Discrimination method of flue-cured tobacco producing areas

A discrimination method and technology of origin, applied in the measurement of color/spectral characteristics, etc., can solve the problems such as the application of automatic sorting and sorting of tobacco leaves, and achieve the effect of low detection environment and sample requirements and simple detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

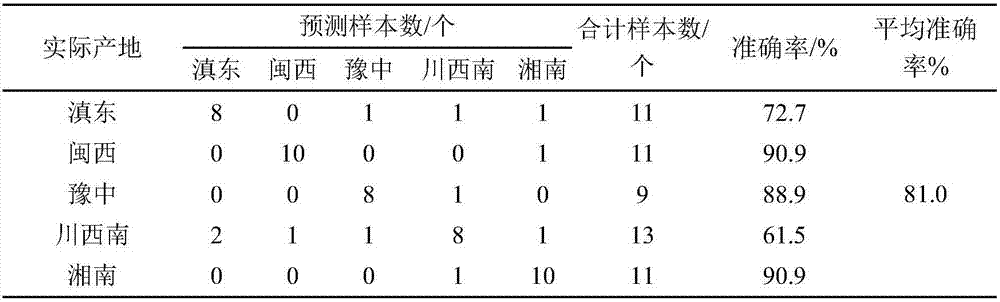

Embodiment 1

[0036] In the method for determining the origin of flue-cured tobacco in this embodiment, the tobacco leaf positions of the tobacco leaves to be determined are not distinguished, including the following steps:

[0037] 1) Establish a discriminant model for the quantitative indicators of tobacco leaf color and the place of flue-cured tobacco production. The discriminant models for different regions are as follows:

[0038] Eastern Yunnan: Y = -1161.9+14.0X 1 –261.6X 3 –76.0X 4 –166.8X 5 +0.30X 6 +47.0X 7 (1);

[0039] West Fujian: Y=-1152.6+7.1X 1 –263.8X 3 –76.9X 4 –170.8X 5 +3.0X 6 +52.1X 7 (2);

[0040] Yuzhong: Y=-1256.0+15.0X 1 –284.4X 3 –83.2X 4 –182.1X 5 +0.26X 6 +49.1X 7 (3);

[0041] Southwest Sichuan: Y = -1171.2+14.0X 1 –263.3X 3 –76.9X 4 –170.7X 5 +0.69X 6 +48.3X 7 (4);

[0042] Shonan: Y = -1185.3+13.8X 1 –275.8X 3 –81.9X 4 –176.4X 5 +1.75X 6 +49.4X 7 (5);

[0043] In formula (1) ~ formula (5), X 1 Positive red and green index a * ; X 3 Is the difference between the front...

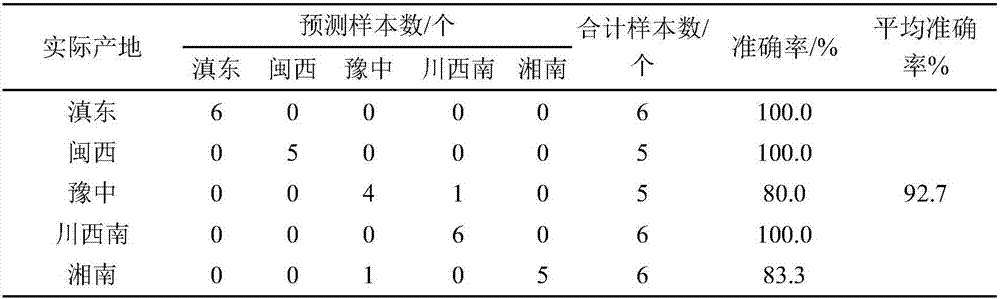

Embodiment 2

[0051] In the method for determining the origin of flue-cured tobacco in this embodiment, the tobacco leaf to be determined as the upper leaf includes the following steps:

[0052] 1) Establish a discriminant model for the quantitative indicators of tobacco leaf color and the place of flue-cured tobacco. The discriminant models for different regions are as follows:

[0053] Eastern Yunnan: Y=-6912.8-406.6X 1 +179.8X 2 –173.2X 3 –30.2X 4 –162.4X 5 (6);

[0054] West Fujian: Y = -7335.3–429.3X 1 +187.1X 2 –167.0X 3 –26.6X 4 –167.4X 5 (7);

[0055] Yuzhong: Y = -7090.4–411.6X 1 +182.4X 2 –187.5X 3 –35.0X 4 –174.3X 5 (8);

[0056] Southwest Sichuan: Y = -7052.0–411.5X 1 +182.1X 2 –168.5X 3 –29.4X 4 –164.0X 5 (9);

[0057] Shonan: Y = -6900.9-400.6X 1 +179.2X 2 –187.0X 3 –36.5X 4 –172.1X 5 (10);

[0058] In formula (6) ~ formula (10), X 1 Positive red-green index a * ; X 2 Is the positive yellow-blue index b * ; X 3 Is the difference between the front and back brightness ΔL * ; X 4 Is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com