Outer diameter measuring device

A measuring device and measuring head technology, which is applied in the direction of mechanical diameter measurement, etc., can solve the problem that it is difficult to accurately determine whether the tested product is qualified or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

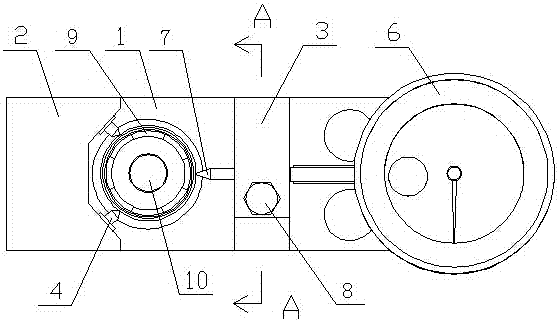

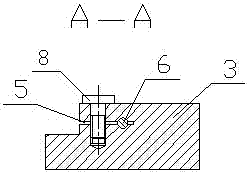

[0008] Depend on figure 1 and figure 2 As shown, the outer diameter measuring device includes a base 1, a stopper 2 is provided at one end of the base 1, a raised rib 3 is provided in the middle of the base 1, and a gap between the stopper 2 and the rib 3 The base is provided with a socket 10, and two horizontal positioning columns 4 are fixed on the side wall of the stop block 1. The rib 3 is provided with a horizontal through hole, and one side of the through hole is provided with the through hole. Connected horizontal notches 5, the ribs above and below the notches 5 form a pair of splints, the dial gauge 6 is installed in the through hole, the probe 7 of the dial gauge 6 is located on the side of the positioning column, and the notches 5 up and down The square ribs are connected by bolts 8.

[0009] When in use, the bolt 8 can be loosened to adjust the position of the dial indicator 6; according to the upper and lower limit values of the measured piston, two standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com