Packaging structure of mowing equipment with foldable charging station

A packaging structure and charging station technology, applied in packaging, packaging food, transportation and packaging, etc., can solve the problems of waste of container space, increase packaging cost, increase logistics cost, etc., achieve cost savings, reduce packaging volume, packaging structure less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

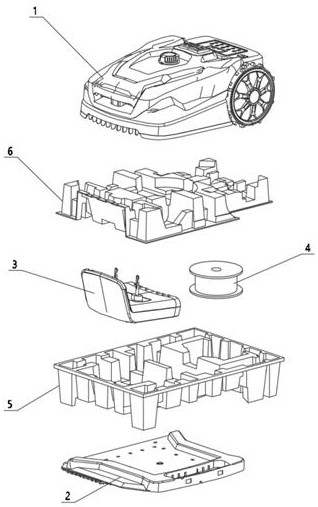

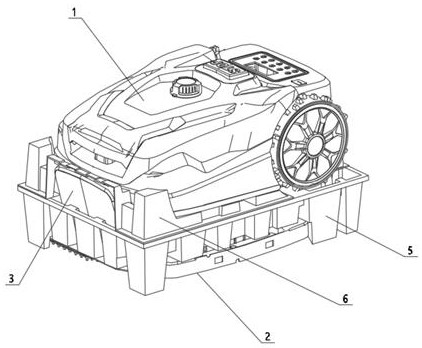

[0055] Such as figure 1 , 3 , 4, the packaging structure includes an upper packaging structure 6 and a lower packaging structure 5. The upper and lower packaging structures are two cover-like structures with opposite openings. The space for placing the charging pile 3, the coil 4 and other spare parts, the bottom of the lower packaging structure is provided with a space for placing the folded substrate, and the top of the upper packaging structure can be placed for mowing equipment 1.

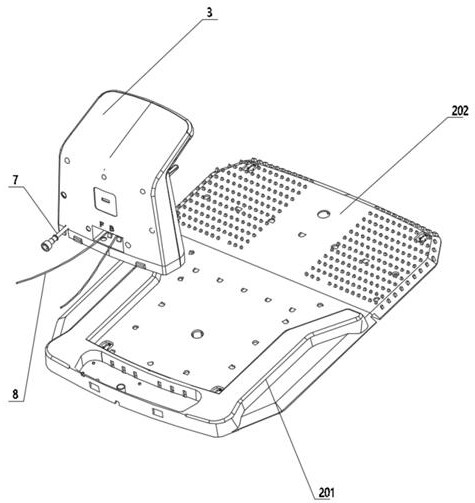

[0056] Such as Figure 5 , 6 Shown is the upper packaging structure 6, the opening of the upper packaging structure 6 faces downward, and the top of the upper packaging structure 6 is provided with front wheel grooves 602 and rear wheel relief openings 603 corresponding to the front wheels, rear wheels, and mowing cutter heads on the mowing equipment. And the cutter head groove 601, the position of the rear wheel relief port 603 is also provided with a shaft groove 604, and the bottom of the...

Embodiment 2

[0062] The difference between Embodiment 2 and Embodiment 1 is that upper positioning parts 605 are provided at the four corners of the upper packaging structure 6, and the upper positioning parts 605 are protrusions that cover the shell of the mowing equipment, and at the same time, the upper positioning parts The outside shape of the outer part fits the outer packing box.

[0063] There is a certain distance between the upper positioning parts 605 at one end of the tail of the mowing equipment, which leaves the middle of the tail of the mowing equipment free for easy grasping. Usually, the gripping position of the mowing equipment is located at the bottom of the middle of the tail of the mowing equipment.

[0064] A substrate groove 504 is provided at the bottom of the lower packaging structure 5 for placing the folded substrate 2 . A lower positioning part 506 is arranged around the bottom of the lower packaging structure 5. The inner side of the lower positioning part 506 ...

Embodiment 3

[0068] As a further improvement of Embodiment 1 and Embodiment 2, after the charging pile 3 is placed in the charging pile placement slot 501, the end of the charging pile 3 is located at the end of the lower packaging structure 5 and protrudes from the opening end of the lower packaging structure 5. The position of the upper packaging structure 6 corresponds to the charging pile 3. There is a charging pile relief opening 606, which leaves space to prevent the charging pile from being squeezed. Forming a section structure similar to a wave or pulse shape, it has a certain degree of elasticity and support strength. During transportation, when the charging pile shakes and collides with the side wall of the packaging structure at the charging pile exit 606, it can be cushioned to improve protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com