Patents

Literature

39results about How to "Reduce length and width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

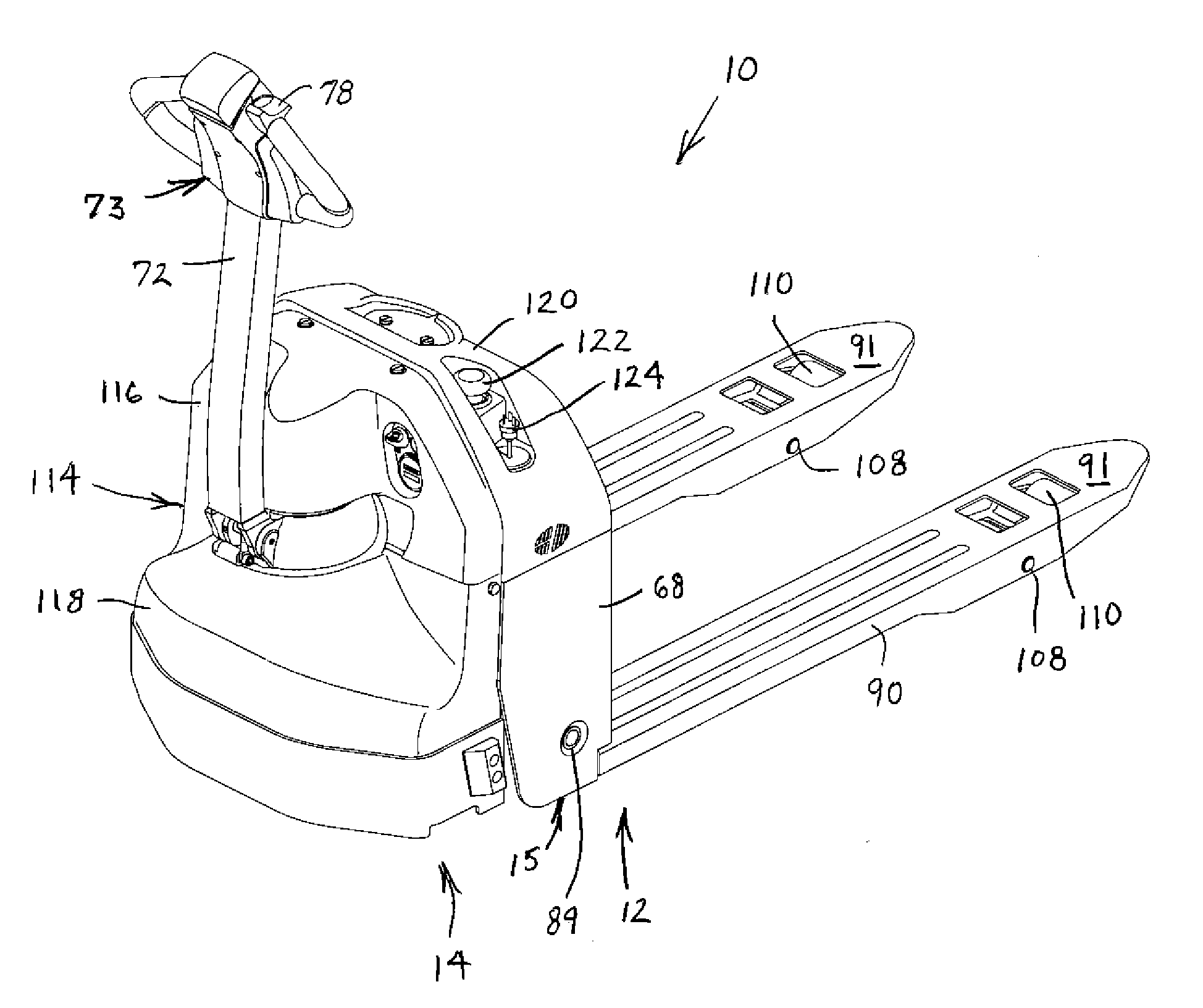

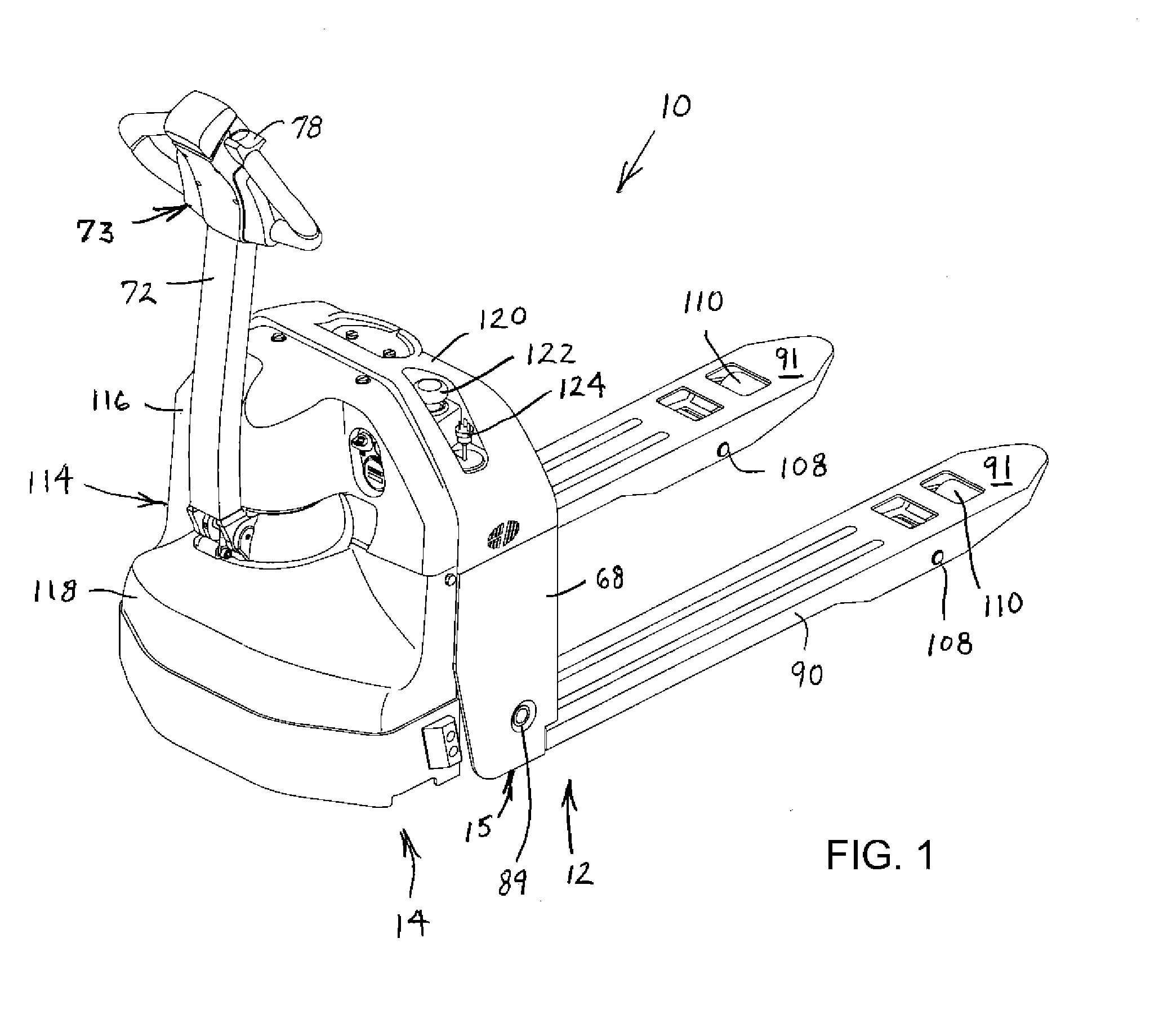

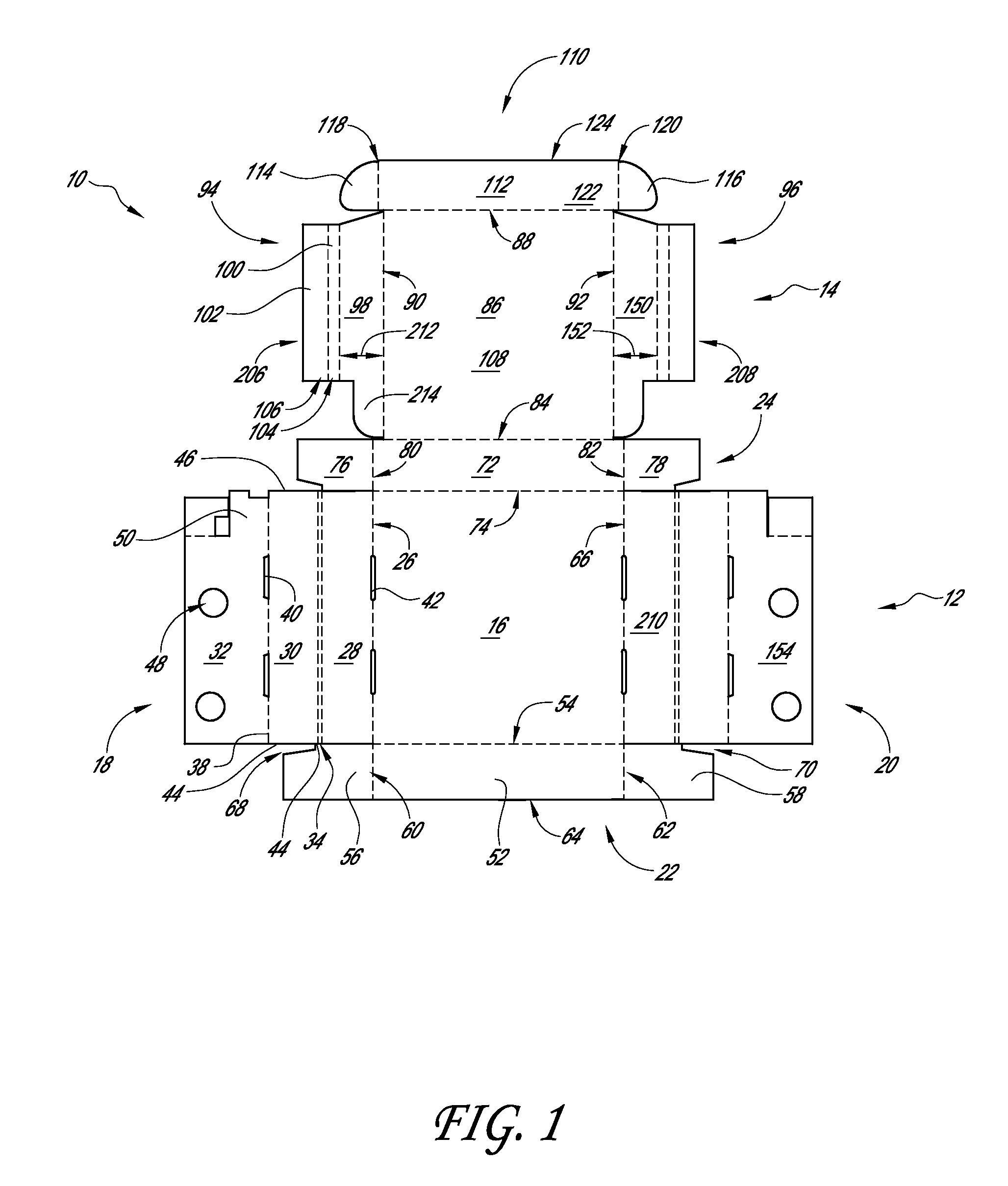

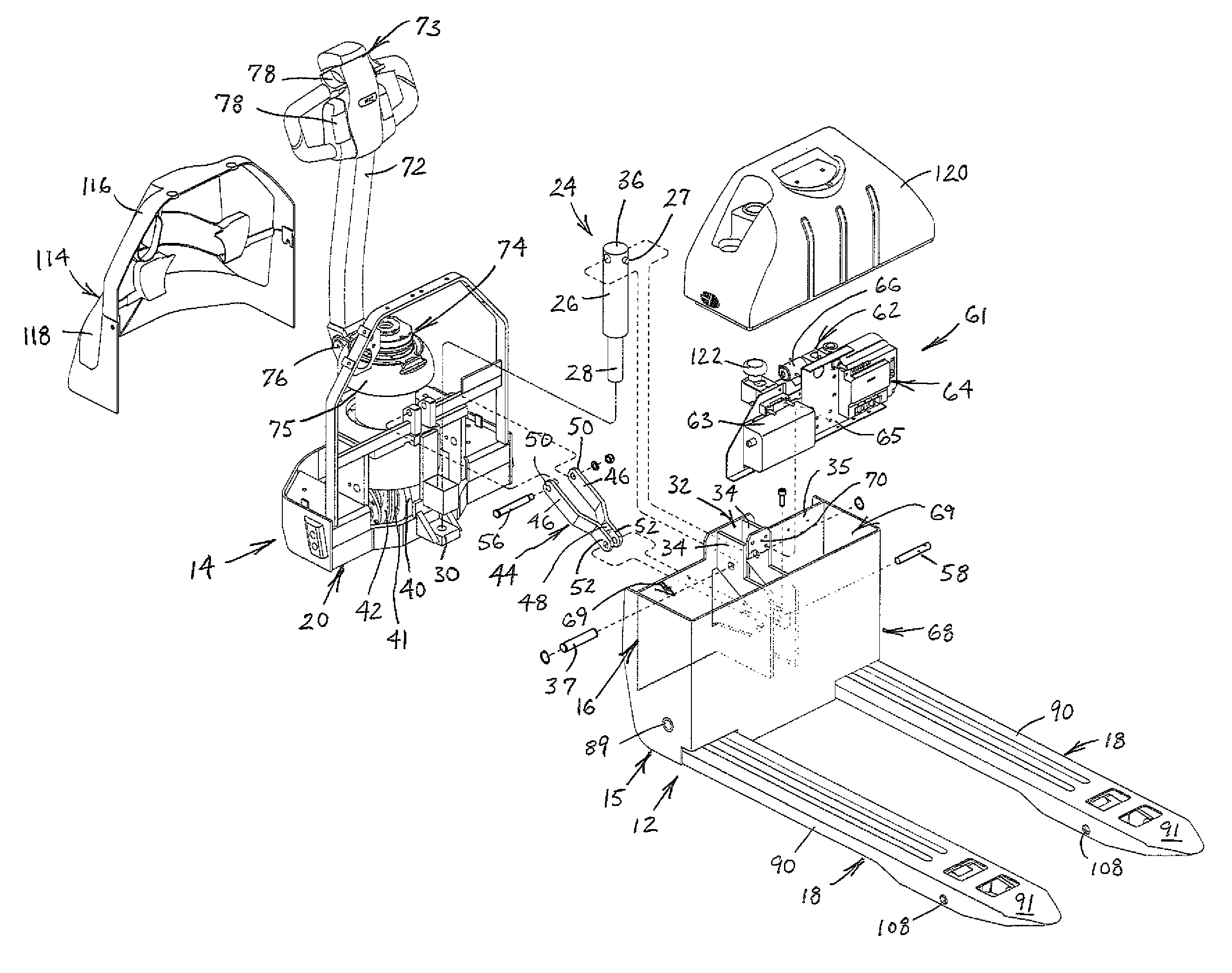

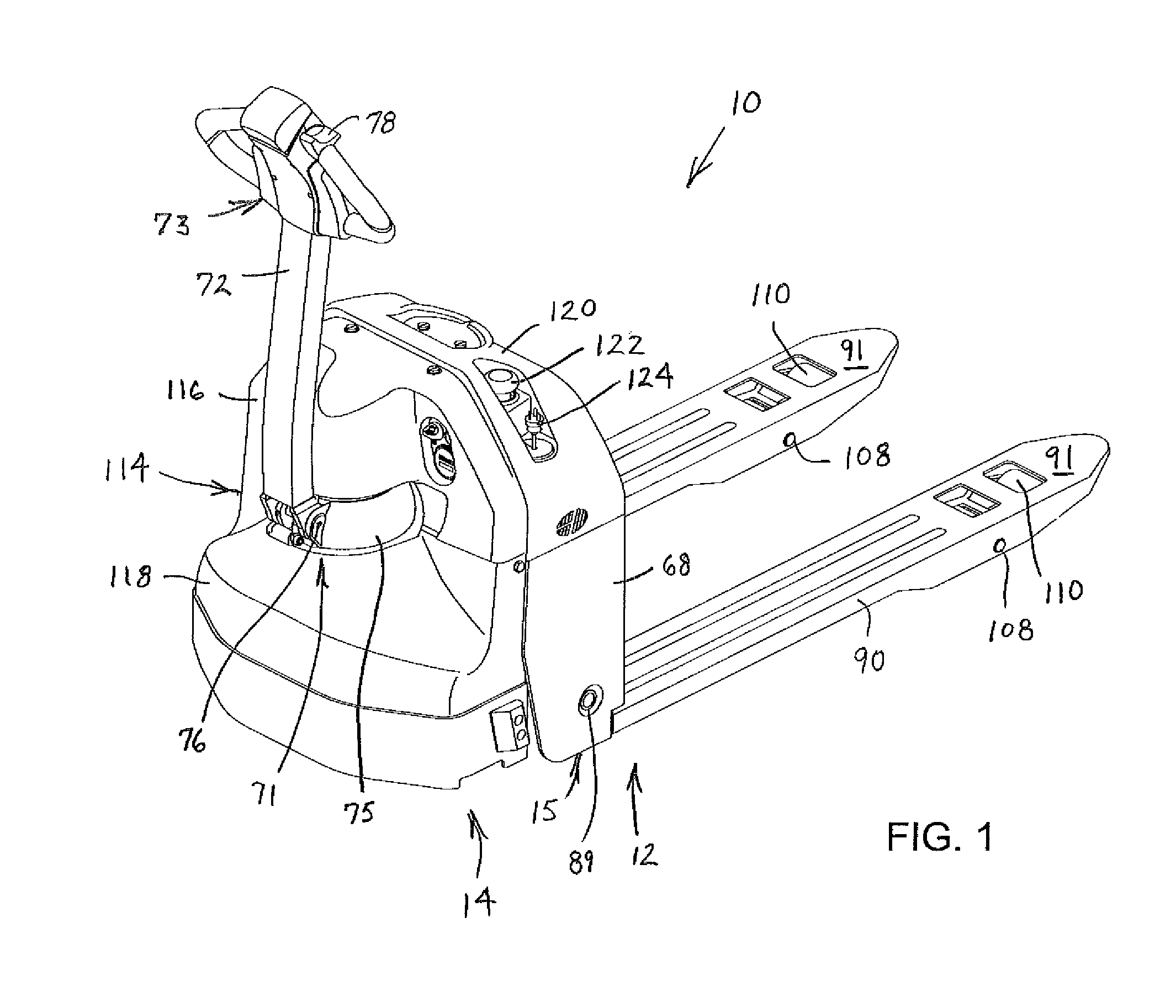

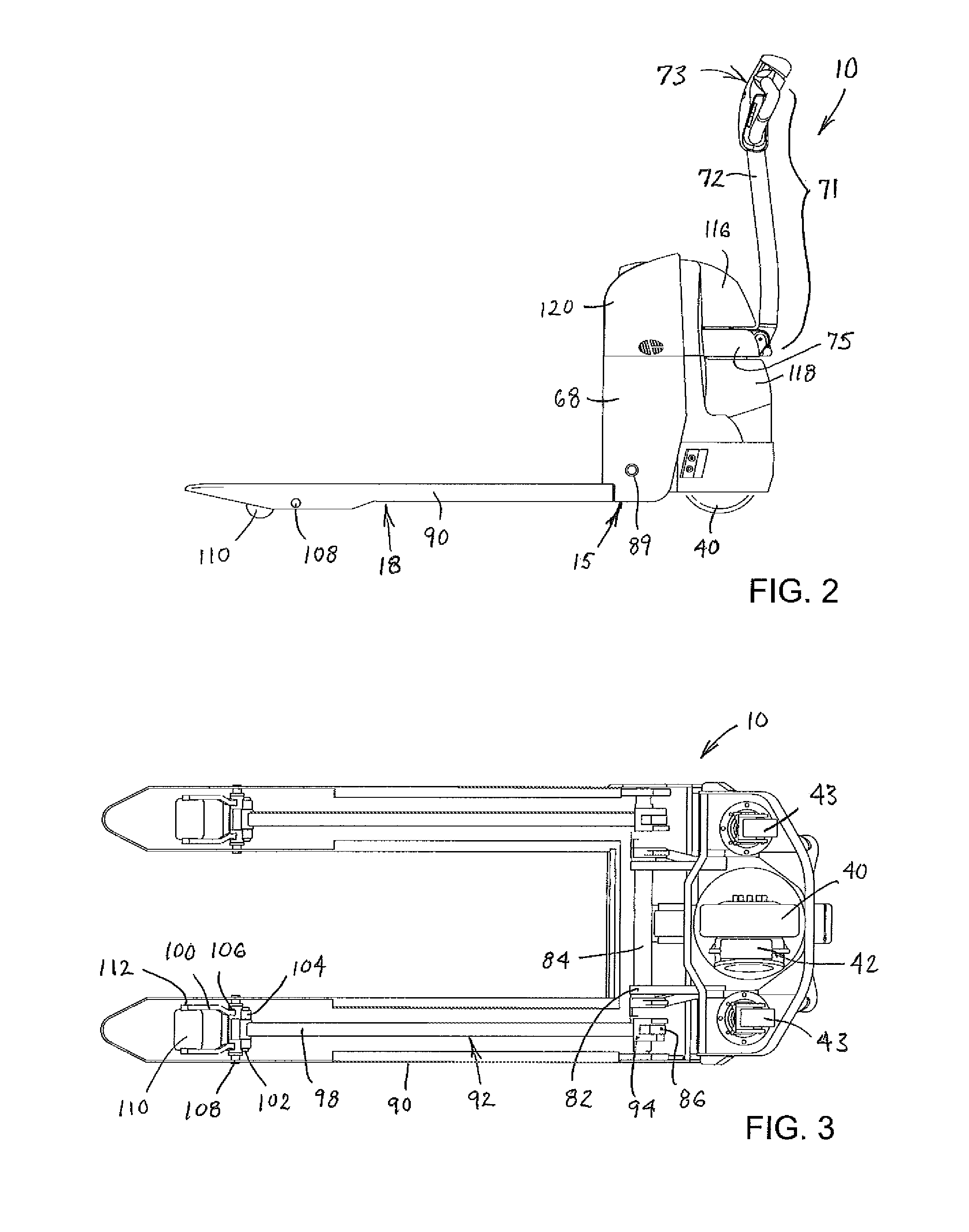

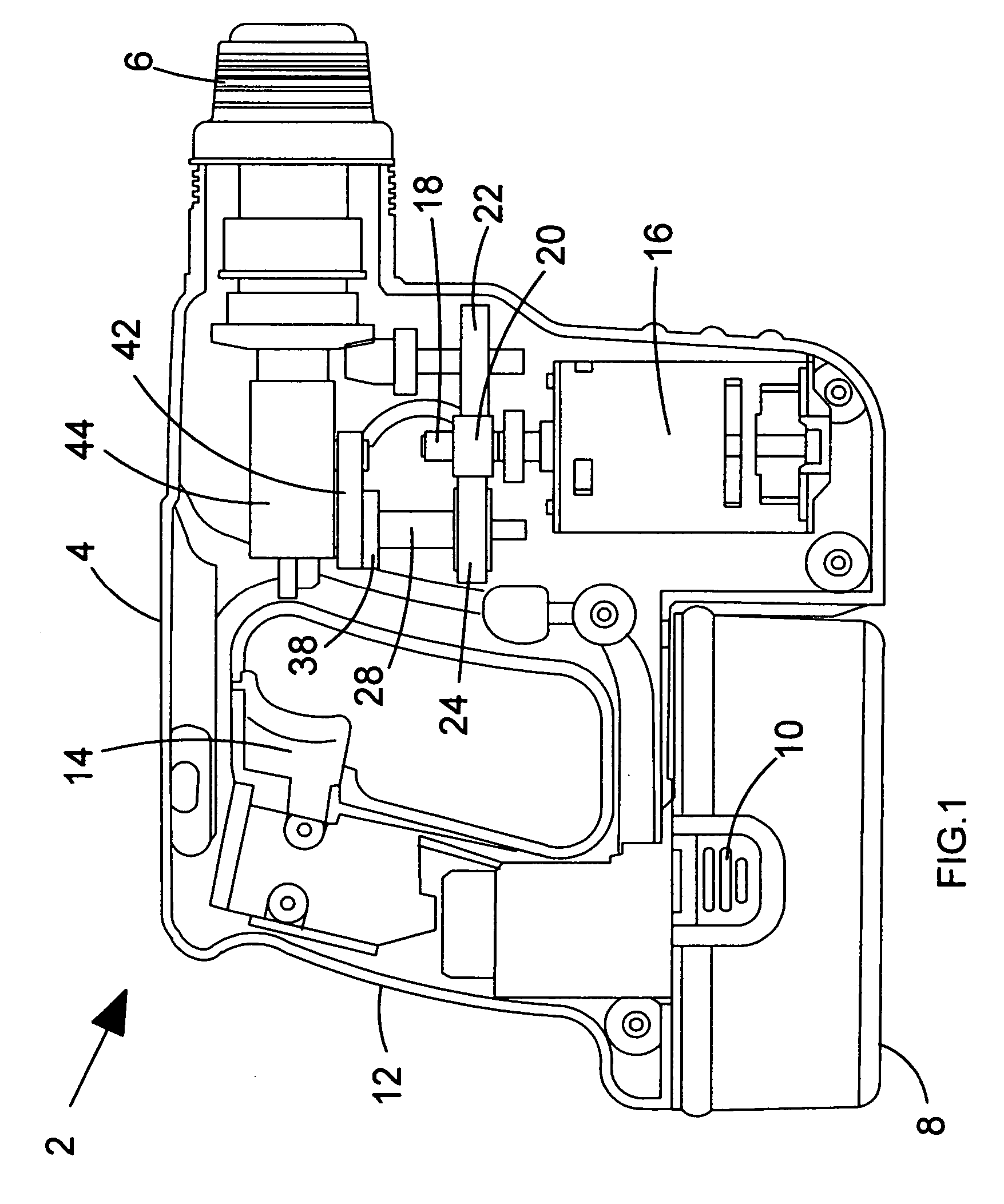

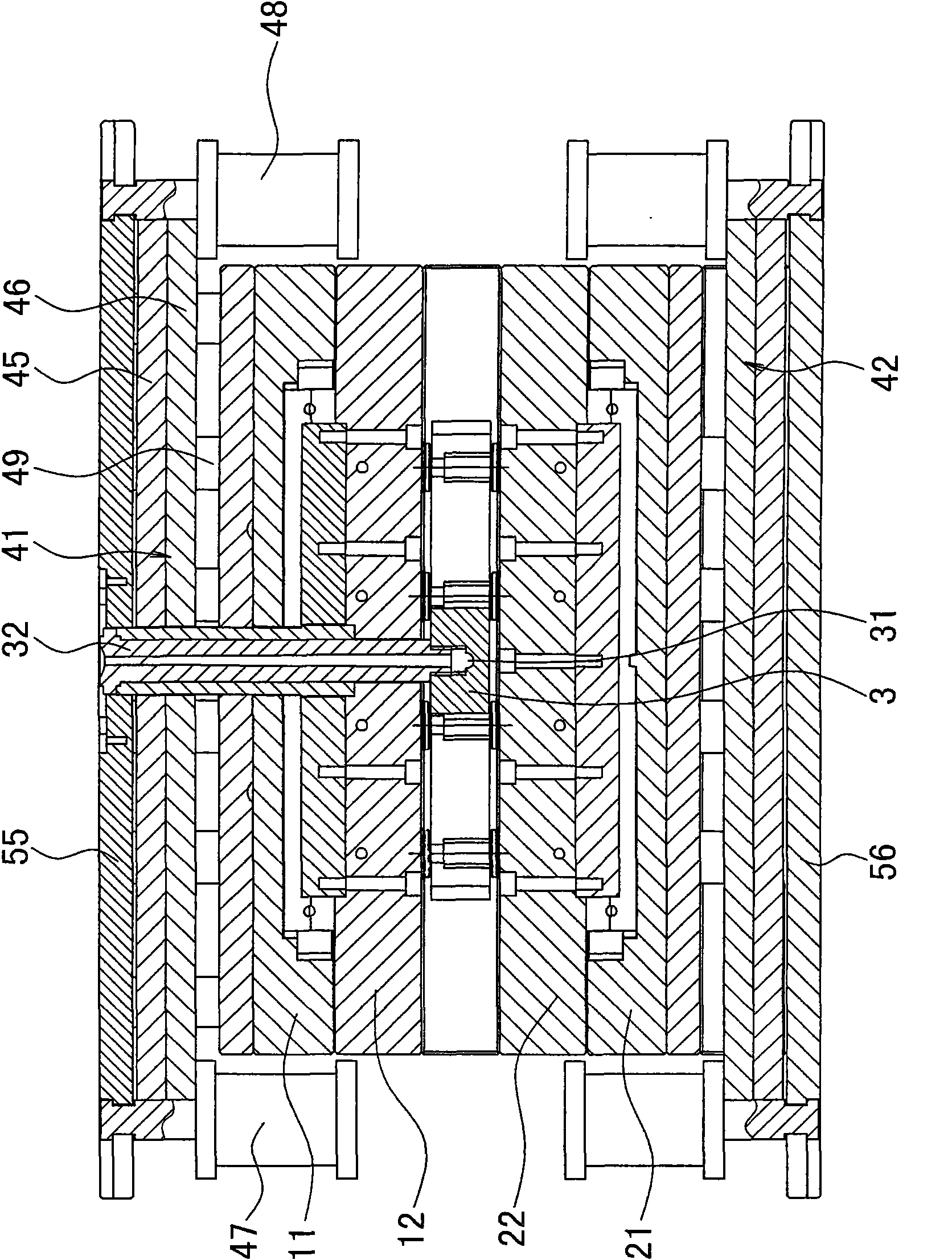

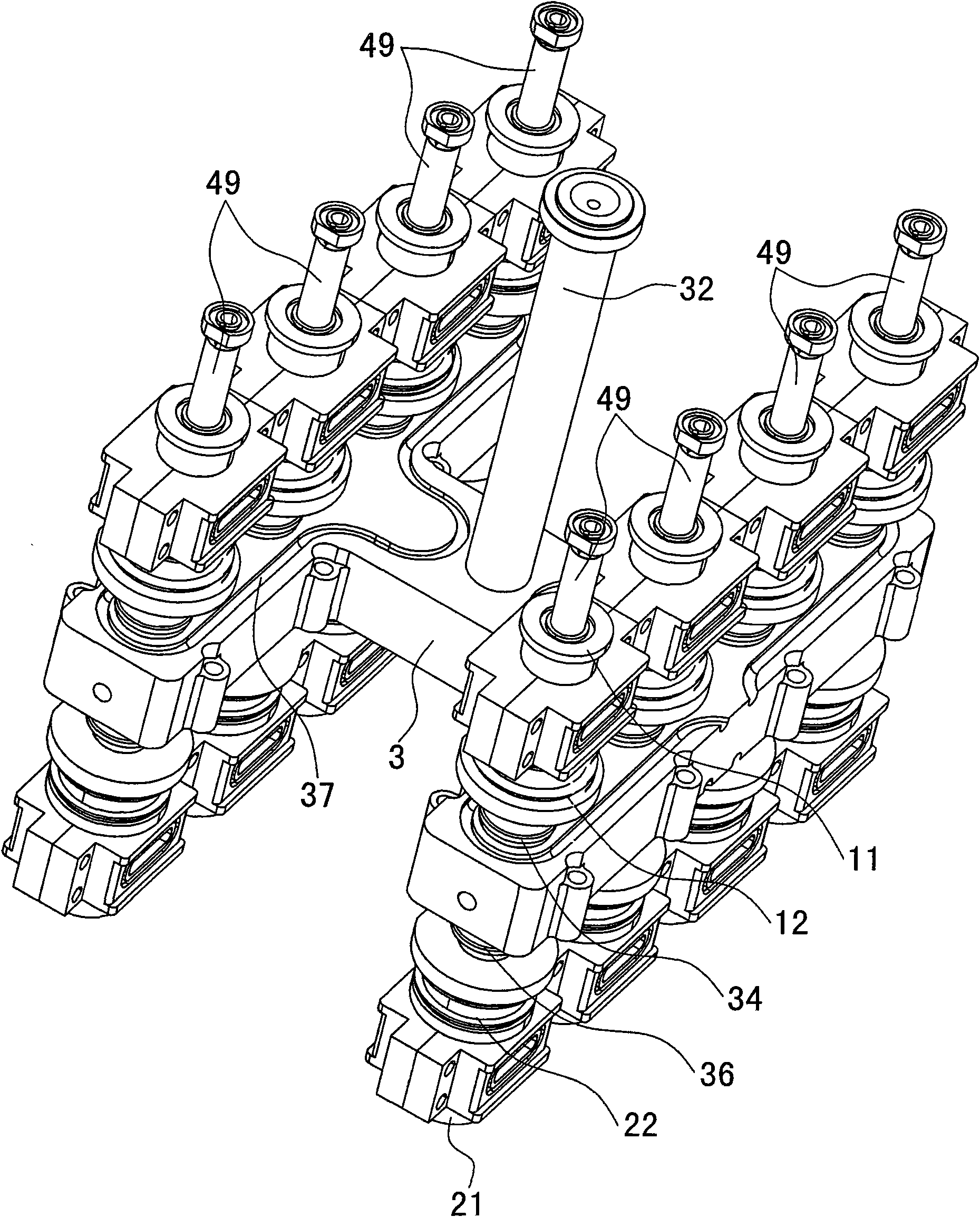

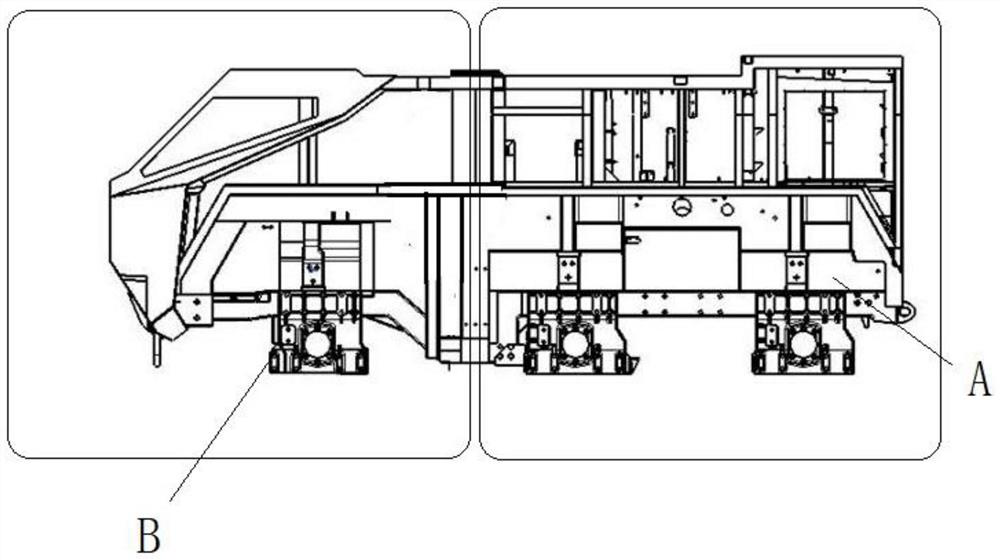

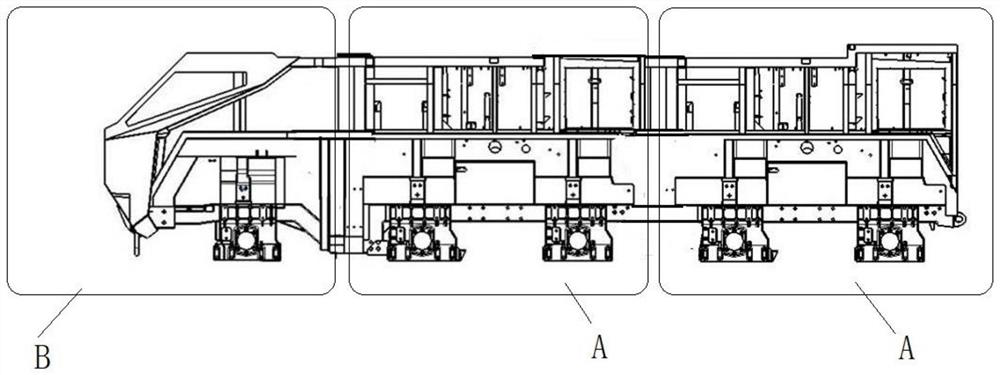

Powered pallet truck

