A reinforcing rib feeding mechanism for welding square steel pipes

A technology of reinforcing ribs and square steel pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated operation, heavy steel plate weight, difficult positioning, etc., to improve processing efficiency and facilitate automatic installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

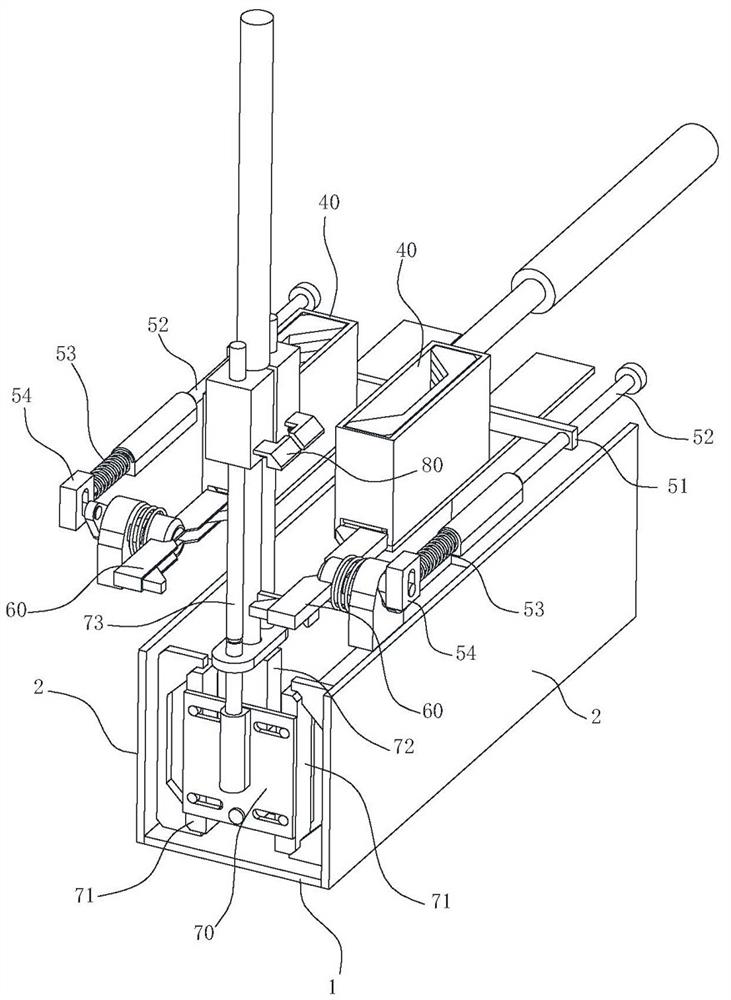

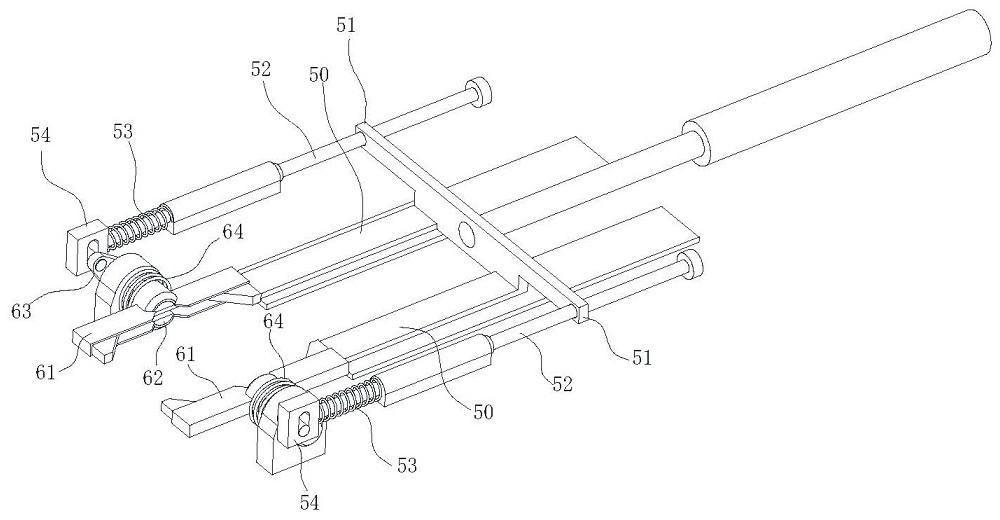

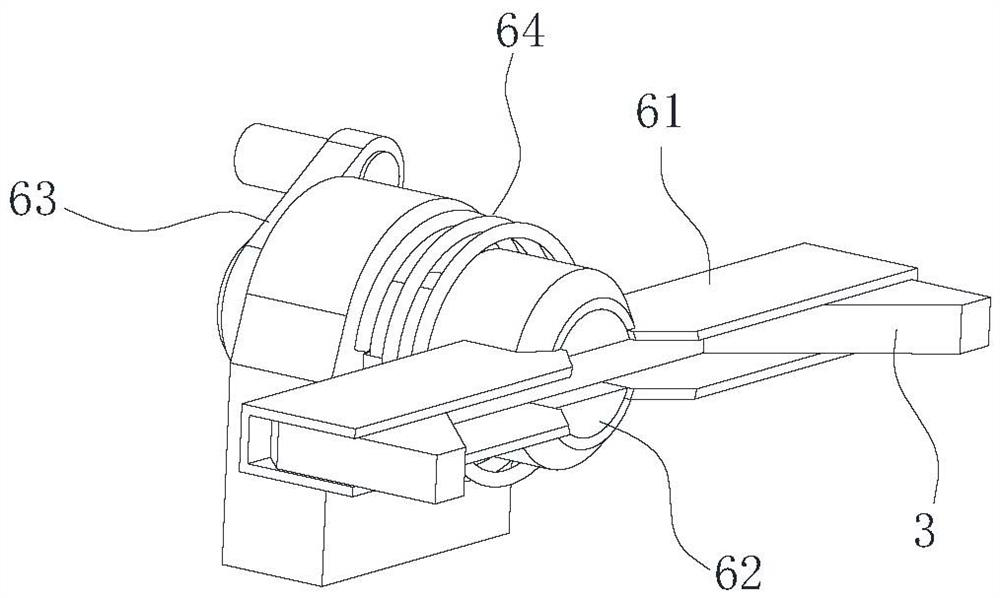

[0026] like Figure 1-7 As shown, a pre-installation equipment for square steel tube reinforcement bars includes a storage tank 40, a pushing mechanism, a turning manipulator 60 and a lifting seat 70. The reinforcement bars 3 are made of steel plates, and the reinforcement bars 3 include two symmetrically arranged triangles. area and the connecting part connecting the two triangular areas; the storage tank 40 is used to store the reinforcing ribs 3, and the reinforcing ribs 3 are stacked horizontally in the storage tank 40, and the pushing mechanism is used to strengthen the reinforcement in the storage tank 40. The ribs 3 are pushed to the turning manipulator 60 one by one, and the turning manipulator 60 is used to turn the reinforcing ribs 3 in the horizontal state to the vertical state; Two side push blocks 71, the side push blocks 71 are slidably connected with the lift seat 70 along the horizontal direction, and the two sides of the movement path of the lift seat 70 are p...

Embodiment 2

[0037] A method for pre-installing a reinforcing bar of a square steel pipe, comprising the following steps:

[0038] Step 1: spot welding one transverse steel plate of the square steel pipe to the two side steel plates;

[0039] Step 2: Place two reinforcing ribs at the inner corners of the transverse steel plate and the two side steel plates described in step 1, respectively. The reinforcing ribs are made of steel plates, and the reinforcing ribs include two symmetrically arranged triangular areas and connect the two triangles. The connecting part of the area; when placed, the two right-angled sides of one triangular area of the reinforcing rib are respectively attached to the corner, and the other triangular area is upwardly arranged to support the square steel tube with another transverse steel plate;

[0040] Step 3: Weld and fix the reinforcing rib with the transverse steel plate and the two side steel plates respectively;

[0041] In the step 2, a square steel pipe r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com