Solar cell module junction box terminal bending device and bending system provided with same

A technology of solar cells and bending devices, which is applied in electrical components, photovoltaic power generation, photovoltaic modules, etc., can solve problems such as rising labor costs, increasing component production costs, and violations of low cost, high efficiency, and high quality. Accuracy and repeatability, convenient automatic installation, reducing the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

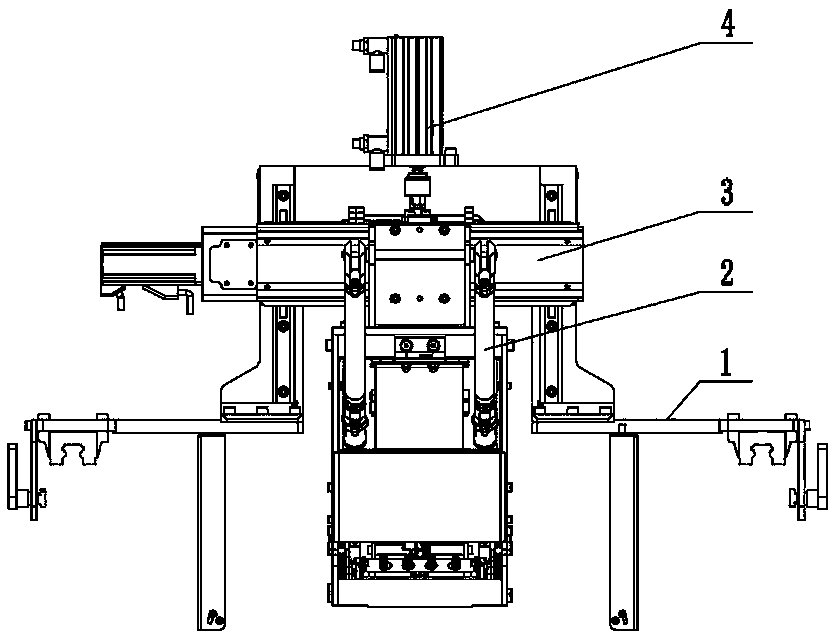

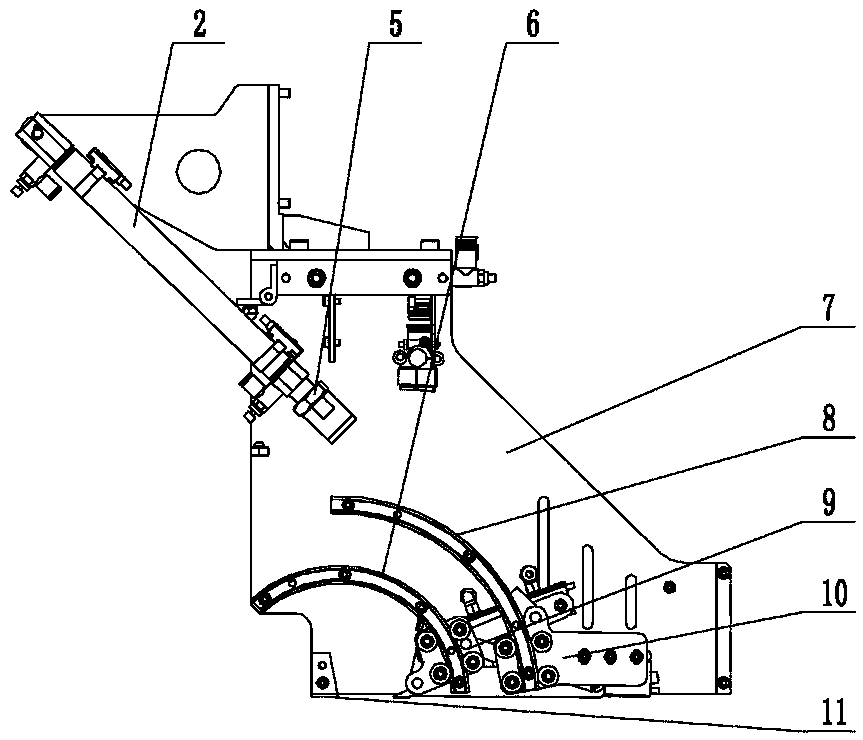

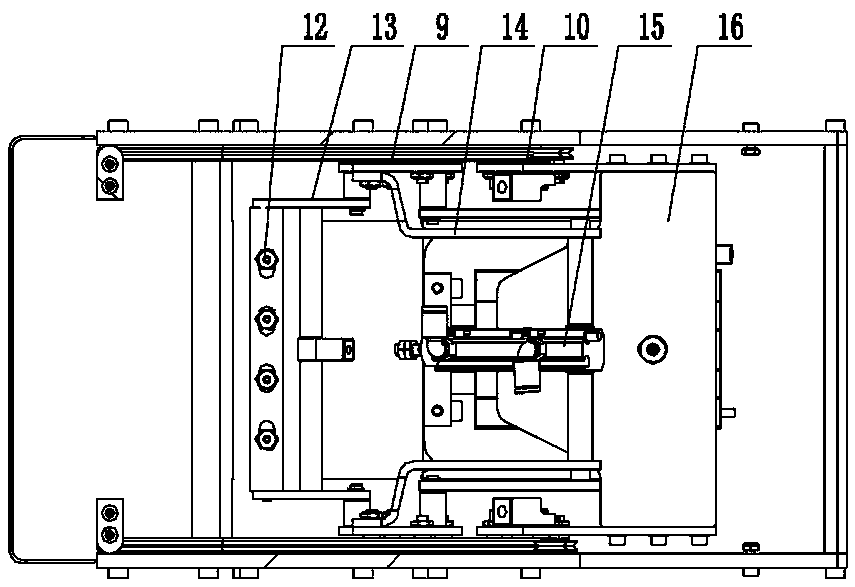

[0022] The solar cell module terminal box terminal bending device of the present invention includes a body 7, which is characterized in that: a positioning block 11 is arranged at the bottom of the body 7, and an inner arc guide rail 6 and an outer arc are arranged on the body 7 with the positioning block 11 as the center of the circle. Guide rail 8, described outer arc guide rail 8 is provided with scraper mechanism by outer slider 10, and described inner arc guide rail 6 is provided with sucker mechanism by inner slider 9; Described body 7 is provided with and scraper plate The bending cylinder 2 connected by the mechanism.

[0023] As a preferred solution of the present invention, a linkage rod is provided between the scraping mechanism and the inner slider 9 .

[0024] The scraper mechanism includes a mounting plate 16, the two sides of the mounting plate 16 are connected to the outer slider 10; a scraper cylinder 21 is arranged below the installation plate 16, and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com