ActiveUS20150102274A1Shorten the lengthReduce widthVehicle with pivoted armsVehicle with removable loadingTruckPallet

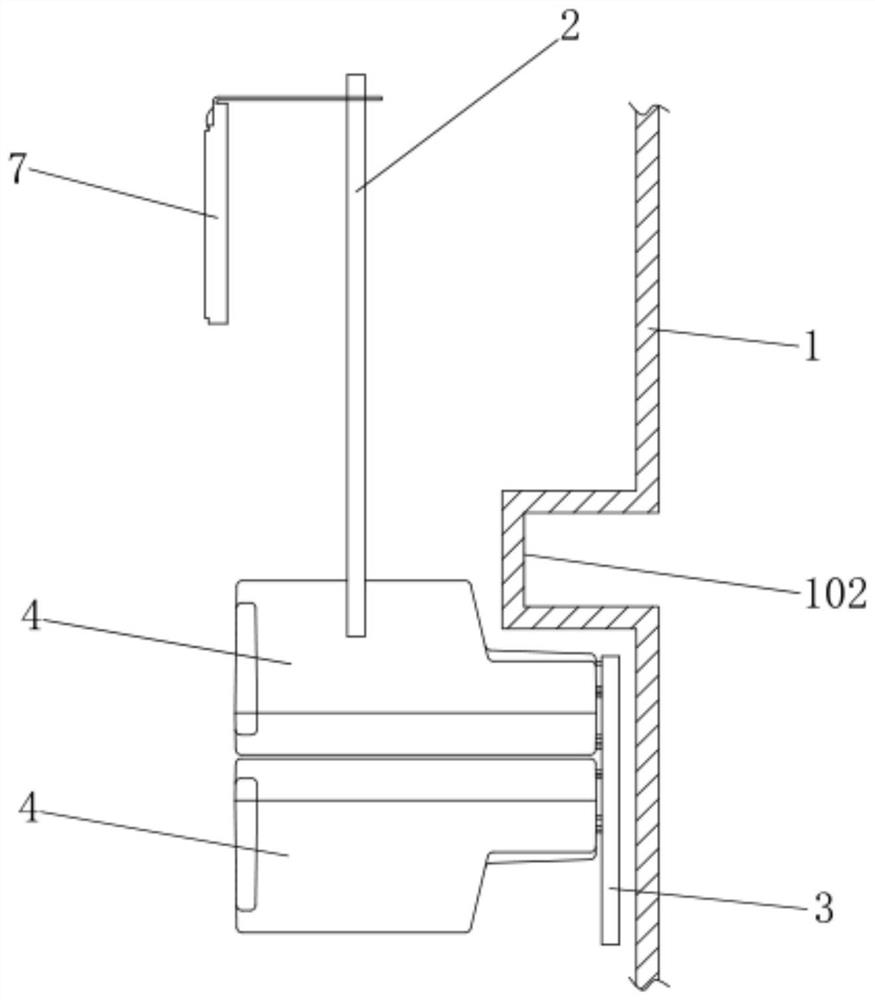

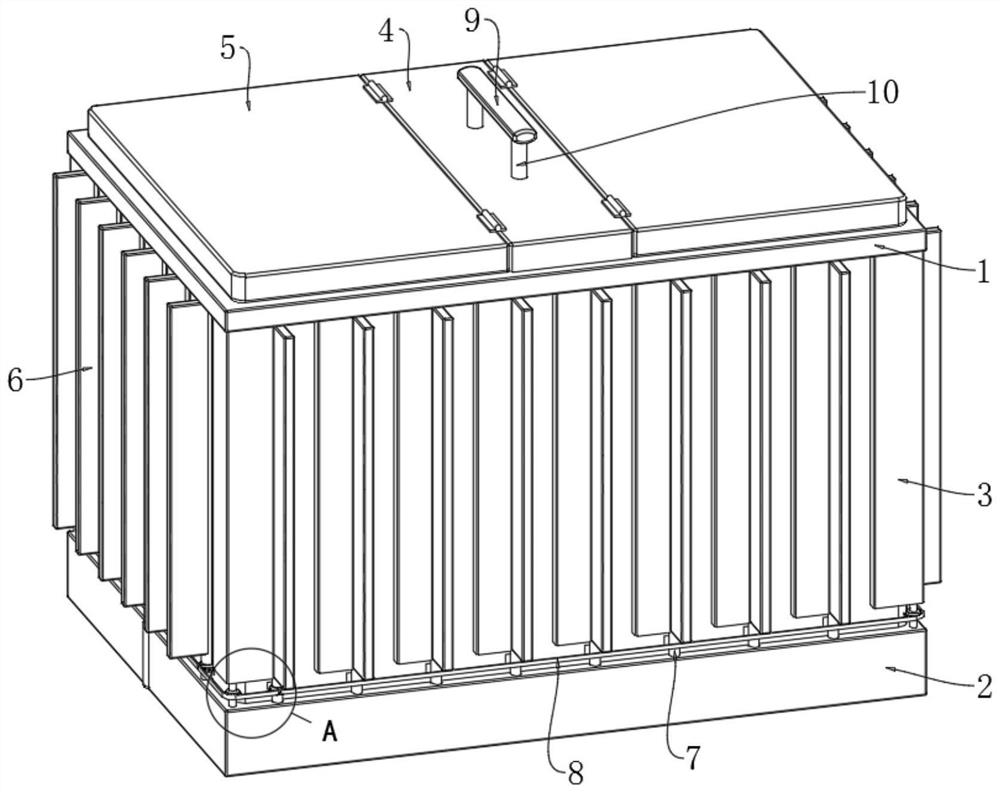

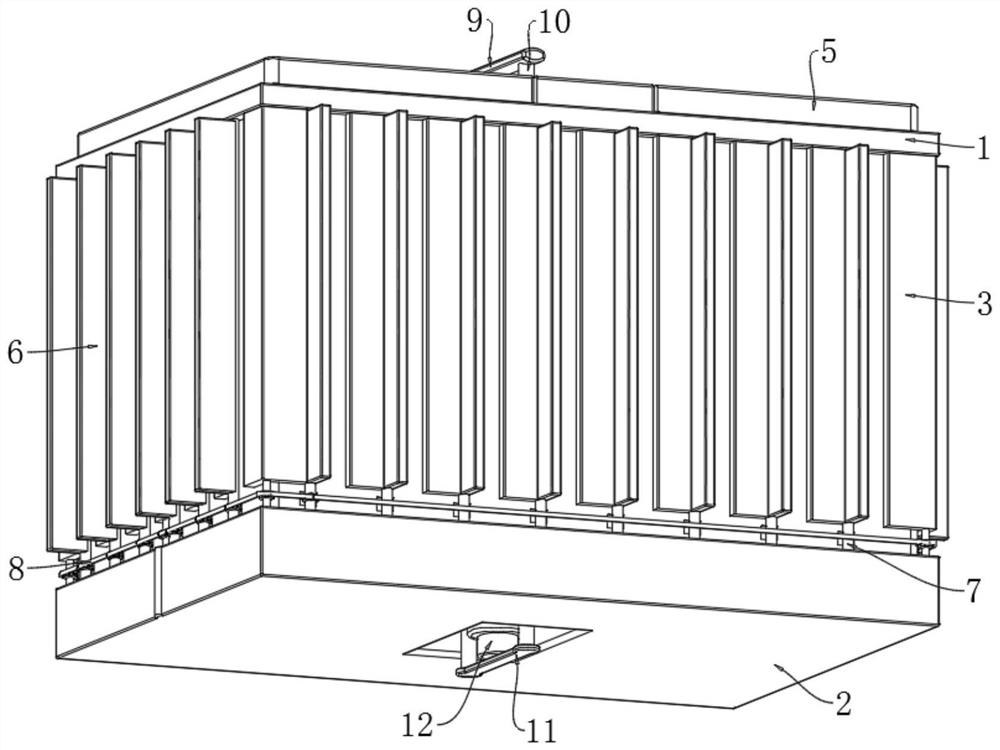

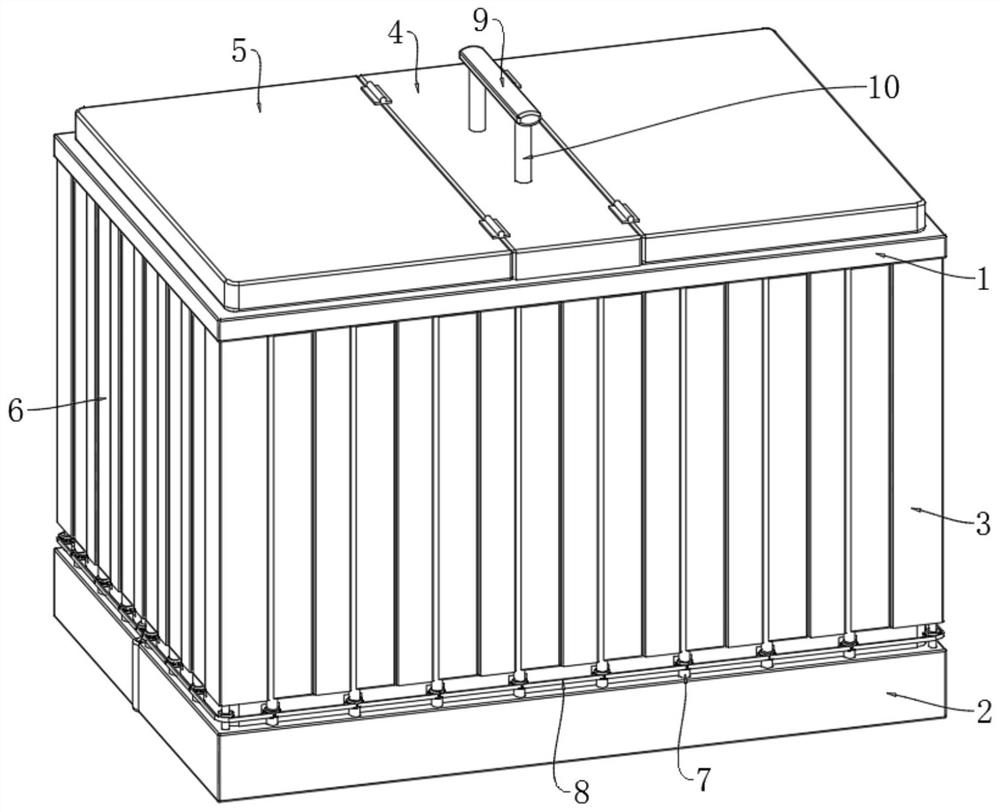

A powered pallet truck is provided having a base support portion and a load lift portion. The powered pallet truck has a lift cylinder device connected at a lower portion to a forward extending lift cylinder device seat on the base frame and pivotally connected at an upper portion within a recessed channel in the load lift frame.

