aviation marker balls. The robot comprises a robot body, a falling off preventing mechanism and an aviation marker ball loading and unloading mechanism, wherein the front end of the robot body is connected with the aviation marker ball loading and unloading mechanism; the rear end of the robot body is connected with the falling off preventing mechanism; the robot body comprises a main body frame; and the main body frame is connected with a power source device and a control box. After the robot for automatically loading and unloading the aviation marker balls is improved, automatic loading and unloading of the aviation marker balls are realized, so that the labor cost is greatly saved, and the production efficiency is improved. The robot body is simple in structure and light in weight, is provided with a falling off preventing device, and can stably run on an aerial cable.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

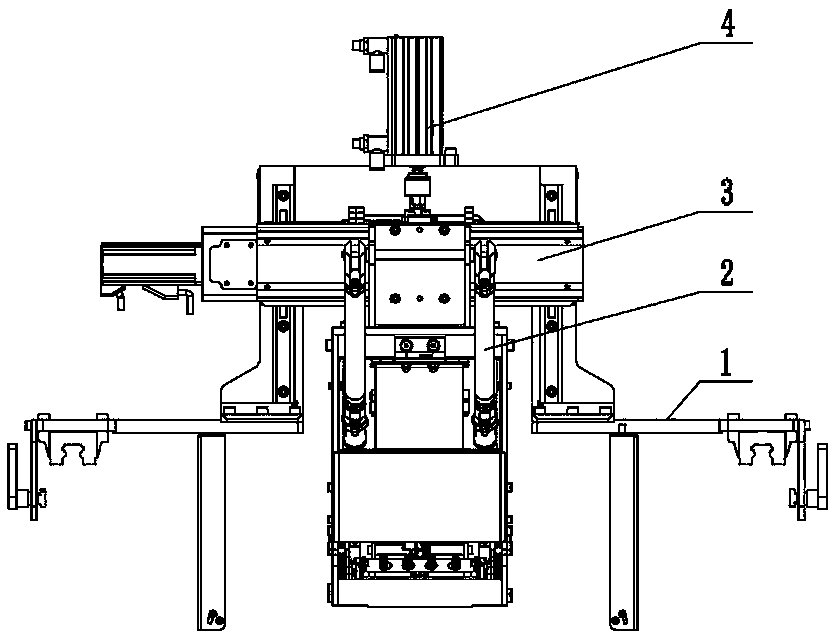

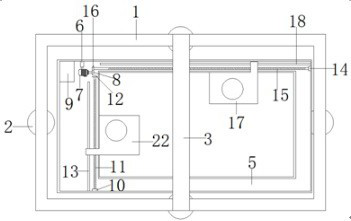

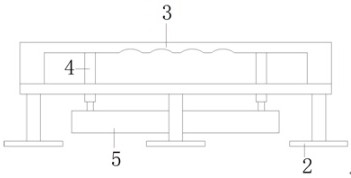

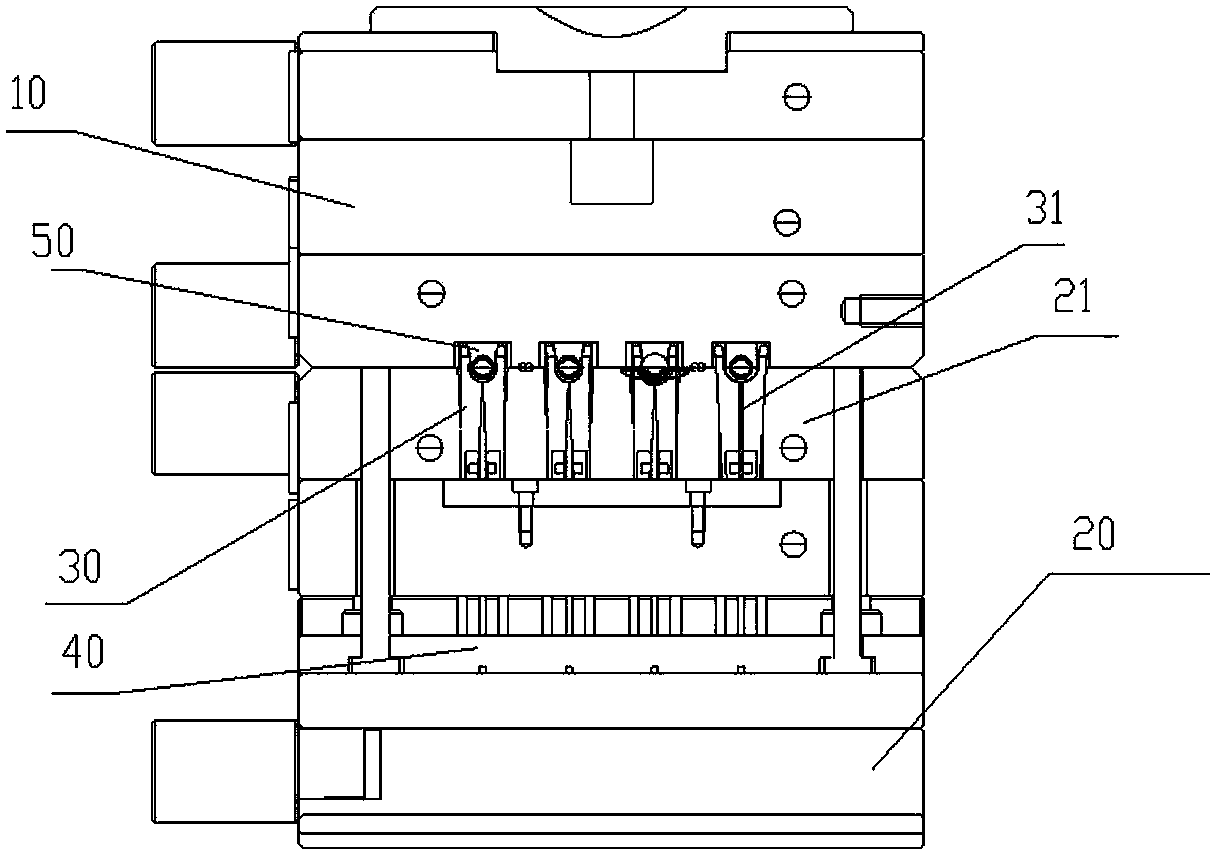

Solar cell module junction box terminal bending device and bending system provided with same

ActiveCN107626853AGuaranteed accuracy and repeatabilityEasy to install automaticallyPhotovoltaicsPhotovoltaic energy generationElectrical batteryEngineering

The invention belongs to the technical field of soar cell module packaging and manufacturing and relates to a solar cell module junction box terminal bending device and a bending system provided withthe solar cell module junction box terminal bending device, in particular to a photovoltaic solar cell module junction box terminal bending device. The solar cell module junction box terminal bendingdevice is compact in structure and high in automation degree and saves the equipment occupied space. The solar cell module junction box terminal bending device comprises a machine body and is characterized in that a locating block is arranged at the bottom of the machine body, the machine body is provided with an inner arc guide rail and an outer arc guide rail with the locating block as the circle center, the outer arc guide rail is provided with a shovel plate mechanism through outer sliding blocks, the inner arc guide rail is provided with a suction cup mechanism through inner sliding blocks, and the machine body is provided with a bending air cylinder connected with the shovel plate mechanism.

Owner:YINGKOU JINCHEN MACHINERY

Method and system for network management data collection

ActiveUS7979531B2Facilitates taskEfficient managementDigital computer detailsMultiprogramming arrangementsWeb serviceNetwork management application

Methods and systems for network management data collection have been provided. Underutilized computers in the network are allocated as a Network Management Data Collection Client (NMDCC) to collect network management data. The NMDCC receives program files from the network management server. The received program files are downloaded by the NMDCC in a compressed manner via a web service. The downloaded program files are executed for collecting the Network Management Data (NMD). The collected NMD is updated back on the network management server. The downloaded program files are discarded when the NMDCC is not collecting the network management data.

