Suspension bridge catwalk laying construction system

A technology for suspension bridges and catwalks, applied in suspension bridges, bridge construction, bridges, etc., can solve problems such as time-consuming and labor-intensive work, safety hazards of high-altitude operations, etc., and achieve the effect of ensuring safety and improving the efficiency of catwalk paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

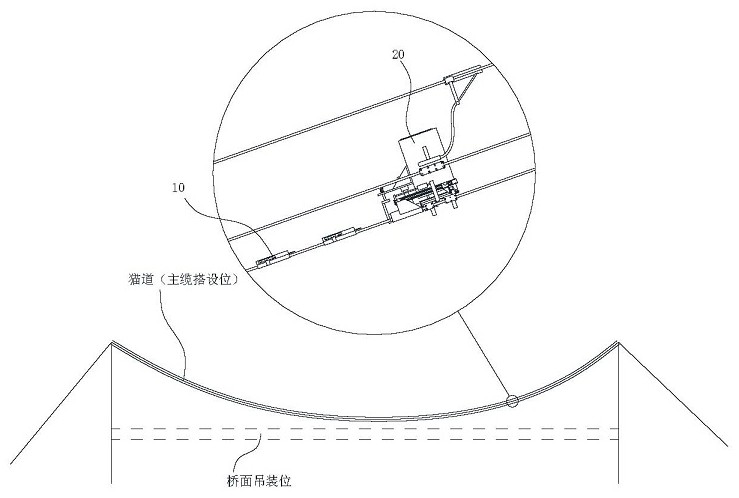

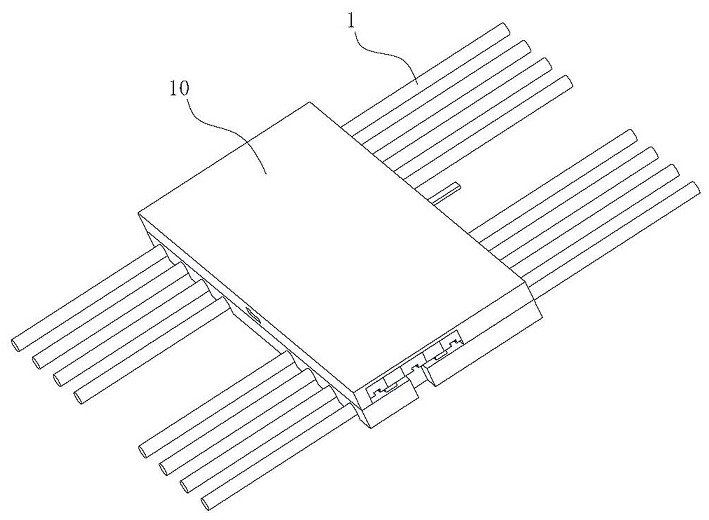

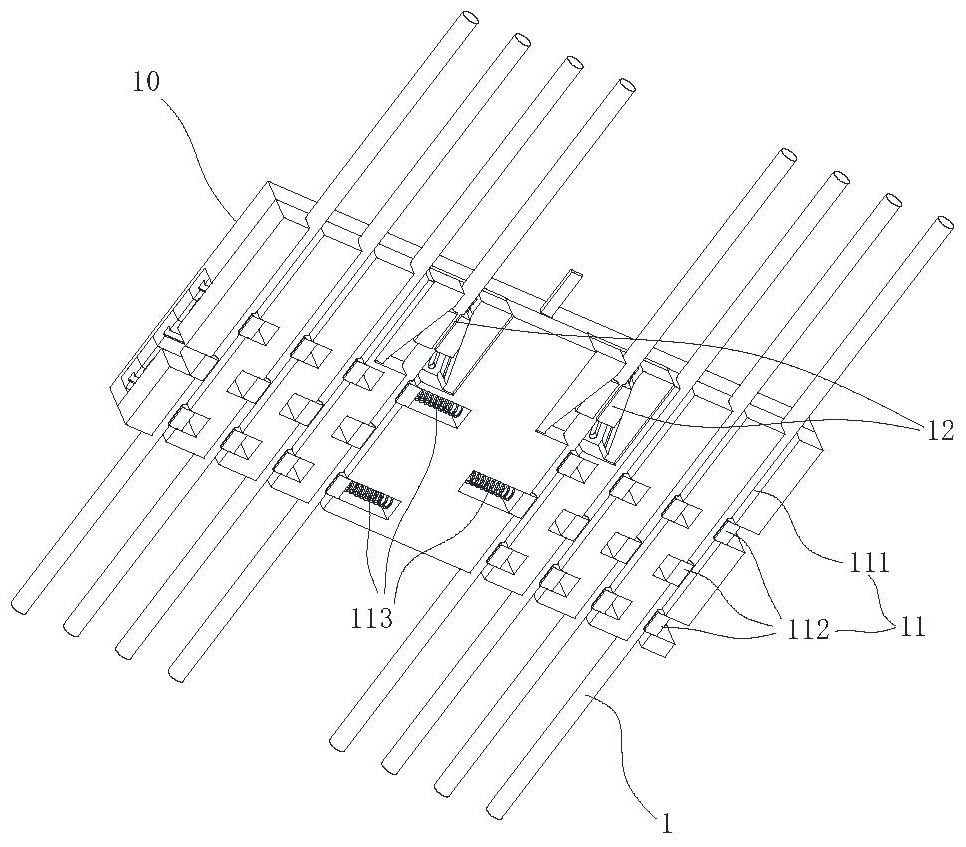

[0039] like figure 1 Shown, a kind of suspension bridge catwalk laying construction system comprises catwalk board 10 and laying device 20; As Figure 1-14 As shown, the catwalk board 10 includes a plate-shaped body, the bottom of the plate-shaped body is provided with a first clamping mechanism 11 for preventing the radial displacement of the plate-shaped body along the catwalk load-bearing cable 1, and for preventing the board The second clamping mechanism 12 for axially displacing the catwalk load-bearing cable 1 along the catwalk load-bearing cable 1; And the first clamping mechanism 11 and the second clamping mechanism 12 can be driven to clamp the catwalk load-bearing cable 1 when the downward pressure is applied to the plate-shaped body; Figure 15-21 As shown, the laying device 20 includes a material storage rack 21 for stacking catwalk boards 10, and the bottom and both sides of the storage rack 21 are respectively provided with a rolling joint with the catwalk load-...

Embodiment 2

[0050] A kind of suspension bridge catwalk laying construction method, comprises the steps:

