Method for heating (frying) and subsequently supporting or displaying food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

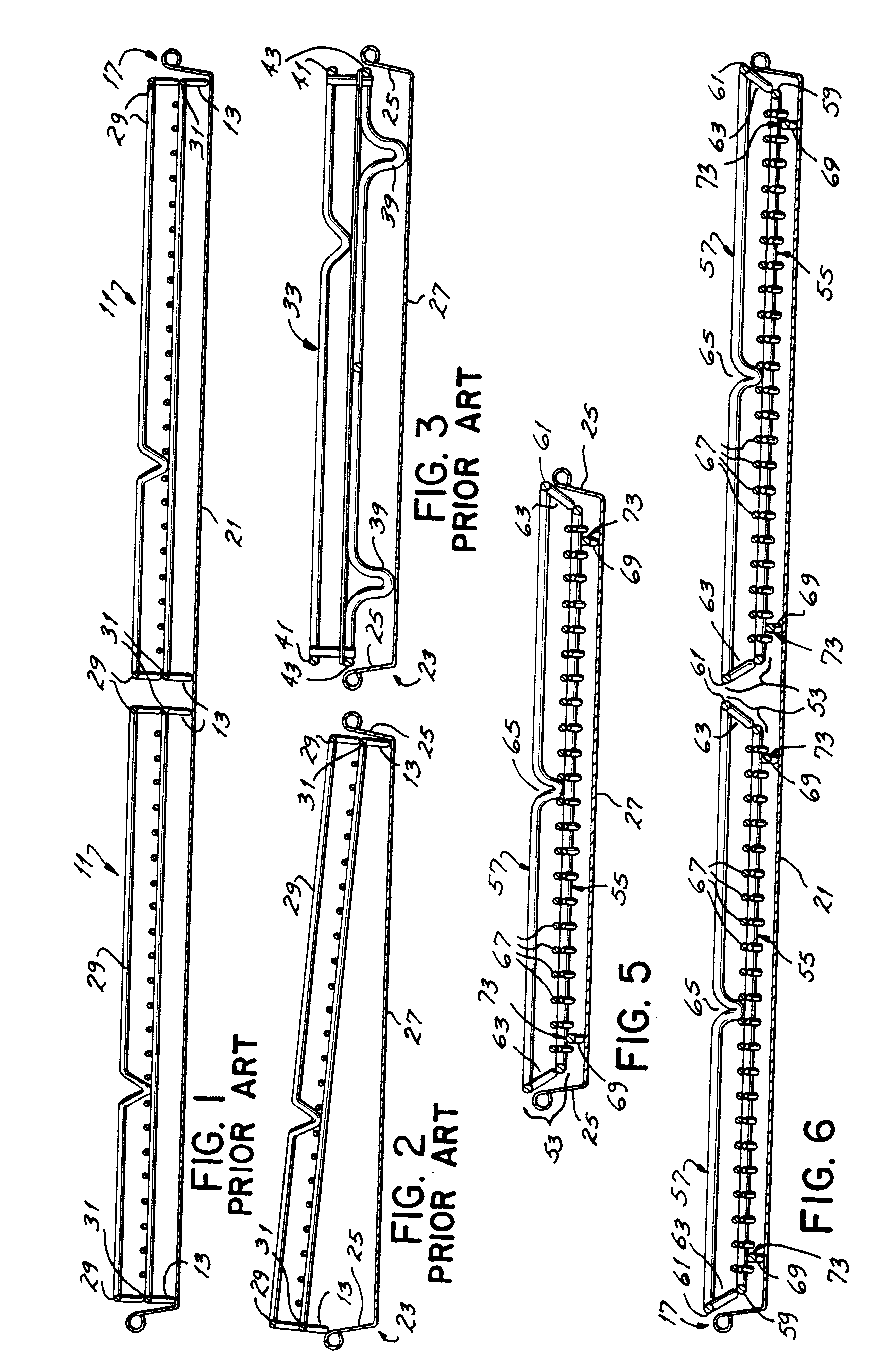

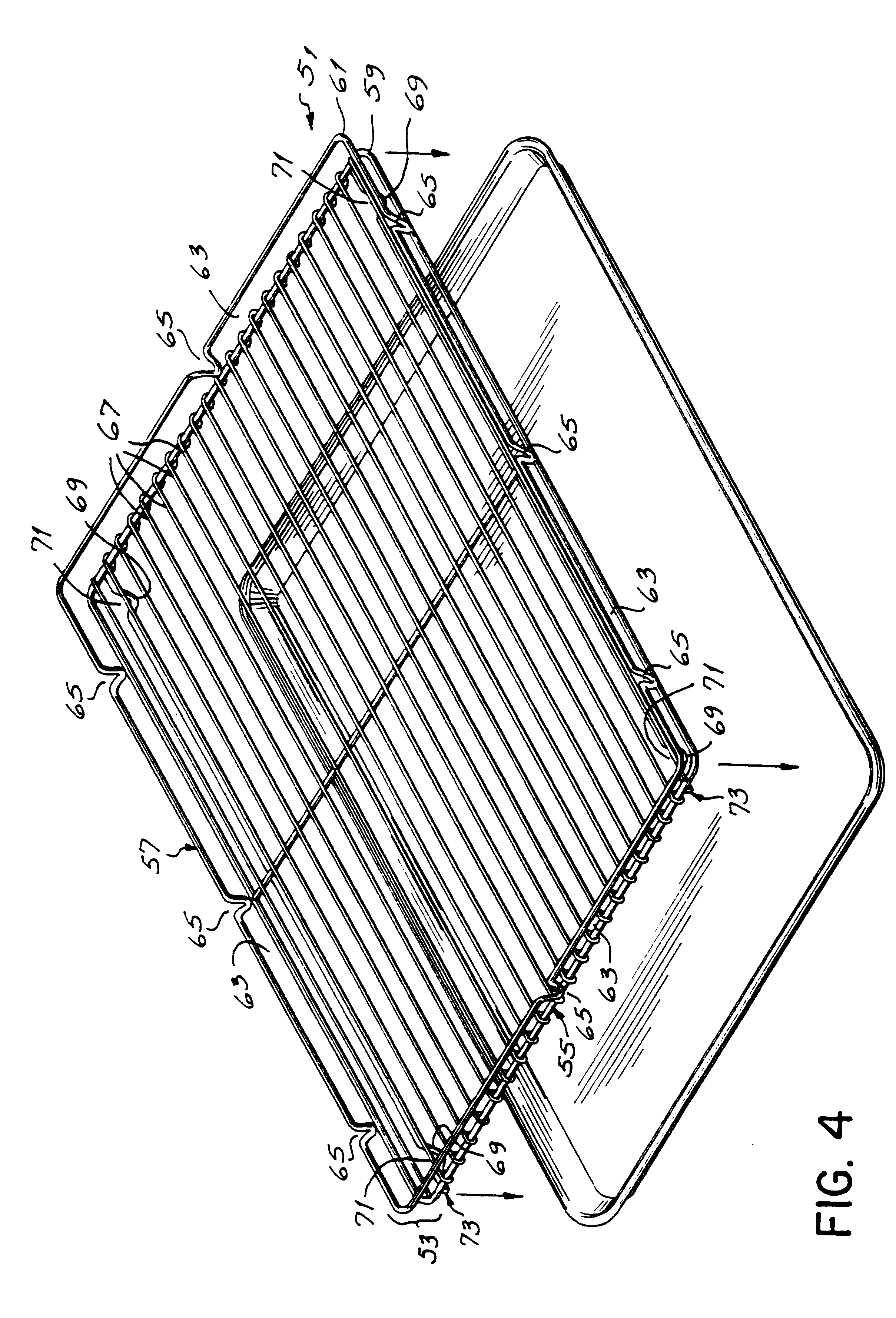

In order to appreciate fully the inventive aspects of the improved wire rack, it is helpful to take a detailed look at some of the features of the racks used in the prior art.