Owner:CISCO TECH INC

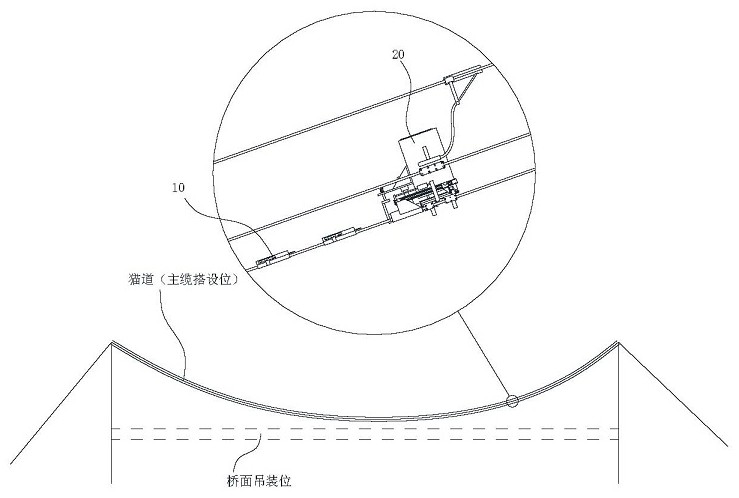

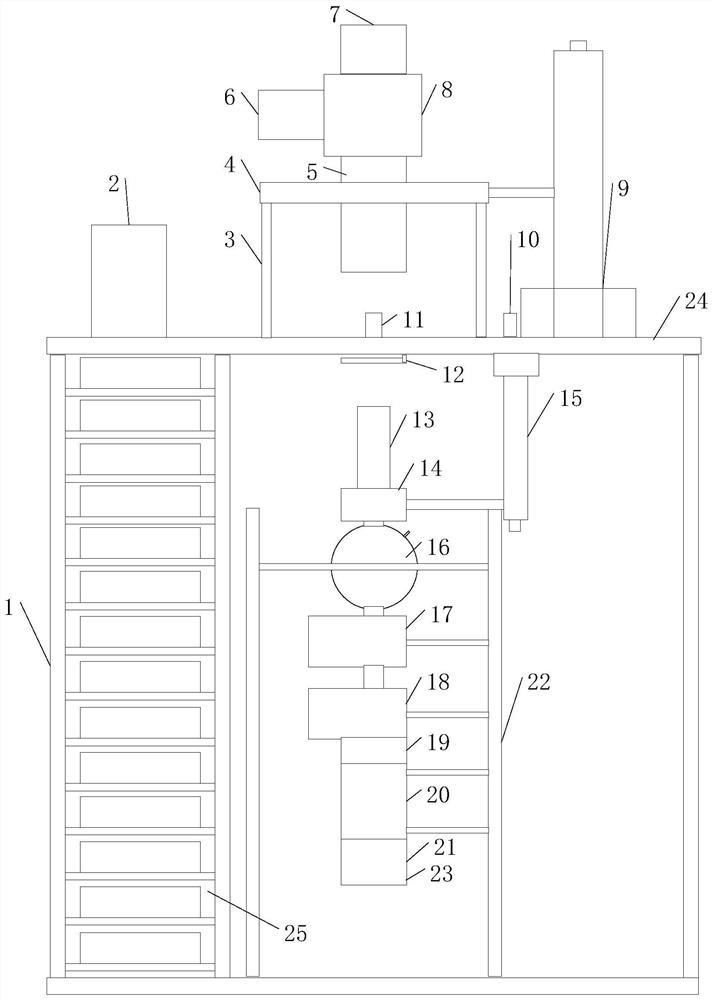

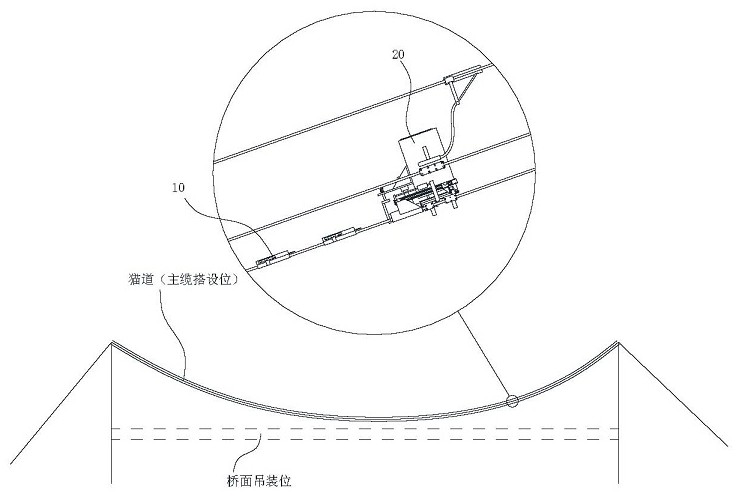

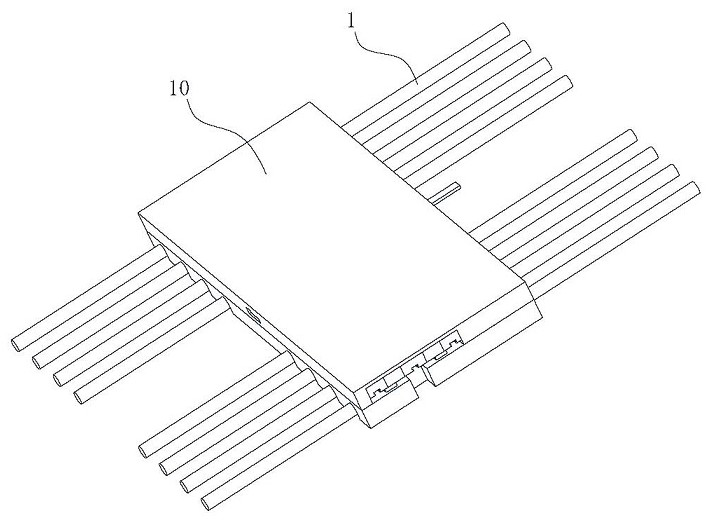

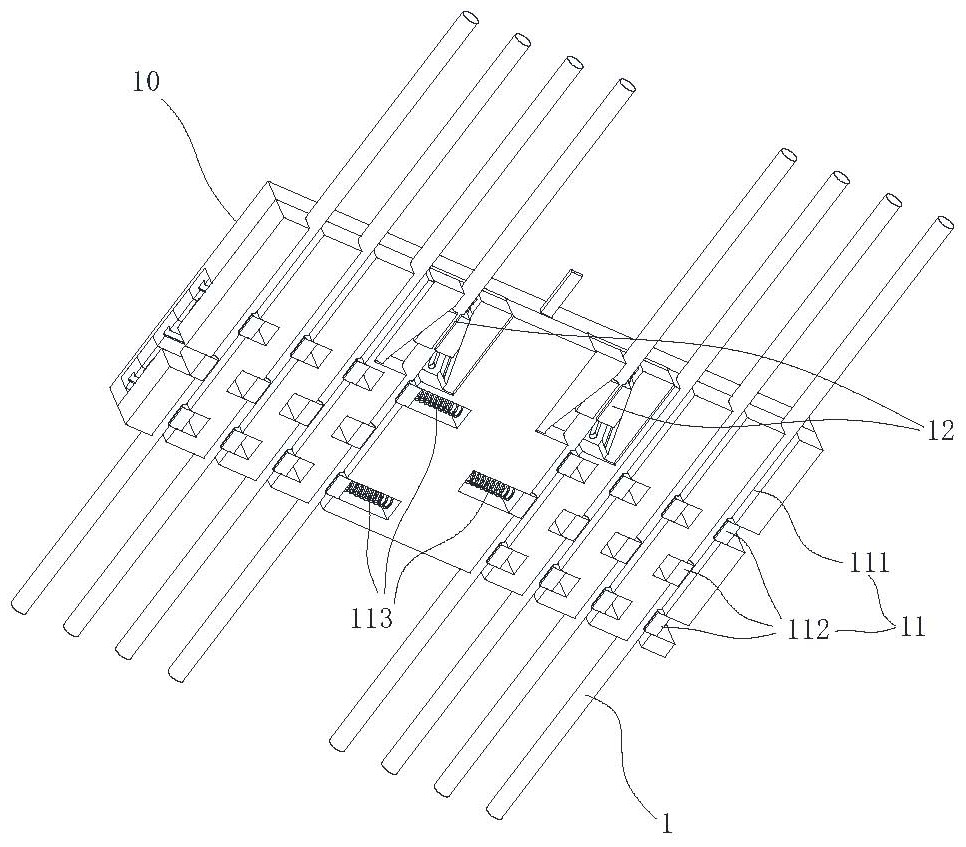

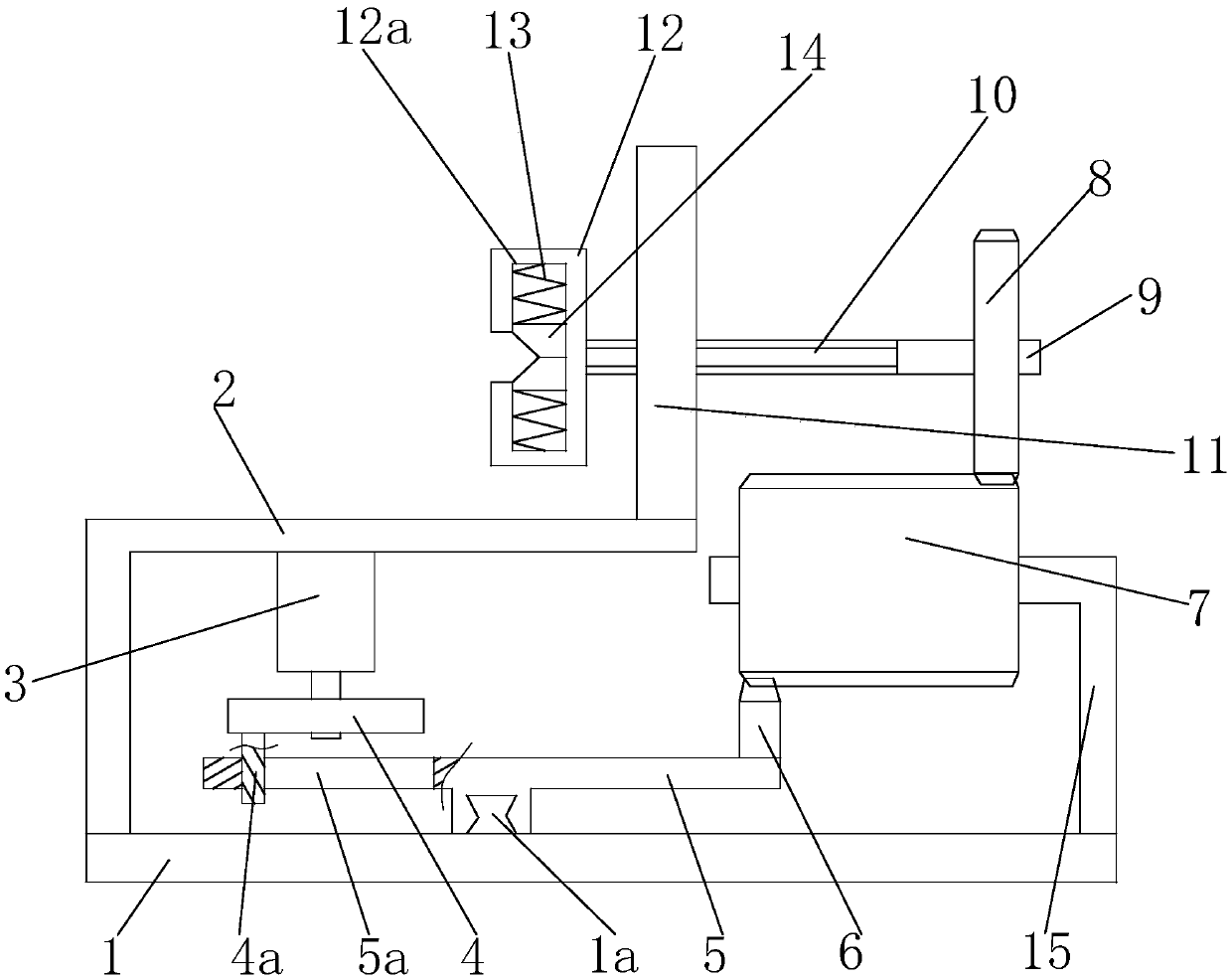

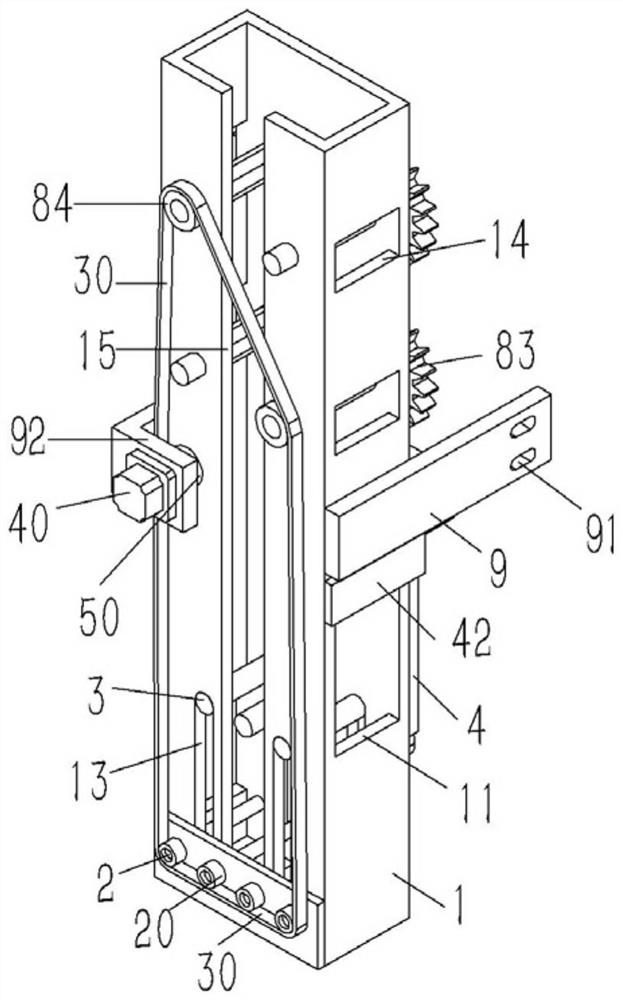

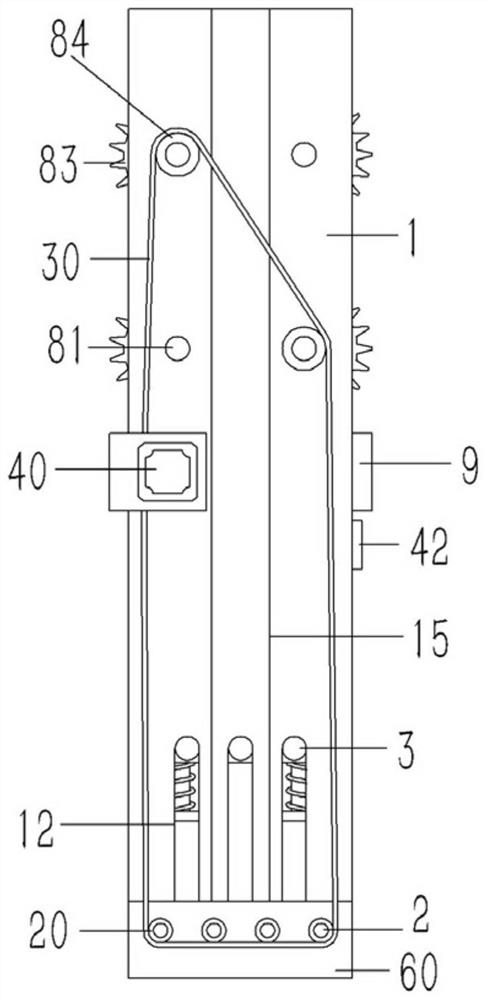

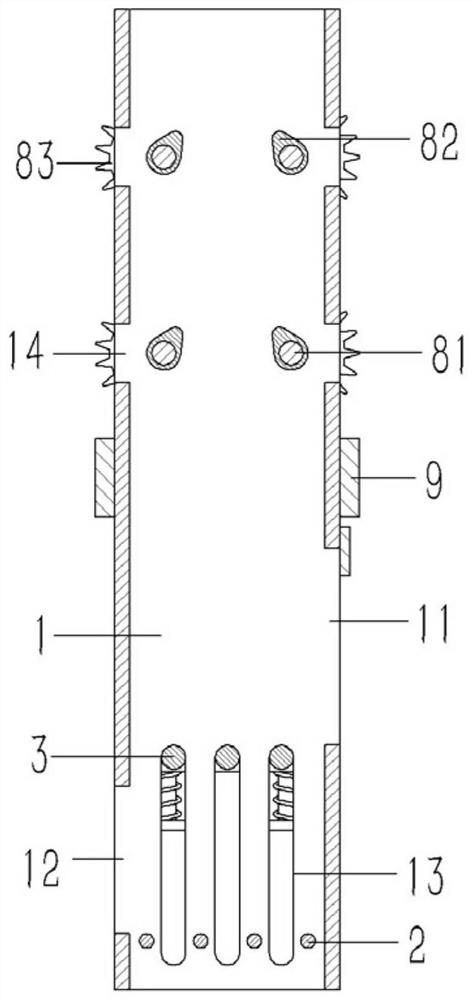

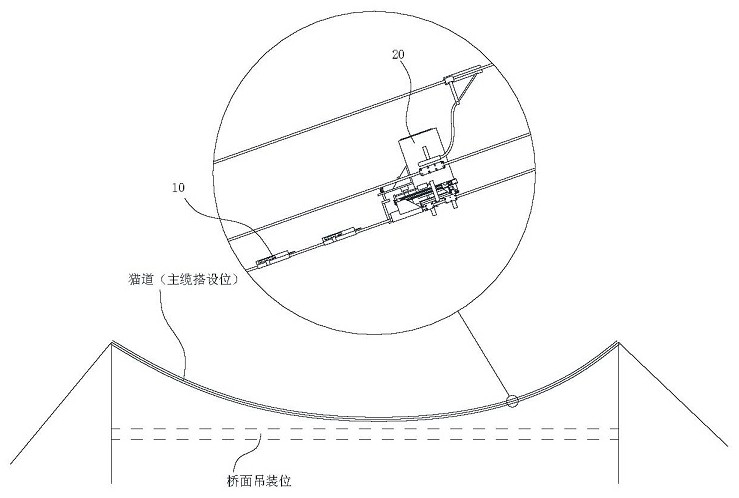

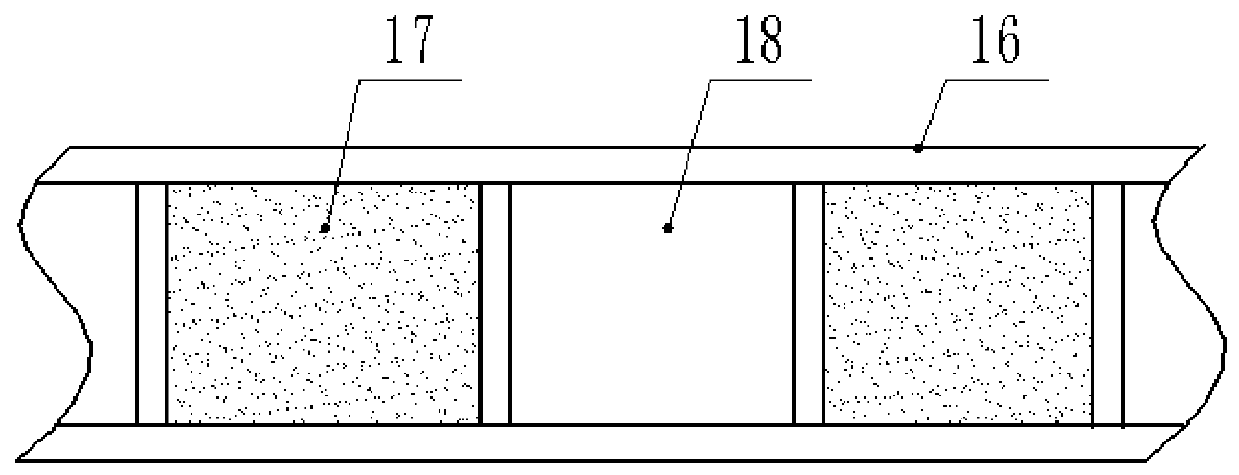

Suspension bridge catwalk laying construction system

InactiveCN111764297AEasy to install automaticallyImprove paving efficiencySuspension bridgeBridge erection/assemblyArchitectural engineeringStructural engineering

The invention belongs to the technical field of bridge construction, and particularly relates to a suspension bridge catwalk laying construction system. According to the invention, the catwalk plate is provided with a first clamping mechanism and a second clamping mechanism which can automatically clamp a catwalk bearing cable; after the catwalk plate is laid on the catwalk bearing cable, downwardpressure is applied to the catwalk plate, and the catwalk bearing cable can be clamped by the first clamping mechanism and the second clamping mechanism, so that axial and radial fixation of the catwalk plate and the catwalk bearing cable is achieved, a connecting piece does not need to be manually arranged, and automatic laying of the catwalk plate is facilitated. According to the laying deviceprovided by the invention, the catwalk plates can be automatically laid, the catwalk plates are pushed to a pressing mechanism one by one through a discharging mechanism, then the catwalk plates are clamped and fixed to the catwalk bearing cable through the pressing mechanism, manual close-range intervention is not needed in the whole construction process, the catwalk laying efficiency is improved, and meanwhile, the safety of constructors is guaranteed.

Owner:安徽晟园景观工程有限公司

Nameplate fixing device for starter production

The invention discloses a nameplate fixing device for starter production, and relates to the related technical field of starters. In the prior art, the nameplate installation position is not accurate,two corners of the nameplate cannot be positioned at the same time during installation, manual installation is required, and time and labor are consumed. A purpose of the invention is to solve the problems in the prior art. According to the scheme, the nameplate fixing device comprises an external bracket, four suction discs are fixedly connected to the back face of the external bracket, a handleis fixedly connected to the front face of the external bracket, a