Three-dimension printer with terminal processing

A three-dimensional printer and terminal processing technology, applied in the field of three-dimensional printing, can solve problems such as affecting human health, and achieve the effects of reducing the difficulty of washing, improving the washing efficiency, and improving the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

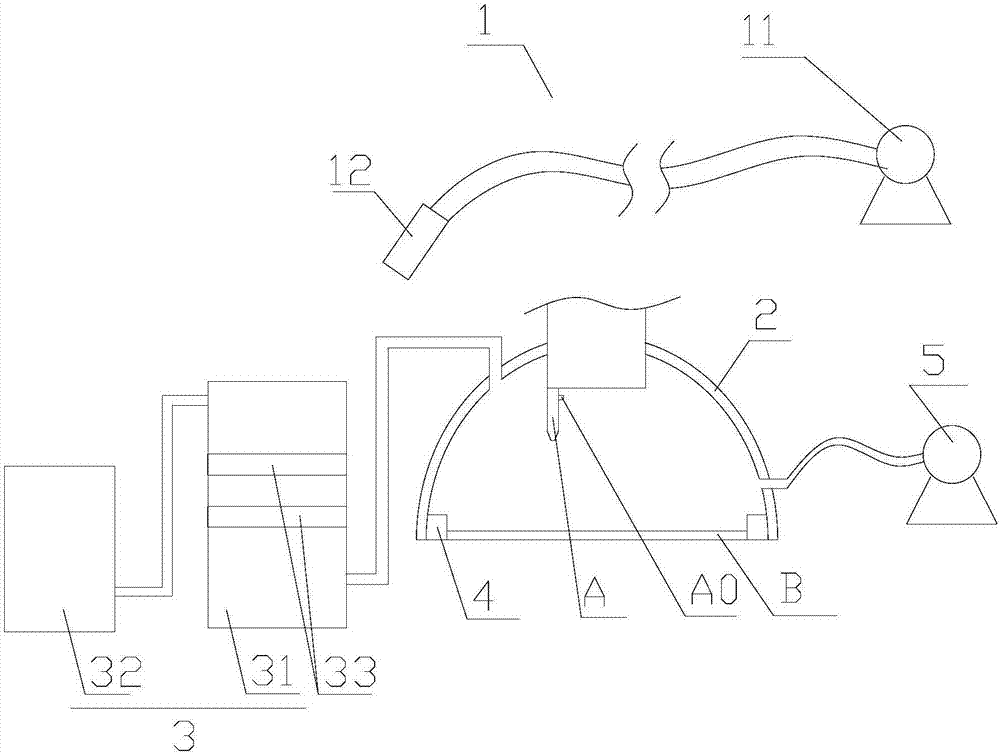

[0018] refer to figure 1 , the present invention proposes a three-dimensional printer with terminal processing, comprising: a powder recoil device 1, a protective shell 2 and a powder recovery device 3.

[0019] The powder recoil device 1 includes a first air pump 11 and a butt joint 12 . One end of the butt joint 12 communicates with the output end of the first air pump 11 , and the other end is a structure that matches the print head A of the printer. The print head A of the printer can communicate with the first air pump 11 through the butt joint 12 . The backflush outlet A0 is provided at the bottom of the nozzle A of the printer. When the nozzle A of the printer is connected with the first air pump, and the first air pump is turned on, the nozzle of the printer can be flushed with air, so that the powder blocked inside the nozzle A of the printer can be flushed out from the reverse flushing outlet A0, and the nozzle A of the printer can be dredged.

[0020] The setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com