Owner:BIG ELEVATOR

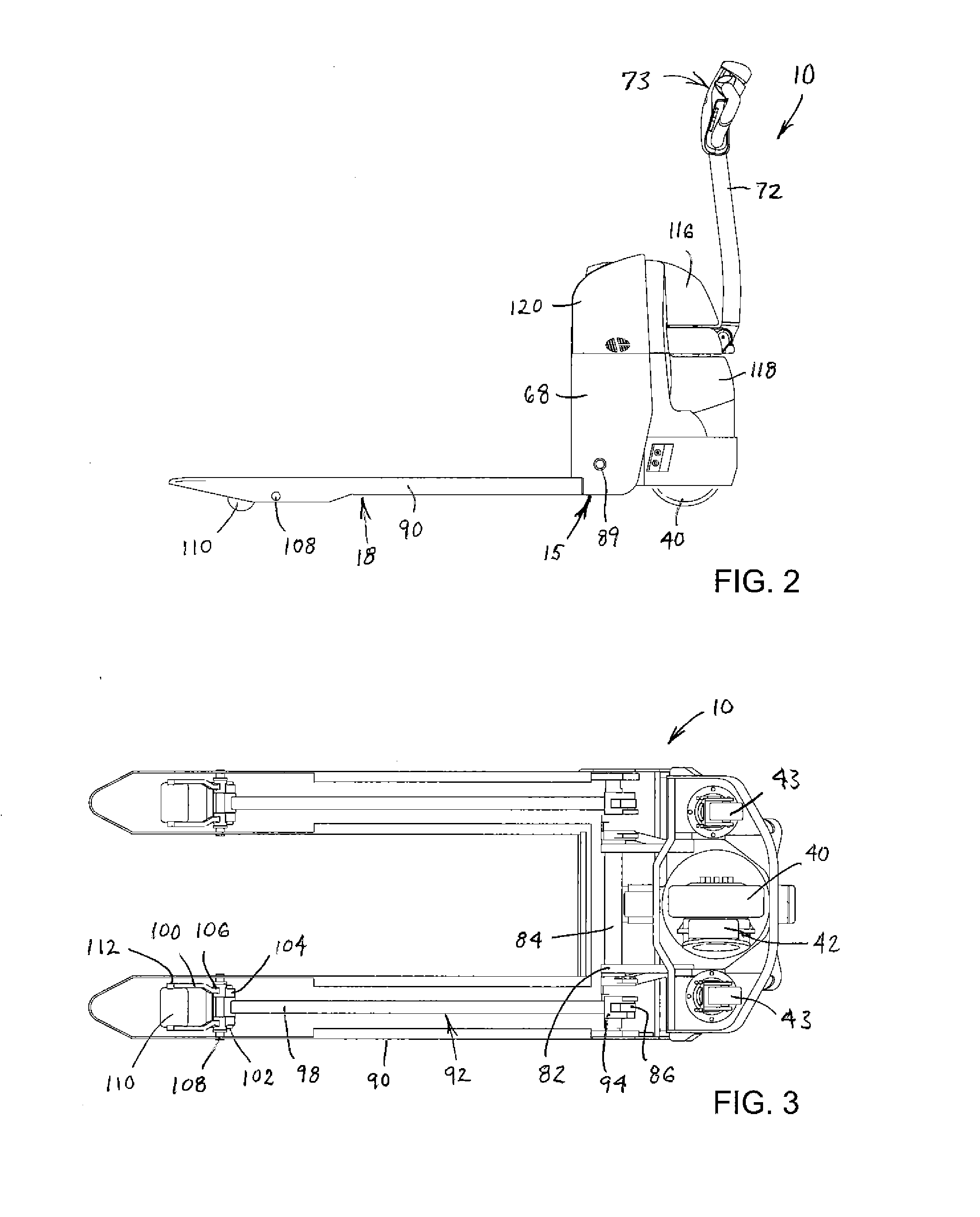

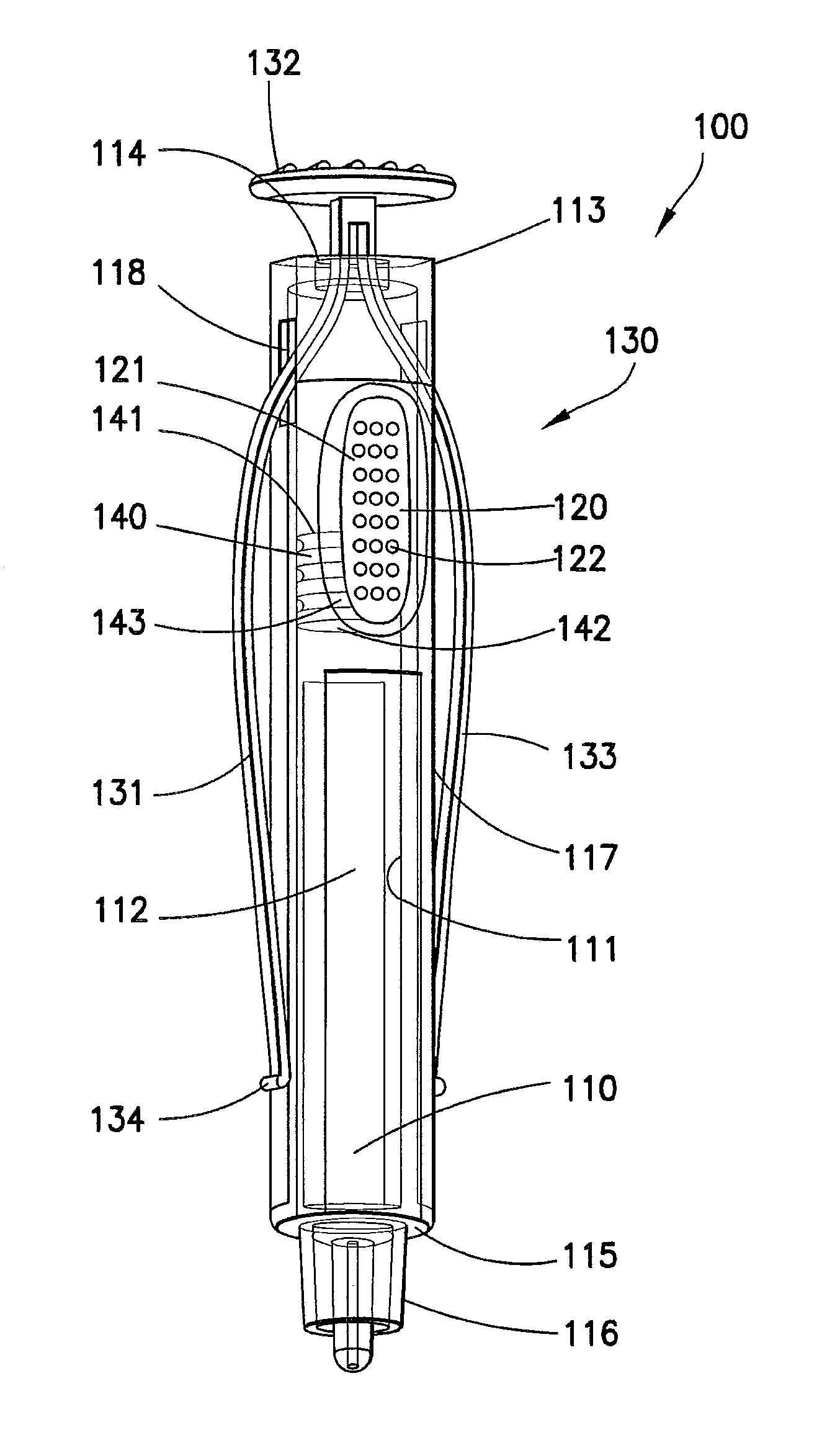

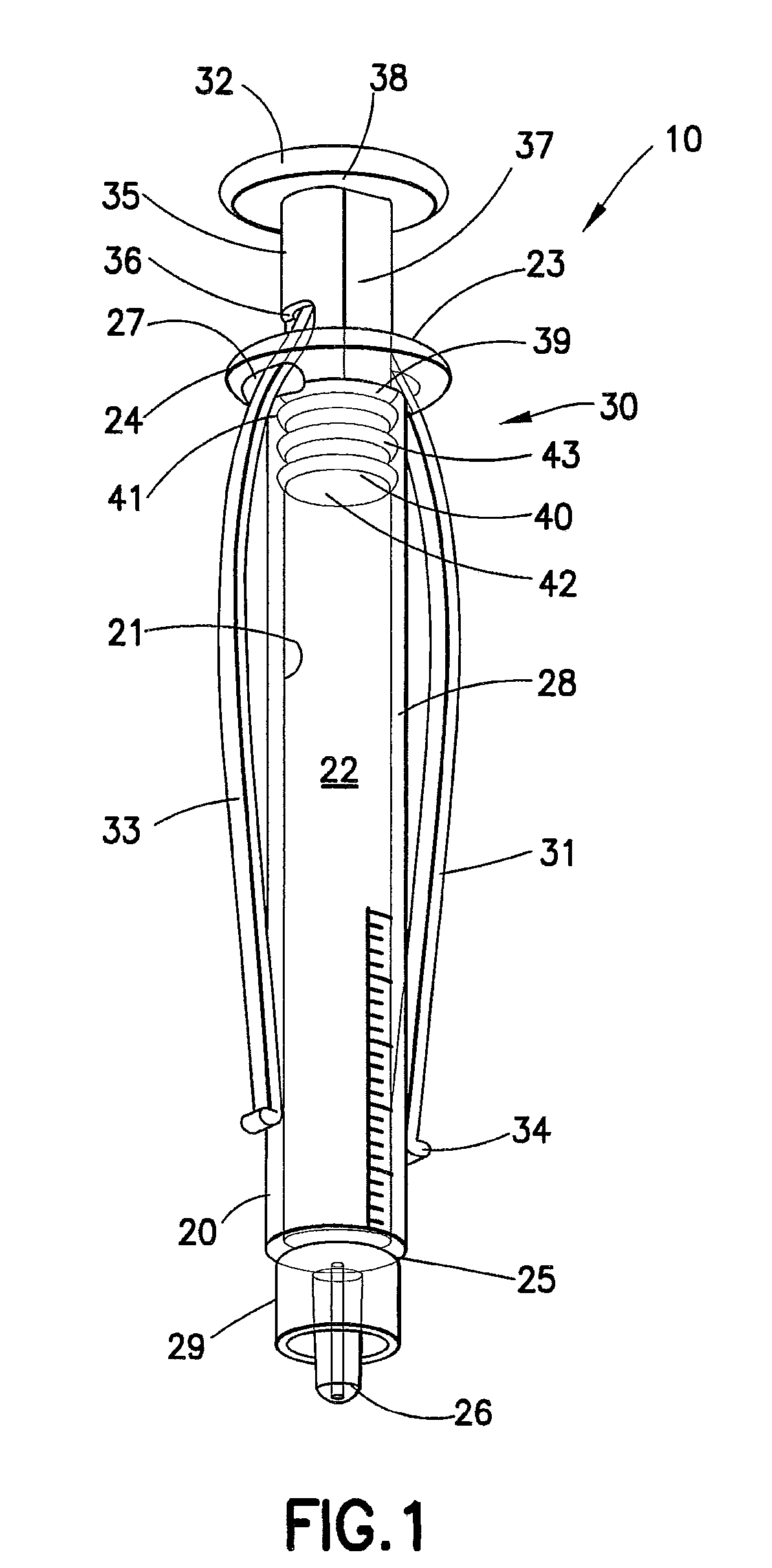

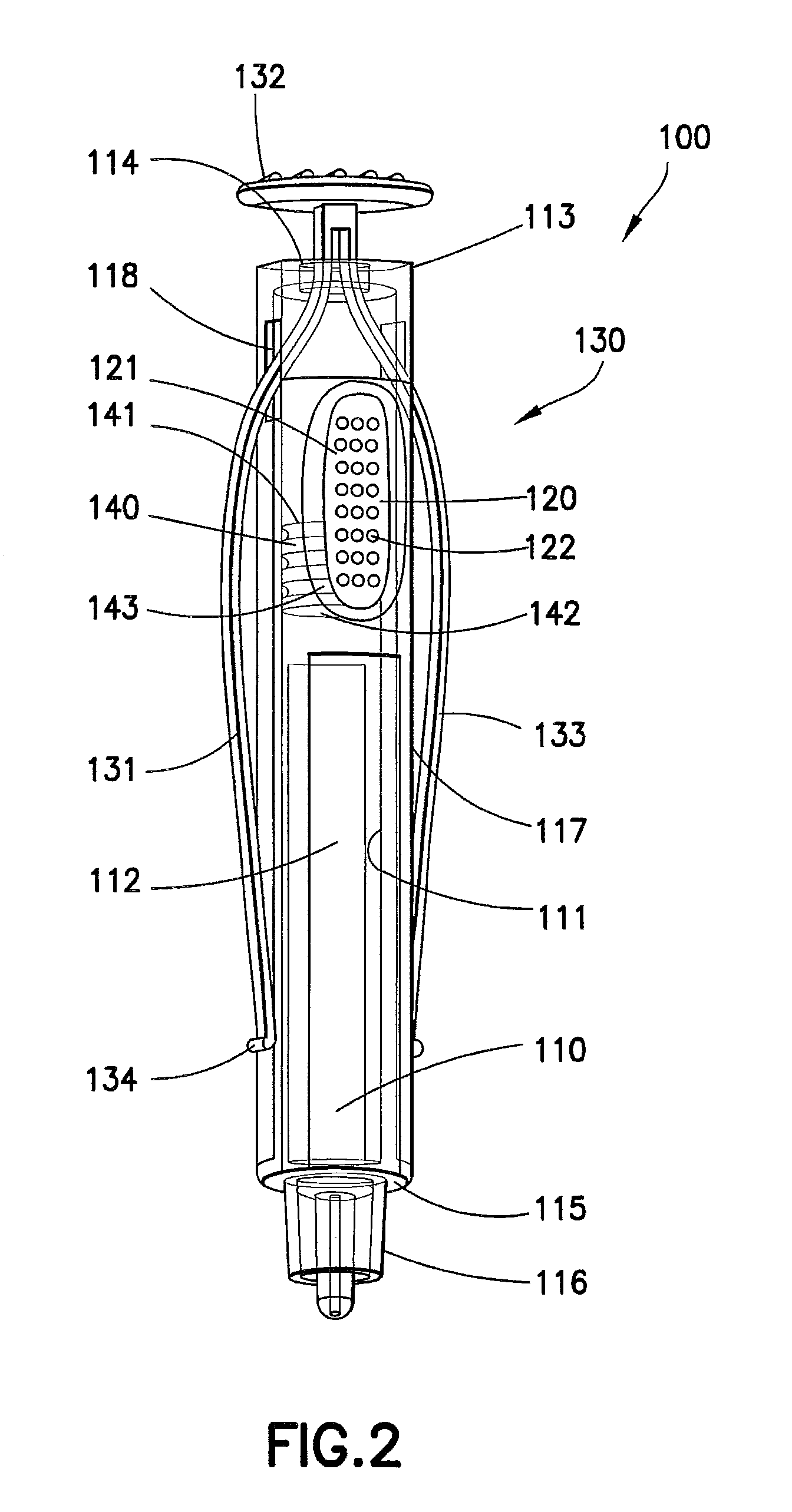

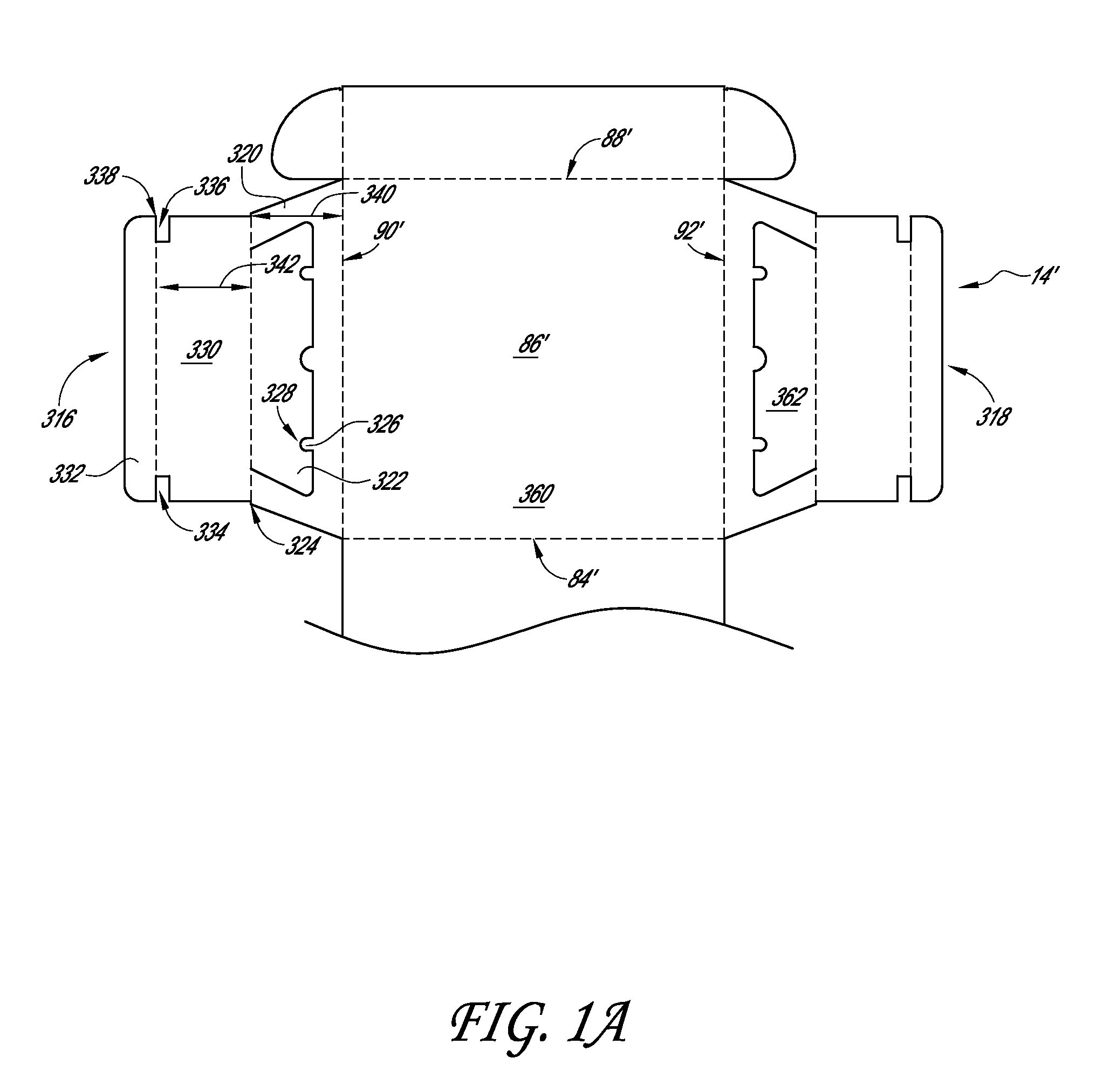

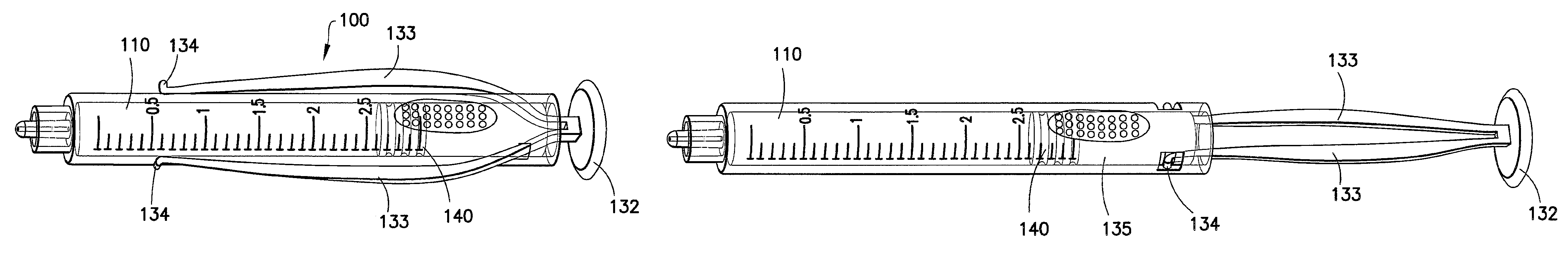

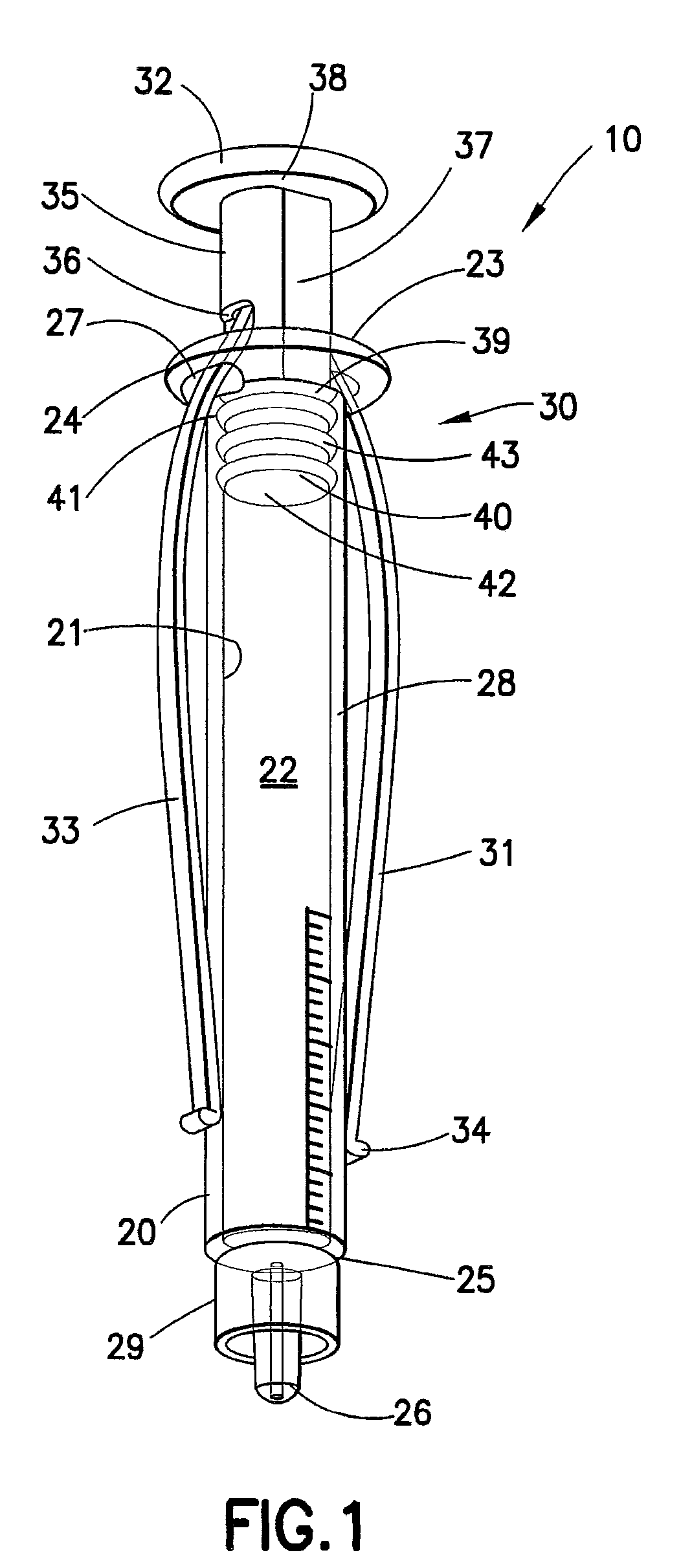

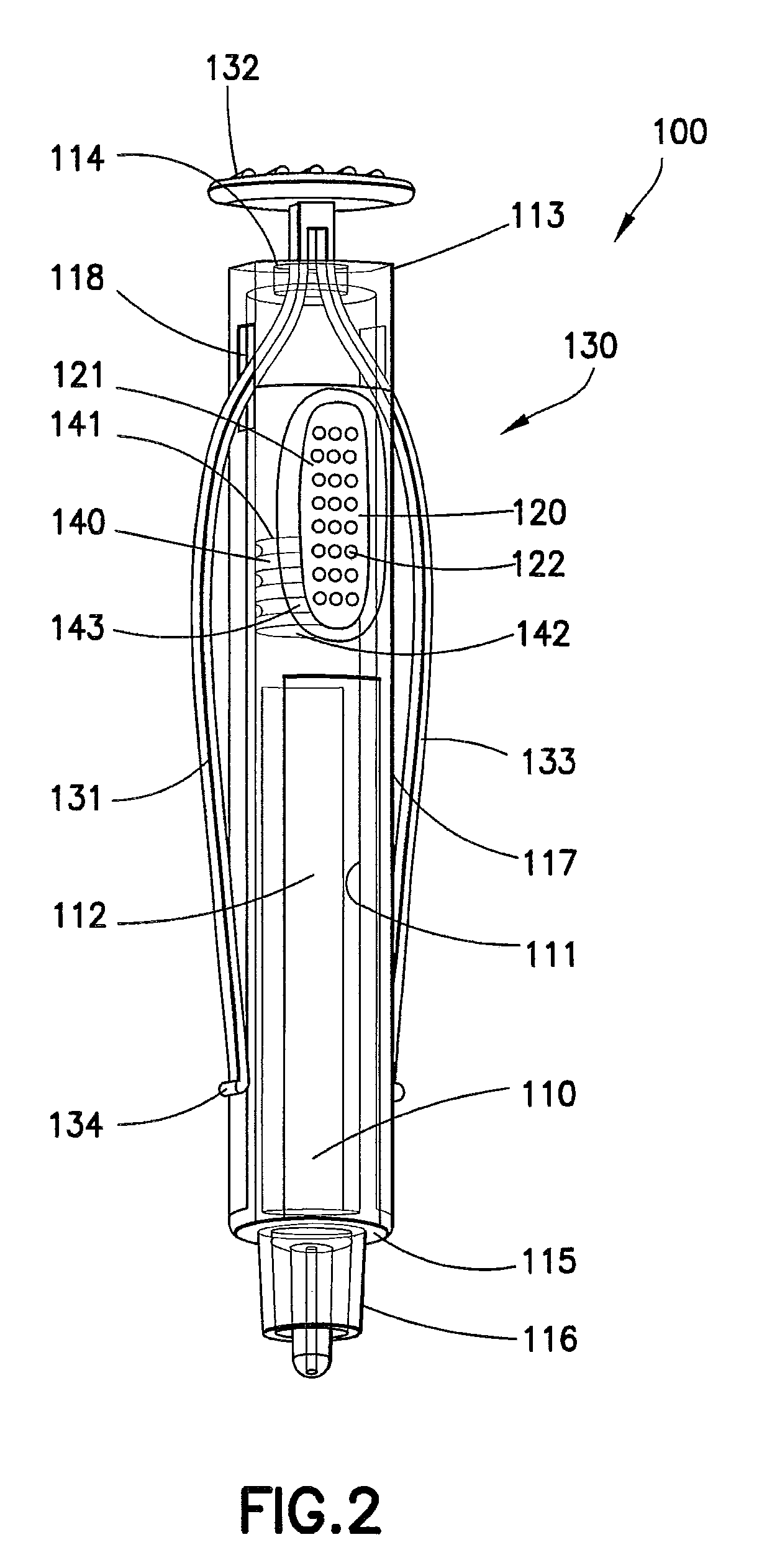

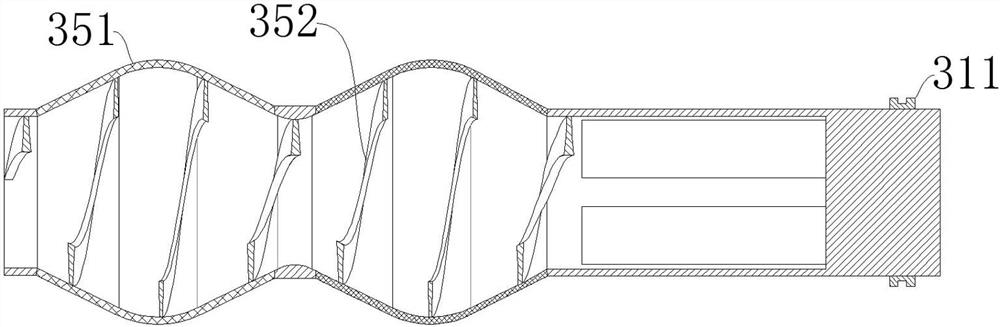

Syringe Having a Collapsible Plunger Rod

ActiveUS20110046569A1Shorten the lengthReduce widthAmpoule syringesMedical devicesEngineeringBiomedical engineering

A syringe assembly includes a syringe barrel having an exterior surface, an inside surface defining a chamber, an open proximal end, a distal end, and an outlet disposed adjacent the distal end in fluid communication with the chamber; and a plunger assembly disposed at least partially within the syringe barrel. The plunger assembly includes an elongated plunger rod and a plunger head. The elongated plunger rod is associated with the plunger head to move the plunger head within the chamber of the syringe barrel through an injection cycle. The plunger rod is adapted to move from a collapsed position extending alongside the exterior surface of the syringe barrel to an extended position engaging the plunger head to move the plunger head through the injection cycle.