fixing mechanism is fixedly connected to the back face of the handle, a power mechanism is fixedly connected into the fixing mechanism, an adjusting mechanism is arranged on the right side of the power mechanism, and a mounting mechanism is arranged on the back face of the adjusting mechanism. According to the nameplate fixing device, the position of the nameplate can be conveniently adjusted, the two corners of the nameplate can be conveniently and automatically fixed and mounted at the same time, mounting is regular, nameplates of different sizes can be mounted, labor saving, high efficiency and convenience are achieved, and the practicability of the device is improved.

Owner:安徽金途矿山设备有限公司

A reinforcing rib feeding mechanism for welding square steel pipes

ActiveCN112536567BEasy to install automaticallyImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeMaterial storage

Owner:安徽腾达钢构有限公司

An automatic feeding mechanism for downlight ear buckles

ActiveCN107380922BEasy to install automaticallySimple structureJigging conveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an automatic feeding mechanism for a down lamp lug buckle. The mechanism comprises a vibrating disc used for holding the lug buckle, a vibrating rail arranged around the side wall of the vibrating disc, and a horizontal feeding rail connected with the tail end of the vibrating rail. The bottom surface of the vibrating rail is an inclined surface which is arranged obliquely downwards from inside to outside. The lower end of the inclined surface is provided with a stopping edge used for preventing the lug buckle from falling off. The vibrating rail comprises an overlapping rejecting segment, an outwards turning rejecting segment, a reverse end rejecting segment, a rotating guide segment and an overturning guide segment which are arranged in sequence. Overlapping rejecting bars are mounted on the overlapping rejecting segment; at least part of the portion, located at the outwards turning rejecting segment, of the stopping edge is provided with short edge segments; the portion, located at the reverse end rejecting segment, of the inclined surface is provided with a rejecting port and an upwards pushing bar; the rotating guide segment is provided with a rotating guide mechanism used for driving the lug buckle to rotate and enabling the thin end of the lug buckle to face forwards ; and the overturning guide segment is provided with an overturning guide mechanism used for driving the lug buckle to overturn until a main plate portion faces upwards. By adopting the automatic feeding mechanism provided by the invention, the lug buckle can be automatically fed unidirectionally.

