Split cupboard connection system

A connection system and split-type technology, applied in the field of kitchen cabinets, can solve problems such as single function, no relatively mature solution to connection problems, no single cabinet temperature adjustment connection method, etc., and achieve the effect of solving installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

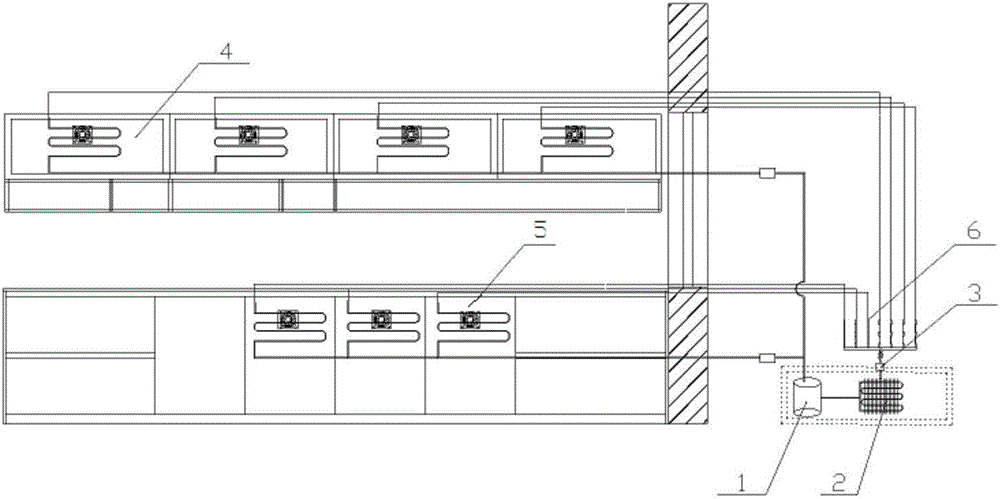

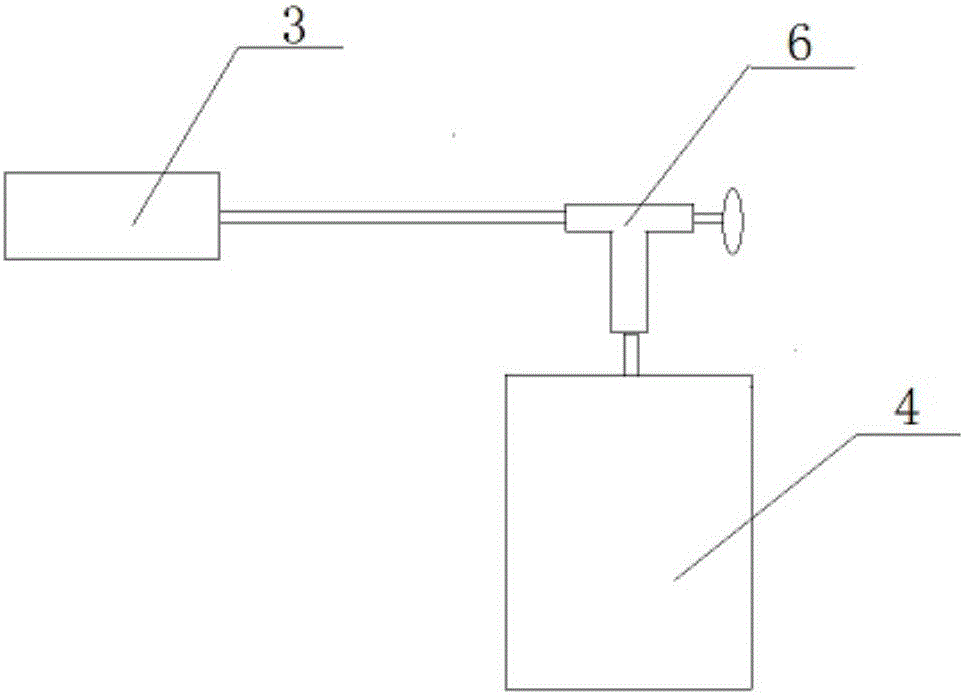

[0018] like figure 1 As shown, a split cabinet connection system according to the present invention includes an external compressor 1, a condenser 2, a dryer 3, a temperature-adjustable cabinet unit 4, a temperature-adjustable control unit 5 and a connector 6. The built-in compressor 1 is connected to the condenser 2, the condenser 2 is connected to the dryer 3, the temperature-adjustable cabinet unit 4 is provided with a temperature-adjustable control unit 5 for independent temperature adjustment, and the outlet of the dryer 3 is connected to the temperature-adjustable cabinet unit 4 The inlets are connected through connector 6.

[0019] The temperature-adjustable cabinet unit 4 is provided with at least one group, and the inlets of a plurality of temperature-adjustable cabinet units 4 are respectively connected to the outlet of the dryer 3 through a connector 6; the connector 6 adopts a check valve; the temperature-adjustable cabinet unit 4 Both the inlet and the outlet of ...

Embodiment 2

[0021] A split cabinet connection system according to the present invention includes an external compressor 1, a condenser 2, a dryer 3, a temperature-adjustable cabinet unit 4, a temperature-adjustable control unit 5, and a refrigeration needle valve. The external compressor 1 is connected to the condenser 2, and the condenser 2 is connected to the dryer 3. The temperature-adjustable cabinet unit 4 is provided with a temperature-adjustable control unit 5 for independent temperature adjustment, and the outlet of the dryer 3 passes through the inlet of the temperature-adjustable cabinet unit 4. The refrigeration needle valve is connected.

Embodiment 3

[0023] A split cabinet connection system according to the present invention includes an external compressor 1, a condenser 2, a dryer 3, a temperature-adjustable cabinet unit 4, a temperature-adjustable control unit 5, and a refrigerant check valve. The machine 1 is connected to the condenser 2, the condenser 2 is connected to the dryer 3, the temperature-adjustable cabinet unit 4 is provided with a temperature-adjustable control unit 5 for independent temperature adjustment, the outlet of the dryer 3 is connected to the inlet of the temperature-adjustable cabinet unit 4 Connected through the refrigerant check valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com