Owner:BECTON DICKINSON FRANCE

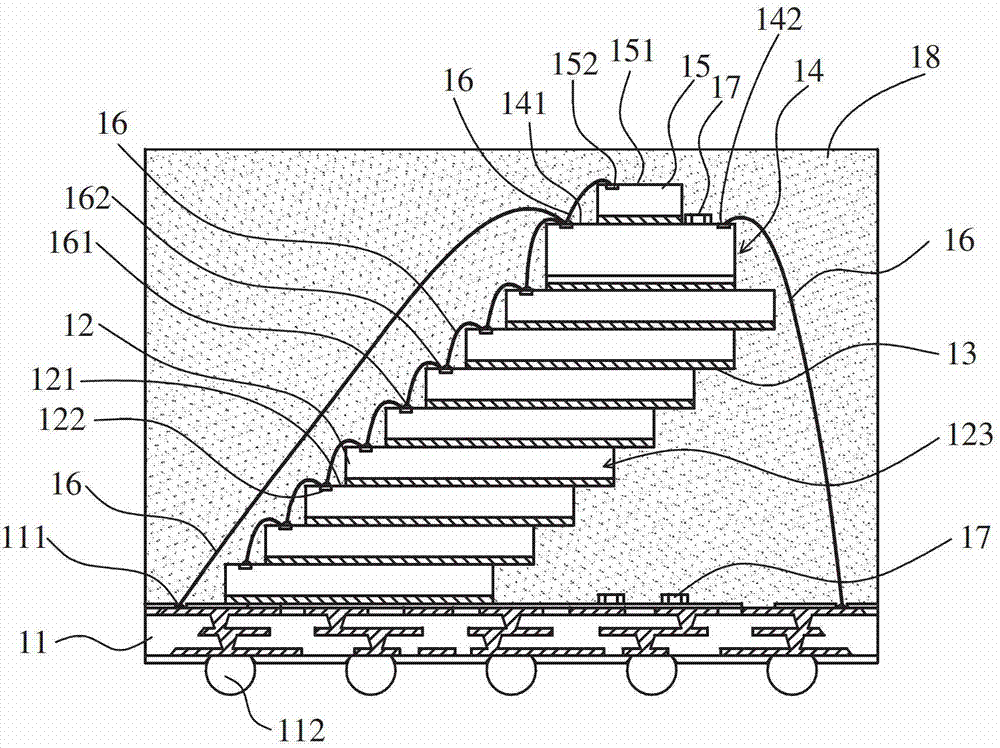

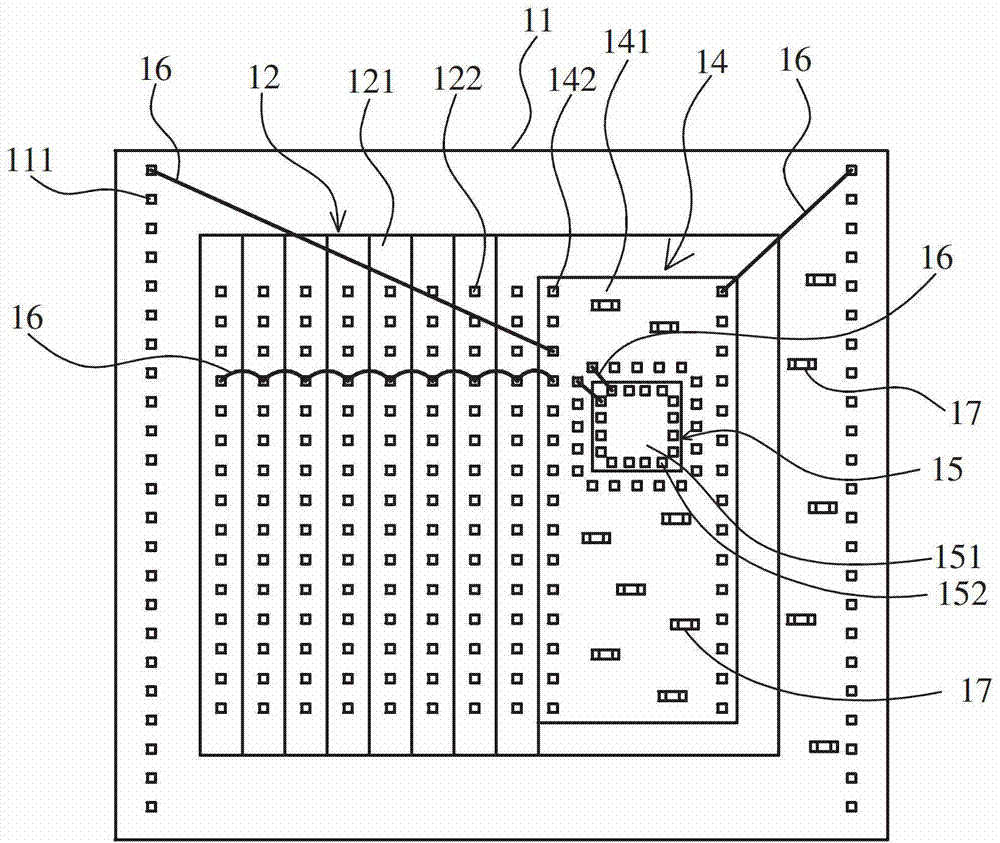

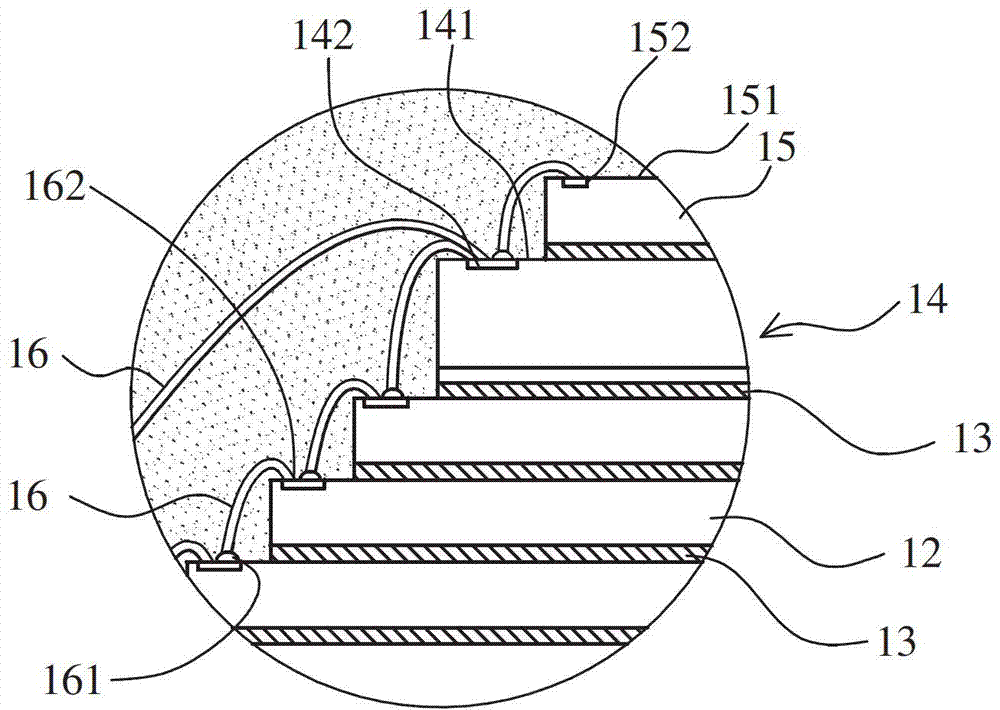

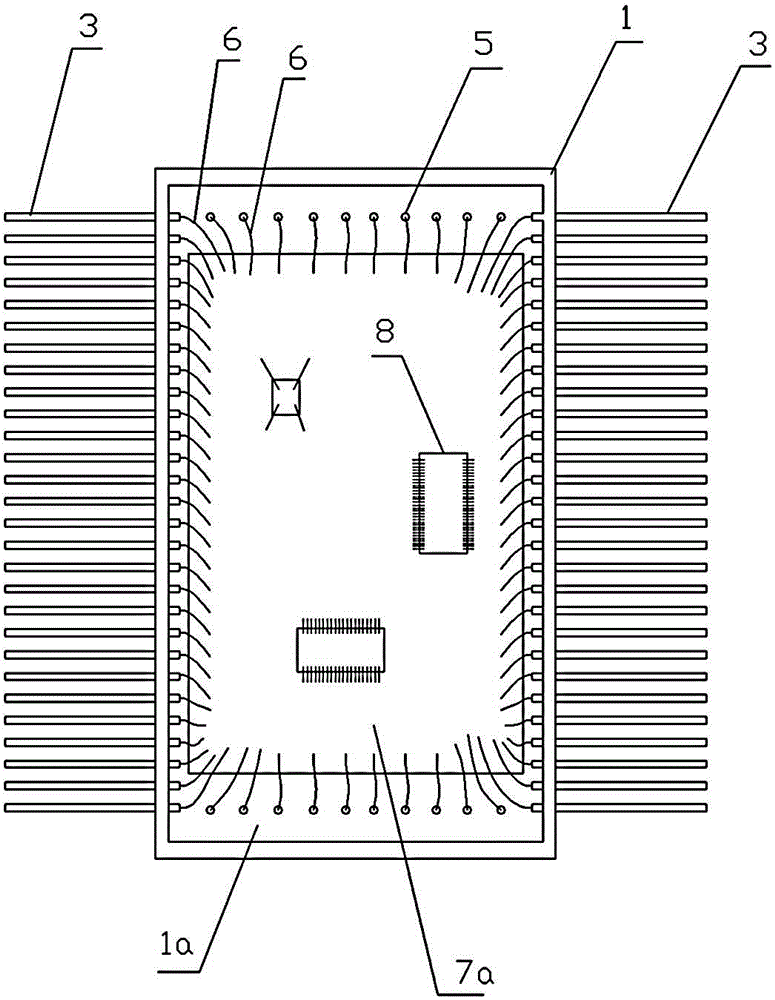

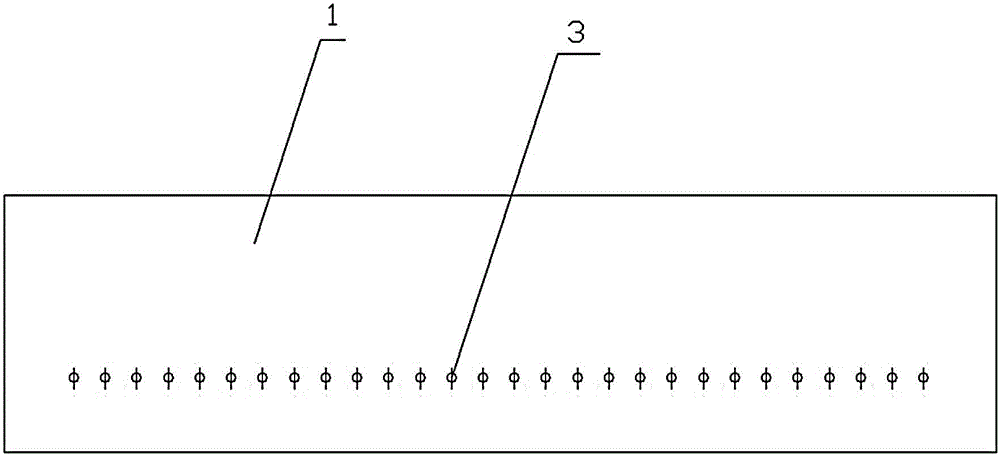

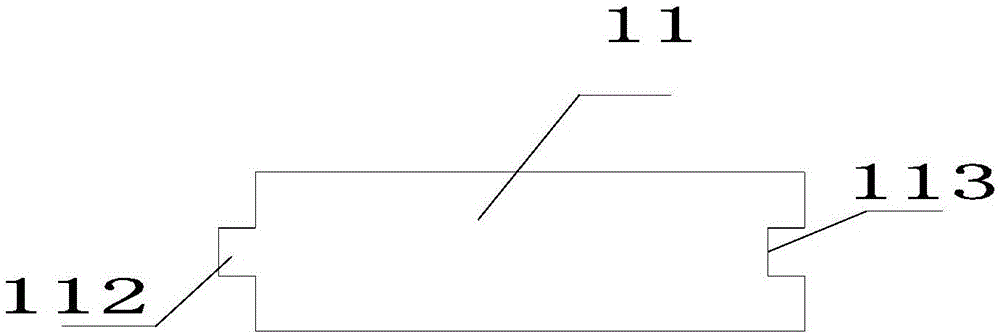

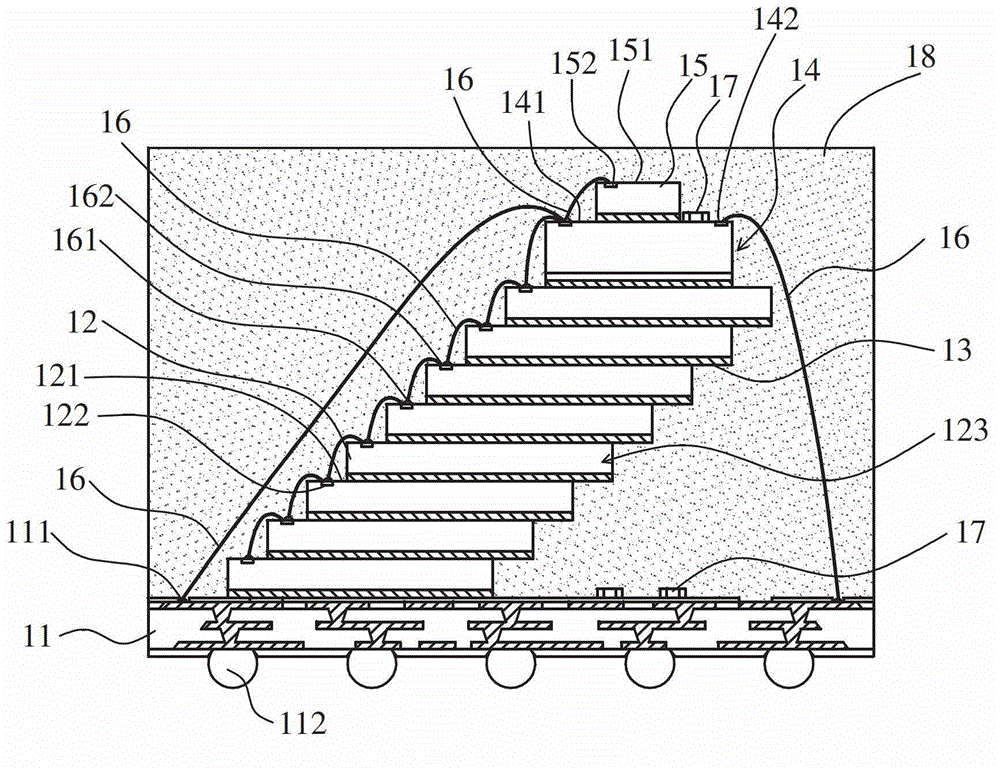

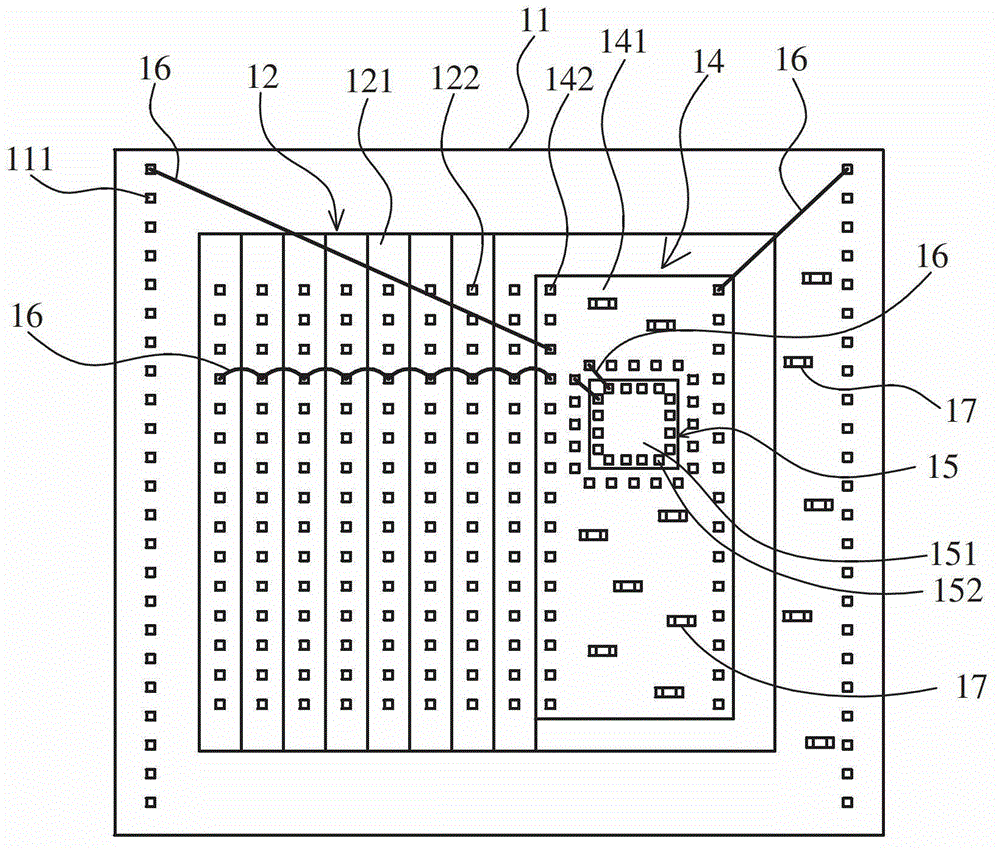

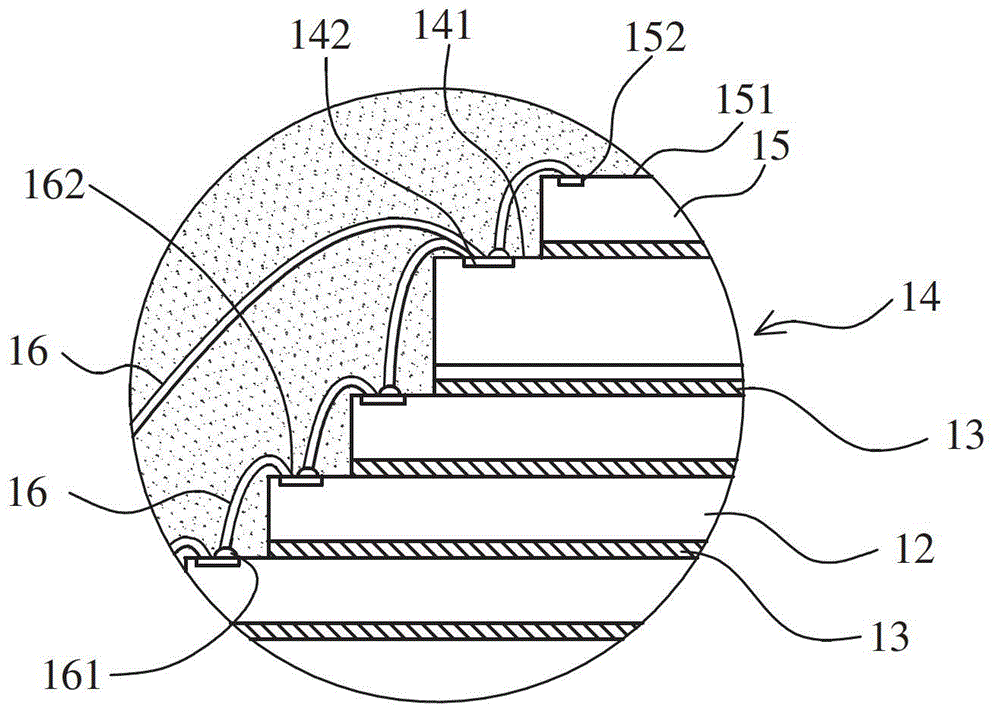

Semiconductor chip stacking structure

ActiveCN102790042ASolution volumeImprove stacking densitySemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor chip

The invention discloses a semiconductor chip stacking structure. A plurality of first chips are stacked, the first chips are arrayed in a stepped stacking manner, a dielectric board is arranged on the first chip on the uppermost layer, a second chip is further arranged on the dielectric board, the first chips are upwards and electrically connected with the dielectric board firstly, and then the dielectric board is electrically connected to a bottom substrate. Therefore, the dielectric board can collect the signals of all chips and transmit the signals to the bottom substrate through less electrical connecting components (such as conducting wires), the number of connecting pads needed by the substrate is relatively reduced, so that the length and width of the substrate can be reduced, and further, the stacking density of the chips is increased, and the packaging size is reduced.

Owner:ADVANCED SEMICON ENG INC

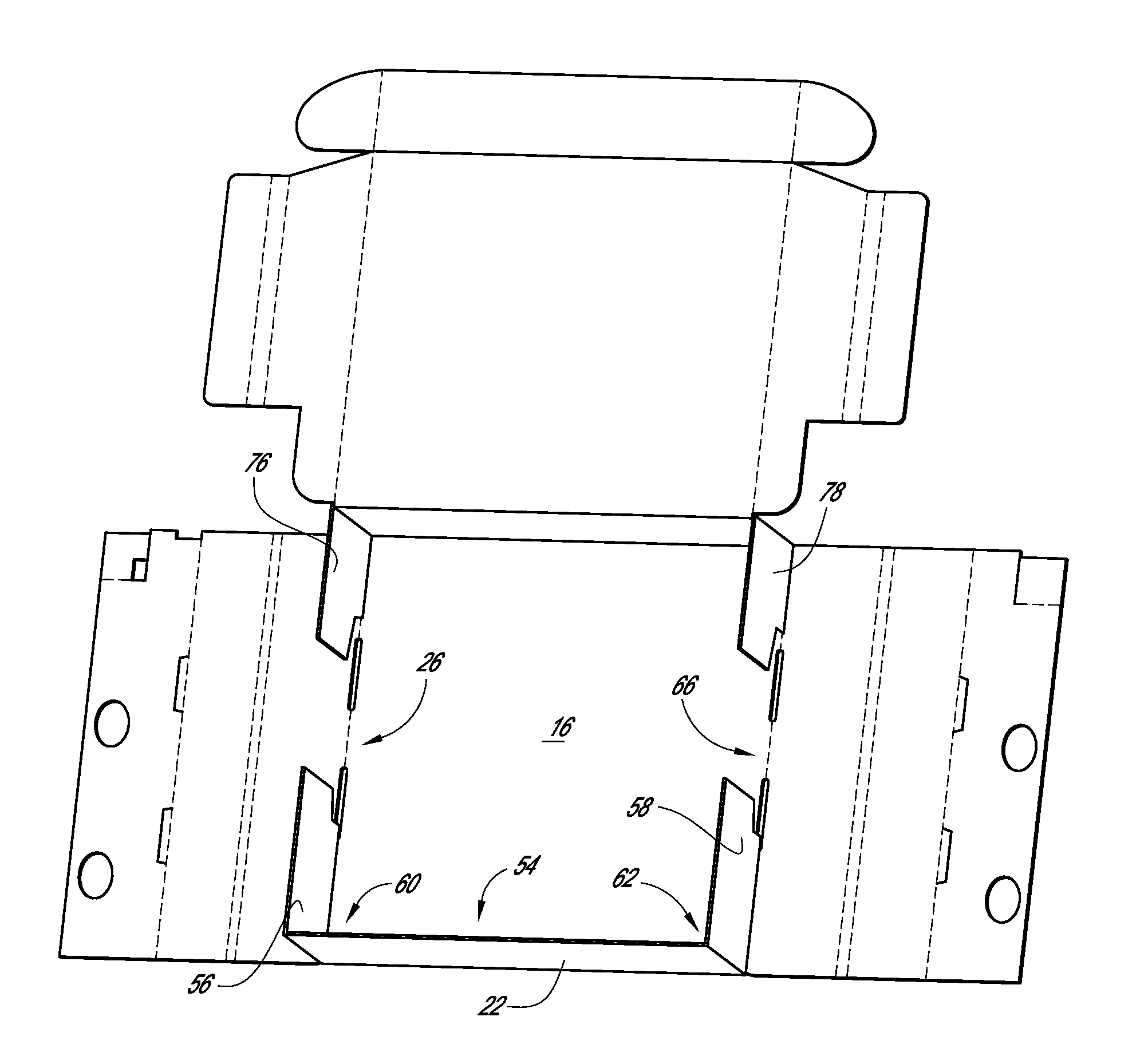

Packaging systems and kits

InactiveUS20130048533A1Shorten the lengthReduce widthContainers to prevent mechanical damageRigid containersLeaf springEngineering

Owner:CLEARPAK

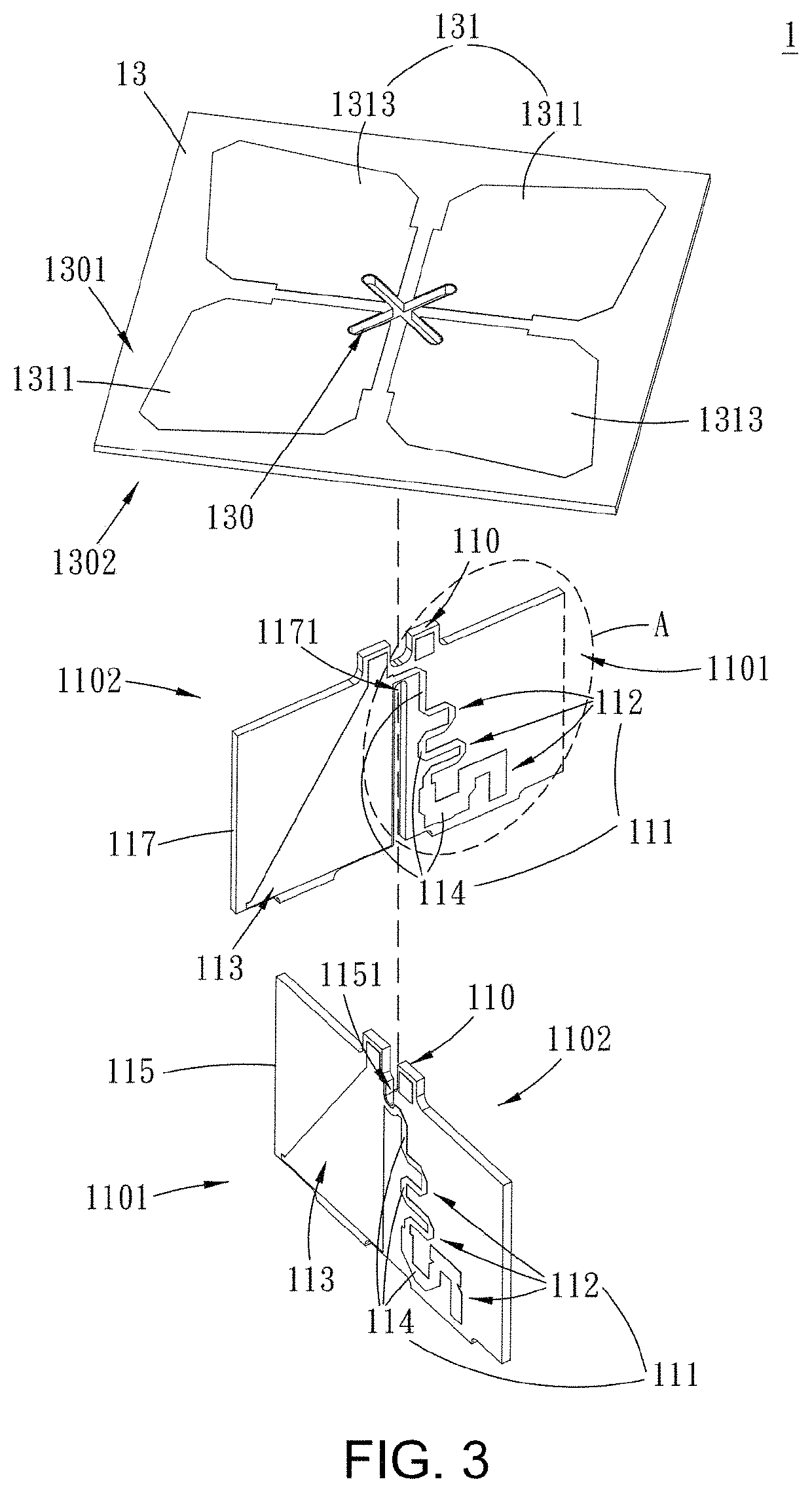

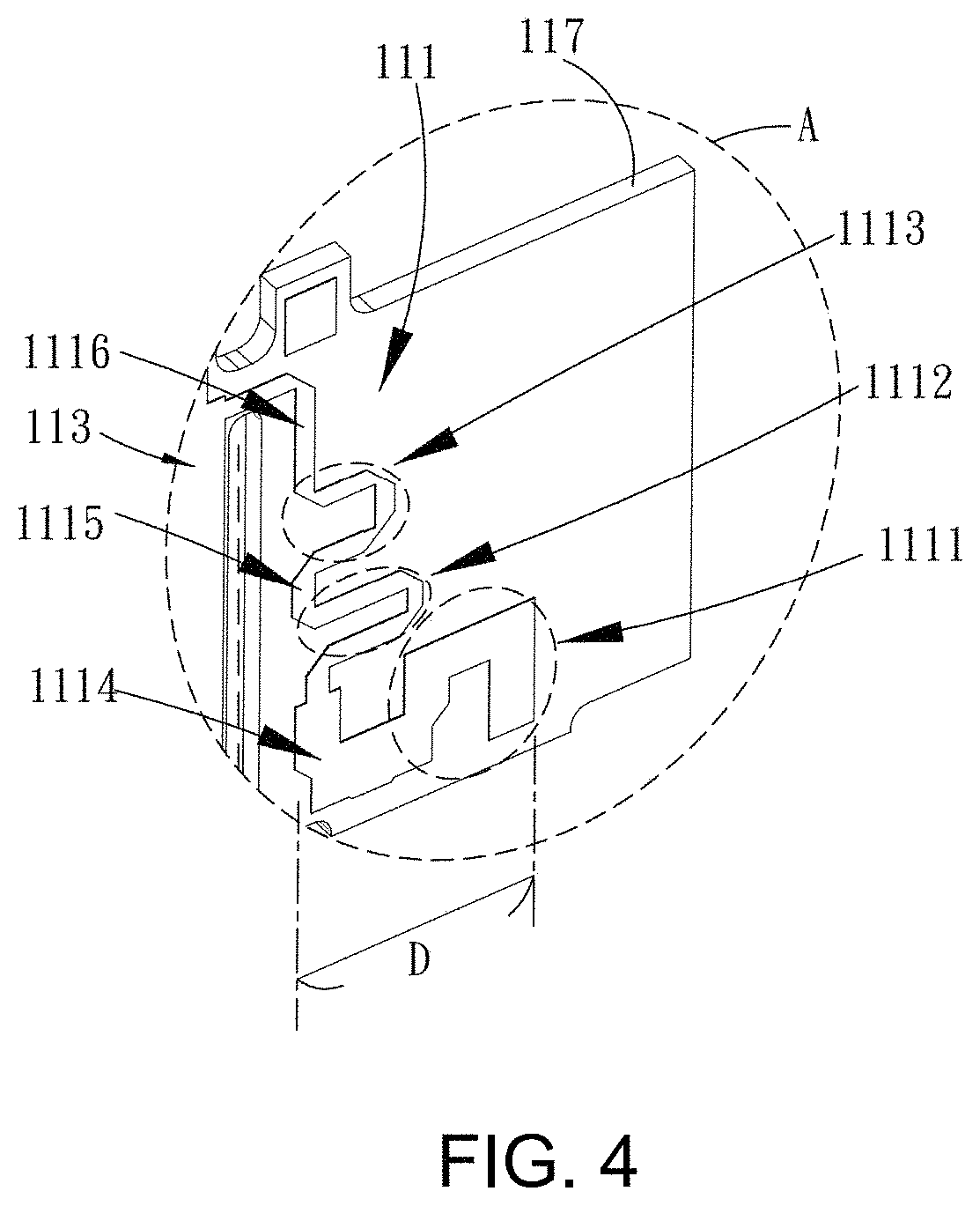

Powered pallet truck

ActiveUS9586605B2Reduce length and widthLower center of gravityLifting devicesHand carts with multiple axesTruckPallet

A powered pallet truck is provided having a base support portion and a load lift portion. The powered pallet truck has a lift cylinder device connected at a lower portion to a forward extending lift cylinder device seat on the base frame and pivotally connected at an upper portion within a recessed channel in the load lift frame.

Owner:BIG ELEVATOR

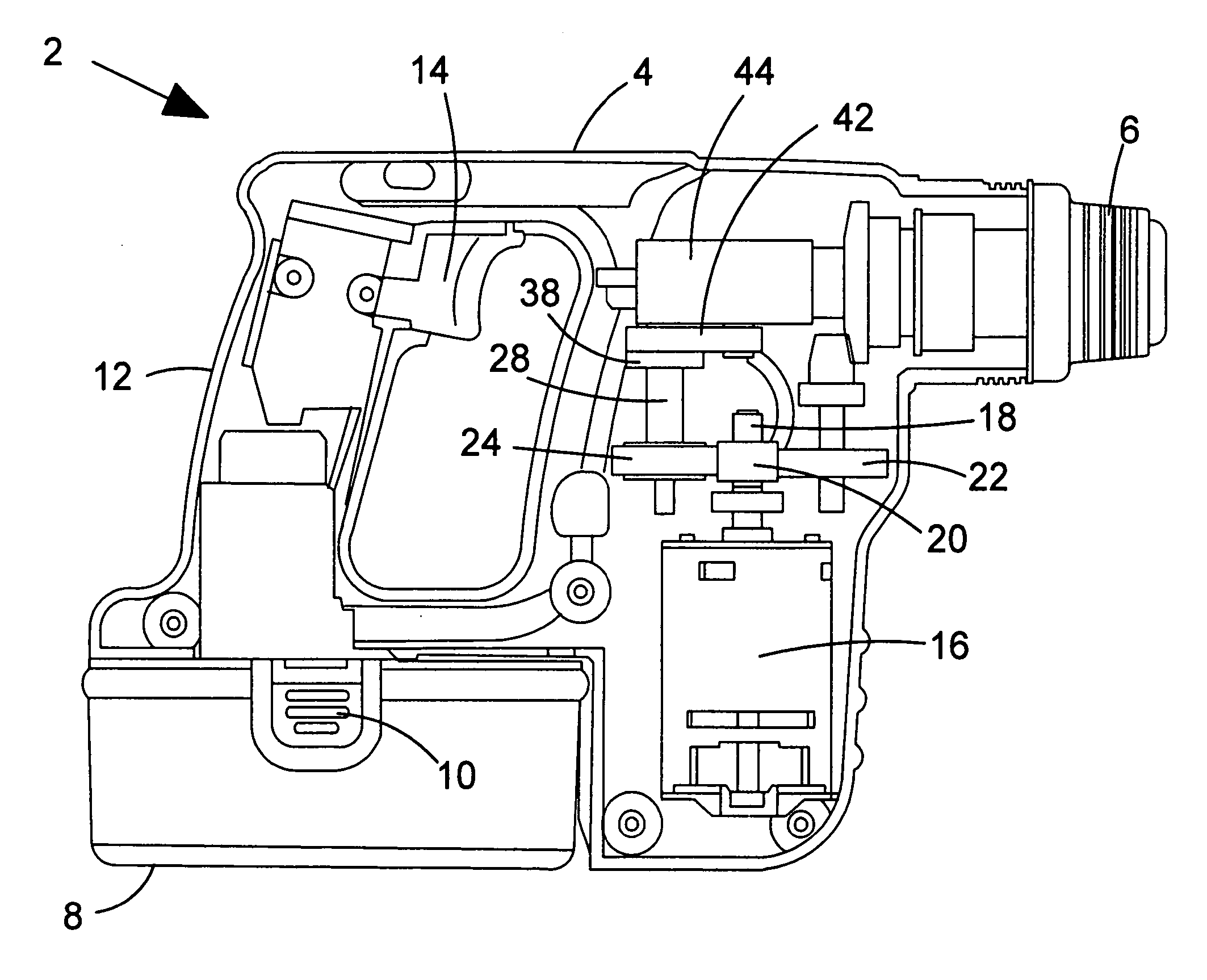

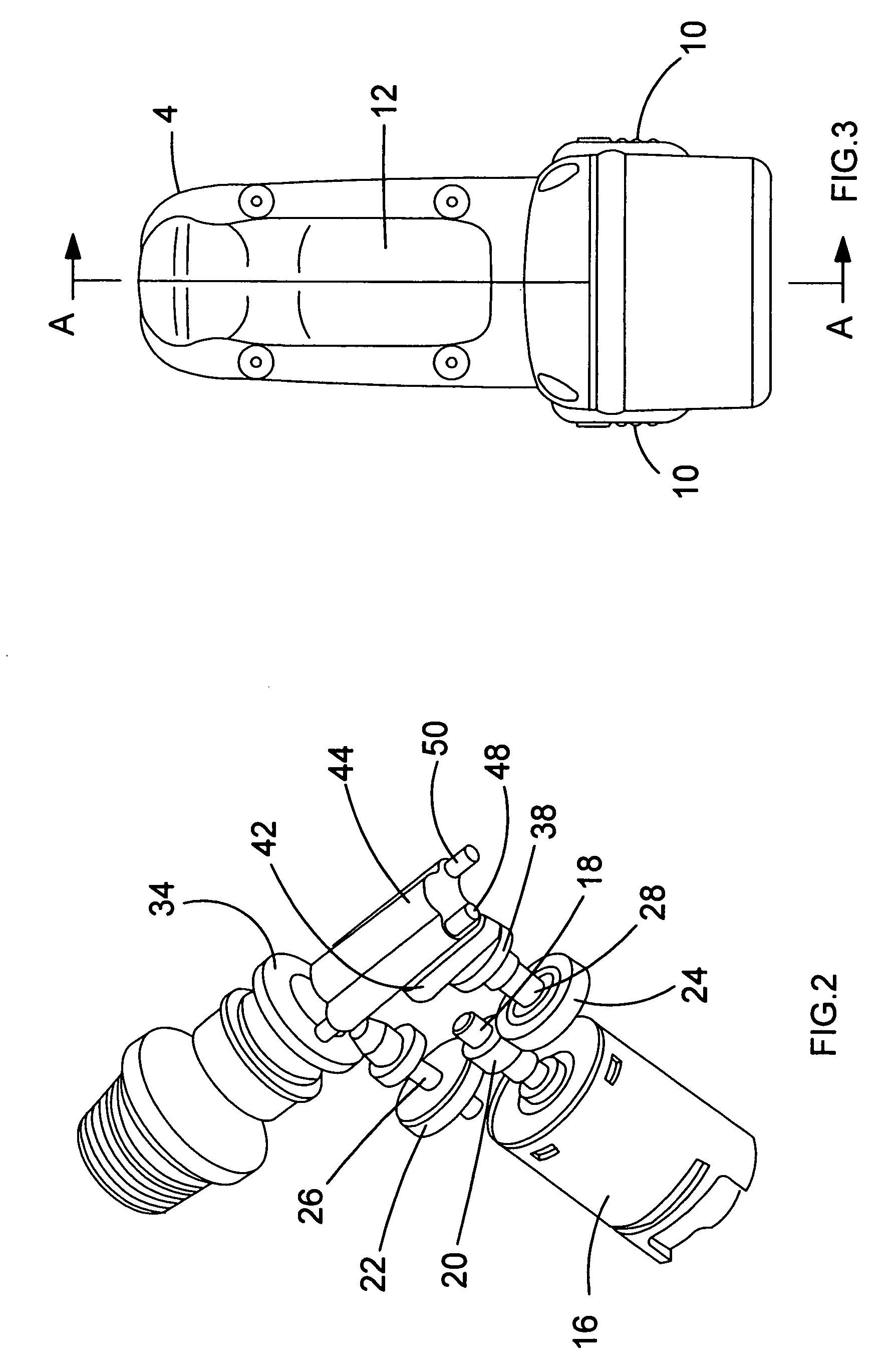

Hammer mechanism for power tool

InactiveUS20060137889A1More compact constructionCompact structureDrilling rodsConstructionsDrive shaftReciprocating motion

A rotary hammer includes a motor with an output shaft and pinion. The pinion drives a gear which is mounted to a drive shaft. A crank plate having an eccentrically disposed crank pin is mounted to the top of the drive shaft. A crank arm is pivotally connected to the crank pin and to the underside of a hollow piston. Hollow piston defines an internal bore, and the hollow piston is slidably mounted on two guide rods. Rotation of the drive shaft and turns the crank plate, and the eccentric motion of crank pin drives the crank arm. Due to the pivotal connection between the crank arm and the hollow piston 44, the hollow piston is caused to reciprocate back and forth along the guide rods.