Owner:FOSHAN ELECTRICAL & LIGHTING

Robot for automatically loading and unloading aviation marker balls

The invention discloses a robot for automatically loading and unloading aviation marker balls. The robot comprises a robot body, a falling off preventing mechanism and an aviation marker ball loading and unloading mechanism, wherein the front end of the robot body is connected with the aviation marker ball loading and unloading mechanism; the rear end of the robot body is connected with the falling off preventing mechanism; the robot body comprises a main body frame; and the main body frame is connected with a power source device and a control box. After the robot for automatically loading and unloading the aviation marker balls is improved, automatic loading and unloading of the aviation marker balls are realized, so that the labor cost is greatly saved, and the production efficiency is improved. The robot body is simple in structure and light in weight, is provided with a falling off preventing device, and can stably run on an aerial cable.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

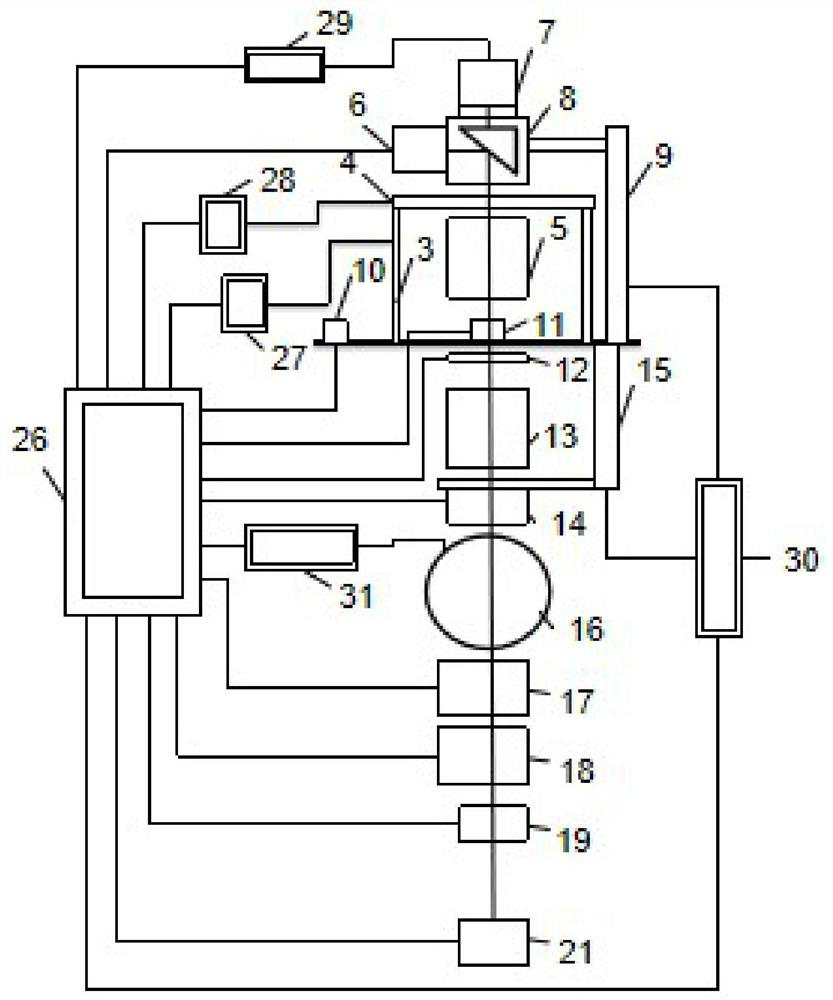

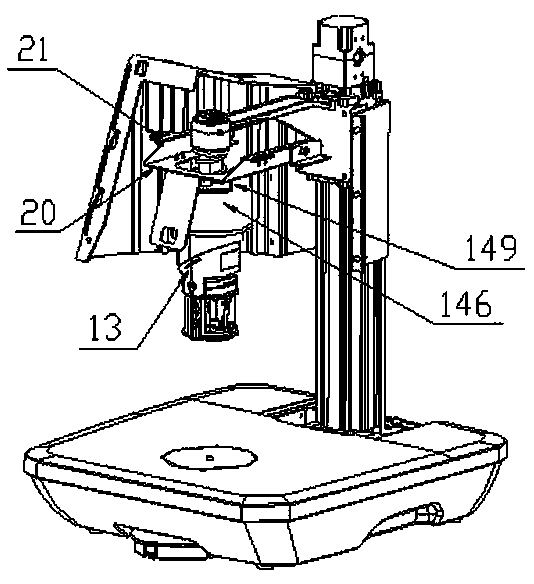

A low-light image intensifier signal-to-noise ratio and halo automatic test system and test method

ActiveCN113432838BAddress automated testing needsEasy to install automaticallyElectrical testingTesting optical propertiesEngineeringFacula

The invention relates to an automatic testing system and testing method for the signal-to-noise ratio and halo of a low-light image intensifier. XY electric translation stage, three-dimensional moving mechanism, light source system obscura, automatic code scanning gun, electric baffle, industrial computer, power supply and controller. Methods include test preparation, performing a halo test, and performing a signal-to-noise ratio test. The halo calculates the actual diameter value of the current small hole spot by identifying and measuring the pinhole image; the signal-to-noise ratio is the noise coefficient. The present invention changes the horizontal light path to the vertical light path, which can improve the image intensifier halo, signal-to-noise ratio It is beneficial to automatically install and remove the image intensifier by using the robot air finger, which improves the test efficiency of the image intensifier, and has the characteristics of convenient operation, reduced labor load and high reliability.

Owner:NORTH NIGHT VISION TECH

Method and system for implementing automatic installation of intelligent cipher key equipment

ActiveCN101382903BSolve the problem that automatic installation cannot be realizedEasy to install automaticallyComputer security arrangementsProgram loading/initiatingSoftware engineeringSmart card

The invention discloses a method and a system for realizing the automatic installation of smart key equipment, which pertains to the smart card field. The method comprises the steps: the smart key equipment declares as USB keyboard equipment to a computer; a pre-defined first keyboard message sequence is sent to the computer and a second keyboard message sequence is obtained by the conversion of the script instruction of a pre-stored operation installation program and sent to the computer; a third keyboard message sequence is sent to the computer and used for the operation of the installationprogram; and when the installation of the installation program is finished, the equipment descriptor is switched into the equipment descriptor required for the normal operation and the equipment declares as the equipment corresponding to the normal operation to the computer. The system comprises the smart key equipment and the computer. The method and the system for realizing the automatic installation of smart key equipment, through the alternation between the smart key equipment and the computer, solve the problem that the smart key equipment can not realize the automatic installation when the autorun function of Windows is shielded, thus facilitating the automatic installation of the smart key equipment.

