Stage wood floor and preparation method thereof

A wooden floor and stage technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of uneven internal and external quality, processing technology standards, etc., to improve stability, improve internal quality, avoid active ingredients and The effect of partial loss of beneficial attributes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

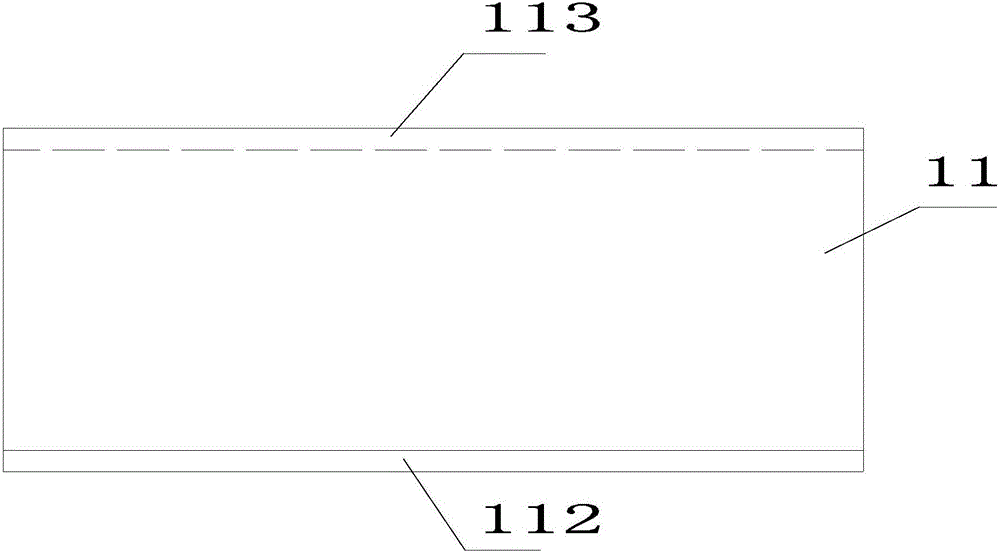

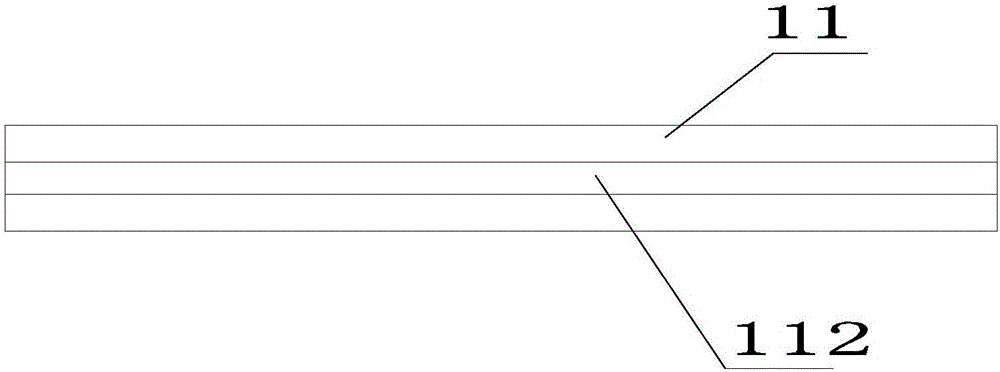

[0044] Such as Figure 1 to Figure 5 As shown, a kind of stage wooden floor of the present embodiment comprises multi-layer spliced plywood 1, between every two spliced plywood 1 is bonded and fixed by adhesive, each spliced plywood 1 is made of a plurality of quarter-cut boards 11 horizontal finger joints.

[0045] The stage wooden floor of this embodiment is formed by horizontal finger-jointing of a plurality of quarter-sawn boards, which greatly reduces the length or width of the wood fiber of the floor blank, thereby greatly reducing the internal stress of the floor blank and improving the stability of the floor. In addition, as trees are natural growths, they must have natural defects such as knots, color difference, pith spots, insect eyes, resin capsules, and partial decay, and the finger-jointed horizontal splicing process can be selected and matched according to people's wishes, so that it can be greatly improved. Improve the intrinsic quality and appearance of...

specific Embodiment approach

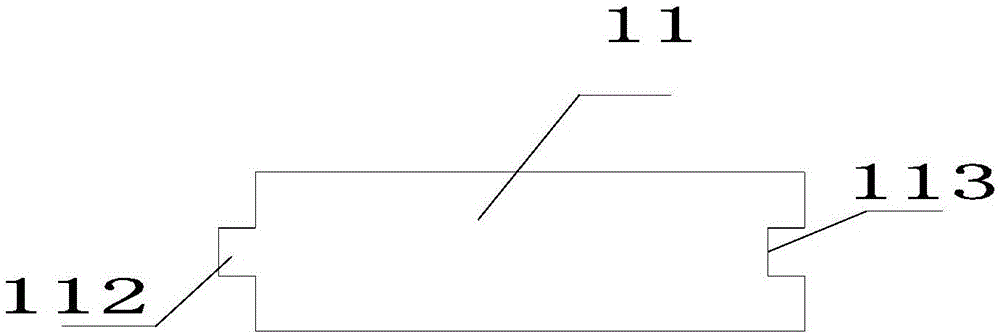

[0049] There are two specific implementations for the finger joint of the quarter-sawn board 11 in this embodiment, as follows:

Embodiment approach 1

[0050] Embodiment 1: The finger-joints 111 of the two quarter-sawn boards 11 that are finger-joined with each other in each spliced plywood layer 1 are in a zigzag shape that engages with each other. Serrated finger joints are located along the length of the quartersawn board. The finger-joining method of this embodiment makes the connection between two adjacent quarter-sawn plates more firm and stable. The serrated finger joints arranged in the length direction increase the connection length of two adjacent quarter-sawn slabs and make the connection more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com