Tooth-toe type rotary tillage knife

A technology of rotary tiller and knife handle, applied in the field of tooth-toe rotary tiller, can solve the problems of high soil cutting resistance and high power consumption of the rotary tiller, and achieves the reduction of soil cutting resistance, strong anti-grass entanglement ability, and low power consumption. The effect of soil entry resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

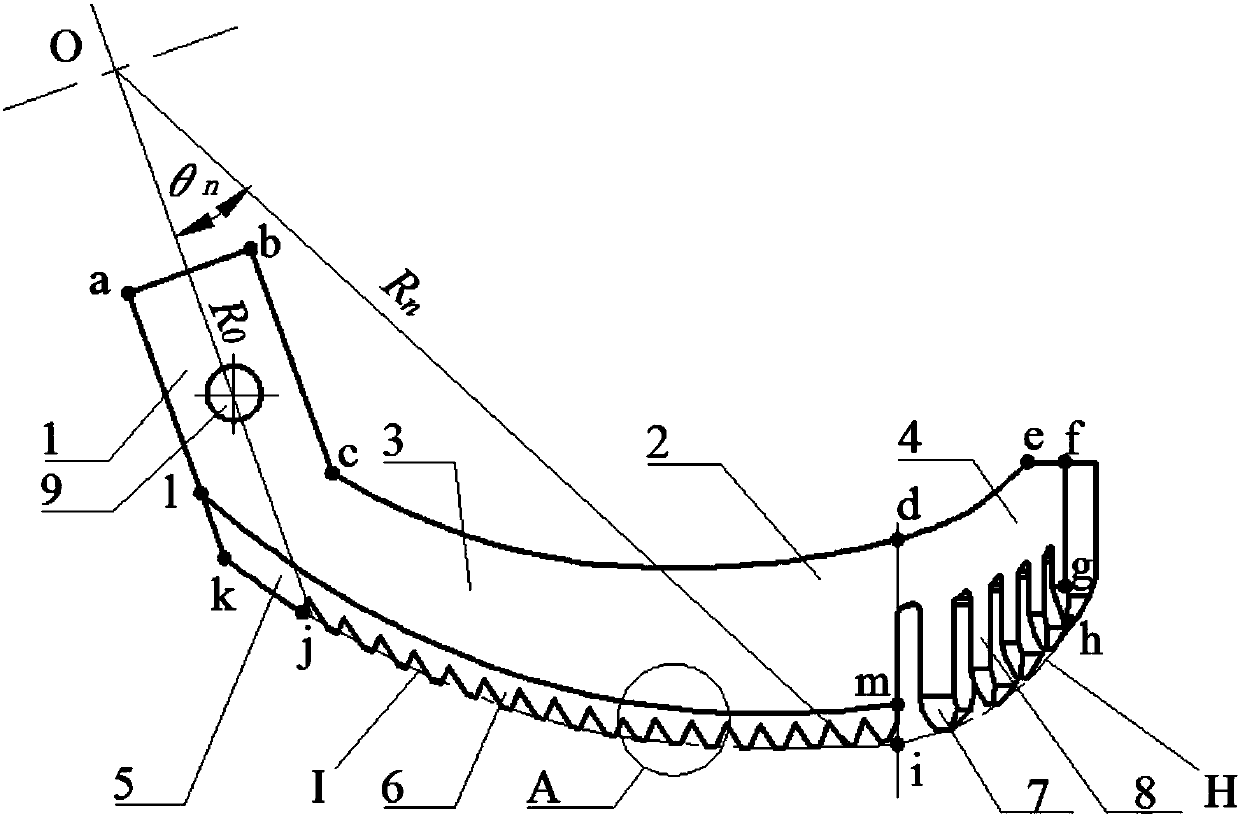

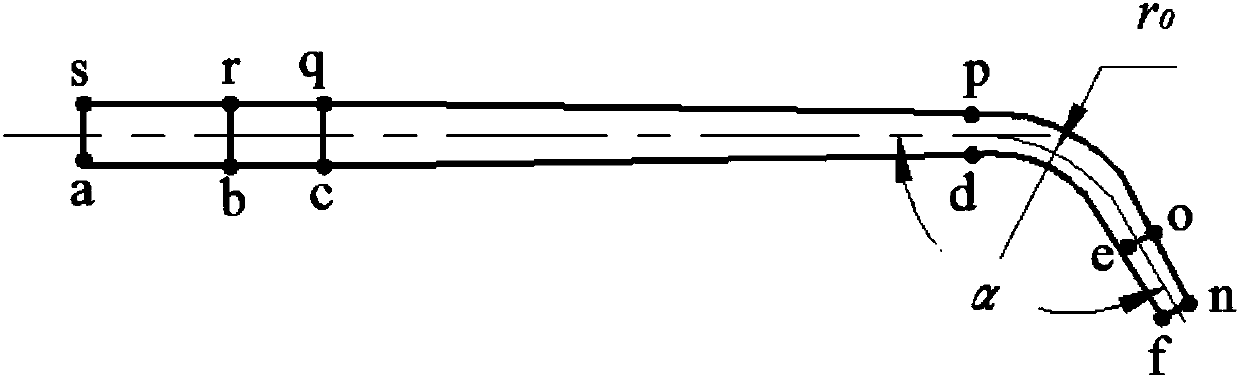

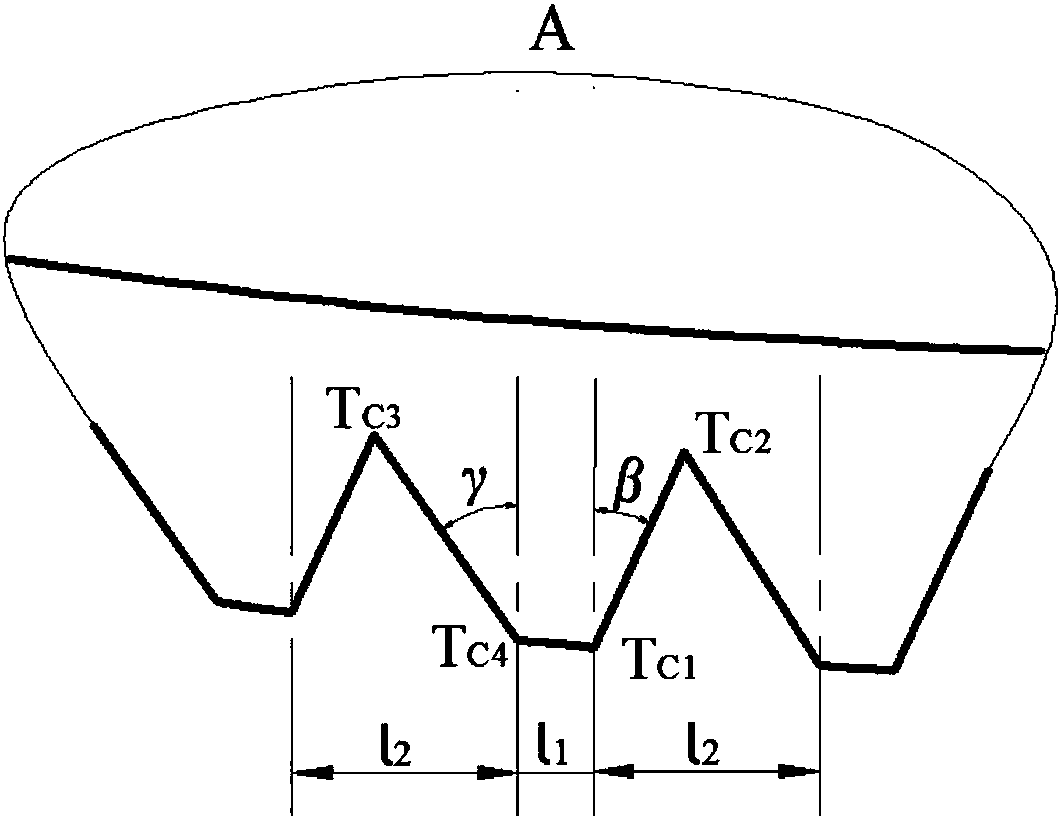

[0044] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, this example tooth-toe type rotary cultivator is made up of handle 1 and cutter body 2; Its figure 1 In the outline of the front view, the line abcla is the handle 1, where ab, bc, cl, and la are straight lines; the line cdefghijklc is the knife body 2, where cd is the curve, de is the curve, hi is the curve H, ij Curve I, jk are curves, di, ef, fg, gh, kl, lc are straight lines, and the corresponding points of curve cd and curve I gradually increase to 45mm at the initial distance of 30mm, and curve de is the extension line of curve cd, Curve jk is the extension line of curve I, point m is located on the connecting line of di, the side tangent plane 3 is inside the cdmijklc connecting line, and the tangent plane 4 is inside the defghimd connecting line. r 0 =30mm bending, the bending angle α is 110°-130°, the side cutting edge 5 is inside the ijklmi connection line, wherein lm is...

Embodiment 2

