A lens drive device

A lens driving device and lens body technology, applied in installation, optics, instruments, etc., can solve problems such as fracture, deformation of the arm 905c, and falling off of the buffer 917

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

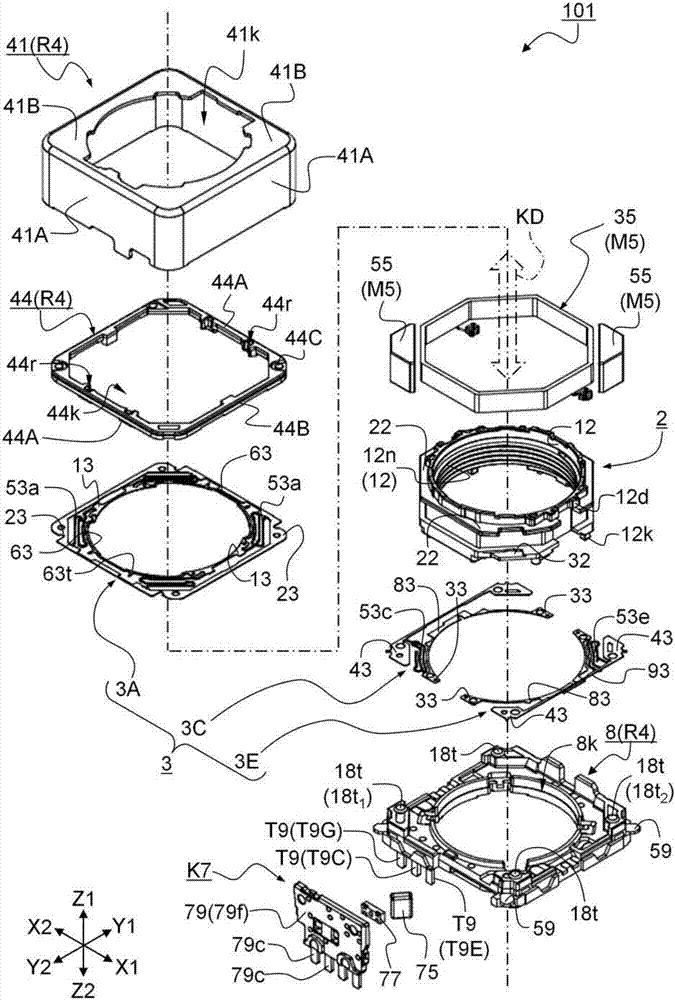

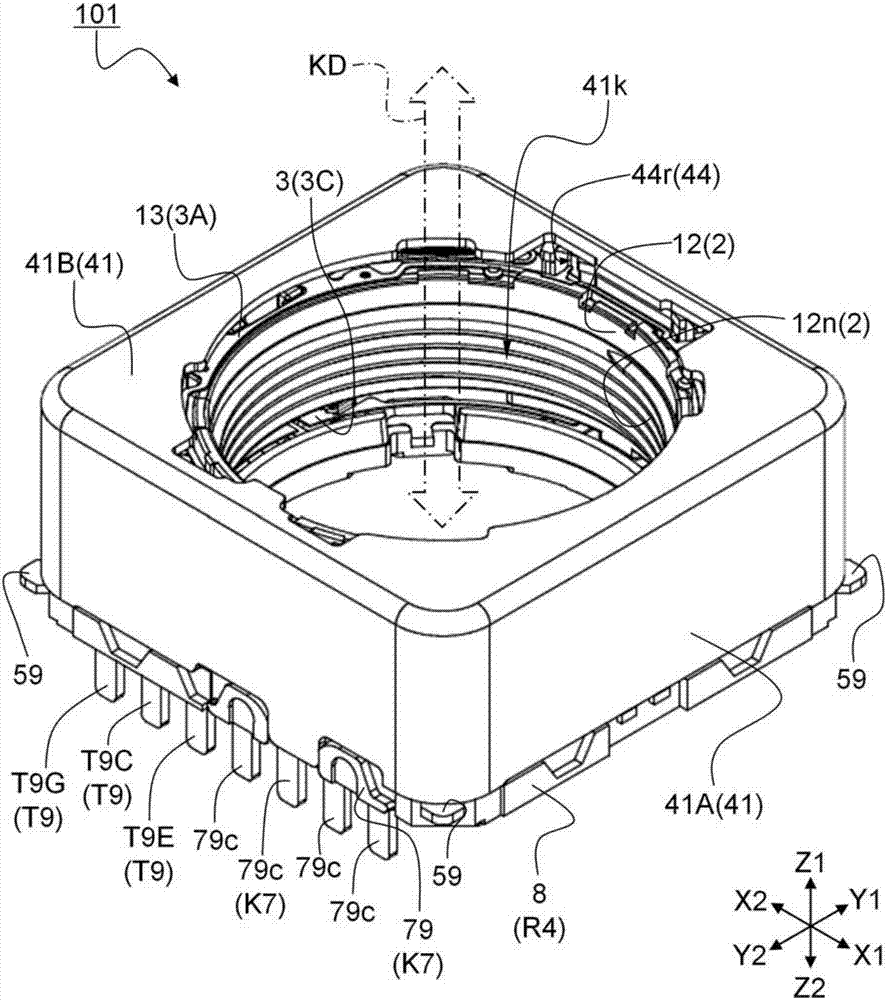

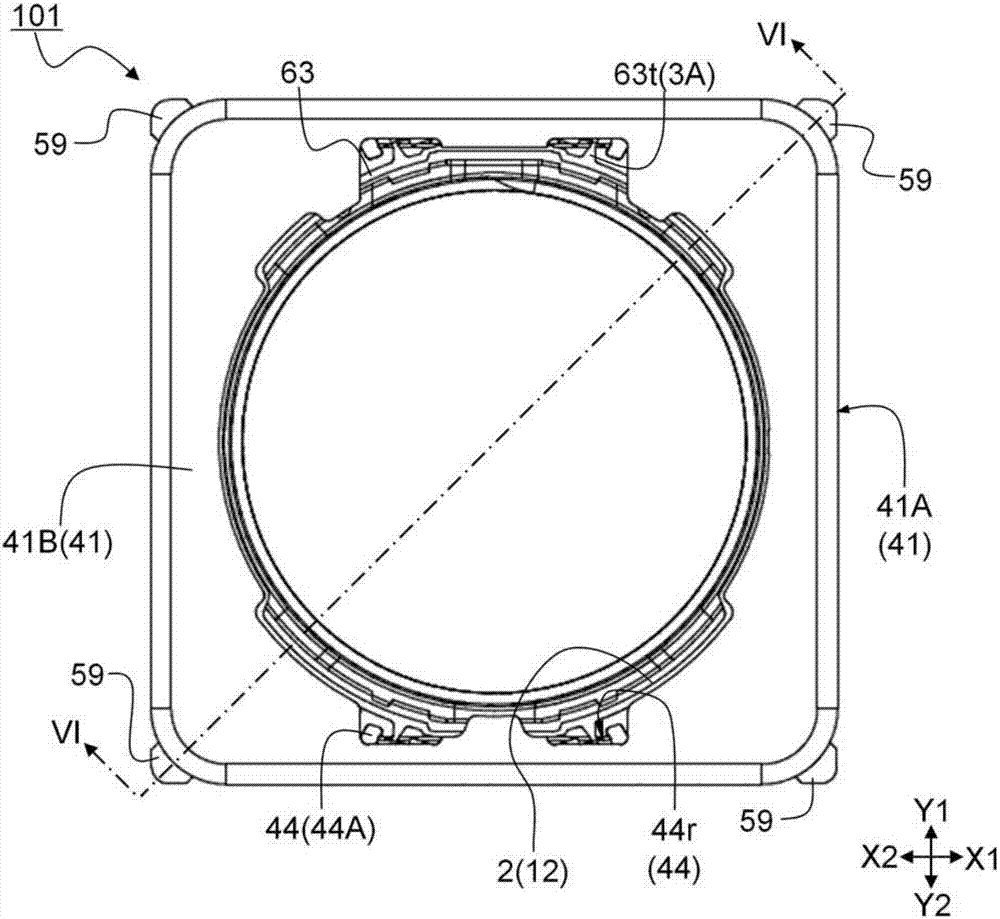

[0060] figure 1 It is an exploded perspective view illustrating the lens driving device 101 according to the first embodiment of the present invention. figure 2 It is a perspective view illustrating the lens driving device 101 according to the first embodiment of the present invention. Figure 3A Viewed from Z1 side figure 2 A top view of the lens driving device 101, Figure 3B Viewed from Y2 side figure 2 The front view of the lens driving device 101. Figure 4A will be figure 2 A perspective view in which the case 41 serving as the fixed-side member R4 of the shown lens driving device 101 is omitted, Figure 4B will be Figure 4A The illustrated perspective view of the frame-shaped member 44 and the position detection unit K7 is further omitted. Figure 5A Viewed from Z2 side figure 2 The bottom view of the lens driving device 101, Figure 5B will be Figure 5A The bottom view of the base part 8 is shown with omission. Figure 6 yes Figure 3A The shown cro...

Deformed example 1

[0133] In the above-mentioned first embodiment, it is preferable that the extended portions 63 extended from the opposing and adjacent first portions 13 are connected to form one connecting portion, but the present invention is not limited thereto. For example, It is a structure in which the part facing and adjacent to the horizontal bar part 73 is notched.

Deformed example 2

[0135] In the above-described first embodiment, a set of sides of the frame-shaped member 44 facing each other is the first extending portion 44A, and the other set of sides intersecting the first extending portion 44A is configured as the second extending portion 44B. , but not limited to this. For example, as long as the first extensions are respectively extended from a set of opposite sides and arranged along the set of sides respectively, and the second extensions 44B are respectively extended from the other set of sides and arranged along the set (another set of sides). One group) side can be set separately. That is, for example, the first extending portion may be separately provided along one set of sides, or the second extending portion may be separately provided along another set of sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com