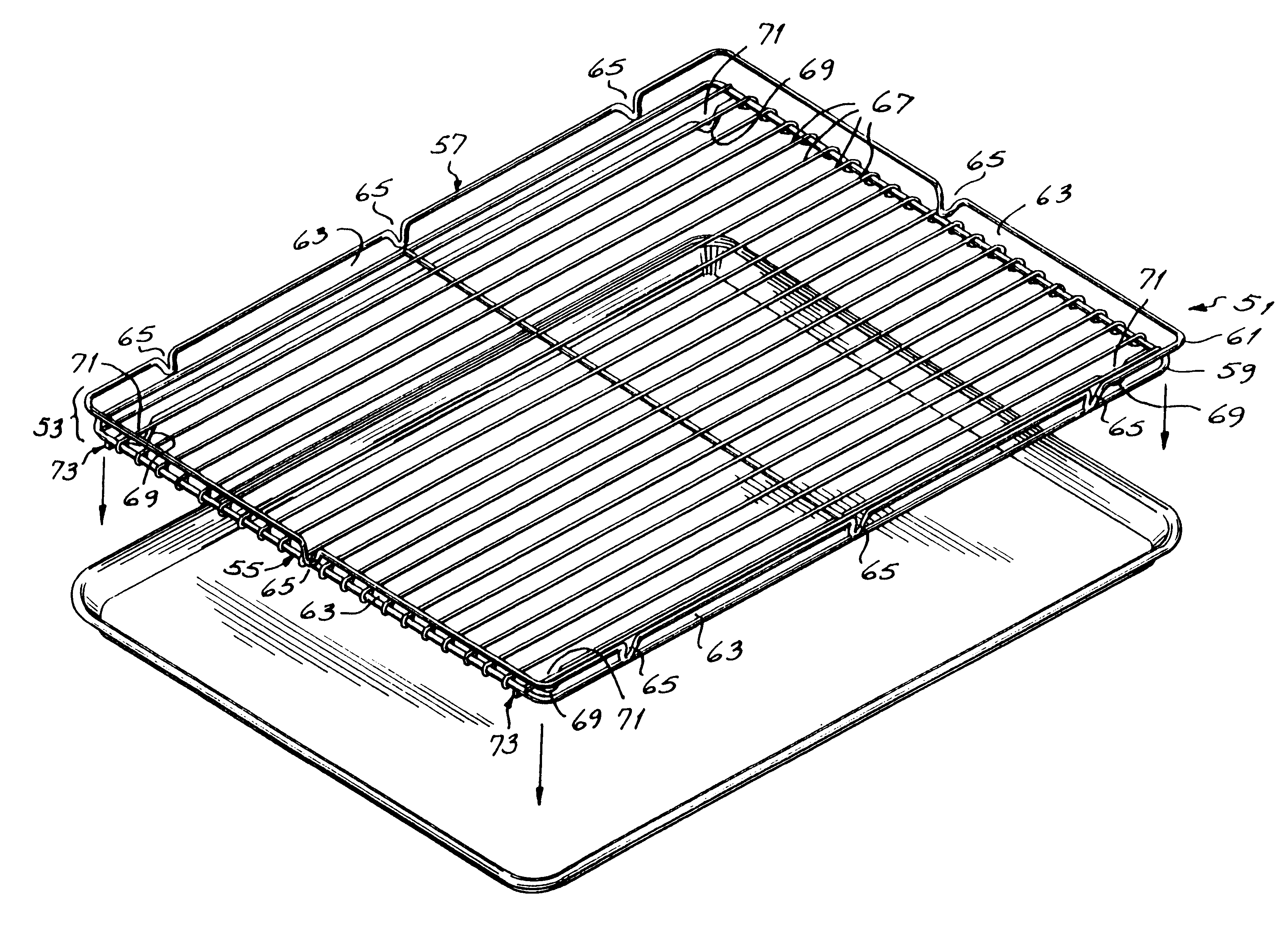

In the fried chicken business, the food goes through several stages of preparation, including a frying stage and a display stage. In the frying stage, pieces of chicken are placed on wire racks and those wire racks are then placed in holding racks which are inserted into pressure fryers, as for example fryers made by the Henny Penny Corporation. The Henny Penny fryers, prevalent throughout much of the industry, cannot accommodate all types of racks. In order to be compatible with these fryers, the racks must fit into special holding racks which then fit into the pressure fryers. Racks previously designed specifically for the Henny Penny Pressure fryer are shown in FIG. 1. These racks 11 (hereinafter Henny Penny racks) are shown side by side in a double rack .[.bunn.]. .Iadd.bun .Iaddend.pan 17. Each Henny Penny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com