Double-sided encapsulation shell for parallel seam welding

A technology of parallel seam welding and encapsulation of shells, which is applied in the direction of electrical components, electric solid devices, circuits, etc., and can solve problems such as the inability to apply double-sided packaging of integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

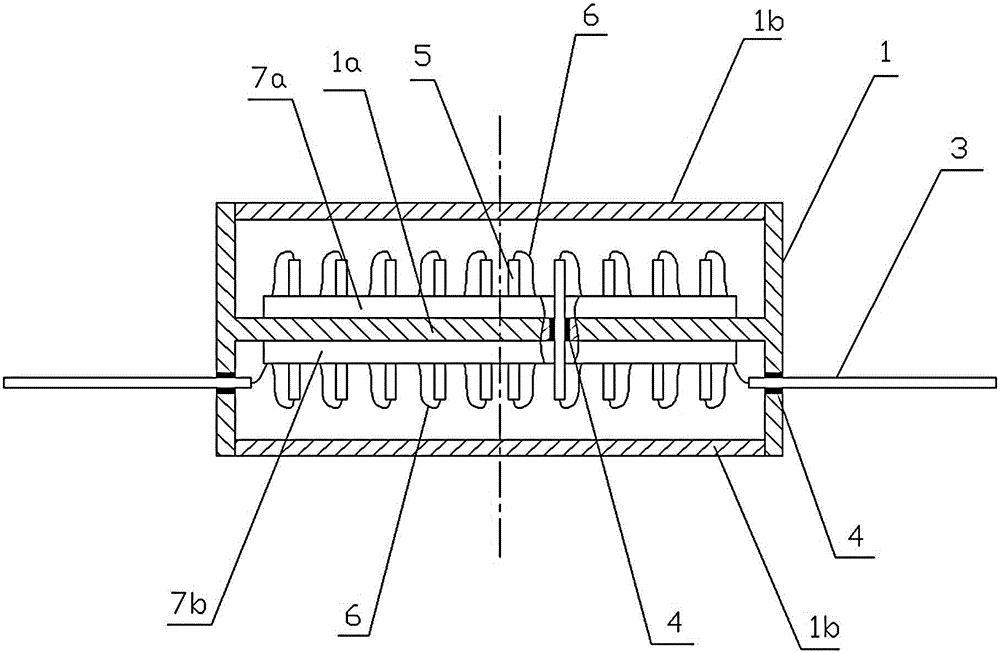

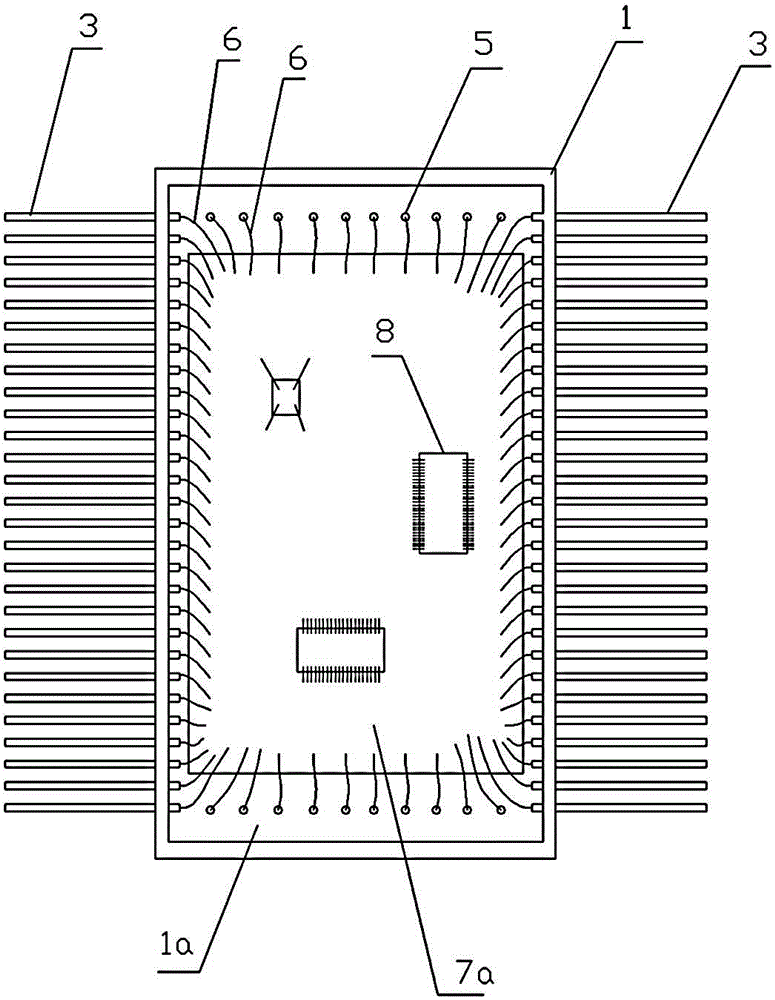

[0021] A double-sided encapsulation enclosure for parallel seam welding, such as figure 1 As shown, a sealed box 1 is included, and a partition 1a is arranged in the sealed box 1. The partition 1a divides the sealed box 1 into upper and lower two-layer box cavities, and a box cover 1b is arranged on each layer of box cavities, and each box cover 1b Seal welding with the sealing box 1 by parallel seam welding. Both the sealed box 1 and the box cover 1b are made of metal. A group of guide pillars 5 are respectively connected to both ends of the partition 1 a, and each guide pillar 5 is sealed and connected to the partition 1 a through a glass insulator 4 . One end of each guide post 5 is in the upper box cavity, and the other end is in the lower box cavity.

[0022] The upper surface of the separator 1a is connected to the upper sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com