[0065] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 As shown, the tooth-toe type rotary cultivator of this example is different from Example 1 in that: there are 5 toes 8 in the tangent plane 4, and the direction from point i to point h is named as the first toe, the second toe, and the third toe. toe, fourth toe, fifth toe. The toe 8, toe length L i with toe width W i meet L i =m×W i , where m is the size factor, its value is 3; the distance between the i+1 toe and the i toe is S i , where S i =p×L i , p is the size factor, its value is 0.5; the distance between the first toe and the straight line di is S 0 , where S 0 =q×L 1 , q is the size factor, its value is 0.77; the toes are free to transition through arc curves; the toe width W 1 =10mm, toe width W i Decrease successively with the difference d as an arithmetic sequence, where d satisfies:

[0066]

[0067] Among them: L 0 is the horizontal length of the projected curve...

Embodiment 3

[0070] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 8 As shown, the tooth-toe type rotary tiller of this example is different from Example 1 in that: there are 7 toes 8 in the tangent plane 4, and the direction from point i to point h is named as the first toe, the second toe, and the third toe. toe, fourth toe, fifth toe, sixth toe, seventh toe. The toe 8, toe length L i with toe width W i Satisfy:

[0071] L i =m×W i

[0072] Among them: m is the size factor, its value is 4;

[0073] The distance between the i+1 toe and the i toe is S i , where S i =p×L i

[0074] Among them: p is the size factor, its value is 0.6;

[0075] The distance from the first toe to the straight line di is S 0 , where S 0 =q×L 1

[0076] Among them: q is the size factor, its value is 0.42;

[0077] Free transition between the toes through arc curves;

[0078] Toe width W 1 =5mm, toe width W i Decrease successively with the difference d as an arithm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com