Method for testing amorolfine hydrochloride and interferent of amorolfine hydrochloride

A technology for the determination of amorolfine hydrochloride, which is applied in the field of analysis and detection of pharmaceutical ingredients, can solve the problems of complex preparation process, increased production cost, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

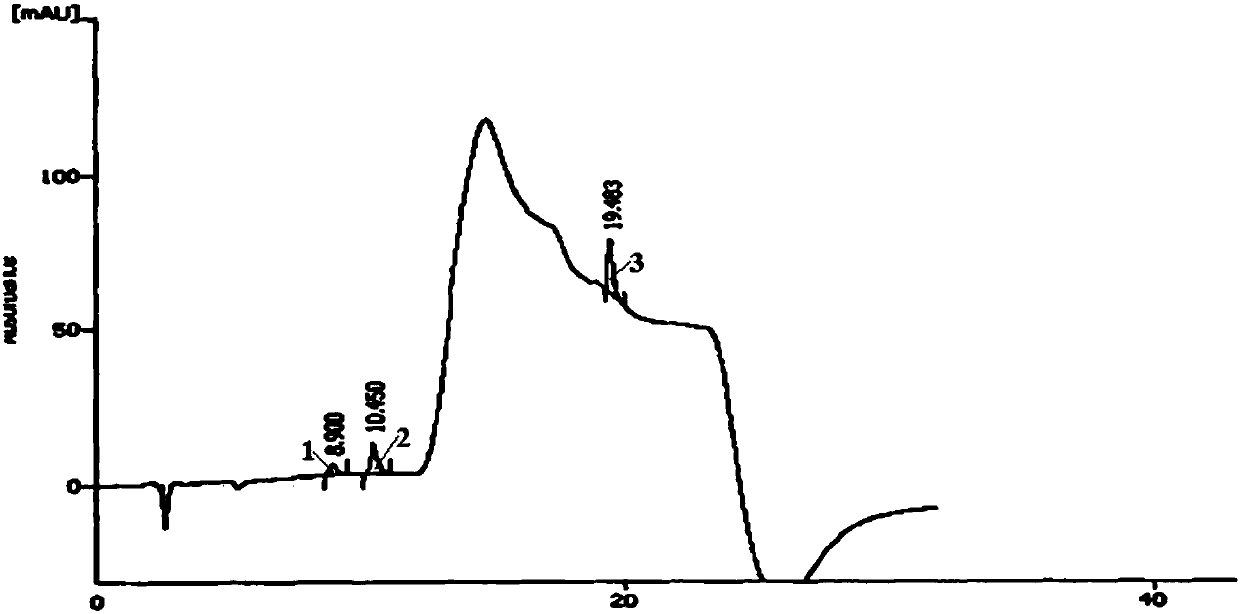

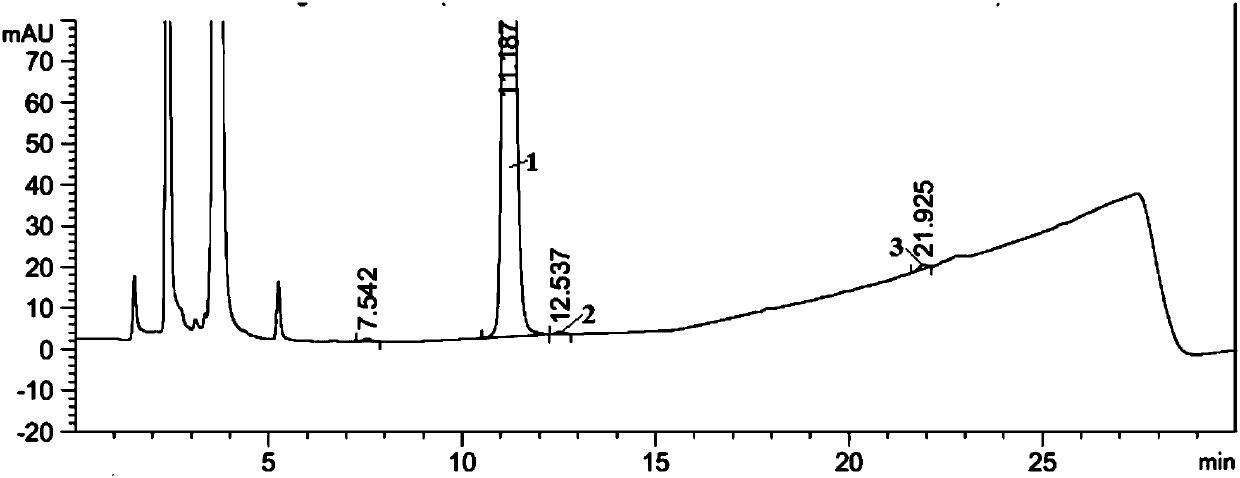

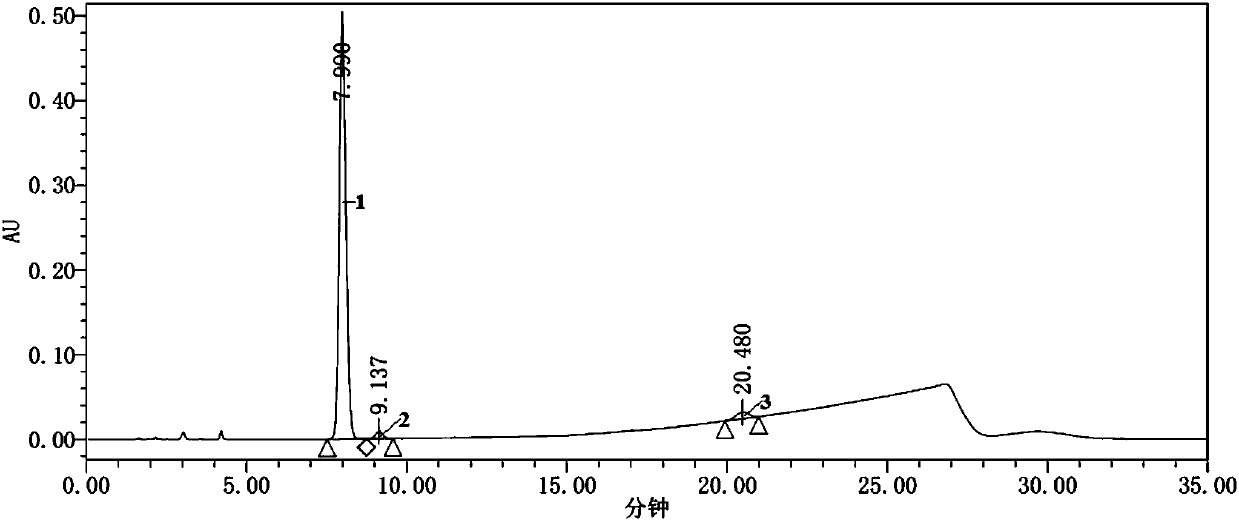

Image

Examples

Embodiment 1

[0078] 1. Experimental part

[0079] 1.1 Sample pretreatment

[0080] The preparation of need testing solution: take amorolfine hydrochloride emulsifiable paste sample, add the methanol solution containing 0.4~0.6% phosphoric acid, vortex instrument oscillation shakes 15~25min, the quality that amorolfine hydrochloride emulsifiable paste sample adds ( g), and the ratio of the volume (ml) added to the phosphoric acid-containing methanol solution is 3:14 to 3:16. Then, sonicate at 45-55°C for 10-20 minutes, cool to room temperature, dilute to volume with pure water, shake well, refrigerate and centrifuge, filter, and take the filtrate as the test solution. Wherein, the conditions of refrigerated centrifugation are as follows: the centrifugation temperature is -5-0° C.; the centrifugation time is 15-30 minutes; the centrifugation speed is 8000-14000 rpm. Filtration is 0.45 μm membrane filtration.

[0081]Preparation of the reference substance solution: Weigh the amorolfine hyd...

Embodiment 2

[0098] 1. Experimental part

[0099] 1.1 Sample pretreatment

[0100] The preparation of need testing solution: precision takes amorolfine hydrochloride emulsifiable paste sample 3g, puts in 25ml measuring bottle, adds the methanol solution 15ml that contains 0.5% phosphoric acid and shakes for 20min, the amorolfine hydrochloride emulsifiable paste sample adds The ratio of the mass (g) to the volume (ml) of the phosphoric acid-containing methanol solution is 3:15. Then, sonicate in a water bath at 50°C for 15 minutes, cool to 20-25°C, dilute to volume with pure water, shake well, refrigerate and centrifuge, filter, and take the filtrate as the test solution. Wherein, the conditions of refrigerated centrifugation are as follows: the centrifugation temperature is 0° C.; the centrifugation time is 15-30 min; and the centrifugation speed is 8000-14000 rpm. Filtration is 0.45 μm membrane filtration.

[0101] Preparation of the reference substance solution: Weigh the amorolfine h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com