Prefabricated Laminated Panel Wire Box Fixtures

A technology of fixing device and laminated plate, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem of increasing the construction cost of mold types, and achieve the effect of reducing the types of molds used, reducing construction costs, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

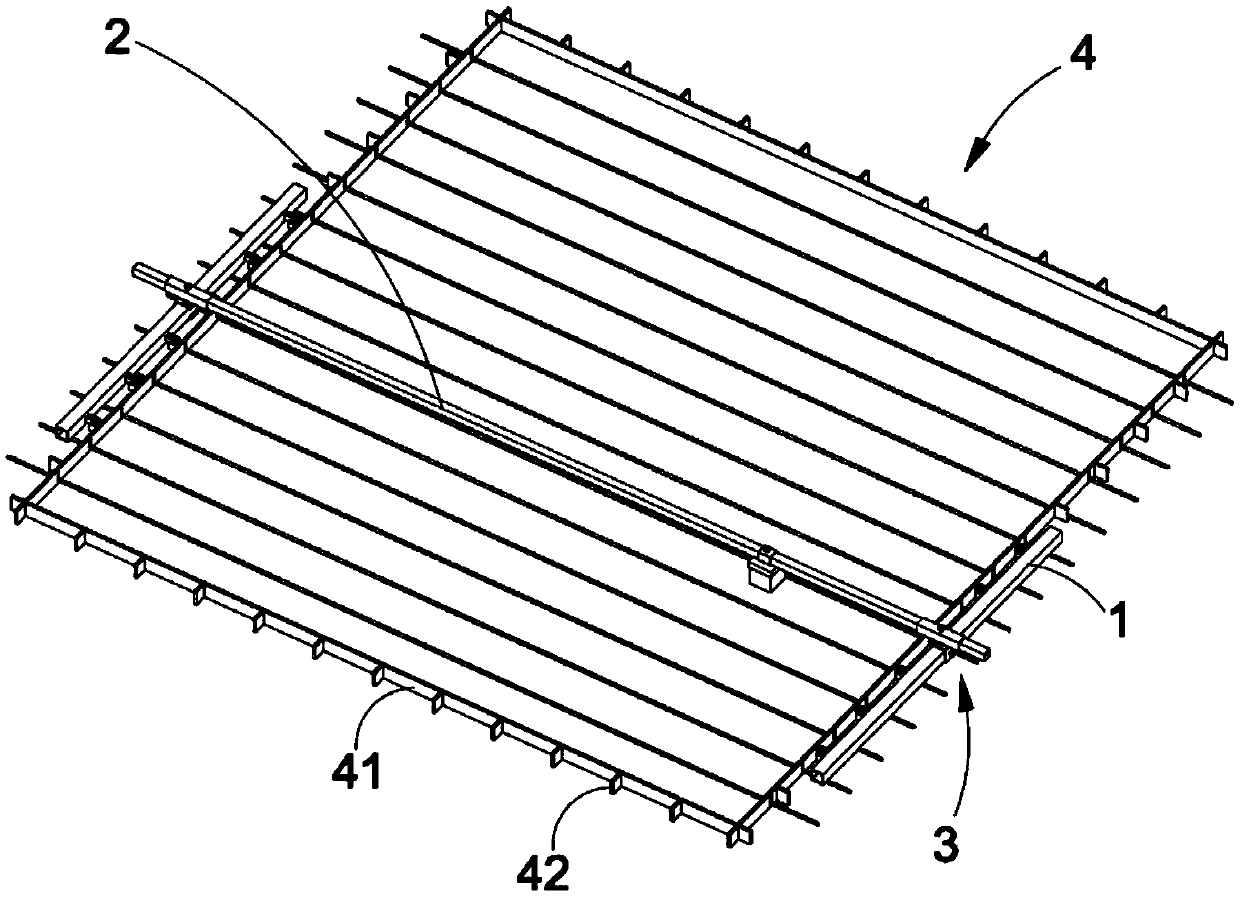

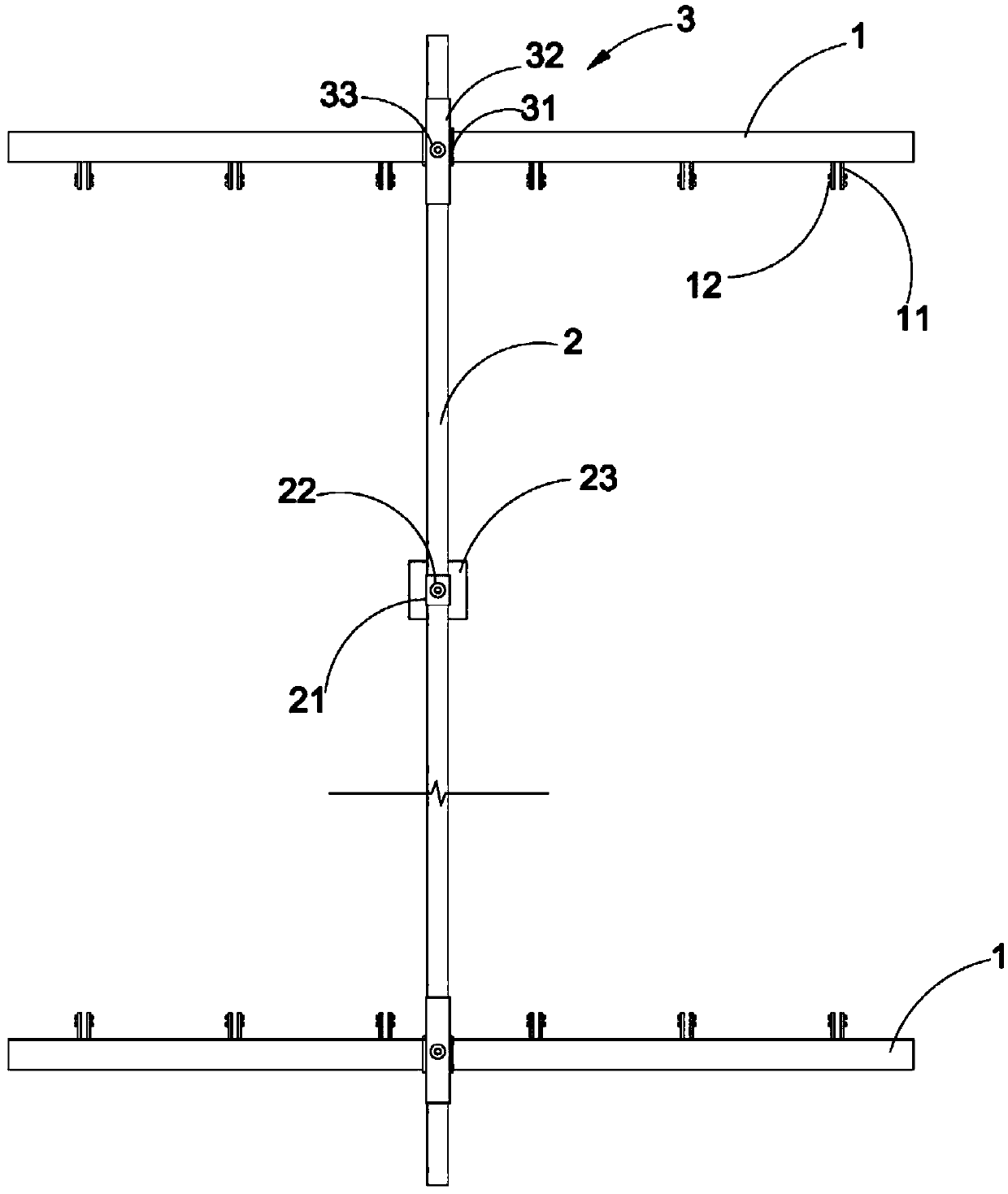

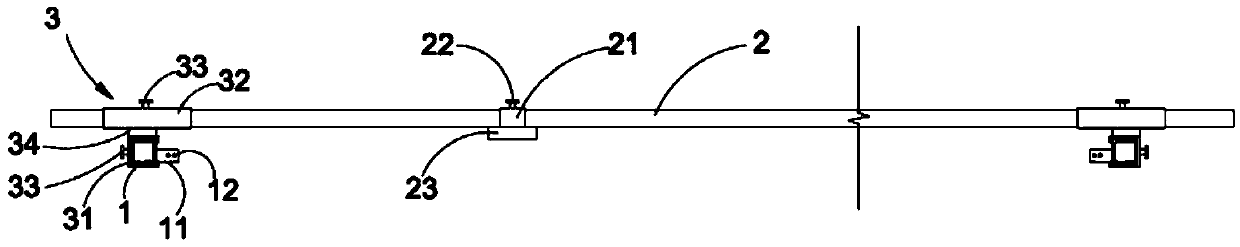

[0028] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings.

[0029] see Figure 1 to Figure 4 , the present invention provides a prefabricated laminated board line box fixing device, the fixing device includes two poles 1 arranged in parallel outside the opposite two side molds 41 and a connecting rod 2 that movably bridges the two poles 1, so The two poles 1 are detachably fastened to the outside of the two side molds 41; the connecting rod 2 moves along the length direction of the two poles 1; The box fixing cap 23 is fixedly connected with the sliding seat 21 to move along the length direction of the connecting rod 2 for adjustment. in:

[0030] Such as figure 1 , figure 2 As shown, stiffening ribs 42 are formed on the peripheral surface of the side mold 41, and a plurality of splints 11 are arranged on the side surface of the support rod 1 facing the side mold 41, and two or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com