Owner:BLACK & DECKER INC

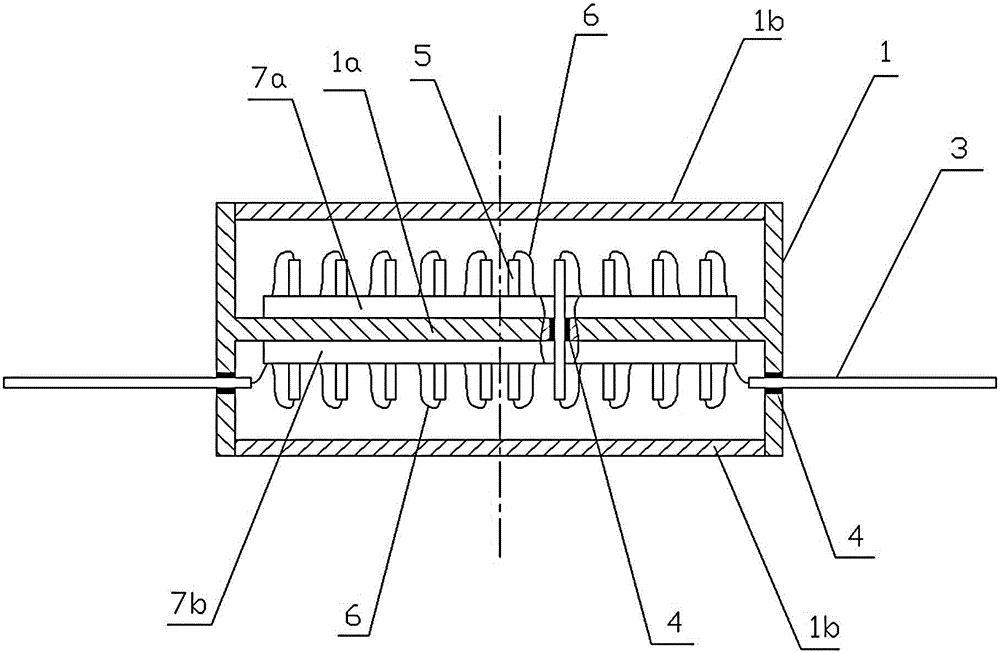

Double-sided encapsulation shell for parallel seam welding

ActiveCN105185749AReduce length and widthIncreased package heightSemiconductor/solid-state device detailsSolid-state devicesEngineeringSeam welding

The invention relates to a double-sided encapsulation shell for parallel seam welding. The double-sided encapsulation shell is characterized in that the shell comprises a metal sealing box (1), a partition board (1a) is arranged inside the sealing box (1), the partition board (1a) divides the sealing box (1) into an upper box cavity and a lower box cavity, and a metal box cover (1b) seal-welded to the sealing box (1) through parallel seam welding is arranged on each box cavity; the upper and lower surfaces of the partition board (1a) are respectively in insulation connection with upper and lower substrates (7a, 7b), the upper and lower substrates (7a, 7b) are electrically connected by a conductive medium, and circuit devices (8) are connected to the upper and lower substrates (7a, 7b); and a group of flat I / O pins (3) are led out from the side wall of the sealing box (1), each I / O pin (3) is in fixed insulation connection with the sealing box (1), and each I / O pin (3) is electrically connected with the upper substrate (7a) or the lower substrate (7b). By adopting the technical scheme, high-reliability double-sided parallel seam welding air-tight encapsulation can be realized, the length and width of encapsulation are reduced, and the encapsulation density is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Method for preparing multiple products including hemicellulose, carboxylated cellulose nanocrystals, fibrils and citrate from fibers by using citric acid

ActiveCN111087491AMeet the requirements for protected coexistenceExtensive sources of raw materialsMaterial nanotechnologyCarboxylic acid salt preparationFiberHemicellulose

The invention discloses a method for preparing multiple products including hemicellulose, carboxylated cellulose nanocrystals, fibrils and citrate multicomponent products from fibers by using citric acid. The method comprises the following steps: with fibers as a base material, preparing hemicellulose through citric acid hydrolysis and alcohol precipitation, preparing citrate through crystallization, preparing cellulose nanocrystals through ultrasonic treatment and centrifugation, and preparing cellulose nanofibrils from solid fibers through homogenization. The method is friendly to environment, free of toxicity, low in risk, high in fiber component utilization rate, diversified in high-value products and high in yield. The prepared cellulose nanocrystals and cellulose nanofibrils have dispersion stability, excellent specific surface area and high carboxyl content, and lay a foundation for nanocellulose modification. Finally, prepared nanocellulose has no residual toxic and harmful substances, and has wide application prospects in the aspect of functional materials taking cellulose as a substrate, especially in the aspects related to health, such as biomedical materials, food, health care products, skin care cosmetics and the like.

Owner:SOUTH CHINA UNIV OF TECH

Syringe having a collapsible plunger rod

ActiveUS8632519B2Reduce length and widthAmpoule syringesMedical devicesBiomedical engineeringPlunger

A syringe assembly includes a syringe barrel having an exterior surface, an inside surface defining a chamber, an open proximal end, a distal end, and an outlet disposed adjacent the distal end in fluid communication with the chamber; and a plunger assembly disposed at least partially within the syringe barrel. The plunger assembly includes an elongated plunger rod and a plunger head. The elongated plunger rod is associated with the plunger head to move the plunger head within the chamber of the syringe barrel through an injection cycle. The plunger rod is adapted to move from a collapsed position extending alongside the exterior surface of the syringe barrel to an extended position engaging the plunger head to move the plunger head through the injection cycle.

Owner:BECTON DICKINSON FRANCE

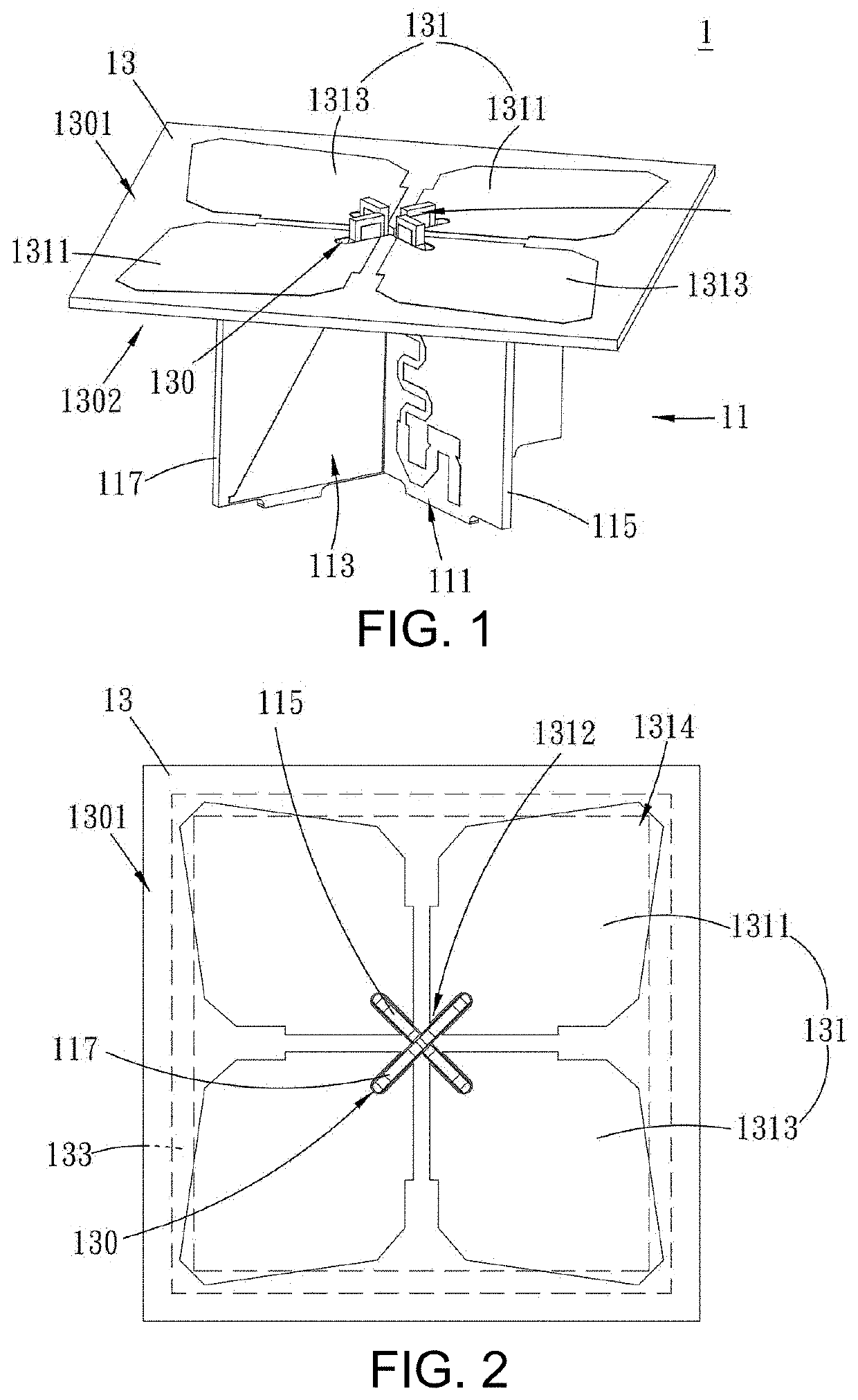

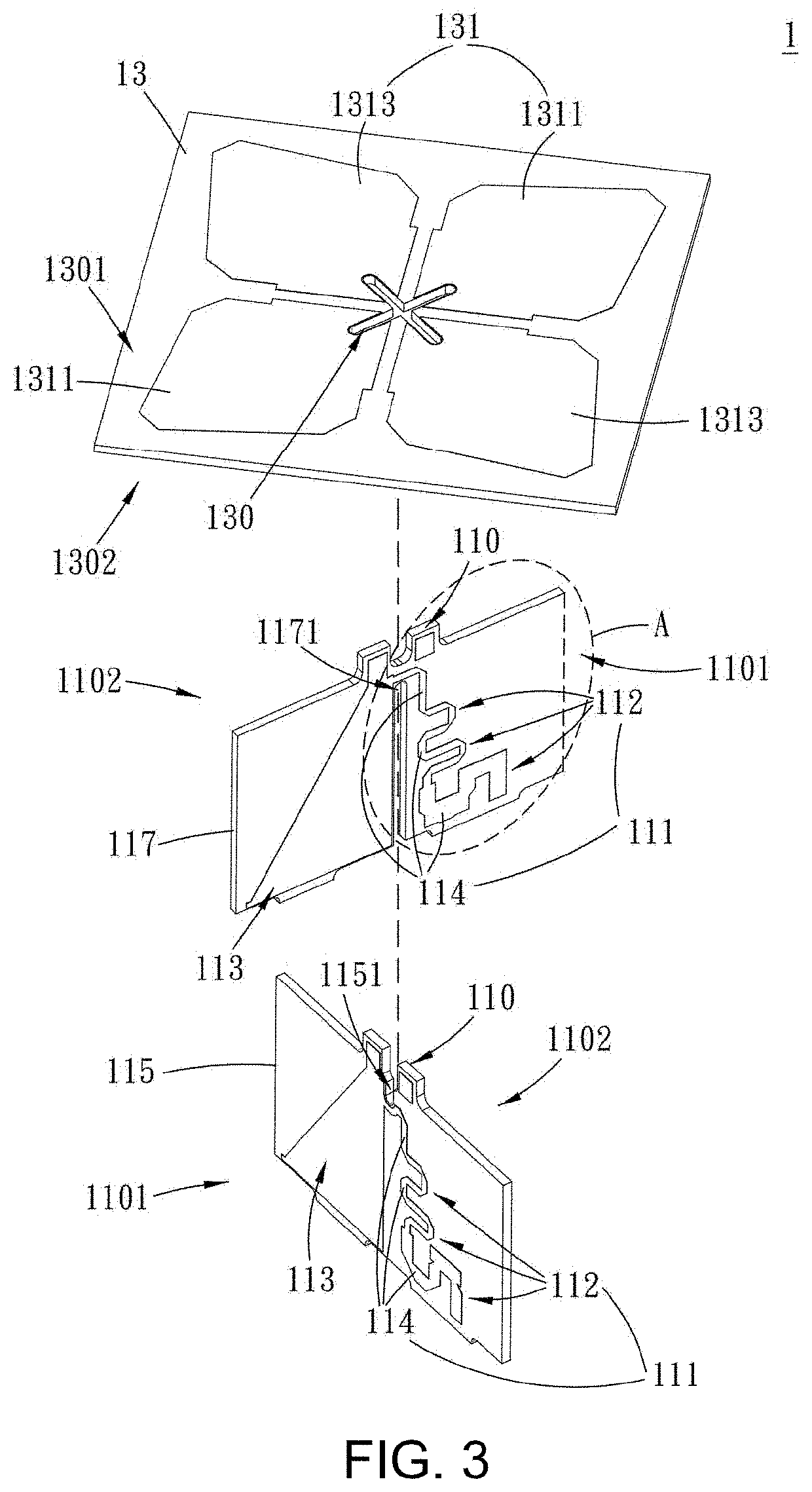

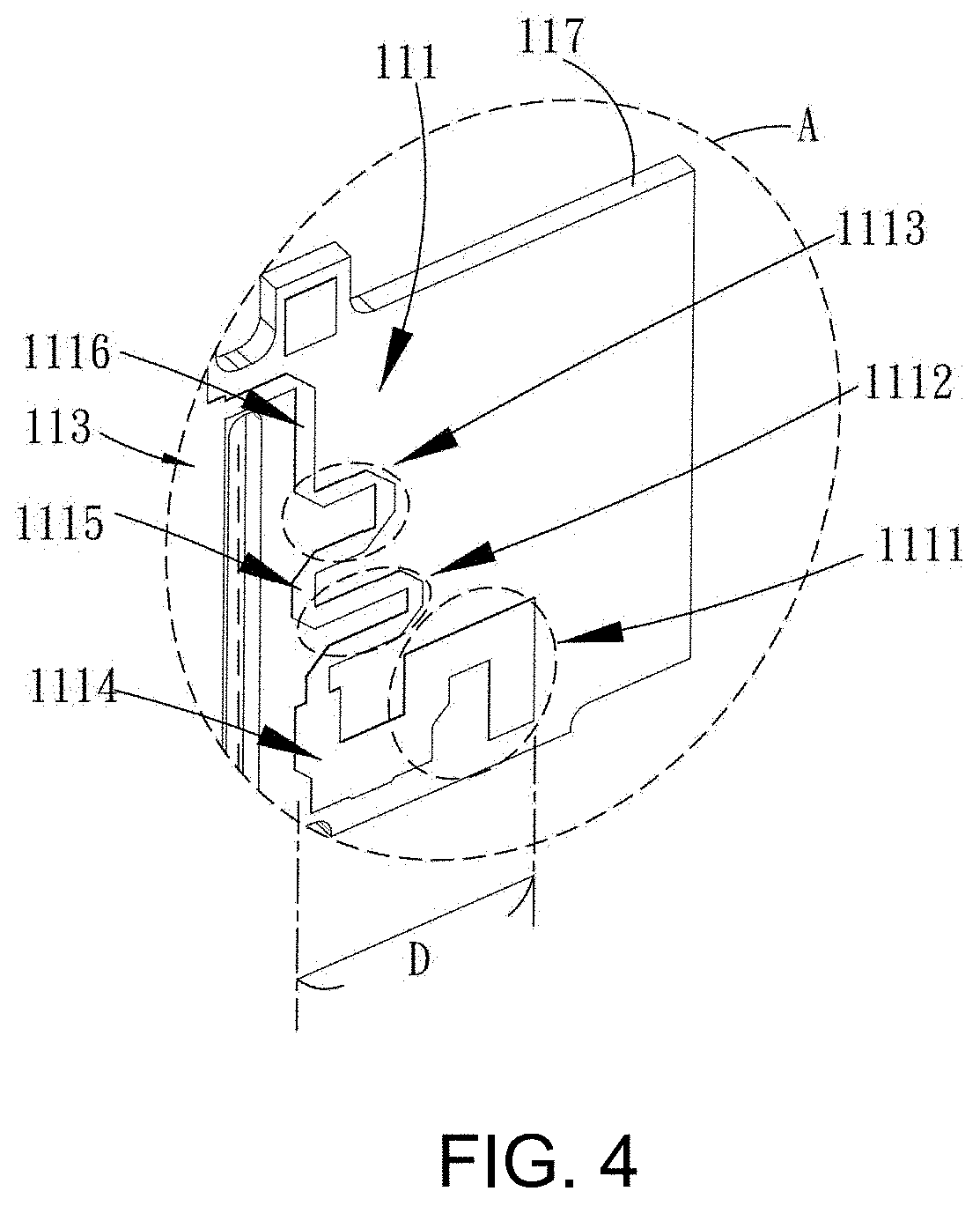

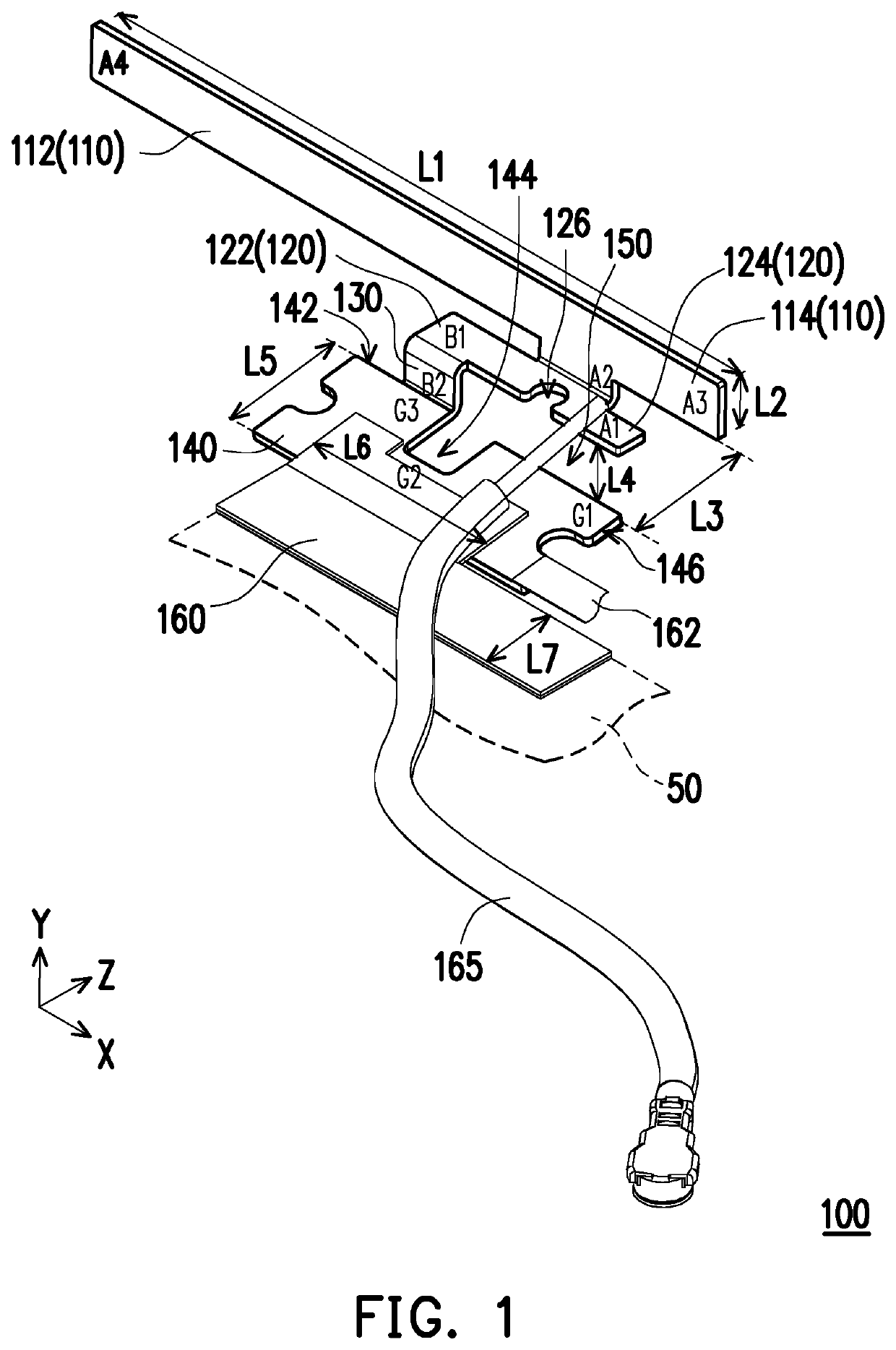

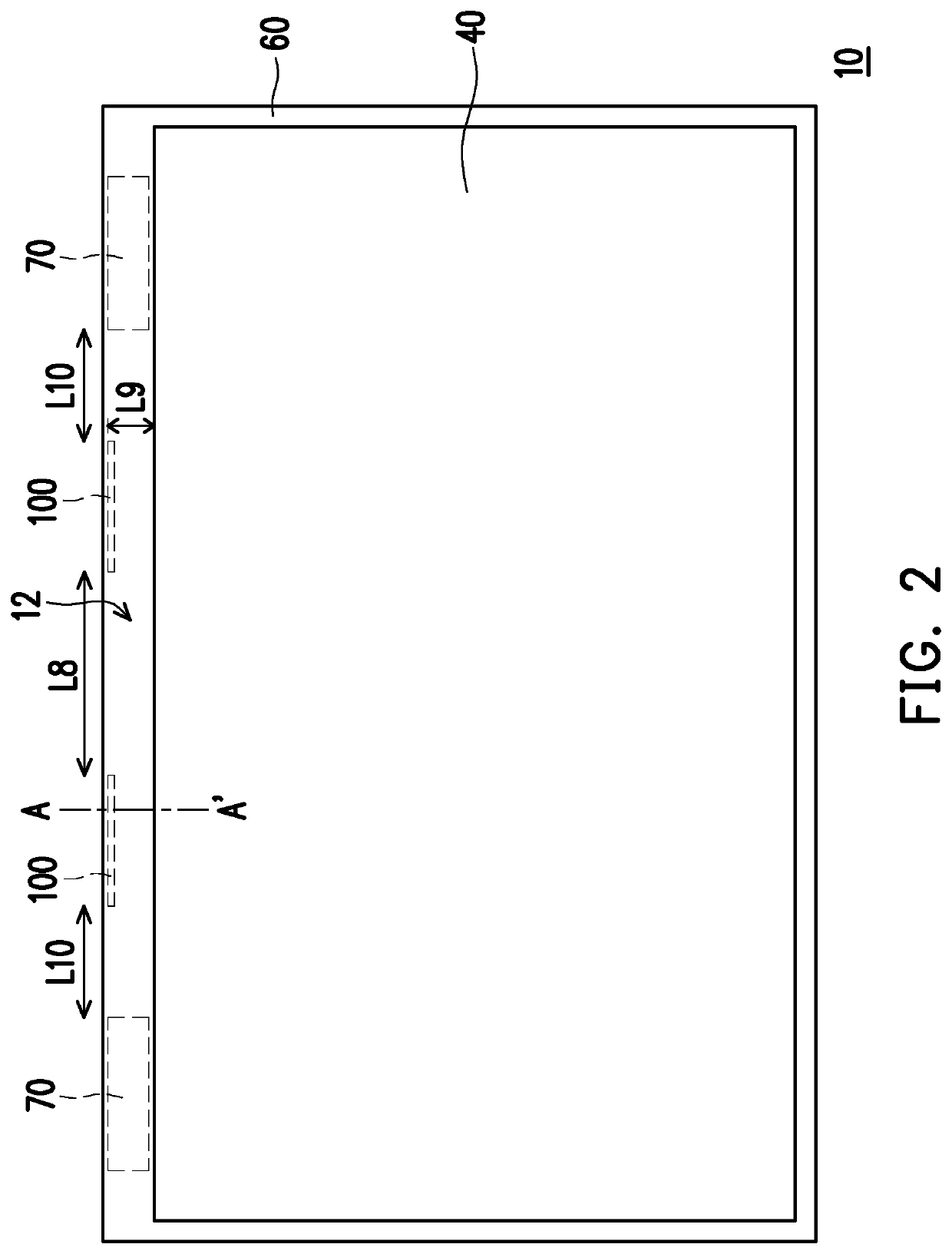

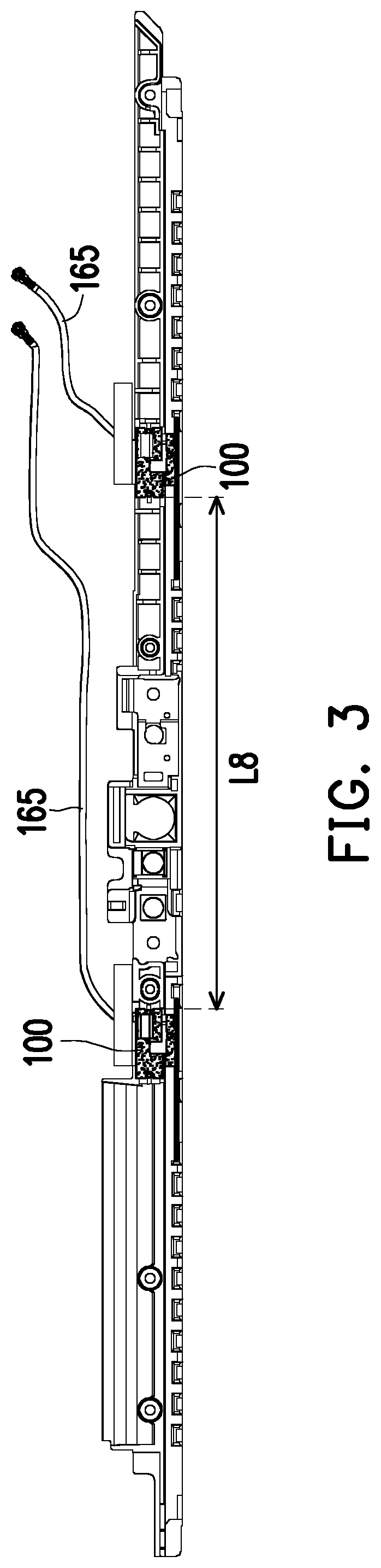

Base station antenna

ActiveUS20210210840A1Reduce heightReduce length and widthAntenna supports/mountingsRadiating elements structural formsEngineeringElectrical connection

The present disclosure provides a base station antenna comprising a balun support component and a substrate. The balun support component comprises a ground circuit and a balun circuit comprising a plurality of bending parts and a plurality of connecting parts which are alternately connected. Each bending part comprises two wires extending in opposite directions and a bending wire connecting the two wires. The substrate comprises a first surface and a second surface opposite to the first surface. The second surface of the substrate is disposed on the balun support component. The first surface comprises an oscillator arm comprising a first end and a second end. The first end is closer to the center of the substrate than the second end. The second surface comprises a metal ring. The balun circuit and the ground circuit are electrically connected to the oscillator arm.

Owner:KUNSHAN LUXSHARE RF TECH CO LTD

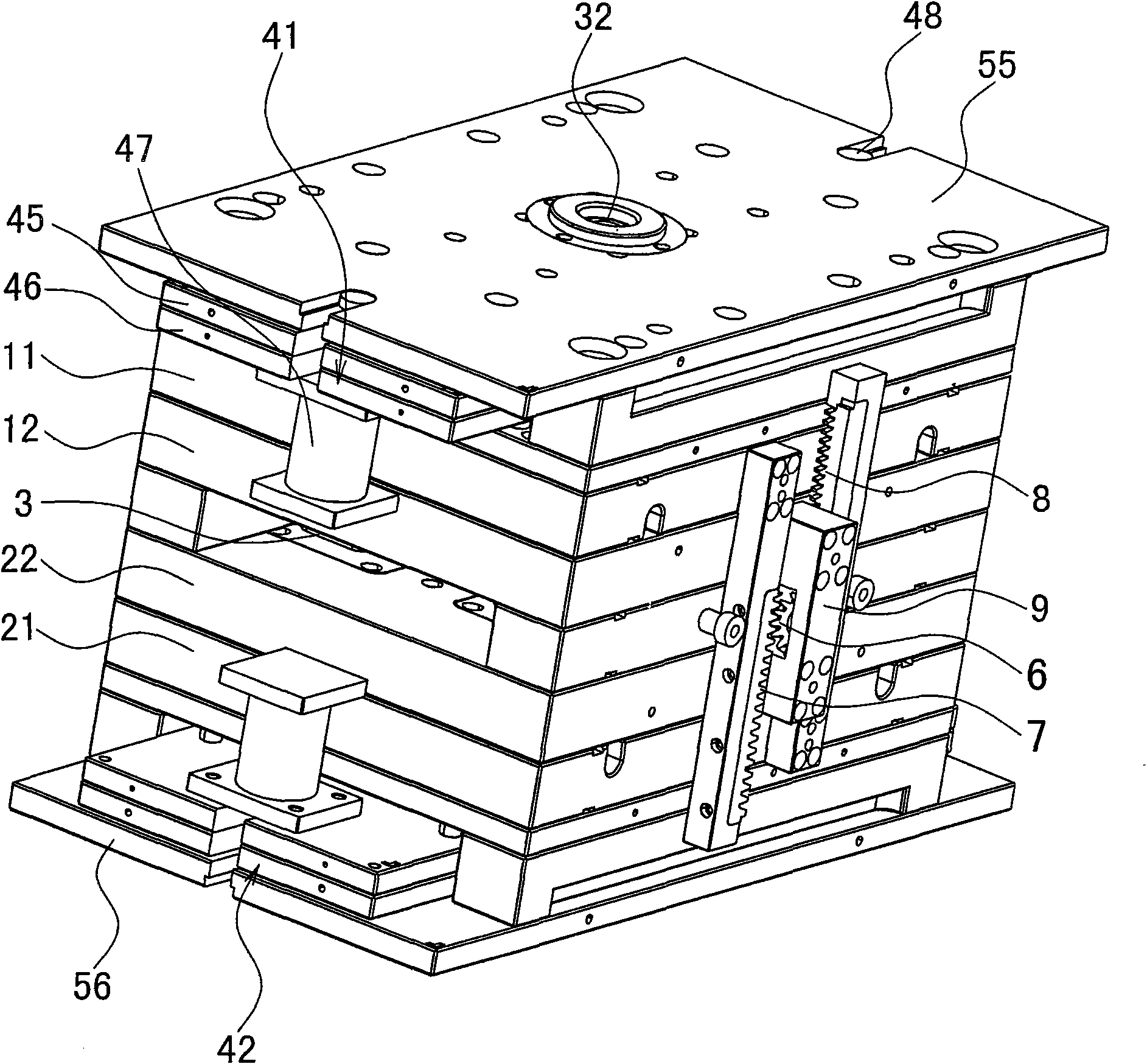

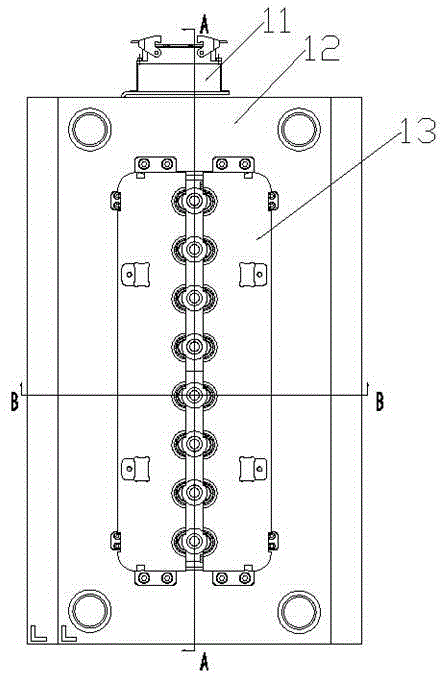

Double-layer injection mold

The invention discloses a double-layer injection module, which comprises mold cores and mold cavities, wherein the mold cores and the mold cavities form two or more than two product molding chambers; the mold cores are driven by an ejecting mechanism; the outer walls of the mold cavities are provided with pouring openings; and one end of each pouring opening is communicated with one molding chamber and the other ends of the pouring openings are communicated with a hot runner plate connected with a spray nozzle of an injection machine. The double-layer injection module is characterized in that: the mold cores and the mold cavities are both comprised of upper and lower layers; the upper-layer mold core and the upper-layer mold cavity are positioned above the hot runner plate; the lower-layer mold core and the lower-layer mold cavity are positioned below the hot runner plate; products in an upper-layer molding chamber and a lower-layer molding chamber are driven by the ejecting mechanism respectively; a branch runner is formed in the middle part of the hot runner plate; the branch runner is communicated with the spray nozzle of the injection machine through a main spray nozzle; the upper and lower wall faces of the branch runner are provided with plastic flow holes respectively; the upper plastic flow holes are communicated with the pouring opening of the upper-layer mold cavity through a first hot spray nozzle respectively; the lower plastic flow holes are communicated with the pouring openings on the lower-layer mold cavity through a second hot spray nozzle; and auxiliary mold opening mechanisms are arranged on the left and right two sides of the hot runner plate respectively.

