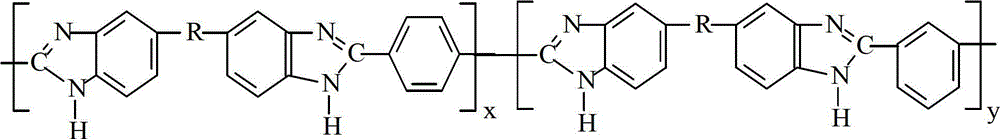

High-temperature resistant benzimidazole optical fiber coating and preparation method of coating

A technology of benzimidazole and optical fiber, which is applied in the field of optical fiber coating and its preparation, can solve the problems such as poor resistance to alternating cycles of cold and heat, low temperature resistance, and application limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067]Dissolve 23.0 g (0.1 mole) of 3,3',4,4'-tetraaminodiphenyl ether (TADE) in 300 ml of N-methyl-2-pyrrolidone (NMP) and stir at room temperature to form a homogeneous solution Finally, add 40.4 grams (0.4 moles) of triethylamine (TEA) and 38.9 grams (0.21 moles) of p-nitrobenzoyl chloride (PNBC), stir and react for 3-5 hours, filter, and add 2.2 grams of metal palladium in the mother liquor When the palladium / carbon catalyst with a mass percentage content of 10% is heated to 90°C-95°C, 88.2 grams (1.5 moles) of a hydrazine hydrate (HH) solution with a mass percentage concentration of 85% is added dropwise, and the reaction is stirred for 5-6 hours. Filtrate while it is hot, recover the palladium / carbon catalyst for recycling, add 60.8 grams (0.6 moles) of concentrated hydrochloric acid (36% by mass percentage) after the mother liquor is cooled, heat and reflux for 3-4 hours, cool to room temperature, add dropwise 336.0 grams (0.84 moles) of 10% sodium hydroxide aqueous sol...

Embodiment 2

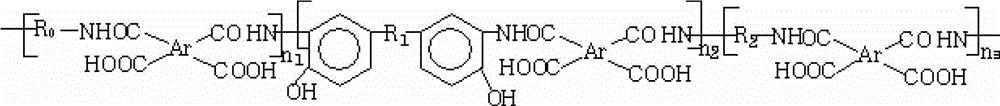

[0069] 22.4 g (0.1 mole) of 2-(4-aminophenyl)-5-aminobenzimidazole (APABI), 36.6 g (0.1 mole) of 2,2-bis(3-amino-4-hydroxyphenyl) hexa Fluoropropane (BAHPFP), 40.0 g (0.2 moles) of 4,4'-diaminodiphenyl ether (DADPE) were dissolved in 1500 g of N,N-methylacetamide (DMAc), cooled to 2°C, and 128.8 g (0.4 moles) 3,3',4,4'-tetracarboxybenzophenone dianhydride (BTDA), after stirring for 5 hours, 1720 grams of homogeneous and transparent viscous polybenzimidazole amic acid (PBIA ) solution, that is, component A, denoted as component A1, with a solid content of 13%.

Embodiment 3

[0071] 22.4 g (0.1 mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (APABI), 43.2 g (0.2 mol) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DADHBP), 36.6 g (0.1 mol) 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHPFP), 51.8 g (0.1 mol) 2,2-bis[4-(4- Aminophenoxy)phenyl]hexafluoropropane (BAPFP) was dissolved in 100 g of N,N-dimethylacetamide (DMAc) and 1000 g of N-methyl-2-pyrrolidone (NMP) and cooled to 0 °C , adding 31.0 g (0.1 mol) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA) and 87.2 g (0.4 mol) of pyromellitic dianhydride, and stirring for 10 hours to obtain 1365 gram of homogeneous transparent viscous polybenzimidazole amic acid (PBIA) solution, ie component A, denoted as component A2, with a solid content of 19.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com