Owner:FEITIAN TECHNOLOGIES

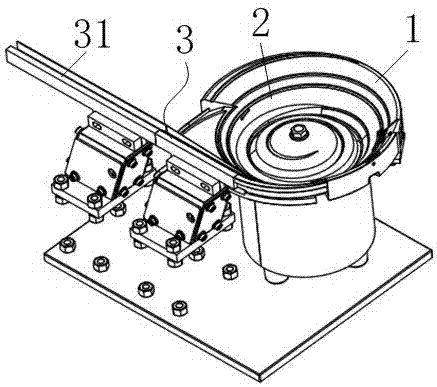

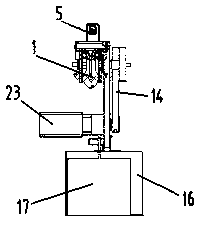

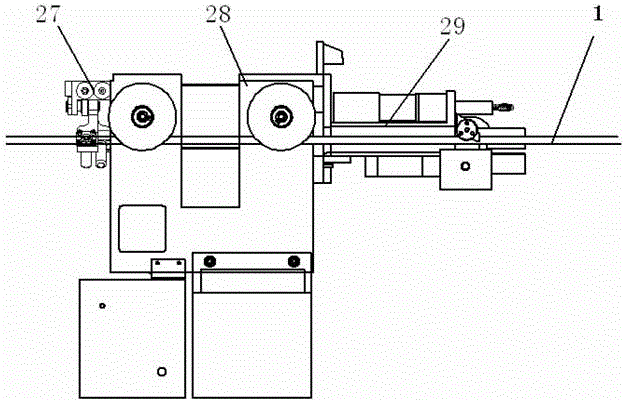

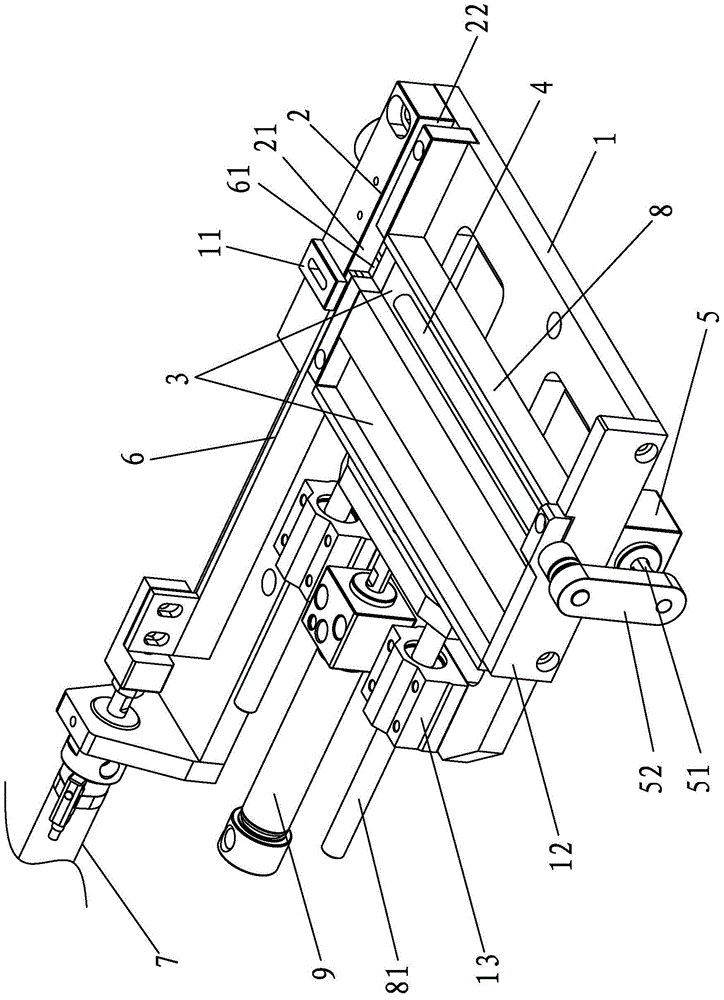

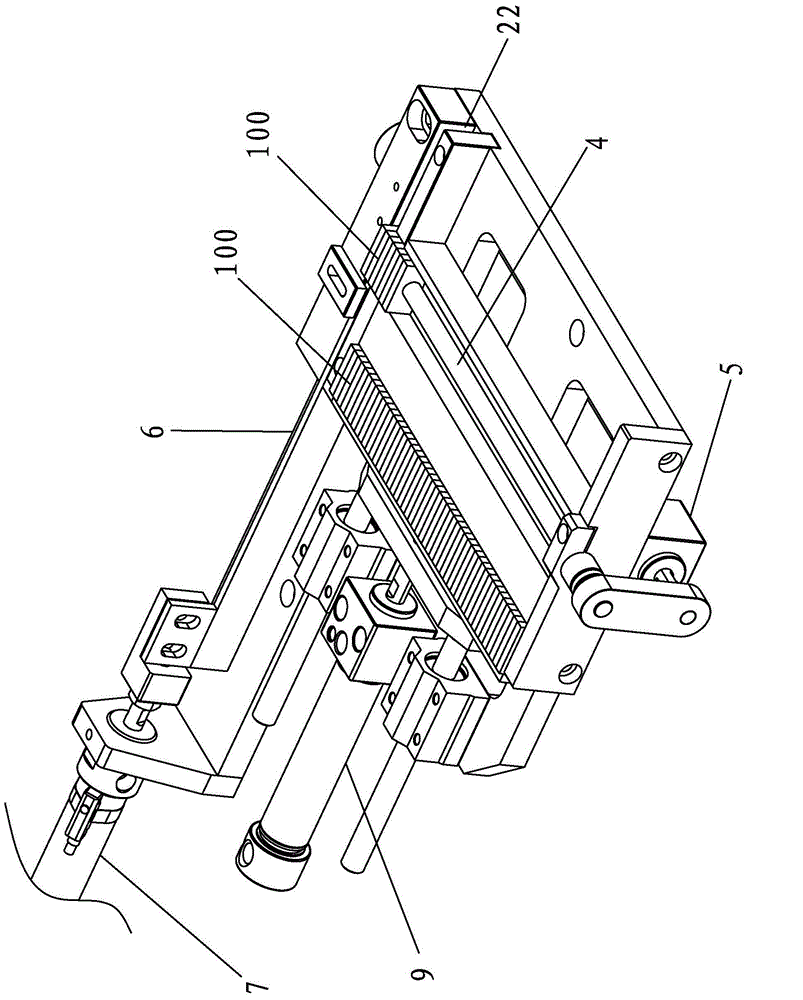

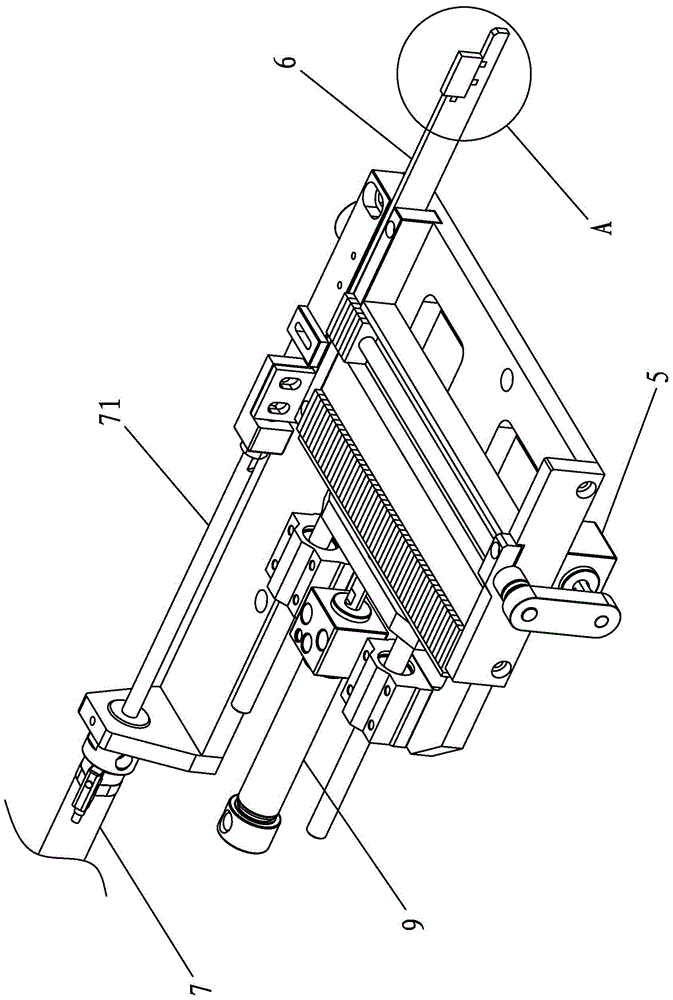

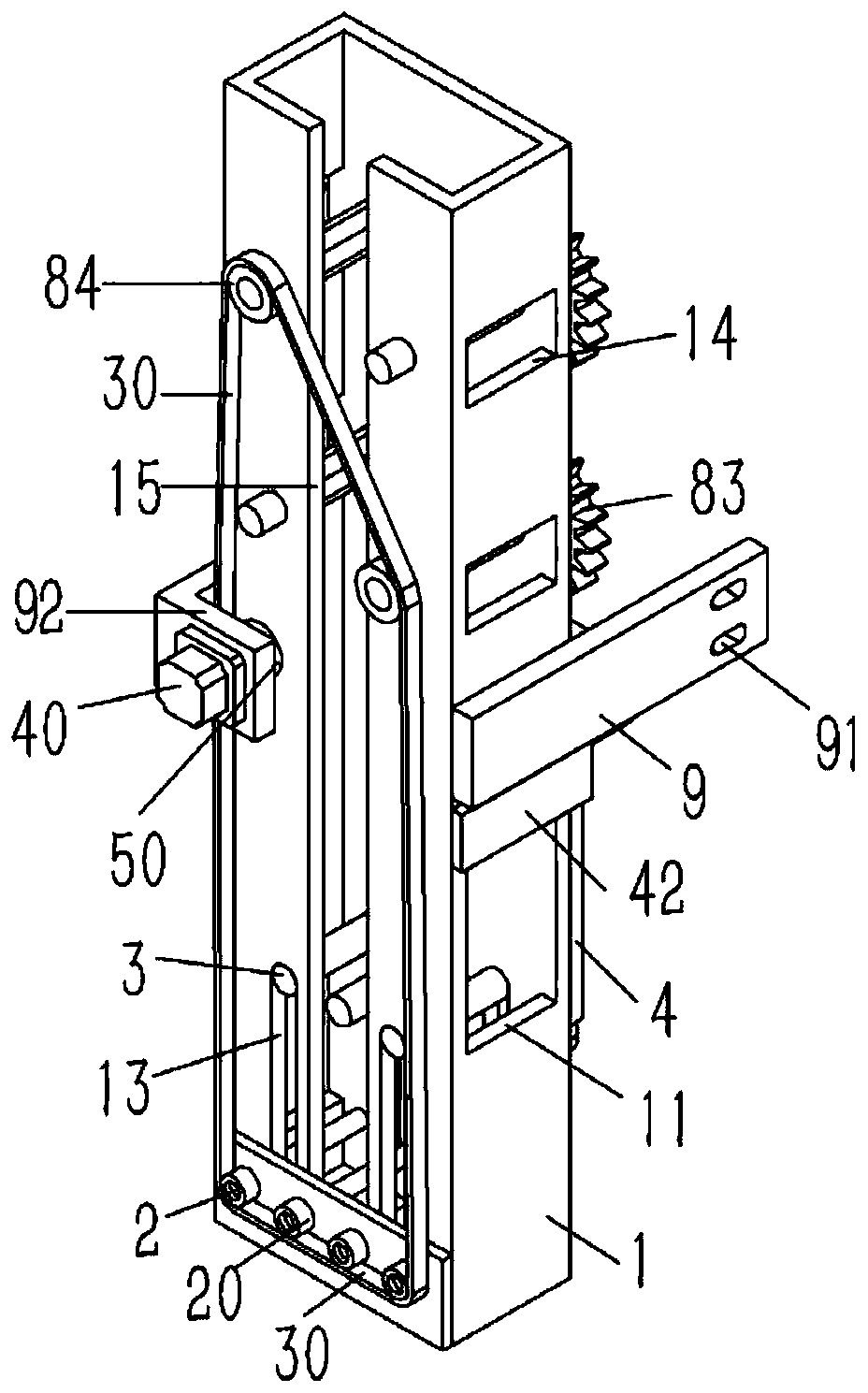

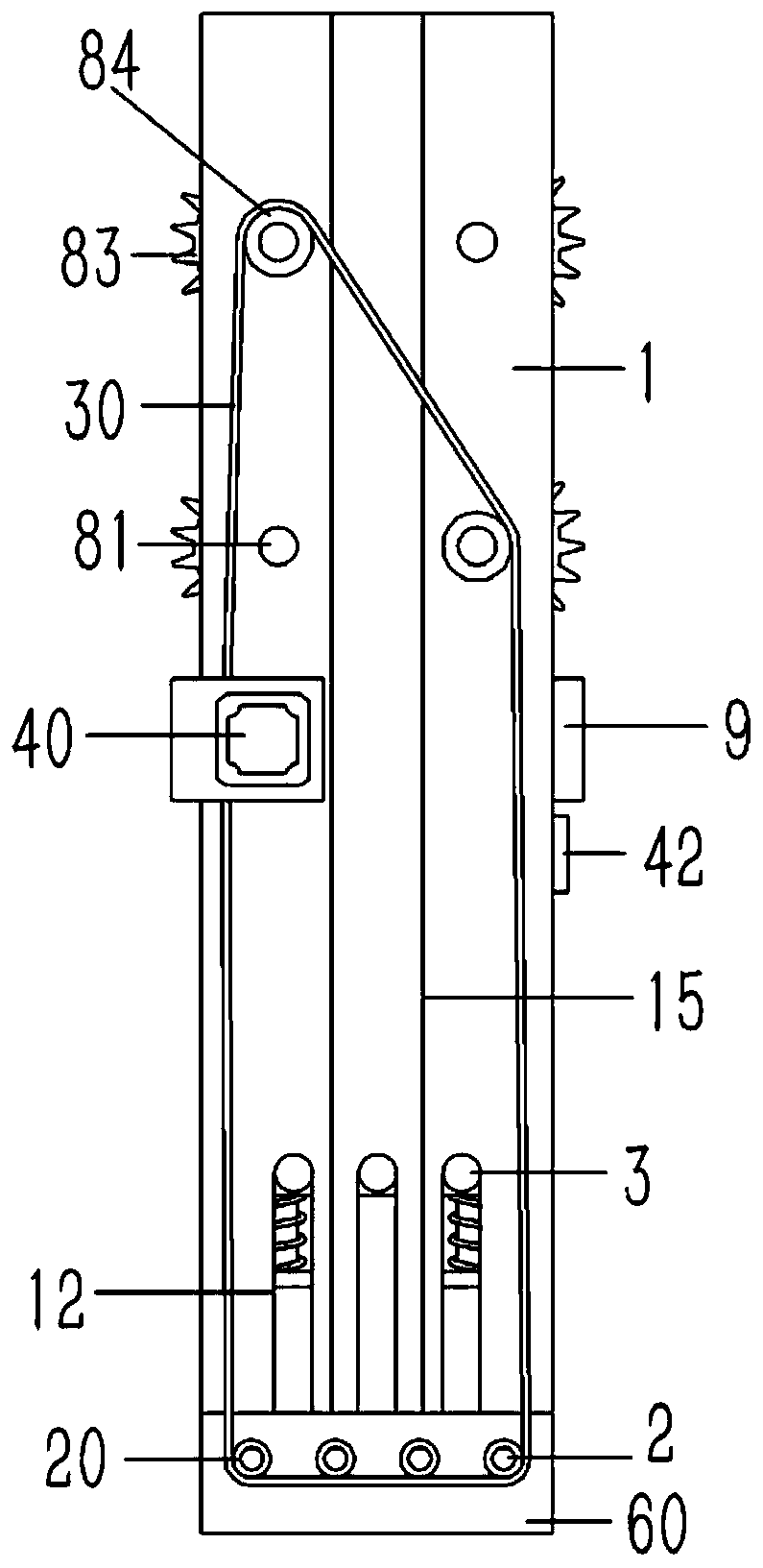

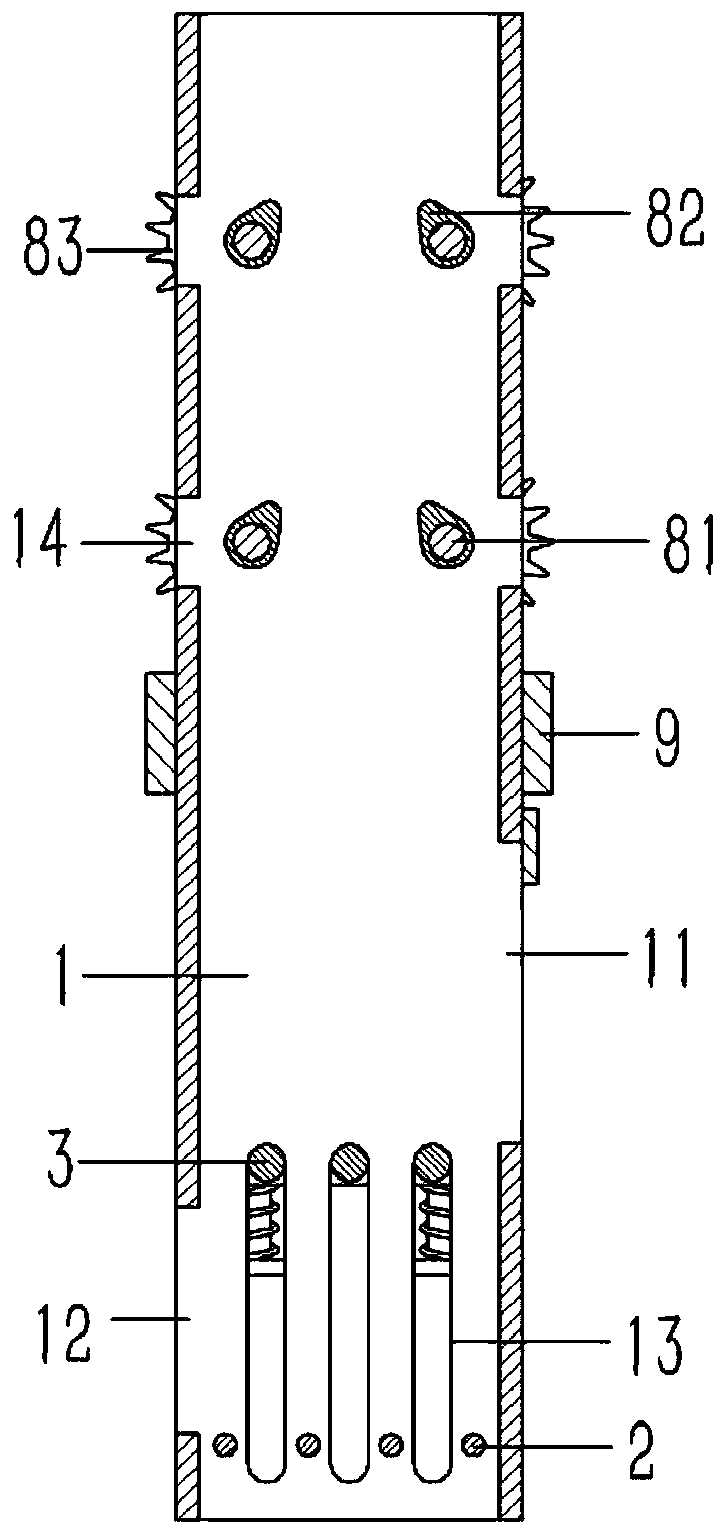

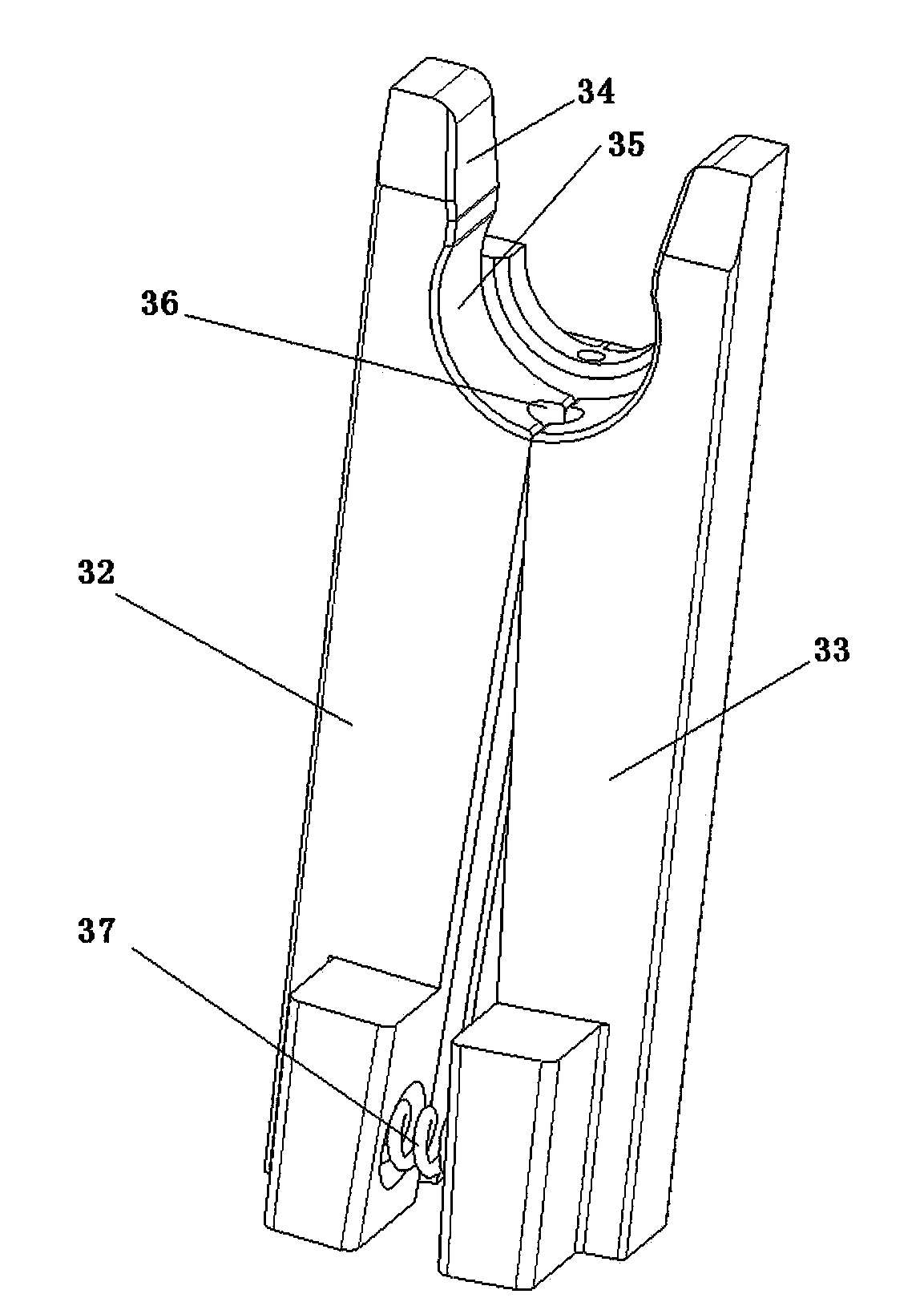

Automatic installation mechanism of tool bit

InactiveCN103551767BSave time with automated installationsEasy to install automaticallyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an automatic installation mechanism of a tool bit. The automatic installation mechanism mainly comprises a base and a carrier plate, wherein a carrier plate groove and a tool bit groove, which form a T-shaped groove structure in a horizontal and vertical manner, are arranged in the base; the carrier plate groove is horizontally extended, and is provided with two free ends and a first knife outlet which is communicated with the tool bit groove, and one free end of the carrier plate groove is opened to form a second knife outlet; a knife push part is arranged in the tool bit groove, and the knife push part is connected with a first drive unit capable of driving the knife push part to move in the tool bit groove back and forth; the carrier plate is movably embedded into the carrier plate groove, a stepped knife placing position is arranged on one end of the carrier plate, and the carrier plate is connected with a second drive unit capable of driving the knife placing position to slide inside and outside the carrier plate groove back and forth. According to the automatic installation mechanism of the tool bit, simple, quick, stable and reliable automatic installation is realized, the automatic installation mechanism has the advantages of simple structure, simplicity in operation, stable and reliable installation and the like. The tool bit groove is further improved, so that the whole installation process is full-automatic quick streamlined operation.