[0051] Step 1: Set up catwalk load-bearing cables 1, catwalk guardrail cables 2 and catwalk traction cables 3, of which catwalk load-bearing cables 1 are 6-8 and are located in the same plane, and catwalk guardrail cables 2 are two in the most Above the two catwalk load-bearing cables 1 on the outside, two catwalk traction cables 3 are respectively located above the two catwalk load-bearing cables 1 in the middle, and the catwalk traction cables 3 are connected to the hoist;

[0052] Step 2: Install the catwalk board 10 laying device 20 on the catwalk load-bearing cable 1 and the catwalk guardrail cable 2, and connect the catwalk board 10 laying device 20 with one of the catwalk traction ropes 3 with a rope and a traction frame 4 ;

[0053] Step 3: Stack the catwalk board 10 in the catwalk board 10 laying device 20, use the catwalk traction rope 3 to place the catwalk board 10 laying...

Embodiment 3

[0061] A method for dismantling catwalk boards, pressurizing the locking plate 114 in the catwalk board 10 from both sides of the catwalk board 10, so that the locking groove 1141 on the locking board 114 is facing the locking pin 115, locking Under the action of the second elastic unit 1152, the pin 115 pushes the locking pin 115 into the locking groove 1141 to lock the first clamping block 112 in the open state, and then the catwalk board 10 is lifted upwards, so that the first clamping mechanism 11 separates with catwalk load-bearing cable 1.

[0062] The removal method also includes: applying pressure to the driving frame 13 in the catwalk board 10 along the length direction of the catwalk load-bearing cable 1, so that the second clamping block 122 moves to the end where the two guide surfaces are far away from each other, and the second clamping block 122 moves the catwalk The load-bearing cable 1 is loosened, and then the locking plate 114 in the catwalk plate 10 is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com