Anti-fool code

A corner code and fool-proof technology, applied in the field of fool-proof corner codes, can solve the problems that the correctness of the corner codes cannot be guaranteed 100%, which is not conducive to production, etc., so as to facilitate automatic production, solve the problem of installation correctness, and reduce the length and width. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

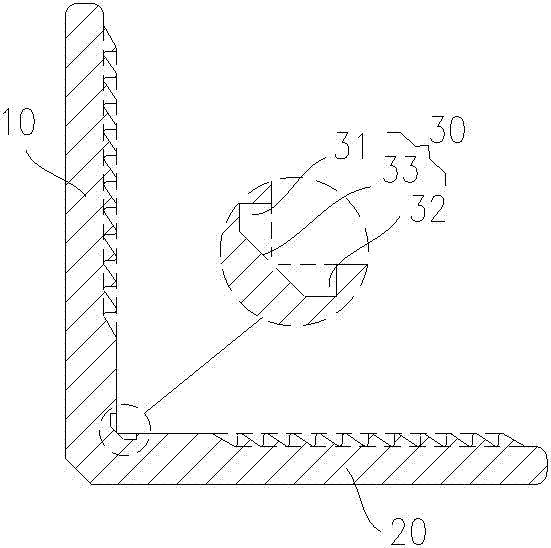

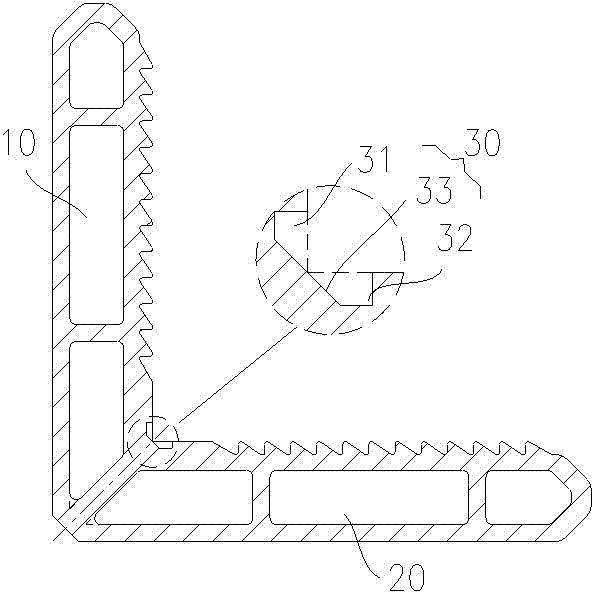

[0014] Examples, see figure 1 and figure 2 Shown: the fool-proof corner code, including a vertical board 10 and a horizontal board 20 whose left side is vertically connected to the lower side of the vertical board 10 . That is, the section of the fool-proof corner code is in the shape of "7". At the same time, the inner corner of the connection between the vertical plate 10 and the horizontal plate 20 is provided with an escape groove 30 .

[0015] Further speaking, the escape groove 30 includes an upper groove 31 opened on the vertical plate 10 and a lower groove 32 opened on the horizontal plate 20, the lower part of the upper groove 31 and the left part of the lower groove 32 pass through A bevel 33 is connected. That is, the escape groove 30 is formed at the junction of the vertical plate 10 and the horizontal plate 20 , and extends upward and rightward. Meanwhile, the intersection line of the plane of the right side of the vertical board 10 and the plane of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com