Owner:福建南安市华天机械有限公司

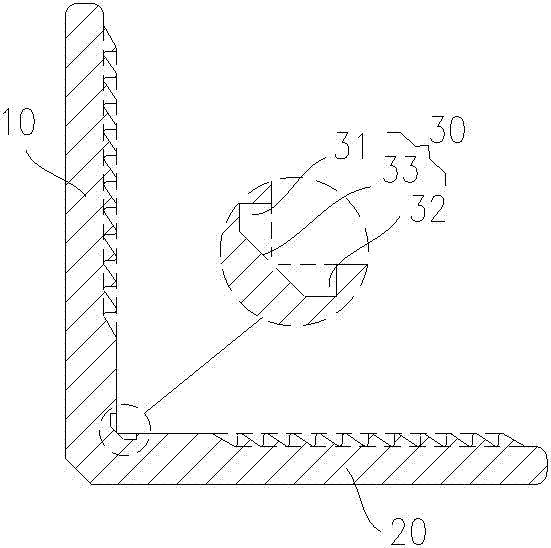

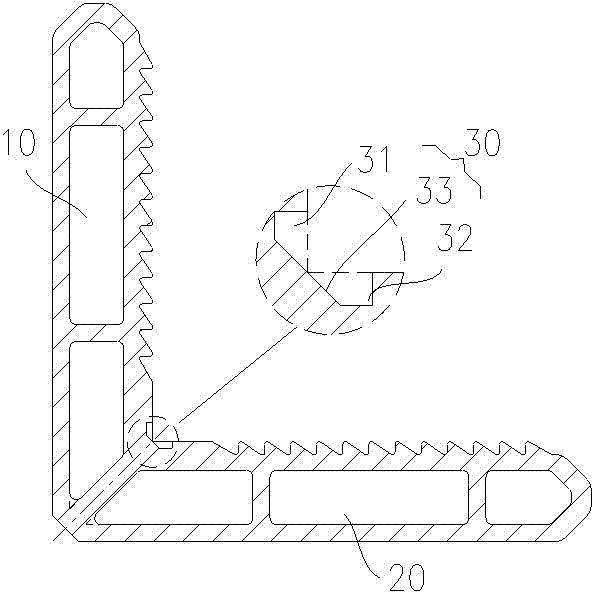

Anti-fool code

ActiveCN105789381BTroubleshoot installation issuesEasy to install automaticallyFinal product manufacturePhotovoltaic energy generationAutomationAerospace engineering

The invention discloses a fool-proof corner connector comprising a vertical plate and a horizontal plate whose left side edge is vertically connected to a lower side edge of the vertical plate. An inner angle of the junction of the vertical plate and the horizontal plate is provided with an empty-avoiding slot, wherein the empty-avoiding slot comprises an upper slot and a lower slot which are set in the vertical plate and the horizontal plate respectively. The lower part of the upper slot and the left part of the lower slot are connected through an inclined plane. An intersecting line of the plane where the right side face of the vertical plate resides and the plane where the upper side of the horizontal plate resides is locate in the incline plane. The advantages of the fool-proof corner connector are that assembly accuracy is high and automation production is facilitated.

Owner:JIANGXI JINKO PV MATERIAL

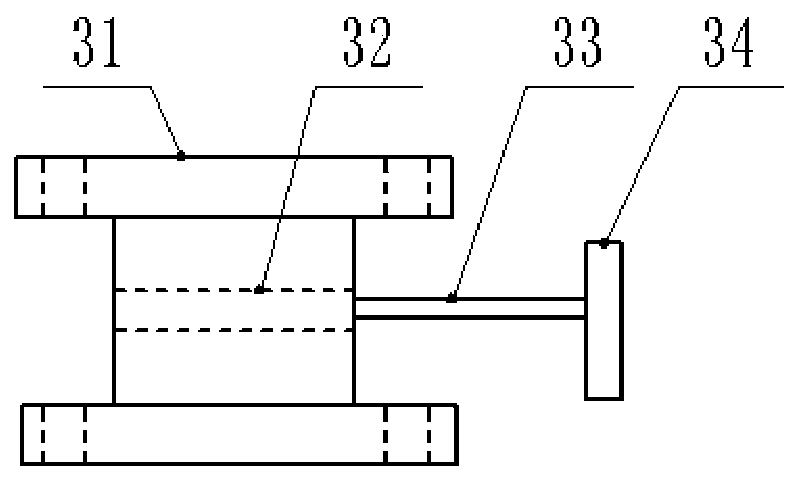

Reinforcing rib feeding mechanism used for welding square steel pipe

ActiveCN112536567AEasy to install automaticallyImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMachiningMaterials science

The invention belongs to the technical field of steel structure production and machining, and particularly relates to a reinforcing rib feeding mechanism used for welding a square steel pipe. The mechanism comprises a storage groove, a pushing mechanism and a turning-over mechanical hand. Each reinforcing rib is made of a steel plate. Each reinforcing rib comprises two triangle areas arranged symmetrically, and a connecting portion for connecting the two triangle areas. The storage groove is used for storing the reinforcing ribs. The reinforcing ribs are horizontally stacked in the storage groove. The pushing mechanism is used for pushing the reinforcing ribs in the storage groove to the turning-over mechanical hand one by one. The turning-over mechanical hand is used for turning over thereinforcing ribs in the horizontal state to the vertical state. According to the mechanism, the reinforcing ribs can be loaded and filled into the turning-over mechanical hand automatically, follow-upautomatic installing of the reinforcing ribs is facilitated, and the machining efficiency is improved.

Owner:安徽腾达钢构有限公司

Suspension bridge catwalk laying construction method

InactiveCN111764295AEasy to install automaticallyImprove paving efficiencySuspension bridgeBridge erection/assemblyArchitectural engineeringStructural engineering

Owner:安徽晟园景观工程有限公司

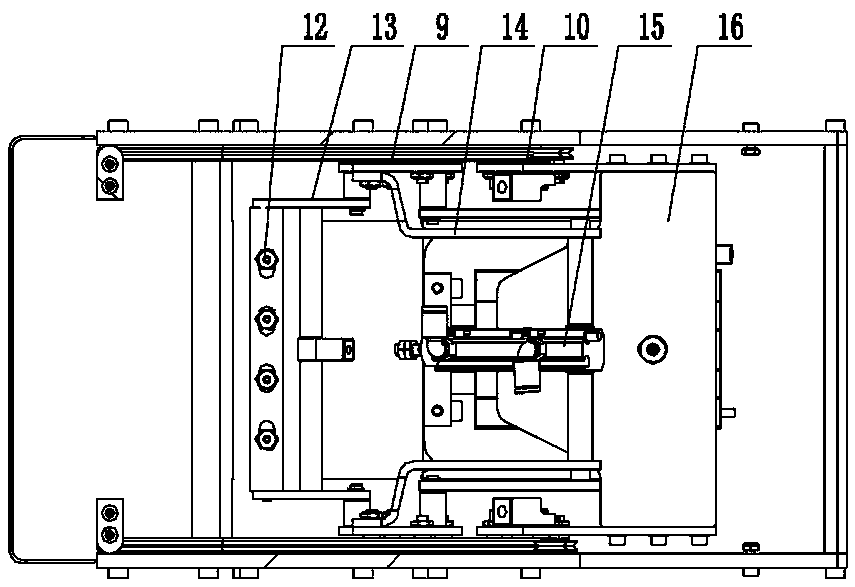

Hex nut assembly machine for screw part of numerical control tool grinding machine

InactiveCN109093371AEasy to install automaticallyHigh degree of automationMetal working apparatusNumerical controlPrecession

The invention relates to a hex nut assembly machine for a screw part of a numerical control tool grinding machine, comprising a bottom plate and an upper platen welded on the bottom plate, a motor ismounted at the bottom of the upper platen, and the motor is connected with a disk. A slide rail is arranged on the bottom plate, and a transmission frame is slidably mounted above the slide rail alonga front and rear direction, the left part of the transmission frame is provided with a transverse slot, an eccentric position on the bottom surface of the disk is provided with a convex block horizontally slidingly matched with the transverse slot, the right side of the transmission frame is welded with a single-sided rack, the single-sided rack is engaged with a thick gear, the thick gear is meshed with a thin gear, the thin gear is connected with a round shaft through a key, the left end of the round shaft is welded with a screw, the right side of the upper end of the upper platen is fixedly provided with a screw seat matched with the thread of the screw, and the left side of the screw is provided with a clamping device. According to the invention, on the basis of the function of clamping hex nuts, the hex nut assembly machine can conveniently automatically complete screwing of a large batch of nuts one by one into a screw component of a grinding machine through left and right reciprocating precession of the clamping device controlled by gear transmission, and has high assembly efficiency.

Owner:WUHU HONGJIN MACHINE TOOL

A discharge packaging device for printing paper rolls

ActiveCN110697125BEasy to install automaticallyEasy to printIndividual articlesPaper tapeStructural engineering

The invention discloses a discharge packaging device for printing paper rolls, which comprises a rectangular and vertical output channel, the lower end of the output channel is inserted with a number of longitudinal roller shafts, and the two ends of the roller shafts are hinged on the output channel. On the road, the front end of the roller shaft passes through the support plate sleeve to fix the first pulley, the support plate is fixed on the front end surface of the output channel, and the front and rear end surfaces of the output channel between the roller shafts are formed with vertical pulleys. The guide groove is inserted into the guide groove, and a support rod is inserted into the guide groove. The rear end of the support rod is fixed on the slide plate, and the slide plate is against the rear end surface of the output channel. The upper end of the slide plate is formed with a horizontal branch plate, and the branch plate There are several T-shaped guide rods plugged in. The upper end of the guide rod passes through the branch plate and is fixed on the fixed block. The fixed block is fixed on the rear end surface of the output channel. A compression spring is inserted on the guide rod. Press against the lower end of the guide rod and the branch plate respectively. The invention can be connected with the production equipment of the paper tape roll, facilitates the automatic installation of the paper tape roll into the packaging box, and facilitates the packaging operation of the printing paper roll.