Owner:ZHEJIANG KAIHUA MOLDS

Method for preparing carboxylated nanocellulose by hydrolyzing citric acid under high-pressure condition

InactiveCN111072786AWide variety of sourcesExtensive sources of raw materialsArtificial filaments from cellulose derivativesFiberAcid hydrolysis

The invention discloses a method for preparing carboxylated nanocellulose by hydrolyzing citric acid under a high-pressure condition. According to the method, a bleached fiber pulp board serves as a base material, citric acid serves as hydrolysate, acid hydrolysis is conducted under high pressure, then cellulose nanocrystals are prepared through centrifugation, and cellulose nanofibrils are prepared from remaining solid fibers through a high-pressure homogenizer. The method is green, non-toxic, short in consumed time and high in yield, and the used citric acid is easy to recycle so that the preparation cost of the nanocellulose is reduced. Besides, the prepared carboxylated cellulose nanocrystals and cellulose nanofibrils have relatively high dispersion stability, excellent specific surface area and relatively high carboxyl content so that more chemical ways are provided for further modification of the nanocellulose. Finally, the prepared nanocellulose has no toxic and harmful substance residues so that the nanocellulose has a wide application prospect in the aspects of food emulsifiers, health care products, skin care products, medical materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

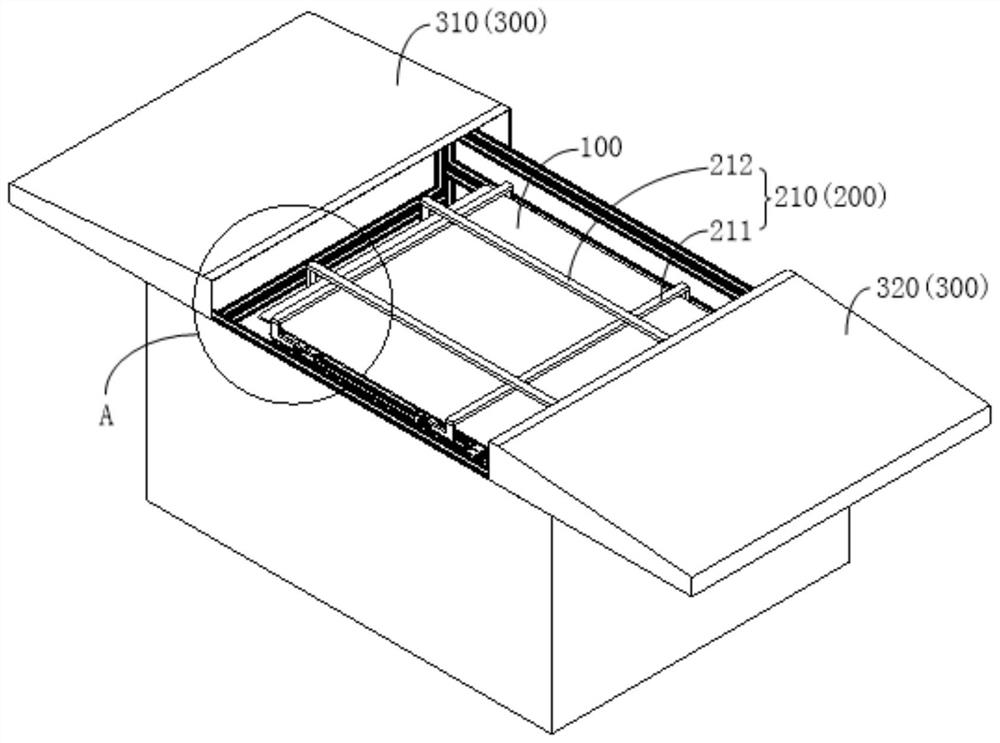

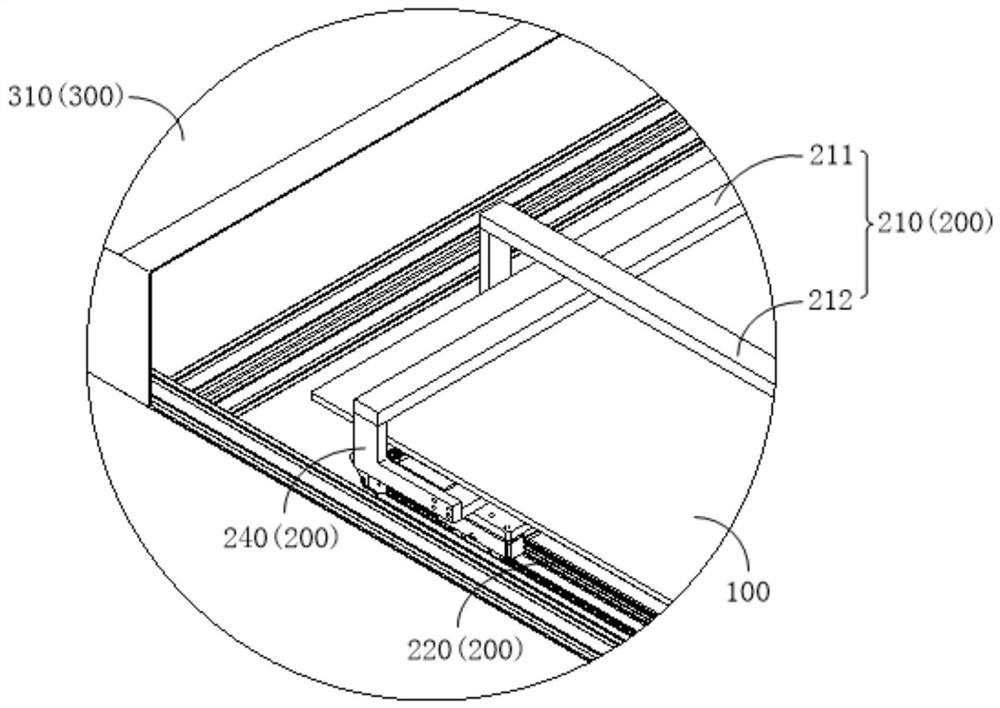

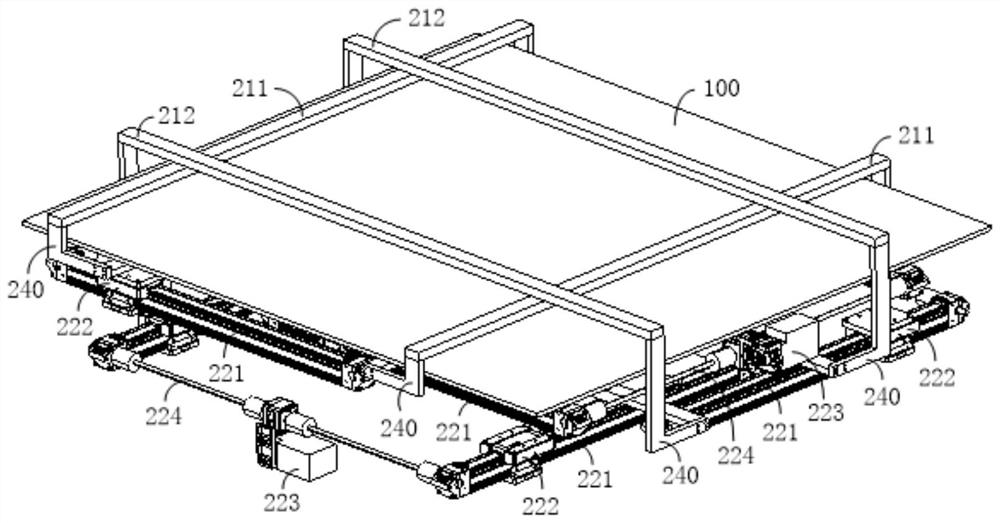

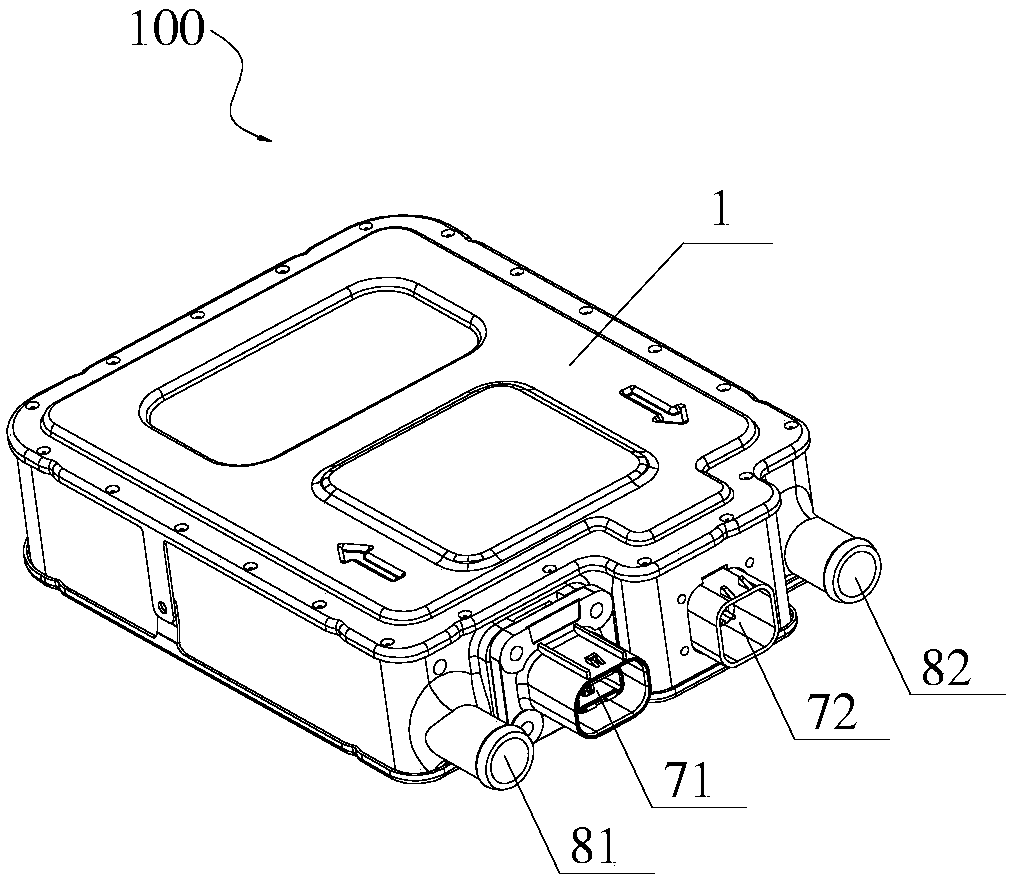

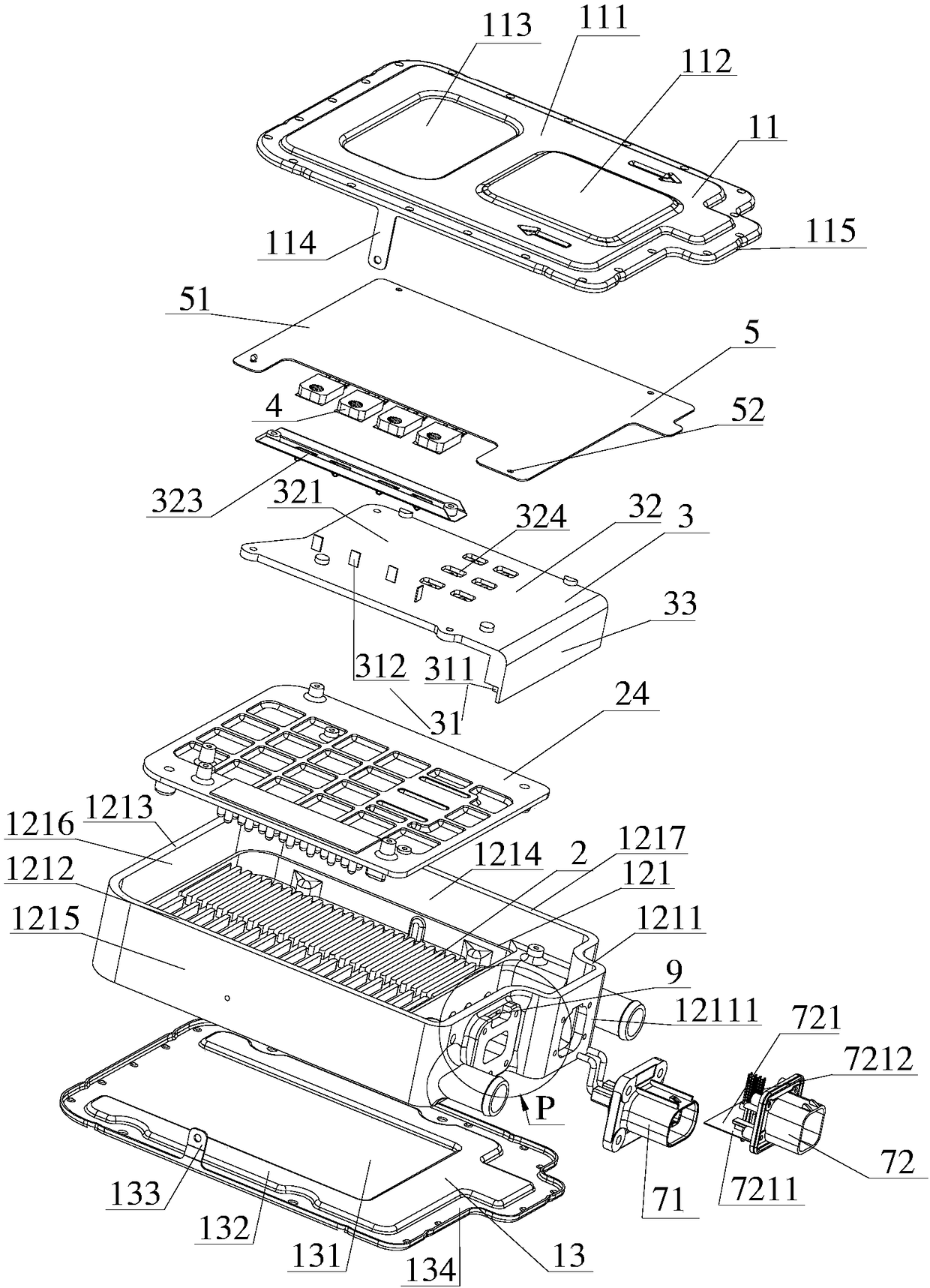

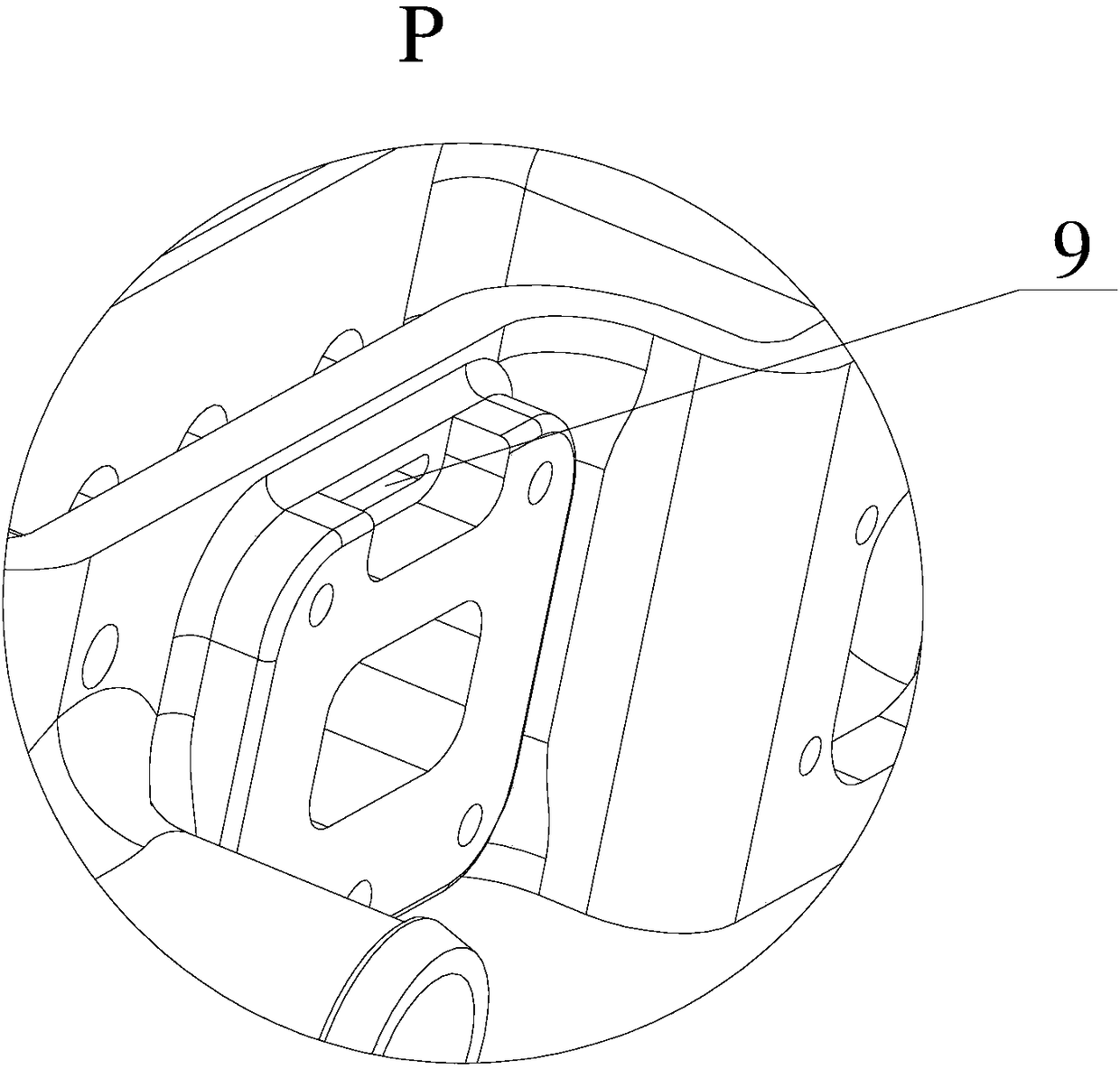

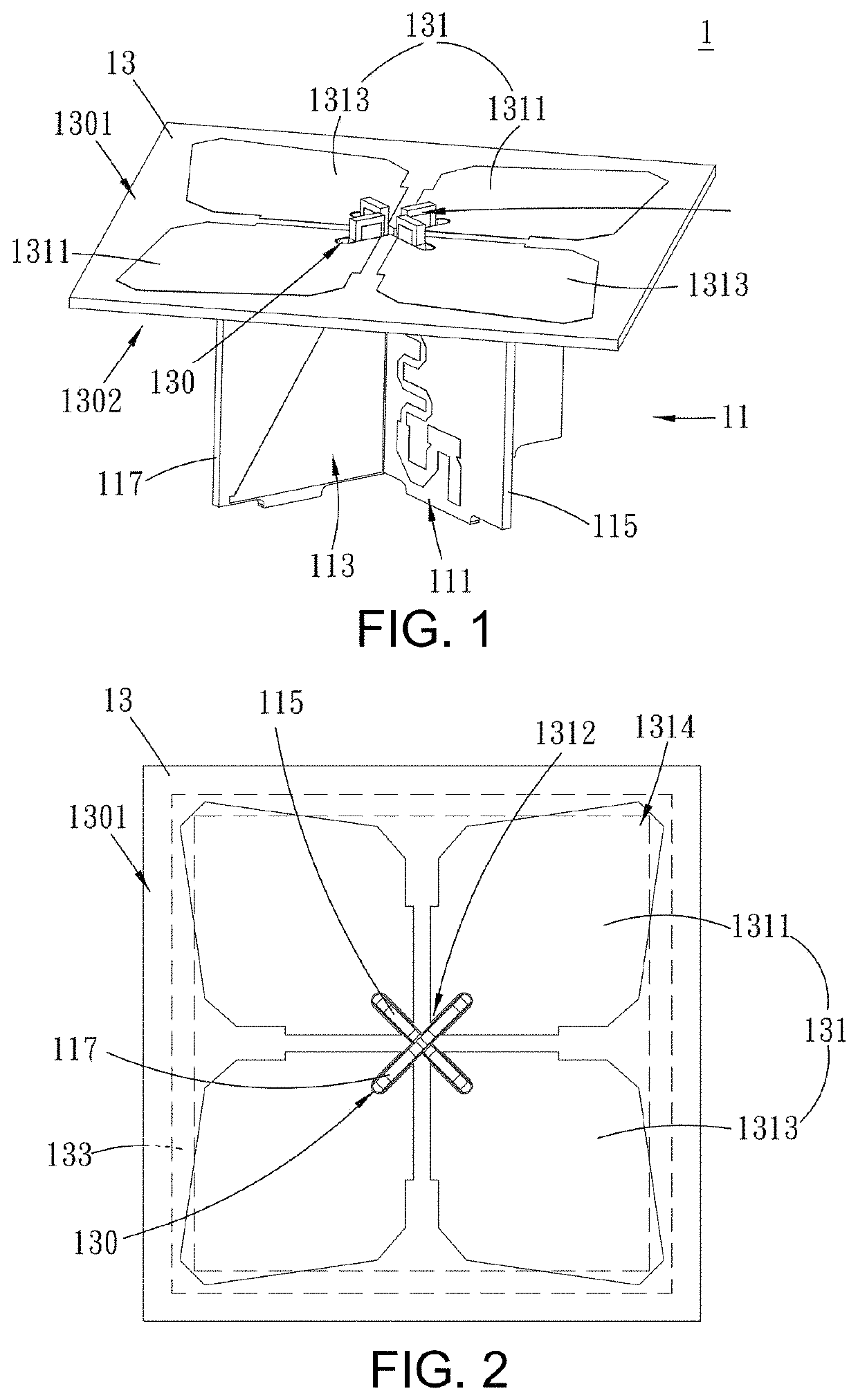

Unmanned aerial vehicle lifting platform and building

ActiveCN111977010AReduce peripheral sizeReduce length and widthHelicopter landing platformAnchoring installationsUncrewed vehicleMechanical engineering

The invention relates to an unmanned aerial vehicle lifting platform and a building. The unmanned aerial vehicle lifting platform comprises a platform which is used for parking an unmanned aerial vehicle, and a positioning mechanism which is used for pushing the unmanned aerial vehicle to a target position, the positioning mechanism comprises a plurality of pushing pieces arranged in a staggered mode to form a # shape, a driving device used for driving the pushing pieces and a controller in communication connection with the driving device, and the driving device is arranged below the platform;the pushing pieces are arranged above the platform, and the two ends of the pushing pieces extend to the edge of the platform and can move along the edge; and the pushing pieces are connected to thedriving device through an adapter piece. Therefore, the end parts of the pushing pieces extend to the edge of the platform, so that the whole platform can be generally used as a landing area of the unmanned aerial vehicle; meanwhile, the adapter piece is arranged, so that the driving device can be completely shielded by the platform, namely hidden below the platform, and is connected with the pushing pieces only through the adapter piece; and therefore, the peripheral size of the platform can be effectively reduced while the size of the landing area of the unmanned aerial vehicle is met.

Owner:BEIJING AIRLANGO TECH CO LTD

Electric heater

The invention relates to an electric heater which comprises an installation wall and a weak current terminal. The installation wall comprises a lug boss; the position of the lug boss corresponds to the position of the weak current terminal; the lug boss can provide a corresponding space for installing the weak current terminal, so that the weak current terminal is prevented from being installed above the electric heater, and the thickness of the electric heater is relatively reduced; and a strong current terminal and the weak current terminal are located on the same side of the electric heater, so that the length or the width of the electric heater is relatively reduced, and the volume of the electric heater provided by the invention is relatively smaller.

Owner:HANGZHOU SANHUA RES INST CO LTD

Stage wood floor and preparation method thereof

The invention relates to a stage wood floor and a preparation method thereof. The stage wood floor comprises multiple splicing plate layers, every two splicing plate layers are fixedly adhered by adhesion agents, and a plurality of radial cutting plates are horizontally connected in a finger-shaped mode to form each splicing plate layer. The radial cutting plates are connected by the aid of a finger-shaped mode to form the stage wood floor, wood fiber lengths or widths of floor blanks are greatly shortened, so that internal stress of the floor blanks is greatly reduced, and stability of the floor is improved. As trees serve as natural growth objects, the trees must have natural defects such as knur, color difference, pith-ray fleck, wormhole, resin pocket and part decadent, and accepting or rejecting collocation can be achieved according to wills of a user by the aid of a finger-shaped connecting and horizontal splicing process, so that internal quality and external image of the stage wood floor can be greatly improved.

