Reciprocating device for drafting mechanism of textile machine and method of operation thereof

A technology of reciprocating devices, textile machines, used in spinning machines, drafting equipment, textiles and papermaking, etc., to solve problems such as uncontrolled moving of tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

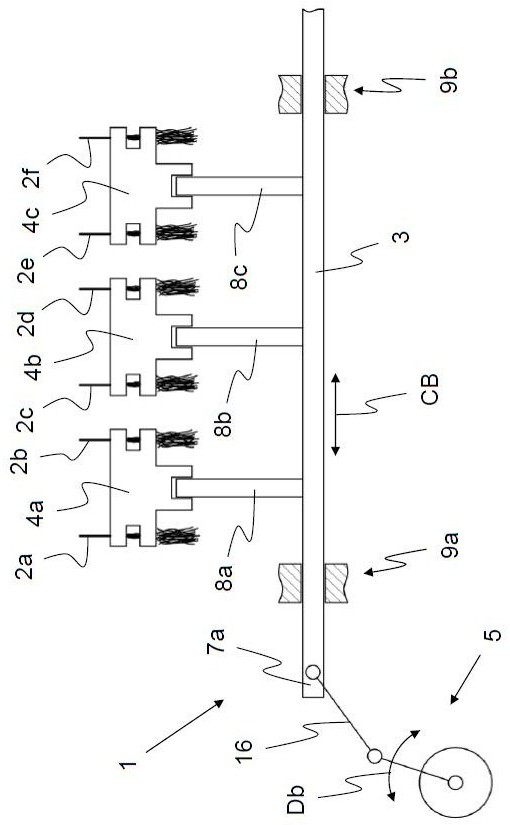

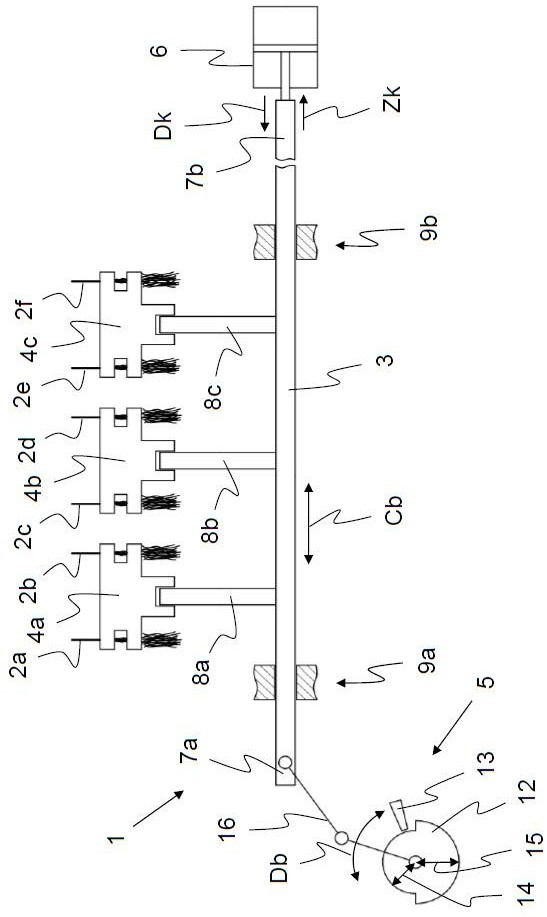

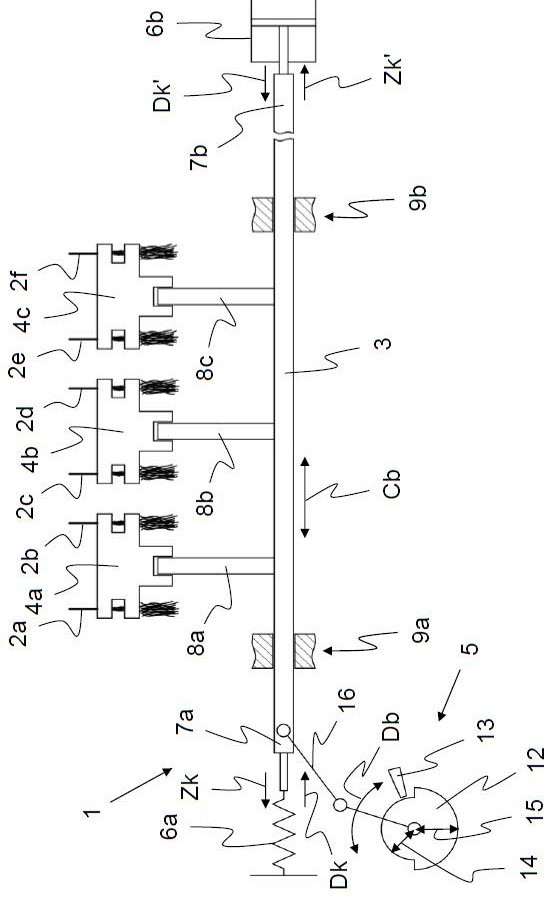

[0043] figure 1 A part of a reciprocating device 1 is shown with a rail 3, a drive 5, a plurality of guide elements 4a-4c. Such a reciprocating device 1 is, for example, known from the prior art and is here part of a not-shown drafting mechanism. The draft mechanism includes a plurality of draft mechanism rolls that draft the composite fibers 2a-2f. The drafting mechanism extends here parallel to the rail 3 .

[0044] In this exemplary embodiment, the drive 5 executes a partial rotational movement Db, which subjects the rail 3 to a reciprocating movement. The drive 5 transmits the rotational movement Db to the rail 3 by means of an articulated coupling 16 . The drive 5 is arranged here on the rail end 7 a of the rail 3 . The reciprocating motion Cb is a back and forth motion, or also called a reciprocating stroke. The rail 3 is supported here in bearings 9a, 9b.

[0045] Furthermore, three connecting arms 8 a - 8 c are arranged on the rail 3 , which transmit the reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com