Owner:台州金荣企业管理合伙企业(有限合伙)

Catwalk plate for suspension bridge construction

InactiveCN111764293AEasy to install automaticallyAchieve fixationSuspension bridgeBridge erection/assemblyClassical mechanicsAxial displacement

Owner:安徽晟园景观工程有限公司

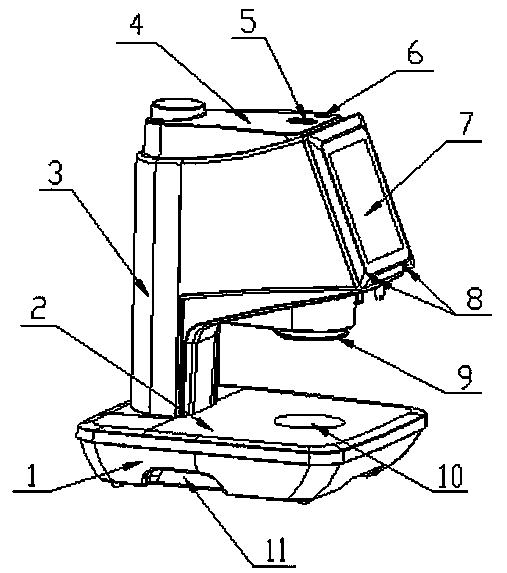

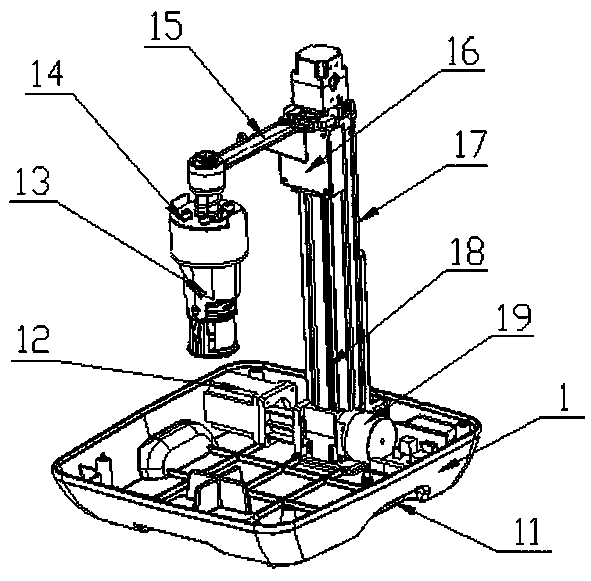

An automatic loading and unloading stamp machine

ActiveCN105904859BProtect the internal structureGuaranteed clarityIndividual entry/exit registersStampingReciprocating motionEngineering

The invention provides an automatic assembly and disassembly type seal machine and relates to the technical field of seal equipment. The automatic assembly and disassembly type seal machine comprises a base. A lifting mechanism is arranged on the base. The lifting mechanism is connected with an installation base. A seal mechanism is installed in the installation base. The installation base comprises a base body. A cavity matched with the seal mechanism is arranged in the base body. An installation part which can move in a reciprocating mode in the radial direction of the cavity is arranged in the cavity. A limiting mechanism is connected to the outer side of the installation part. The limiting mechanism is connected with a limiting switch. The seal mechanism comprises a seal body and a shell. A groove matched with the installation part is formed in the shell. According to the automatic assembly and disassembly type seal machine, the limiting mechanism is started or stopped through the limiting switch to make the seal mechanism be taken out of the installation base or installed in the installation base, the seal machine does not need to be disassembled, no special tool is needed, and operation is easy; and meanwhile, the seal machine is provided with a cover body, so that the internal structure of the seal machine is effectively protected, the appearance of the seal machine is tidy and attractive, and automatic assembly and disassembly of the seal mechanism are completed more conveniently under the effect of a display screen.

Owner:QINGDAO YINGTAI INFORMATION TECH CO LTD

Method for automatically installing operating system

InactiveCN100447742CAutomatic installation is reliableEasy to install automaticallyProgram loading/initiatingOperational systemBIOS

Owner:LENOVO (BEIJING) LTD

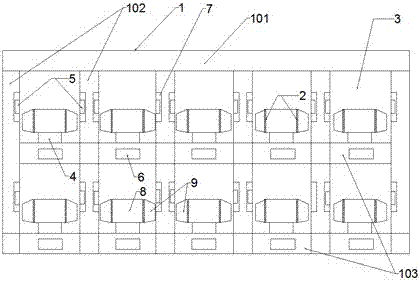

Manipulator storage cabinet

PendingCN107538523AEasy to install automaticallyThe automatic installation went smoothlyManipulatorEngineeringManipulator

The invention discloses a manipulator storage cabinet which comprises storage cabinet fixing rods, partition boards fixed between the storage cabinet fixing rods, storage rooms, manipulator fixing assemblies, pushing pieces and positioning assemblies, wherein the storage rooms are formed between every two adjacent partition boards and are used for storing manipulator operating heads; the manipulator fixing assemblies are arranged in the storage rooms and are used for fixing the rear ends of the operating heads; the pushing pieces push manipulators out of the storage rooms and fix the manipulators at the rear ends of the manipulator fixing assemblies; and the positioning assemblies are arranged on the storage cabinet fixing rods. According to the manipulator storage cabinet, the pushing pieces push the operating heads out of the storage rooms, so that automatic assembling of the manipulator is facilitated; then the manipulator fixing assemblies are adopted to stably fix the operating heads so as to ensure smooth automatic installation; the positioning assemblies enable the manipulators to automatically identify the required placement positions of the operating heads and to preciselyfind mounting parts on the operating heads so as to finish precise installation.

Owner:镇江玄润电气设备有限公司

Discharging and packaging device for printing paper roll

ActiveCN110697125AEasy to install automaticallyEasy to printIndividual articlesPaper tapeEngineering

The invention discloses a discharging and packaging device for a printing paper roll. The discharging and packaging device includes a rectangular and vertical output groove channel, a plurality of longitudinal roll shafts are connected to the lower end of the output groove channel in an inserted mode, and the two ends of the roller shafts are hinged to the output groove channel; the front ends ofthe roll shafts penetrate through a supporting plate to be fixedly provided with first pulleys in inserted and sleeved modes, and the supporting plate is fixed on the front end surface of the output groove channel; vertical guide grooves are formed in the front end surface and the rear end surface, between the roll shafts, of the output groove channel, supporting rods are connected into the guidegrooves in an inserted mode, the rear ends of the supporting rod are fixed on a sliding plate, the sliding plate abuts against the rear end surface of the output groove channel, and a horizontal branch plate is formed at the upper end of the sliding plate; the branch plate is connected with a plurality of T-shaped guide rods in an inserted mode, the upper ends of the guide rods penetrate through the branch plate to be fixed to a fixed block, and the fixed block is fixed to the rear end surface of the output groove channel; and compression springs sleeve the guide rods in an inserted mode, andthe two ends of the compression springs are pressed against the lower ends of the guide rods and the branch plate correspondingly. The discharging and packaging device can be used for connecting production equipment of a paper tape roll, and the paper tape roll can be conveniently and automatically installed in a packaging box, so that the packaging operation of the printing paper roll is facilitated.

Owner:台州金荣企业管理合伙企业(有限合伙)

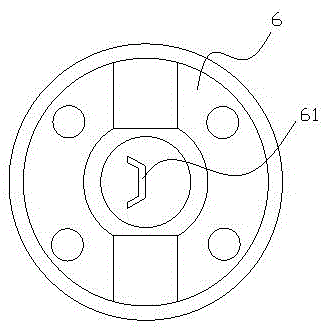

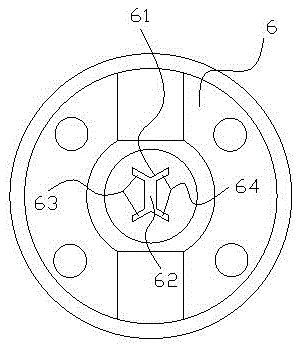

Easily assembled electric cooker temperature limiter

InactiveCN105559615AEasy to install automaticallyImprove the degree of automated productionCooking vesselsSoft magnetEngineering

The invention provides an easily assembled electric cooker temperature limiter. The electric cooker temperature limiter is composed of an inner cup and an outer cup, wherein the inner cup is supported in the outer cup by virtue of an outer spring; a soft magnet is arranged at the top of the inner cup by virtue of an aluminum cover and a soft magnetic support; a hard magnetic support is movably arranged on the lower part of the inner cup, and an inner spring is arranged between the hard magnetic support and the inner top surface of the inner cup; a hard magnet is fixedly arranged on the hard magnetic support; a pull rod is arranged on the hard magnetic support by virtue of a middle mounting hole; the pull rod moves downwards and sequentially runs through the bottoms of the inner cup and the outer cup; the mounting hole comprises a strip-shaped main body part and connecting parts which are connected to two sides of the main body part in a splayed form; the two pairs of the connecting parts are symmetrical about the linear mirror image of the main body part; and the cross-section shape of a mounting part at one end of the pull rod is adaptive to the shapes of the main body part of a mounting hole and one pair of the connecting parts.

Owner:阮保清

Injection molding encapsulation mould with positioning fixture mechanisms

Owner:PERLMAN ELECTRICAL KUSN

A kind of valve tightness detection device

ActiveCN108279096BImprove sealingImprove accuracyDetection of fluid at leakage pointIodine solutionsPulley

The invention relates to the valve detection processing field, and discloses a valve tightness detecting device. The valve tightness detecting device comprises a detecting table and an iodine solutionbox; a frame is arranged on the detecting table, a first pressing plate and a second pressing plate are glidingly connected to the frame, and a pull rope is connected to the middle of the first pressing plate and the second pressing plate; a fixed pulley, a first rotary wheel and a second rotary wheel are rotationally connected to the frame; the pull rope strides over the fixed pulley, the firstrotary wheel is connected with the second rotary wheel through a belt; a roll belt are wound between the first rotary wheel and the second rotary wheel, and a wafer is arranged on the roll belt; a first plug rod is connected to the first pressing plate, and a second plug rod is connected to the second pressing plate; plug holes are arranged at the parts where the detecting table is faced to the first plug rod and the second plug rod; a detecting site is arranged between two plug holes, and provided with a fluid leaking hole; the iodine solution box is connected with a fluid pipe, a free end ofthe fluid pipe is located at the upper part of the detecting site, a switch is arranged on the fluid pipe and connected with a torsional spring. Through the invention, the detecting efficiency and accuracy of the valve can be improved.

Owner:重庆新锐科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com