Stuffing feeding mechanism of steamed-stuffed bun making machine

A steamed bun machine and stuffing technology, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of long extrusion cycle, poor taste of steamed buns, and inability to adjust the delivery volume of fillings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

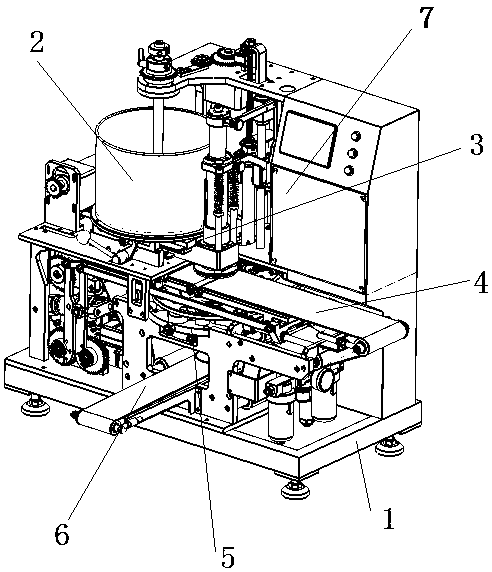

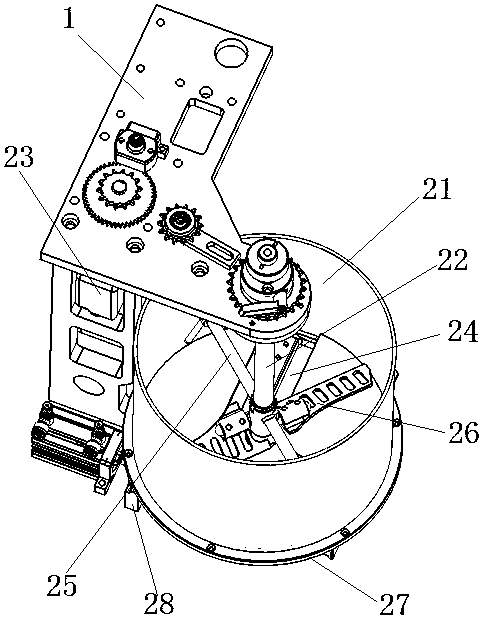

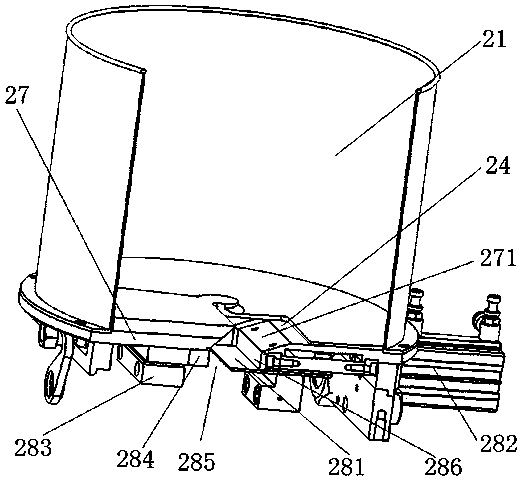

[0049] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as Figure 1-11 , a bionic steamed stuffed bun machine, comprising a frame 1, a stuffing mixing mechanism 2, a stuffing feeding mechanism 3, a dough conveying mechanism 4, a flower kneading forming mechanism 5 and a steamed stuffed bun output mechanism 6, and the frame 1 is installed on the basis of equipment installation , used to support the stuffing mixing mechanism 2, the stuffing mechanism 3, the dough conveying mechanism 4, the kneading forming mechanism 5 and the steamed stuffed bun output mechanism 6, in the present embodiment, materials such as steel plates and steel pipes commonly used in the industry are used to fix each other to the machine of the present invention Frame 1, the top of frame 1 is provided with stuffing mixing mechanism 2, and stuffing mixing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com