Owner:梁贤录

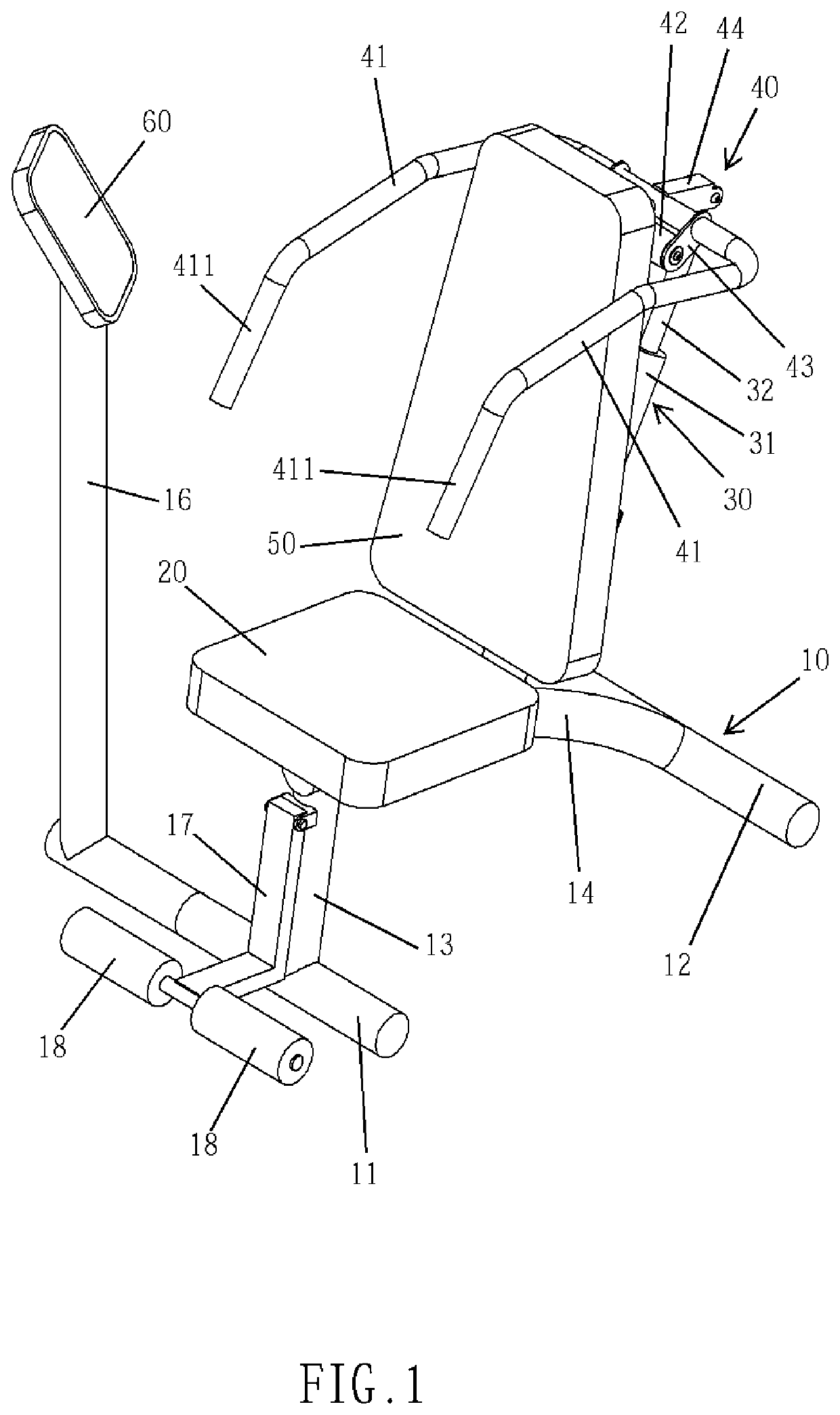

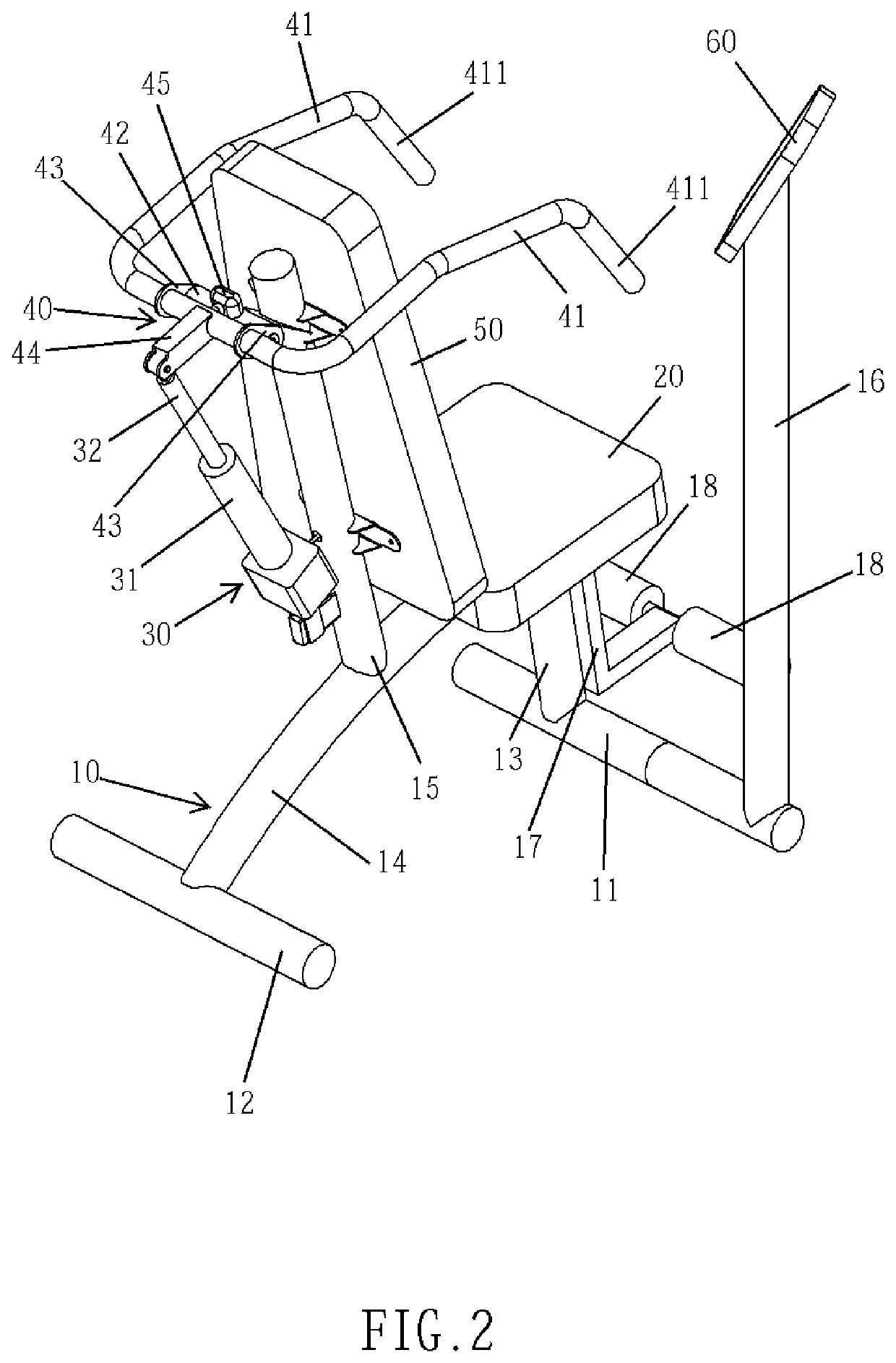

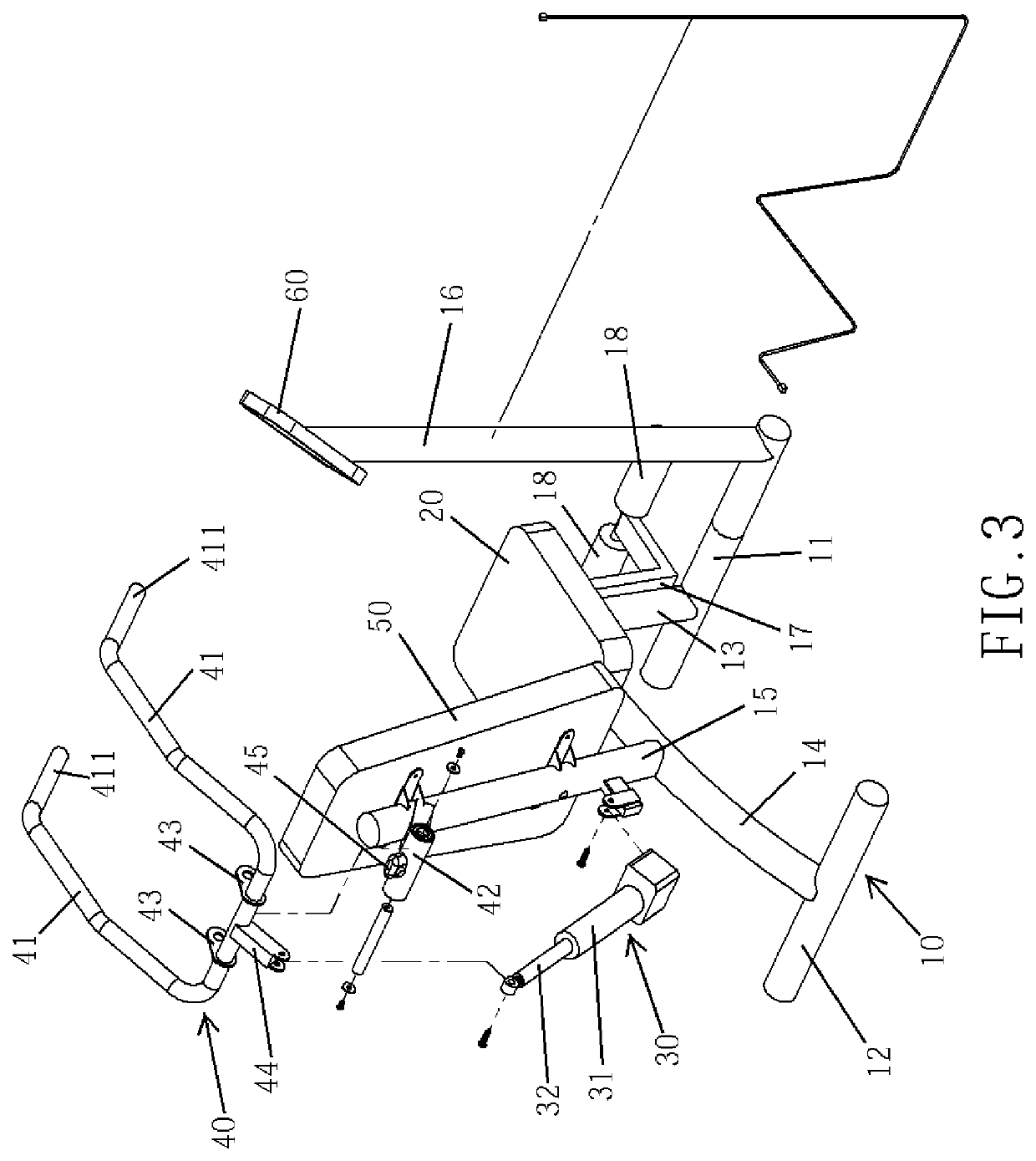

Exercising Device with Rehabilitation Function

An exercising device includes a main frame, a seat, a backrest, a swing unit, a magnetically controlled damper, and an electronic control panel. The swing unit is swingably mounted on the upright of the main frame. The swing unit includes two handlebars extending from the upright to the seat respectively. The magnetically controlled damper is pivotally mounted between the swing unit and the main frame. The electronic control panel is electrically connected with the magnetically controlled damper. When the two handlebars are moved by the user, the magnetically controlled damper provides a damping force to retard movement of the two handlebars. The electronic control panel controls and regulates the resistance of the magnetically controlled damper.

Owner:HIGH SPOT HEALTH TECH

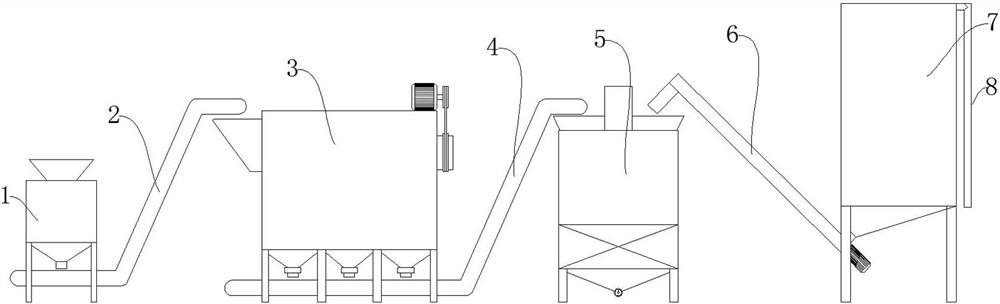

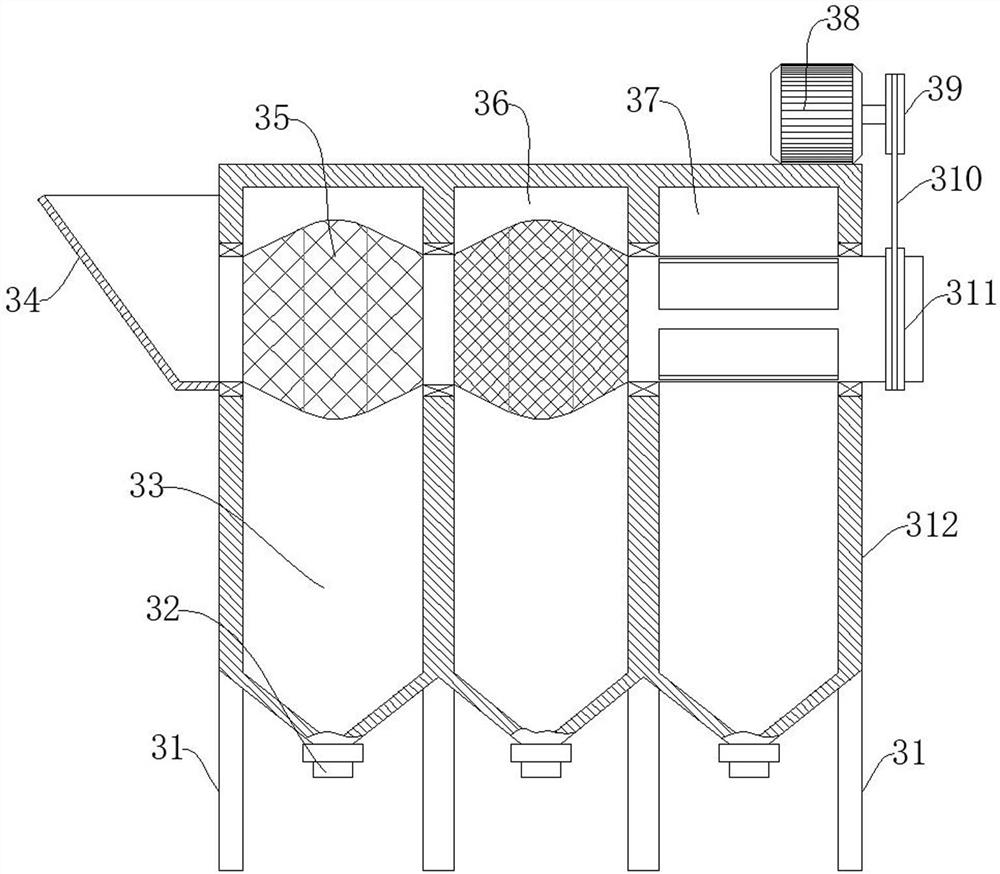

Concrete production equipment

PendingCN113715174AReduce length and widthImprove screening efficiencySievingDischarging apparatusConstruction engineeringStructural engineering

The invention discloses concrete production equipment, and relates to the technical field of concrete production. The concrete production equipment comprises a pulverizer, a first conveying device, a screening machine, a second conveying device, a stirring device, a lifting pipe, a storage tank and a feeding pipe, wherein the first conveying device is arranged on the lower portion of the pulverizer, the other end of the first conveying device extends to the position above the screening machine, and the second conveying device is arranged below the screening machine. The concrete production equipment has the beneficial effects that a screening cylinder and spiral blades in the screening cylinder are arranged, and a rolling mode is adopted for screening materials, so that the length and the width of the equipment are reduced, and meanwhile, the screening efficiency is improved; a first bin, a second bin and a third bin are arranged for storing materials separately, a discharging valve can be opened for use according to requirements, and the discharging valve is convenient to use; a discharging box is arranged, the discharging amount can be quantitatively controlled according to the proportion, the proportion mixing is guaranteed, and the concrete mixing quality is met; and a discharging hopper is arranged, ingredients are preliminarily mixed and then enter a stirrer, so that the stirrer can conveniently stir the ingredients, and the concrete can be stirred more fully.

Owner:洛阳腾飞建材有限公司

Method for preparing carboxylated nanocellulose by hydrolyzing citric acid under microwave condition

The invention discloses a method for preparing carboxylated nanocellulose by hydrolyzing citric acid under a microwave condition. The method comprises the following steps: adding a bleached fiber pulpboard into a citric acid solution, hydrolyzing under a microwave condition, preparing cellulose nanocrystals through centrifugation, and preparing cellulose nanofibrils from residual long fibers through a high-pressure homogenizer. The method is green, non-toxic, short in consumed time, low in power consumption and relatively high in yield, and the used citric acid is easy to recycle, so that thepreparation cost of the nanocellulose is reduced, and engineering preparation of the nanocellulose is facilitated. Besides, the prepared cellulose nanocrystals and cellulose nanofibrils have relatively high dispersion stability, excellent specific surface area and relatively high carboxyl content, so that more chemical ways are provided for further modification of nanocellulose. Finally, the prepared nanocellulose has no residues of toxic and harmful substances, and has a wide application prospect in the aspect of functional materials taking cellulose as a substrate, especially in the aspectof materials related to human health.

Owner:SOUTH CHINA UNIV OF TECH

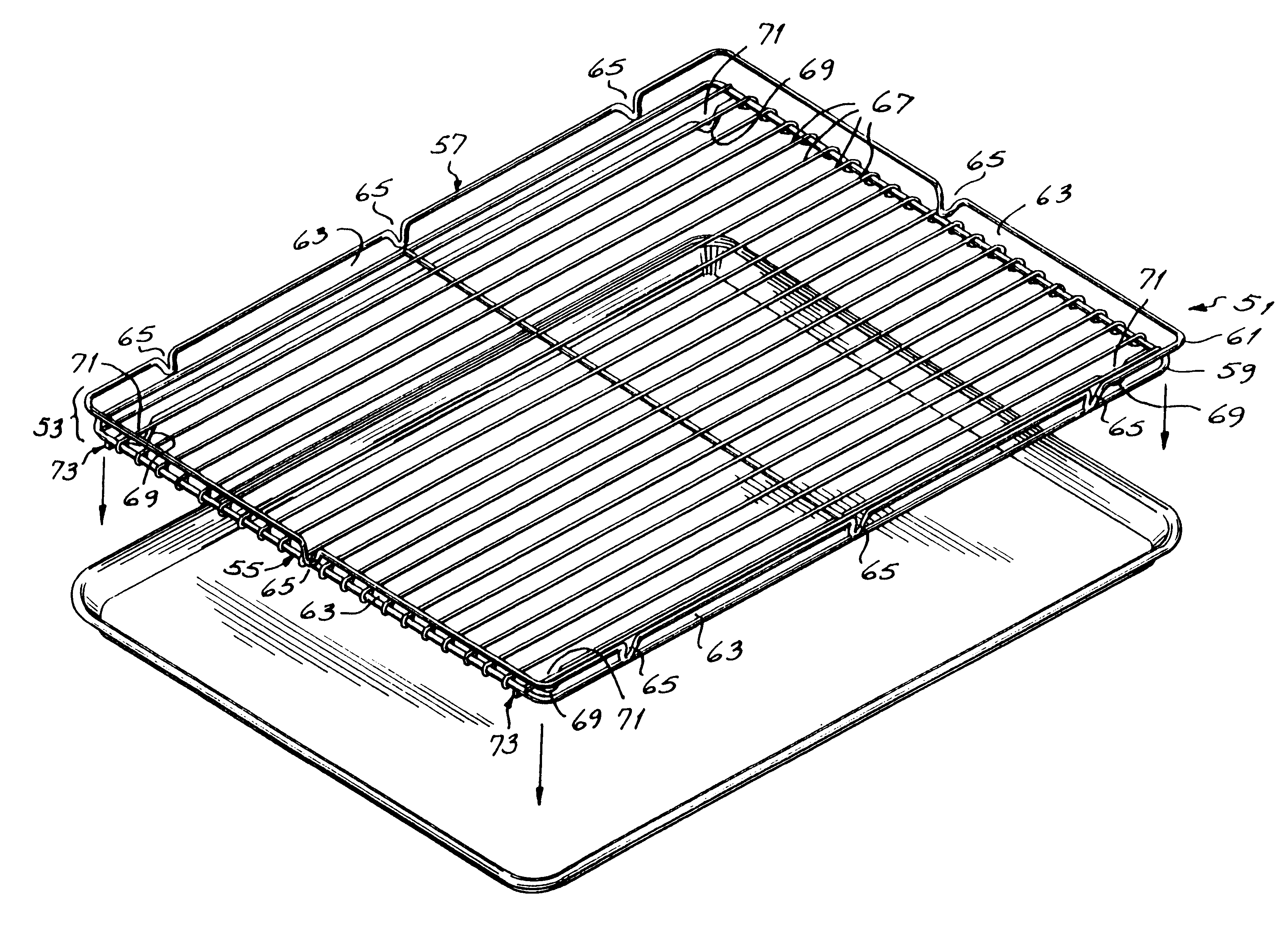

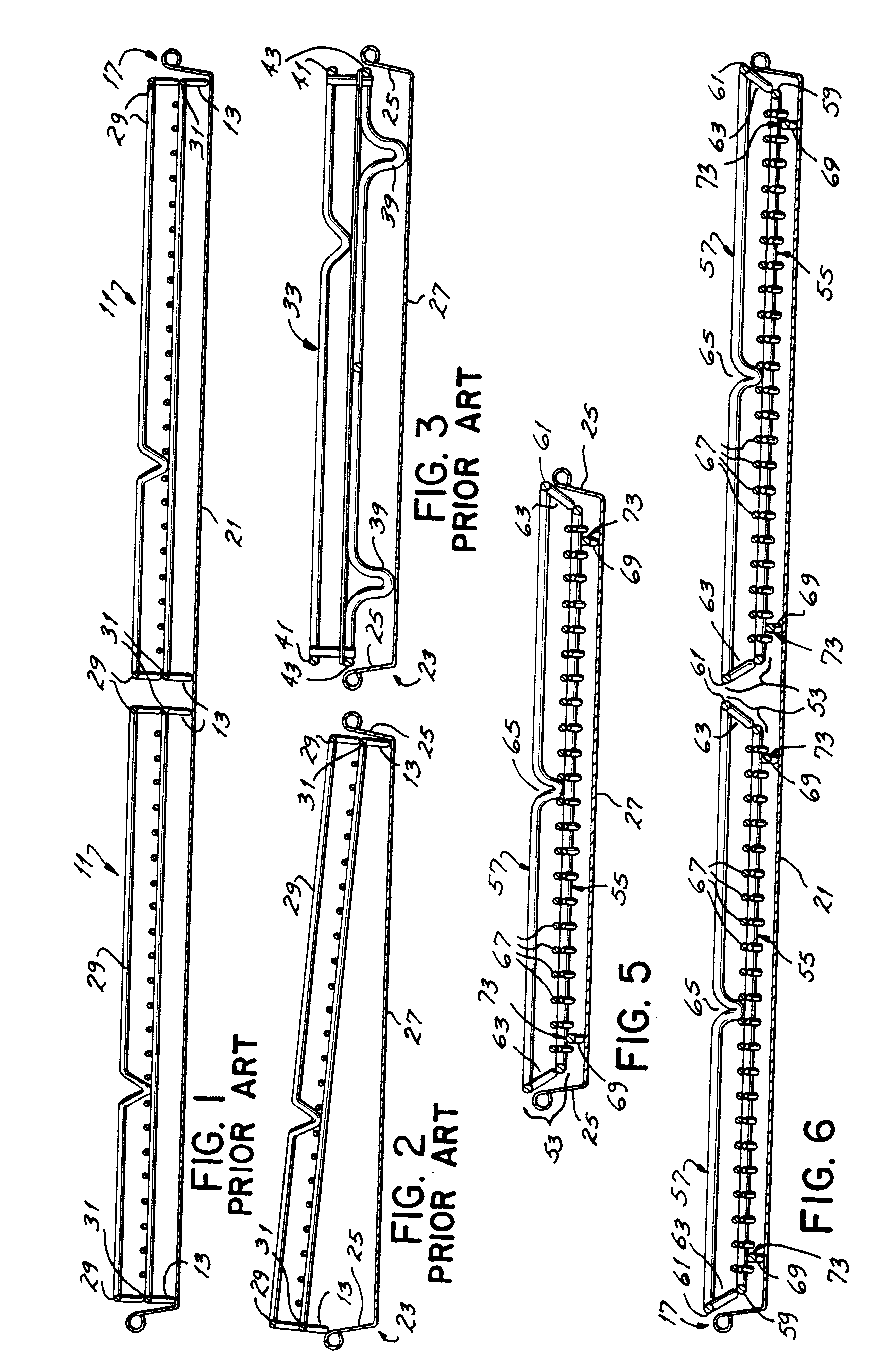

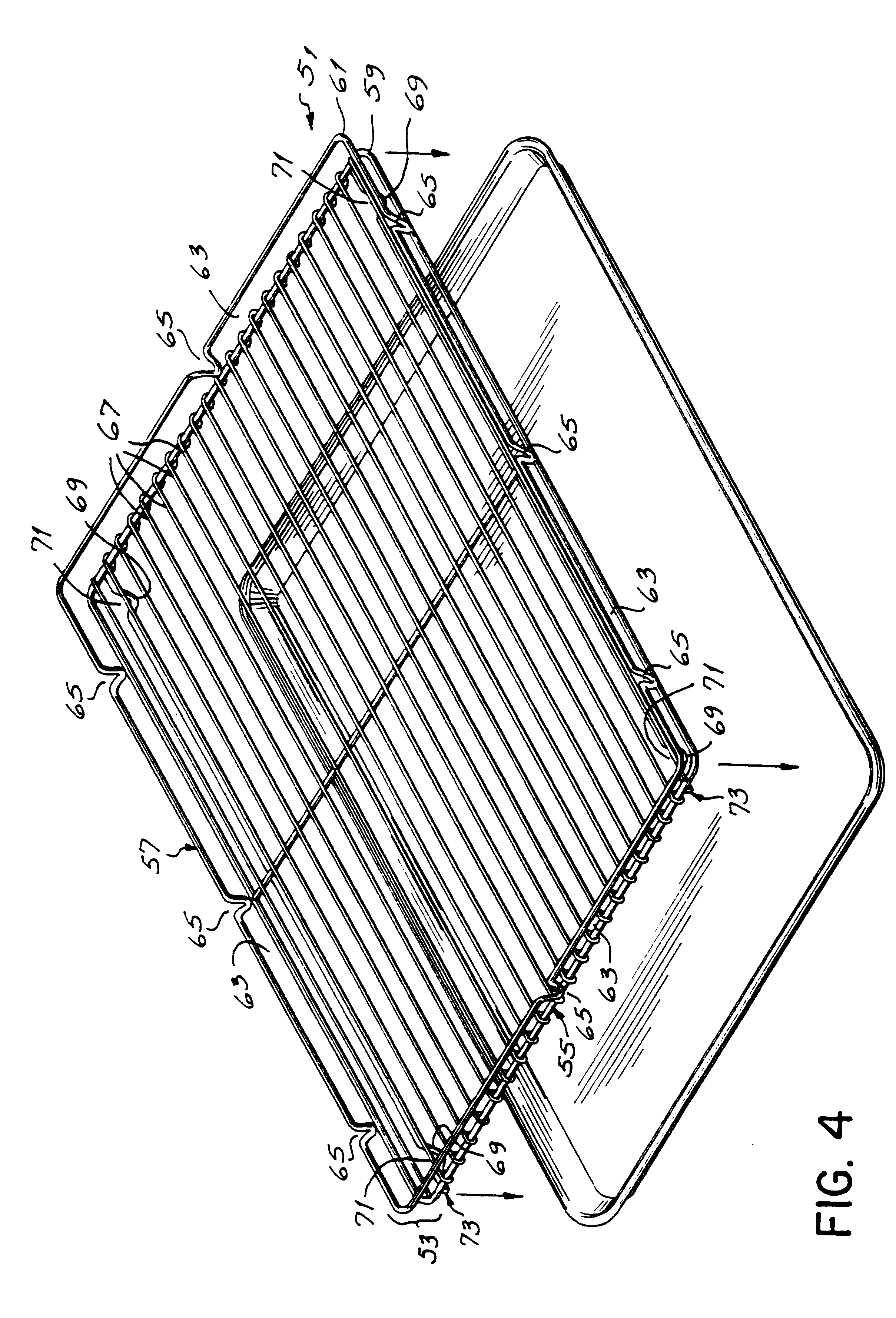

Method for heating (frying) and subsequently supporting or displaying food

<DEL-S DATE="20010424" ID="DEL-S-00001">An improved wire rack for supporting food such as chicken in a Henny Penny pressure fryer and subsequently displaying the fried food in either a single bunn pan or a double bunn pan. The improved rack is capable of being used in all three environments (fryer, single plan and double pan) largely because it has a lower rectangular peripheral edge with a shorter length and width relative to the length and width of the upper rectangular peripheral edge.<DEL-E ID="DEL-S-00001"> <INS-S DATE="20010424" ID="INS-S-00001">A method of heating and subsequently supporting or displaying food, according to the principles of the invention, includes the steps of: placing the food on a wire rack, (the wire rack including: a rectangular frame having a lower border rod and an upper border rod, the lower border rod defining a lower rectangular peripheral edge having a length and a width, and the upper border rod defining an upper rectangular peripheral edge having a length and a width, the upper rectangular peripheral edge having a larger circumference than the lower rectangular peripheral edge, thereby enabling the wire rack to be positioned respectively, in a stable, uncocked position, in a heating device and as a sole rack in a single rack bun pan and as one of a pair of the wire racks in a double rack bun pan, the rectangular frame further including tapered sides between the upper rectangular peripheral edge and the lower rectangular peripheral edge; and a number of support members in the form of a number of wires extending between and attached to opposed sides of the lower border rod so as to create a support surface for the food); positioning the wire rack in a heating device, heating the food in the heating device; removing the wire rack and heated food from the heating device; and placing the wire rack in one of a single rack bun pan and a double rack bun pan, thereby subsequently supporting the food and, if desired, displaying the food.<INS-E ID="INS-S-00001">

Owner:FALCON FABTORS

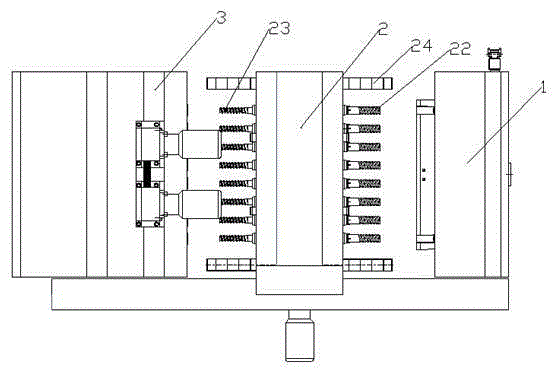

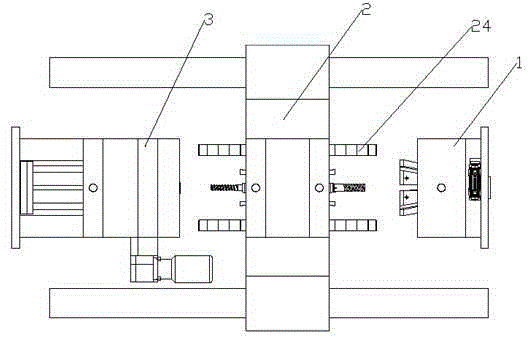

Railway embedded sleeve automatic thread demoulding injection mold and demoulding method

ActiveCN106671353AIncrease productivityReduce length and widthInjection molding machineInjection molding process

The invention relates to a railway embedded sleeve automatic thread demoulding injection mold and a demoulding method. The railway embedded sleeve automatic thread demoulding injection mold comprises a front mold, a back mold, a thread demoulding device, a sliding rotation support and a motor; the back mold is installed on the sliding rotation support, the motor is installed below the sliding rotation support, and the sliding rotation support is installed on an injection molding machine tie bar and can slide along the injection molding machine tie bar; the front mold and the thread demoulding device are arranged at the front portion and the back portion of the back mold correspondingly, the front mold is installed on an injection molding machine fixed mold plate, and the thread demoulding device is installed on an injection molding machine movable mold plate; and the front mold and the back mold are combined into the complete mold, injection molding of the sleeve product is completed, the sleeve product is unscrewed from a back mold thread mold core through thread demoulding device and is ejected out of the mold. Two working procedures including the railway embedded sleeve injection molding process and the thread demoulding process are separated, and automatic thread demoulding is achieved after injection molding; and after the two independent mechanisms are separated, the length and width sizes of the mold can be decreased, one injection molding machine is used, the number of mold cavities can be increased, and the production efficiency of the mold is improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Antenna module and electronic device

PendingUS20220328961A1Shorten the lengthReduce widthSimultaneous aerial operationsAntenna supports/mountingsLow frequency bandMechanical engineering

An antenna module includes a first, a second, a third radiators, and a ground radiator. The first radiator includes a first section and a second section. The second radiator is connected to the first radiator, and includes a third section and a fourth section connected to each other. The fourth section includes a feed end. The third radiator is connected to the third section of the second radiator. The ground radiator is connected to the third radiator. The first, the second, the third, and the ground radiator are sequentially connected in a bent manner to form a stepped shape. The first section of the first radiator and the fourth section of the second radiator jointly resonate at a low frequency band, and the second section of the first radiator, the second radiator, the third radiator, and the ground radiator jointly resonate at a high frequency band.

