Preparation method of linear polyimide-maleimide copolymer film containing active groups

A technology of maleimide copolymer and maleimide resin, which is applied in the field of preparation of polyimide film, can solve the problem that it is difficult to prepare high molecular weight polyimide resin, which has not yet been published in the literature or Problems such as patent reports, comprehensive performance decline of film products, etc., to achieve excellent dimensional stability, molecular weight control, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

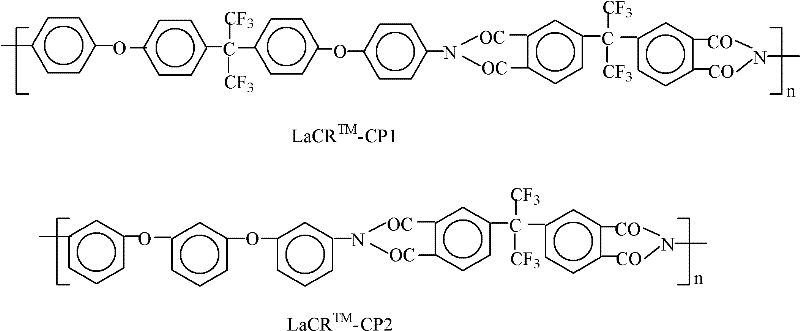

[0032] 21.6 grams (0.1 mol) of 3,3'-diamino-4,4'-dihydroxybiphenyl containing hydroxyl aromatic dibasic primary amine and 432.0 grams of N,N-dimethylacetamide strongly polar aprotic Add the organic solvent into the polymerization bottle, stir at room temperature, after completely dissolving, cool in an ice-water bath to below 5°C, add 10.9 grams (0.05 moles) of pyromellitic dianhydride and 15.5 grams (0.05 moles) of 3,3′,4, Aromatic dibasic acid anhydride of 4'-tetracarboxydiphenyl ether dianhydride, stirred, and reacted for 3 hours at a temperature range of 5°C-10°C, to obtain a homogeneous, transparent, viscous hydroxyl-containing aromatic polyamide Acid resin solution, solid content is 10wt%, is recorded as HPAA-1 resin solution;

[0033] 72.0 grams of 1,4-bis(2,4-dimaleimidophenoxy)benzene, 100.0 grams of 2,2-bis[4-(4-maleimidophenoxy)benzene Base] propane and the maleimide resin of 20.0 grams of 4,4'-bismaleimidodiphenylmethane were dissolved in 768.0 grams of N, N-dimet...

Embodiment 2

[0036] 21.6 grams (0.1 moles) of 3,3'-diamino-4,4'-dihydroxybiphenyl and 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane The strong polar aprotic organic solvent containing hydroxyl aromatic dibasic amine and 277.2 grams of N-methyl-2-pyrrolidone and 300.0 grams of N, N-dimethylacetamide is added to the polymerization bottle, stirred at room temperature, completely After dissolving, cool in an ice-water bath to below 5°C, add 43.6 grams (0.2 moles) of pyromellitic dianhydride as an aromatic dibasic acid anhydride, stir, and react within the temperature range of 5°C-10°C for 3 hours to obtain homogeneous Phase, transparent, viscous hydroxyl-containing aromatic polyamic acid resin solution, with a solid content of 15wt%, is recorded as HPAA-2 resin solution;

[0037] Dissolve the maleimide resin of 21.0 grams of 4,4'-bismaleimido-diphenylmethane in 49.0 grams of N-methyl-2-pyrrolidone strong polar aprotic organic solvent, stirring and dissolving at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com