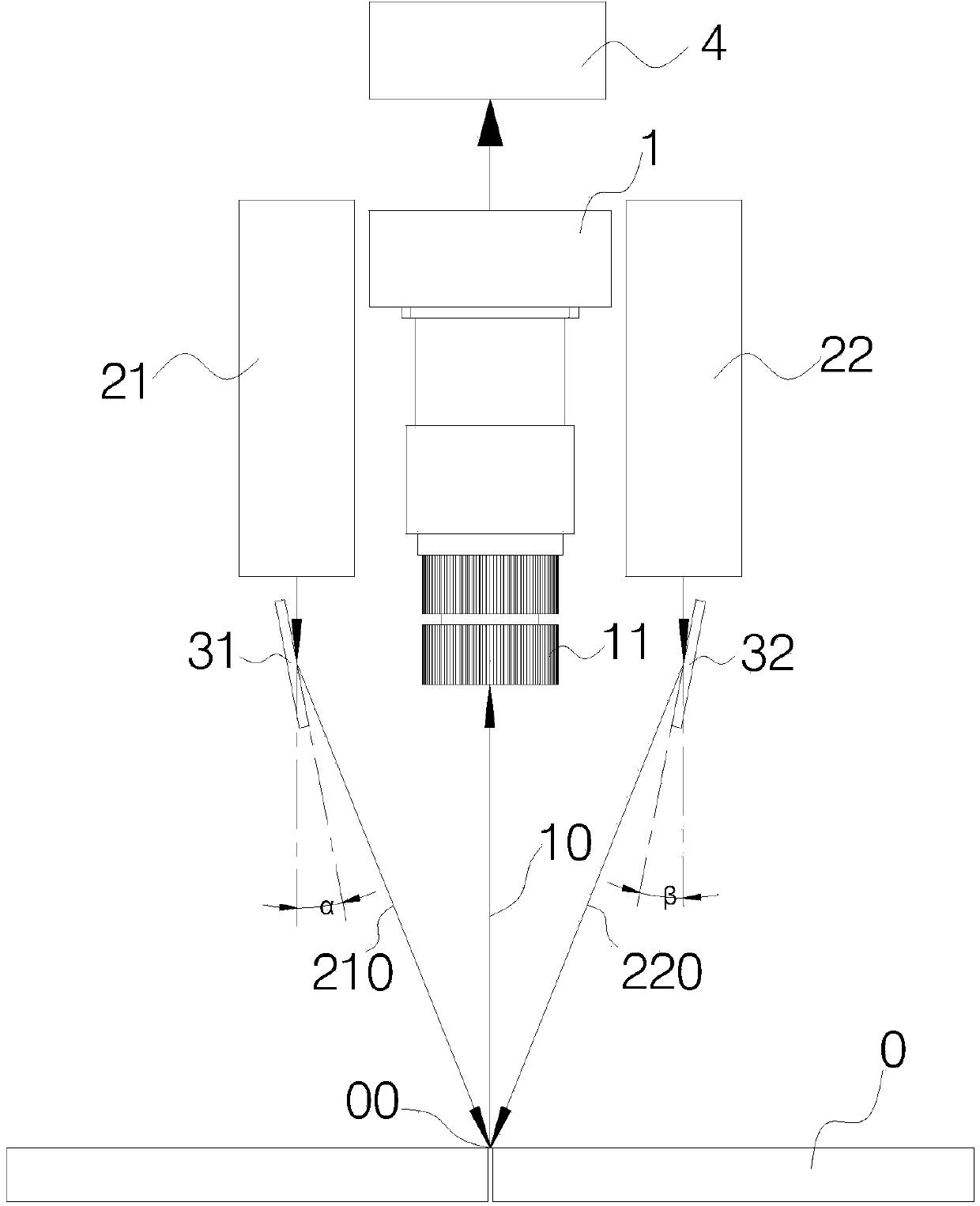

Unbeveledend butt weld detection system based on reflecting two-way converging adjustable light path

A technology of butt weld and detection system, which is applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems that affect the development of automatic welding technology of welds, difficult to achieve high-precision detection, and small weld characteristics. It can improve the stability and anti-interference of detection, facilitate later imaging, and stabilize the wavelength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific illustrations and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0012] reference figure 1 , The embodiment of the present invention provides a non-grooved butt weld detection system based on a reflective two-way convergence and adjustable optical path, which includes an imaging device 1 and an image controller 4 connected to it. The imaging device is a CCD camera or a CMOS A camera, a light source generating device 21 and a light source generating device 22 are symmetrically fixed on both sides of the imaging device 1, the light source is a laser, and a mirror 31 and a mirror are respectively arranged vertically below the light outlets of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com