Owner:PEGATRON

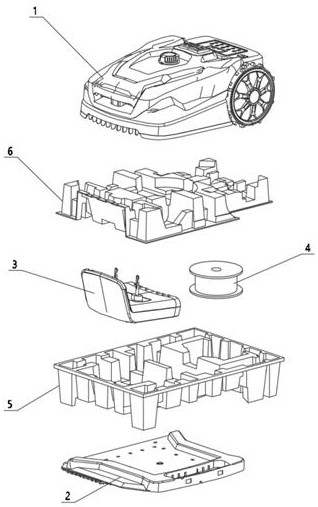

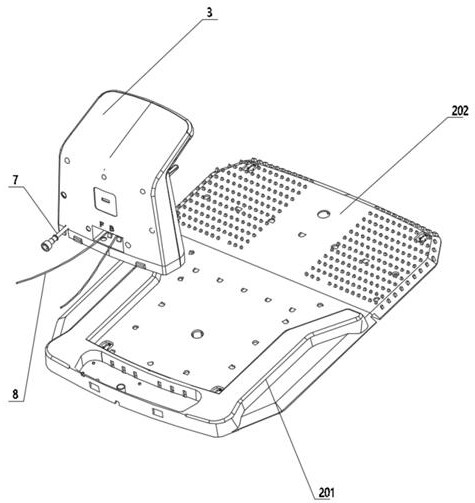

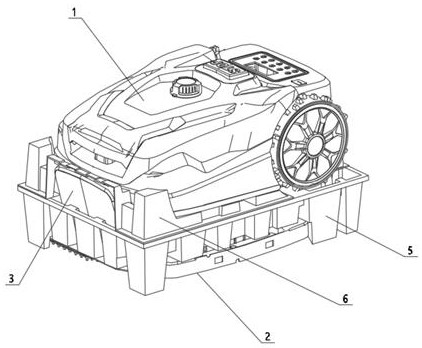

Packaging structure of mowing equipment with foldable charging station

PendingCN113734593AReduce length and widthReduce packaging costsPackaging vehiclesContainers for machinesLogistics managementStructural engineering

The invention discloses a packaging structure of mowing equipment with a foldable charging station. A charging pile of the foldable charging station is detachably connected with a base plate, the base plate comprises at least two base plate units, the charging pile is connected with one base plate unit, the base plate units are unfolded or folded in a movable connection mode, and the charging pile is connected with a power source and a boundary line coil; the packaging structure comprises a first packaging structure and a second packaging structure, and after the first packaging structure and the second packaging structure are in contact with each other, a space for placing the charging pile and the coil is formed inside; the bottom of a complete structure formed after the first packaging structure and the second packaging structure make contact with each other is provided with a space for containing the folded base plate; and the mowing equipment is placed on the top of the complete structure formed after the first packaging structure and the second packaging structure make contact with each other. According to the packaging structure of the mowing equipment with the foldable charging station, the packaging and logistics cost can be reduced.

Owner:NANJING SUMEC INTELLIGENT TECH CO LTD

Semiconductor chip stack structure

ActiveCN102790042BSolution volumeImprove stacking densitySemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor chip

The invention discloses a semiconductor chip stacking structure. A plurality of first chips are stacked, the first chips are arrayed in a stepped stacking manner, a dielectric board is arranged on the first chip on the uppermost layer, a second chip is further arranged on the dielectric board, the first chips are upwards and electrically connected with the dielectric board firstly, and then the dielectric board is electrically connected to a bottom substrate. Therefore, the dielectric board can collect the signals of all chips and transmit the signals to the bottom substrate through less electrical connecting components (such as conducting wires), the number of connecting pads needed by the substrate is relatively reduced, so that the length and width of the substrate can be reduced, and further, the stacking density of the chips is increased, and the packaging size is reduced.

Owner:ADVANCED SEMICON ENG INC

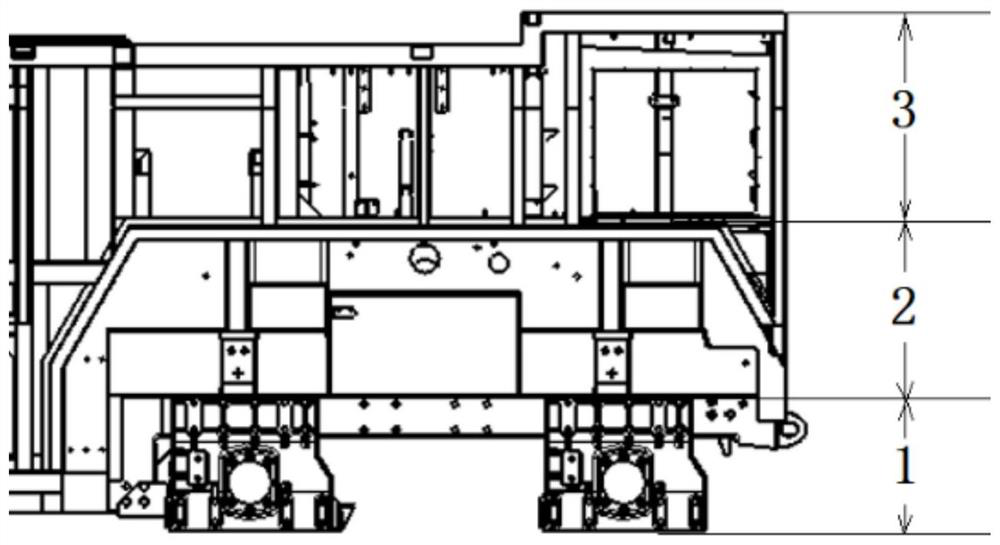

Frame for hybrid electric vehicle, power system and vehicle

ActiveCN113103859AGuaranteed normal drivingReduce length and widthHybrid vehiclesGas pressure propulsion mountingElectric vehicleControl theory

The invention discloses a frame for a hybrid electric vehicle, a power system and a vehicle, the frame for the hybrid electric vehicle comprises a vehicle body front floor, the rear end of the vehicle body front floor is at least connected with one rear frame assembly, and the rear frame assembly comprises a lower-layer frame used for installing vehicle chassis system components. A middle-layer frame used for installing a traditional power system is connected to the upper portion of the lower-layer frame, and an upper-layer frame used for installing a high-pressure power system and other special equipment is connected to the upper portion of the middle-layer frame. The frame is compact in structure, reasonable in power system arrangement and resistant to water logging, has the functions of double-engine running, single-engine running and single-engine power generation, and can meet the function requirement for power generation in the running process.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

Base station antenna

ActiveUS11171411B2Reduce length and widthReduce the overall heightAntenna supports/mountingsRadiating elements structural formsWire rodConverters

The present disclosure provides a base station antenna comprising a balun support component and a substrate. The balun support component comprises a ground circuit and a balun circuit comprising a plurality of bending parts and a plurality of connecting parts which are alternately connected. Each bending part comprises two wires extending in opposite directions and a bending wire connecting the two wires. The substrate comprises a first surface and a second surface opposite to the first surface. The second surface of the substrate is disposed on the balun support component. The first surface comprises an oscillator arm comprising a first end and a second end. The first end is closer to the center of the substrate than the second end. The second surface comprises a metal ring. The balun circuit and the ground circuit are electrically connected to the oscillator arm.

Owner:KUNSHAN LUXSHARE RF TECH CO LTD

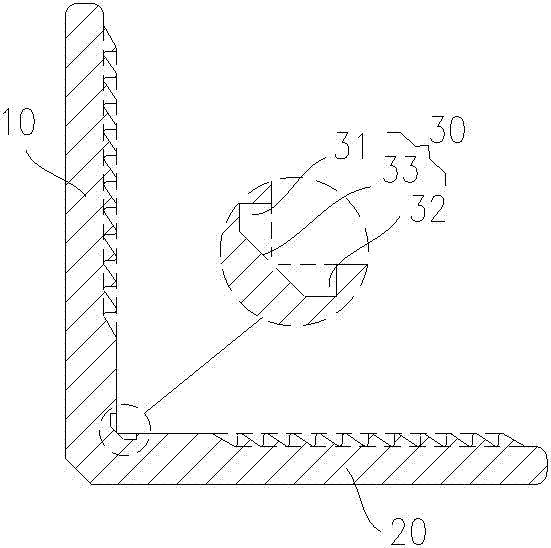

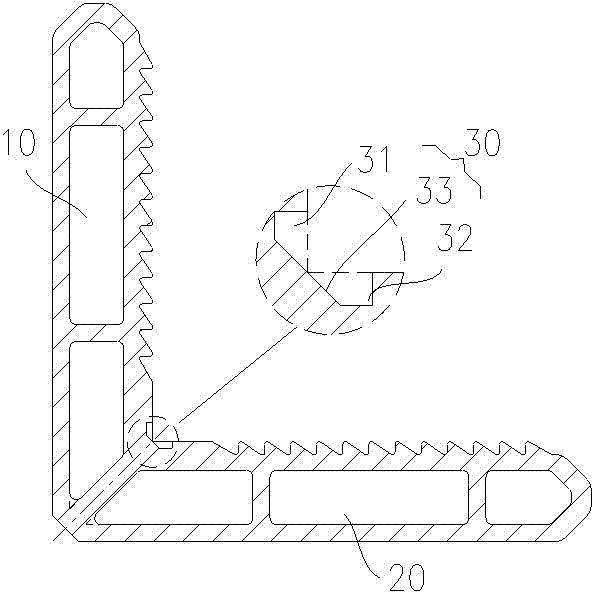

Anti-fool code

ActiveCN105789381BTroubleshoot installation issuesEasy to install automaticallyFinal product manufacturePhotovoltaic energy generationAutomationAerospace engineering

The invention discloses a fool-proof corner connector comprising a vertical plate and a horizontal plate whose left side edge is vertically connected to a lower side edge of the vertical plate. An inner angle of the junction of the vertical plate and the horizontal plate is provided with an empty-avoiding slot, wherein the empty-avoiding slot comprises an upper slot and a lower slot which are set in the vertical plate and the horizontal plate respectively. The lower part of the upper slot and the left part of the lower slot are connected through an inclined plane. An intersecting line of the plane where the right side face of the vertical plate resides and the plane where the upper side of the horizontal plate resides is locate in the incline plane. The advantages of the fool-proof corner connector are that assembly accuracy is high and automation production is facilitated.

Owner:JIANGXI JINKO PV MATERIAL

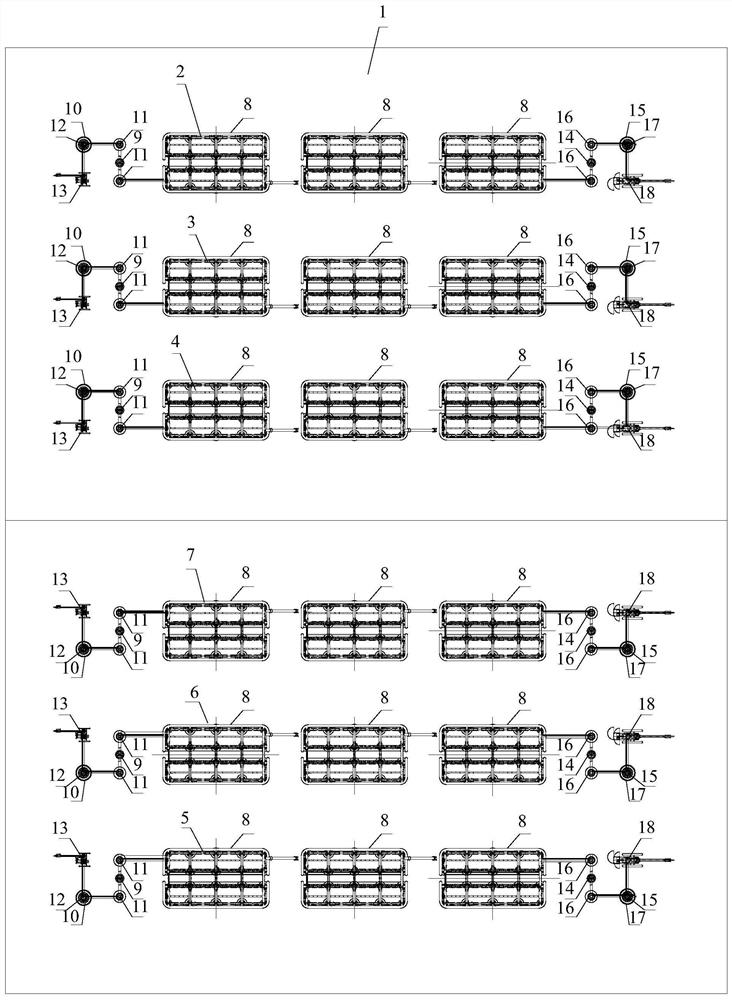

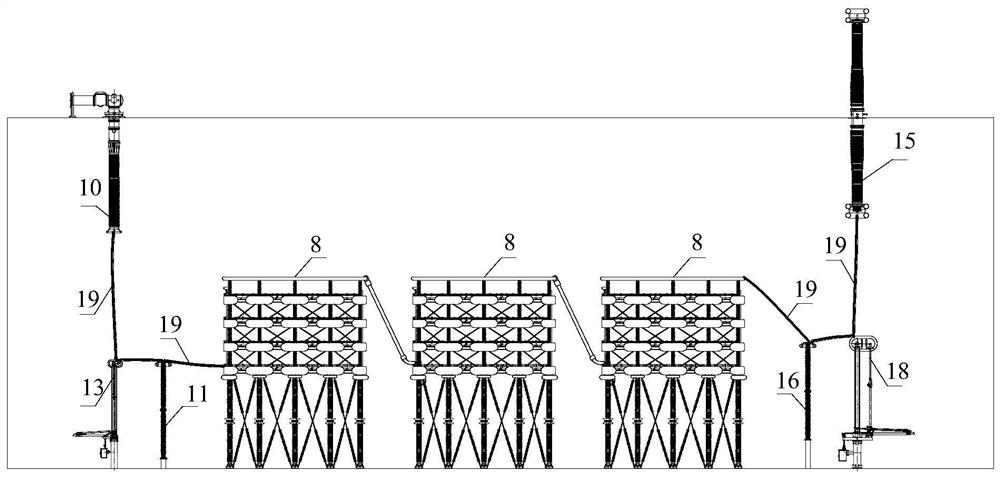

Layout structure and size calculation method of valve hall of offshore flexible DC converter station

ActiveCN112636611BReduce length and widthLow costConversion constructional detailsElectric power transfer ac networkMarine engineeringOffshore wind power

The present invention relates to the technical field of offshore wind power flexible direct current transmission engineering, and discloses an arrangement structure of valve halls of an offshore flexible direct current converter station, including valve halls, the number of which is two, and the two valve halls are arranged symmetrically. There are positive pole A-phase bridge arm, positive pole B-phase bridge arm and positive pole C-phase bridge arm, and the other valve hall is equipped with negative pole A-phase bridge arm, negative pole B-phase bridge arm and negative pole C-phase bridge arm, and two valve halls The six bridge arms inside are symmetrically arranged in "ABCCBA". The invention also discloses a size calculation method for the layout structure of the valve hall of the offshore flexible DC converter station. The valve hall layout structure and size calculation method of the offshore flexible DC converter station of the present invention has simple layout and wiring, clear wiring of the incoming and outgoing lines, and the DC field does not need to pass through the high and low pipe busses to carry out the DC pole line confluence, which can greatly reduce the The length and width of the valve hall of the offshore flexible DC converter station are small, which reduces the project cost.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

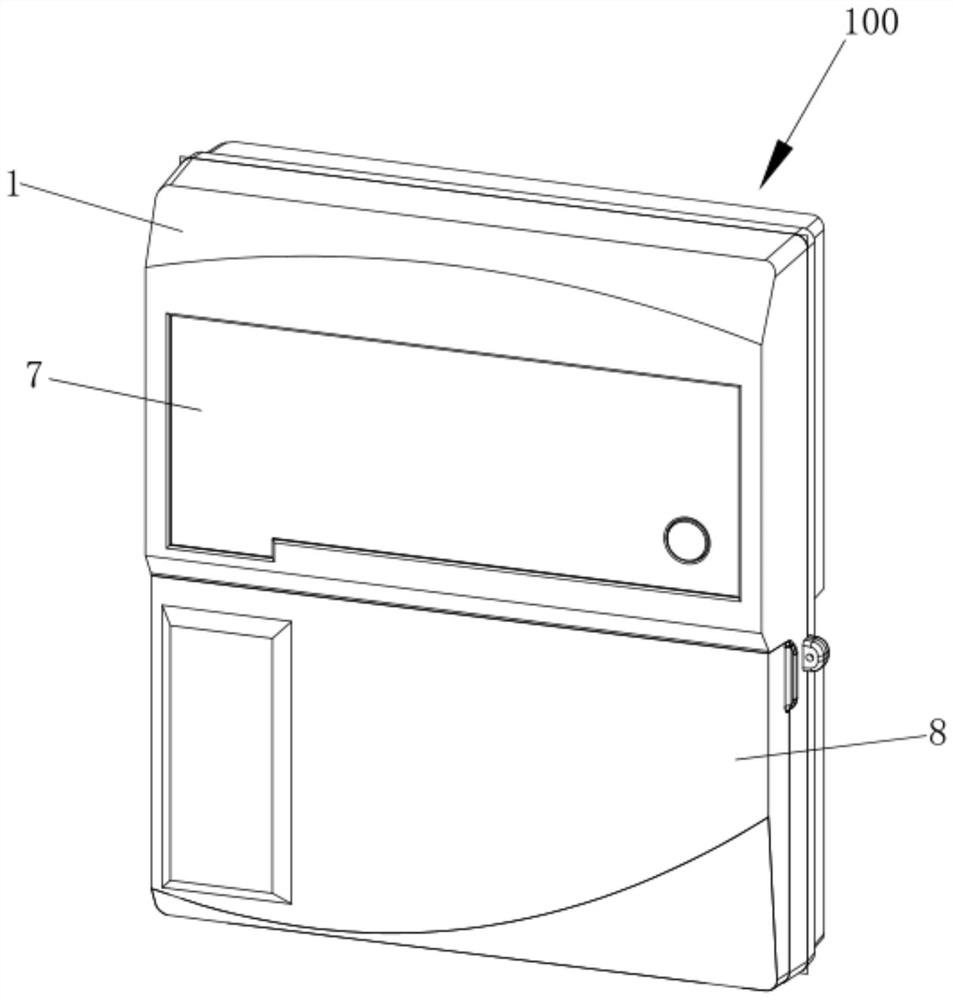

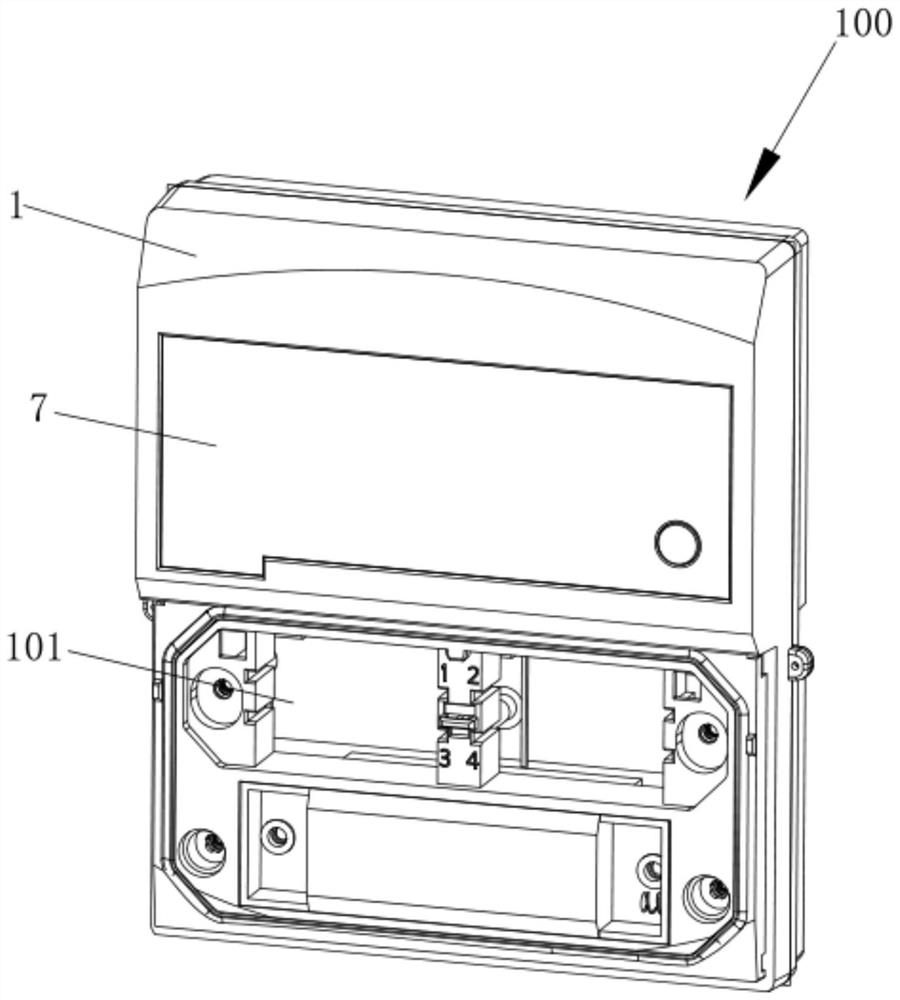

Gas meter with plug-in structure

PendingCN114387726AReduce space consumptionReduce thicknessApparatus for hiring articlesGas meterElectrical connection

The invention discloses a gas meter with a pluggable structure. The gas meter comprises a controller, and the controller comprises a controller shell and a control mainboard arranged in the controller shell; a module pulling and inserting opening is formed in one side face of the controller shell, a switching circuit board is electrically connected to the side, opposite to the module pulling and inserting opening, of the control mainboard, a module is detachably connected to the switching circuit board, and the module is inserted into the controller shell from the module pulling and inserting opening. The switching circuit board is arranged on the side, opposite to the module plugging port, of the control mainboard, and the module is plugged into the controller shell from the module plugging port to be connected with the switching circuit board in a plugging manner, so that the plugging design of the module is realized, and the optimization design of the internal space of the controller shell is also realized; on the premise of not sacrificing the installation number of the modules, the thickness, the length and the width of the whole controller shell can be reduced, and the purposes of reducing the product cost and beautifying the product appearance are achieved.

Owner:SHENZHEN FRIENDCOM TECH DEV

Thermotank shell with automatic trigger protection function

PendingCN114803112AReduce length and widthEasy to carryShock-sensitive articlesContainers to prevent mechanical damageElectric machineryImpact

The invention discloses a constant-temperature box shell with an automatic trigger protection function, relates to the technical field of constant-temperature boxes, and solves the problems that an existing constant-temperature box is prone to being impacted seriously after falling off, medicine is damaged, and use is inconvenient. A plurality of outer baffles are fixedly arranged on the outer side of the main box body; a top plate is fixedly arranged in the middle of the top of the main box body; the left side and the right side of the top plate are each rotationally provided with a cover plate through a hinge. Two connecting rods are embedded in the base and the top plate in a sliding manner; a lower connecting plate is fixedly arranged at the bottom ends of the two connecting rods; a springback switch is embedded in the inner side of the bottom of the base; and a motor is embedded in the left side of the top of the base. According to the device, all the impact blades can be rapidly unfolded to cope with impact, the impact force on the constant-temperature box can be effectively reduced, and the medicine in the constant-temperature box can be well protected.

Owner:郭秉生

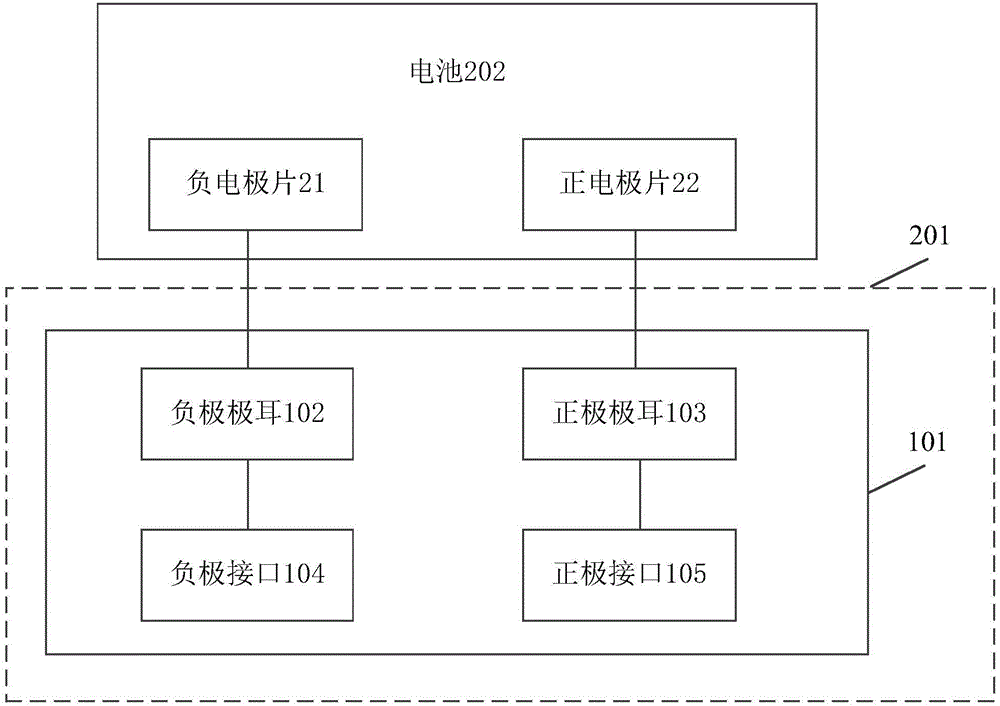

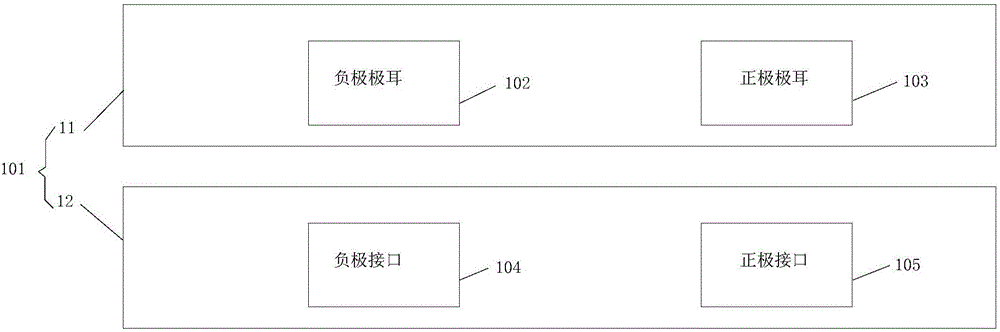

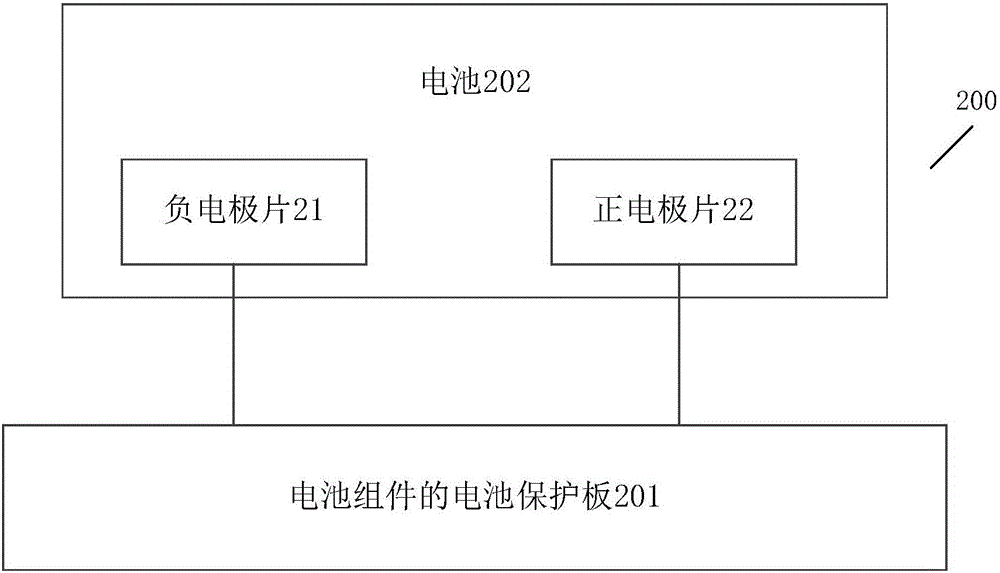

Terminal, battery module and battery protection plate for battery module

ActiveCN106684277AReduce wire resistanceReduce length and widthFinal product manufactureSmall-sized flat cells/batteriesElectrode interfaceWire resistance

The invention discloses a terminal, a battery module and a battery protection plate for the battery module. The battery protection plate for the battery module comprises a body, a negative electrode tab and a positive electrode tab arranged on the body, and a negative electrode interface and a positive electrode interface formed in the body, wherein the positive electrode tab is connected with a negative electrode plate of a battery in the battery module while the positive electrode tab is connected with a positive electrode plate of a battery in the battery module; the negative electrode interface is connected with the negative electrode tab while the positive electrode interface is connected with the positive electrode tab, wherein the distance between the negative electrode interface and the negative electrode tab is less than a first preset distance; and the distance between the positive electrode interface and the positive electrode tab is less than a second preset distance. Therefore, the positive electrode interface and the negative electrode interface can be arranged according to the positions of the positive electrode tab and the negative electrode tab, so that length and width of routing wires can be reduced, the wire resistance of the battery protection plate is lowered, and a heating condition caused by an overhigh current can be relieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com